Industri pembuatan asfalt global mencecah $36.7 bilion pada 2025, dengan Amerika Syarikat mewakili segmen pasaran terbesar. Walau bagaimanapun, saiz sahaja tidak menjamin kualiti perkhidmatan. Pengurus perolehan yang menilai vendor bahagian loji asfalt mesti mengimbangi keutamaan yang bersaing: mengakses alat ganti dengan cepat semasa kecemasan, mendapatkan harga yang kompetitif untuk pembelian yang dirancang, menilai kepakaran teknikal pembekal dan mewujudkan perkongsian jangka panjang yang boleh dipercayai.

Tidak seperti perolehan komoditi, mendapatkan bahagian loji asfalt memerlukan pemahaman yang sofistikated tentang pembezaan pembekal, keupayaan vendor dan strategi inventori. Panduan ini mengkaji cara pembuat keputusan industri menilai dan membandingkan pembekal untuk mengoptimumkan masa operasi peralatan, mengawal kos dan mengurangkan risiko operasi.

Pembeli mencaribahagian tumbuhan asfaltjatuh ke dalam tiga senario pembelian utama, masing-masing dengan tahap kecemasan dan kriteria keputusan yang berbeza:

Penyumberan Penyelenggaraan Terancang: Pengurus kemudahan yang melaksanakan penyelenggaraan berjadual—seperti penggantian penapis bermusim, naik taraf tali pinggang penghantar atau baik pulih penunu—beroperasi dengan garis masa lanjutan yang diukur dalam minggu atau bulan. Pembeli ini menekankan daya saing harga, diskaun pukal dan perundingan teknikal untuk memastikan mereka memilih komponen yang betul untuk konfigurasi loji khusus mereka.

Pembinaan Perhubungan Vendor: Pasukan perolehan yang menjalankan penilaian vendor formal untuk mewujudkan perjanjian pembekal pilihan mencari keupayaan komprehensif merentas pelbagai dimensi. Inisiatif penyumberan strategik ini melibatkan RFP, audit tapak, pemeriksaan kewangan dan penilaian kebolehskalaan untuk mengunci dari segi yang menguntungkan dan mengurangkan pemecahan rantaian bekalan.

Memahami senario yang memacu gelagat pembelian organisasi anda adalah asas untuk menilai pembekal dengan berkesan. Vendor yang cemerlang dalam respons kecemasan mungkin tidak menawarkan harga terendah untuk pesanan pukal, manakala pembekal yang menyediakan perundingan teknikal yang unggul mungkin kekurangan kedalaman inventori untuk keperluan mendesak.

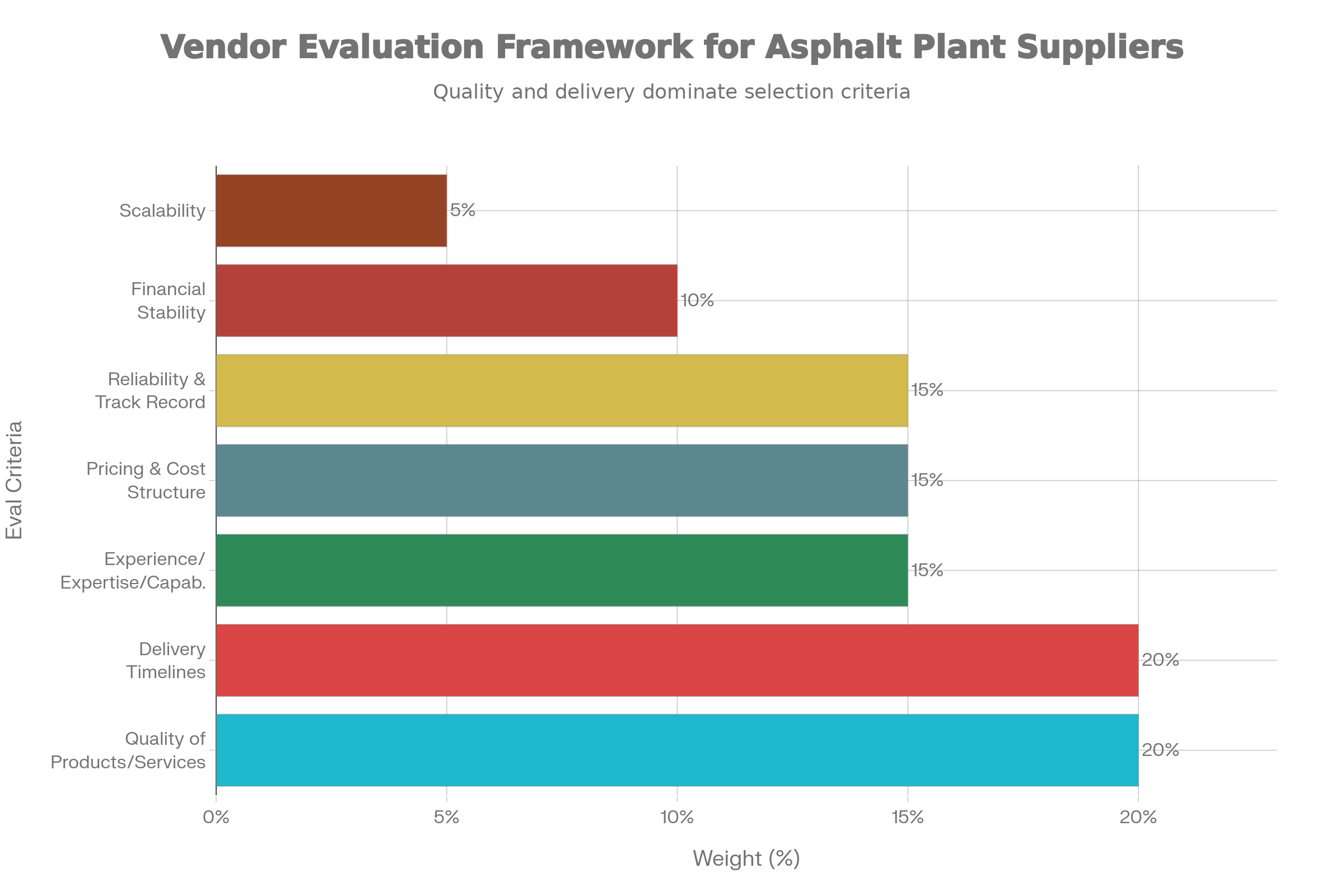

Amalan terbaik perolehan dalam industri pembinaan dan peralatan bertumpu pada rangka kerja penilaian yang konsisten. Penyelidikan merentas rantaian bekalan pembinaan, protokol pemilihan vendor dan piawaian perolehan peralatan mengenal pasti tujuh kriteria utama yang meramalkan prestasi pembekal dan kepuasan pembeli.

Kualiti Produk dan Perkhidmatan (20% Berat): Kualiti mewakili wajaran paling berat dalam pemilihan vendor kerana kecacatan produk secara langsung mengancam integriti operasi. Untuk loji asfalt, ini bermakna mengesahkan bahawa komponen pembekal memenuhi piawaian AASHTO dan ASTM, membawa pensijilan yang betul (seperti ISO 9001:2000), dan menyertakan dokumentasi jaminan kualiti. Menilai pembekal memerlukan permintaan spesifikasi produk, data ujian dan rujukan daripada pelanggan terdahulu yang boleh membuktikan ketahanan dan kebolehpercayaan di bawah tekanan operasi.

Apabila menilai kualiti, pasukan perolehan hendaklah meminta salinan sistem kawalan kualiti pembekal, termasuk metodologi ujian, audit pematuhan dan proses tindakan pembetulan. Pembekal yang menawarkan pilihan pemeriksaan pihak ketiga—seperti melalui makmal ujian bebas—menunjukkan keyakinan terhadap sistem kualiti mereka dan mengurangkan risiko pembeli.

Garis Masa Penghantaran (20% Berat): Diikat dengan kualiti, prestasi penghantaran secara langsung memberi kesan kepada masa operasi kilang. Pengurus perolehan mesti memahami masa petunjuk pembekal merentas tiga dimensi: penghantaran standard untuk pembelian yang dirancang, ketersediaan dipercepatkan untuk keperluan mendesak dan liputan geografi untuk operasi berbilang tapak.

Masa membawa berbeza dengan ketara mengikut jenis bahagian. Komponen dan pengikat elektrik standard mungkin tiba dalam masa 24–48 jam dari hab berasaskan Louisville (seperti yang dikendalikan oleh pengedar utama), manakala komponen penunu khusus atau pelapik dram mungkin memerlukan 3–8 minggu daripada pengilang atau pembekal antarabangsa. Pembekal progresif menerbitkan klasifikasi masa utama untuk inventori mereka, membolehkan pasukan perolehan mengoptimumkan tahap stok keselamatan dan titik pesanan semula.

Pengalaman, Kepakaran dan Keupayaan (15% Berat): Pengetahuan teknikal memisahkan pembekal komoditi daripada vendor khusus. Pembekal dengan 30+ tahun dalam perkhidmatan loji asfalt memiliki kepakaran terkumpul merentas pelbagai pengeluar peralatan (Astec, Gencor, ADM), konfigurasi loji (pegun, mudah alih, aliran berterusan) dan penjanaan komponen (peralatan warisan melalui model semasa).

Kepakaran ini diterjemahkan kepada nilai praktikal: mengesyorkan saiz galas yang betul untuk model pengadun tertentu, mengenal pasti bahan pengedap yang tidak serasi yang menyebabkan kegagalan pramatang, atau menasihati pilihan pengubahsuaian untuk peralatan usang. Pasukan pemerolehan harus menilai sama ada jurutera jualan pembekal, juruteknik perkhidmatan lapangan dan kakitangan sokongan memegang pensijilan yang berkaitan dan mempunyai pengalaman langsung menyelesaikan masalah loji asfalt.

Harga dan Struktur Kos (15% Berat): Walaupun kualiti dan penghantaran menerima wajaran yang lebih tinggi, penetapan harga secara langsung memberi kesan kepada margin operasi. Penilaian pembekal yang berkesan membandingkan bukan sahaja harga unit tetapi jumlah kos pendaratan, termasuk kos penghantaran, pengendalian dan dipercepatkan. Pembekal yang menawarkan diskaun pukal, harga berperingkat untuk pembelian berulang dan struktur harga yang telus mengurangkan kos perolehan jangka panjang.

Pasukan perolehan yang canggih menggunakan analisis jumlah kos pemilikan (TCO), yang merangkumi harga pemerolehan, kos penyimpanan inventori, risiko usang dan kos peluang modal. Harga unit yang lebih tinggi sedikit daripada pembekal yang menawarkan penghantaran 2 minggu mungkin terbukti lebih menjimatkan kos berbanding pembekal diskaun dengan masa pendahuluan 6 minggu, kerana penghantaran yang lebih pantas mengurangkan pelaburan saham keselamatan.

Kebolehpercayaan dan Rekod Jejak (15% Berat): Reputasi pembekal mencerminkan konsistensi dalam memenuhi komitmen merentas dimensi kualiti, penghantaran dan perkhidmatan. Ulasan dalam talian, testimoni industri, kajian kes dan rujukan pelanggan memberikan bukti prestasi sebenar dan bukannya janji pemasaran.

Pembekal industri pembinaan sering mengambil bahagian dalam program pensijilan dan memegang anugerah industri (seperti pengiktirafan pembekal tahun ini daripada OEM peralatan utama). Penilaian kestabilan kewangan—meneliti keuntungan, kecairan dan kepercayaan kredit—meramalkan keupayaan pembekal untuk menahan kemelesetan pasaran tanpa mengganggu perkhidmatan.

Kestabilan Kewangan (10% Berat): Pembekal yang tidak stabil dari segi kewangan menghadapi risiko gangguan operasi jika mereka menghadapi kekangan aliran tunai, muflis atau pemerolehan oleh pesaing. Menilai kesihatan kewangan memerlukan menyemak penyata kewangan terkini, nisbah hutang dan risiko tumpuan pelanggan. Pembekal yang menjana 30% pesanan rujukan dan 15% pembelian berulang (menunjukkan kepuasan pelanggan yang tinggi) menunjukkan kemampanan kewangan.

Kebolehskalaan (5% Berat): Apabila kontraktor asfalt mengembangkan operasi atau menjalankan projek yang lebih besar, kapasiti pembekal mesti menampung permintaan yang meningkat. Menilai skalabiliti bermakna menilai kapasiti pembuatan, daya tahan rantaian bekalan dan tahap kakitangan. Pembekal yang mengendalikan 200,000+ kemudahan meter persegi dengan 1,000+ kakitangan mahir menunjukkan kapasiti untuk mengendalikan pertumbuhan volum tanpa penurunan kualiti.

Pasaran bahagian loji asfalt termasuk pengedar bebas (seperti Bahagian Hotmix) dan pembekal OEM bersepadu (seperti Astec Industries). Setiap model operasi menawarkan kelebihan yang berbeza:

Bahagian & Perkhidmatan Hotmix: Beroperasi dari Louisville, Kentucky—rumah kepada UPS Worldport—Hotmix Parts telah meletakkan dirinya sebagai peneraju tindak balas kecemasan dalam sokongan loji asfalt. Dengan 70,000+ item dalam stok dan sokongan pelanggan 24/7, syarikat menyasarkan pasukan perolehan yang menghadapi kegagalan peralatan yang tidak boleh bertolak ansur dengan kelewatan. Model perkhidmatan mereka menggabungkan penghantaran alat ganti pantas dengan perundingan kejuruteraan lapangan, membolehkan pengendali loji mendiagnosis masalah dan melaksanakan pembaikan tanpa penglibatan pengilang.

Kelebihan daya saing: Penghantaran pada hari yang sama atau keesokan harinya untuk kebanyakan item dalam stok memanfaatkan status hab logistik Louisville. Lebih 30 tahun pengalaman industri diterjemahkan kepada kepakaran diagnostik merentas semua jenama tumbuhan utama. Kedudukan "Anything for an Asphalt Plant" mereka menggambarkan keluasan inventori yang meliputi komponen terpakai, bahagian yang diperbaharui dan item yang sukar ditemui untuk peralatan lama.

Motion Engineering Inc.: Dengan pengkhususan 40+ tahun dalam bahagian industri untuk loji asfalt, Motion Engineering membezakan kepakaran teknikal dan penyumberan yang sukar ditemui. Daripada bersaing dalam jumlah inventori, Motion Engineering memfokuskan pada menyelesaikan cabaran penyumberan yang kompleks—mencari komponen usang, alat ganti pembuatan tersuai dan menyediakan perundingan kejuruteraan tentang penyepaduan peralatan.

Kelebihan daya saing: Motion Engineering memberi perkhidmatan kepada pengurus kemudahan yang mengendalikan peralatan warisan di mana pembekal standard tidak boleh mendapatkan bahagian. Pasukan teknikal mereka menyediakan perkhidmatan reka bentuk untuk projek pengubahsuaian, membolehkan kontraktor menaik taraf loji yang sudah tua tanpa penggantian borong. Pengkhususan ini mewujudkan kedudukan kompetitif yang boleh dipertahankan dalam segmen pasaran pengubahsuaian dan peningkatan.

Stansteel: Diposisikan sebagai "pengilang #1 Amerika" peralatan loji asfalt, Stansteel menggabungkan pengedaran bahagian dengan perkhidmatan pembuatan dan penyepaduan tersuai. Beroperasi sebagai pembekal dan penyepadu sistem, Stansteel menyediakan perkhidmatan kepada kontraktor yang merancang naik taraf loji utama atau pemasangan tersuai.

Kelebihan daya saing: Keupayaan pembuatan Stansteel membolehkan prototaip pantas dan komponen tersuai yang tidak dapat dihasilkan oleh pengedar standard. Perkhidmatan penyepaduan—menyelaraskan komponen daripada pelbagai pembekal ke dalam reka bentuk sistem yang koheren—merayu kepada kontraktor membina kemudahan baharu atau melakukan pemodenan menyeluruh.

Kumpulan AIMIX: Mengendalikan kemudahan pembuatan 200,000 meter persegi dengan 1,000+ kakitangan mahir, Kumpulan AIMIX mewakili model pembekal global bersepadu. Aktif di 150+ negara dengan 500+ projek yang berjaya, AIMIX memberi perkhidmatan kepada kontraktor antarabangsa dan pengeluar berskala besar yang memerlukan peralatan serta sokongan alat ganti yang komprehensif.

Kelebihan daya saing: AIMIX menggabungkan pembuatan peralatan dengan rangkaian sokongan selepas jualan setempat, mengurangkan pergantungan kepada logistik antarabangsa. Jejak pembuatan seluas 200,000 meter persegi membolehkan penyepaduan menegak—menghasilkan komponen secara dalaman daripada bergantung kepada pembekal luar, yang mengurangkan masa pendahuluan dan meningkatkan konsistensi kawalan kualiti.

Astec Industries: Sebagai OEM (pengilang peralatan asal) untuk loji asfalt yang dijual di bawah jenama Astec sejak 1972, Astec mengawal kitaran hayat produk yang lengkap daripada reka bentuk melalui bekalan alat ganti. Syarikat itu menekankan teknologi penunu yang inovatif (termasuk penunu Whisper Jet LE) dan kawalan loji bersepadu IoT.

Kelebihan daya saing: Sebagai OEM, Astec memiliki dokumentasi teknikal yang pasti, spesifikasi reka bentuk dan pengetahuan proprietari tentang pengendalian peralatan. Kontraktor yang mengendalikan peralatan Astec mendapat sokongan teknikal yang paling berwibawa dan akses kepada komponen yang direka khusus untuk konfigurasi loji mereka.

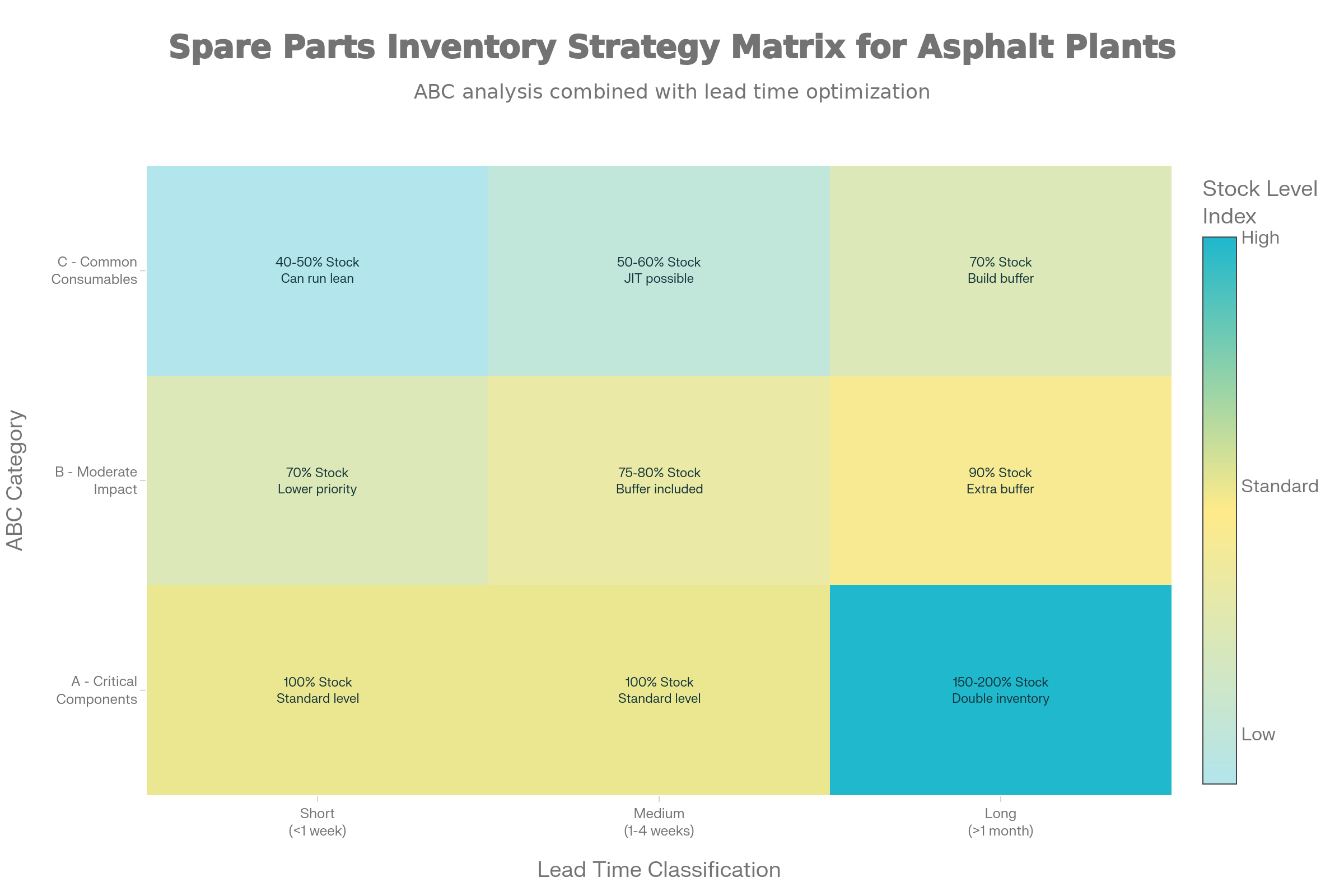

Kos masa henti yang tidak dirancang untuk loji asfalt melebihi $5,000–$10,000 sejam apabila mengambil kira buruh, kehilangan kapasiti pengeluaran dan penalti kelewatan projek. Pengurus kemudahan yang berfikiran ke hadapan menggunakan analisis inventori ABC untuk mengoptimumkan strategi stok alat ganti, memastikan komponen kritikal kekal tersedia sambil mengawal kos pembawaan.

Kategori A – Komponen Kritikal (Sasaran Ketersediaan 100%): Item yang kegagalannya menyebabkan penutupan loji serta-merta memerlukan kesediaan inventori kekal. Pelapik dram pengering, motor elektrik, kotak gear dan penapis rumah beg mewakili komponen Kategori A. Kos masa henti untuk mencari bahagian ini melebihi kos pembawaan inventori, membenarkan 100% ketersediaan stok.

Untuk item Kategori A dengan masa memimpin pembekal yang panjang (melebihi 4 minggu), amalan terbaik perolehan melibatkan mengekalkan beberapa unit dalam stok. Untuk masa pendahuluan yang lebih pendek, stok sandaran unit tunggal terbukti mencukupi. Pengurus kemudahan harus mewujudkan titik pesanan semula automatik yang terikat dengan corak penggunaan, memastikan stok gantian tiba apabila inventori di tangan kehabisan.

Kategori B – Komponen Kesan Sederhana (70–80% Sasaran Ketersediaan): Item yang menyebabkan strategi inventori berperingkat waran masa henti yang ketara tetapi bukan bencana. Tali sawat penghantar, galas, injap hidraulik dan termokopel merupakan contoh bahagian Kategori B. Komponen ini mempunyai hayat berguna yang lebih lama daripada bahan habis pakai, tetapi kegagalannya menjejaskan kecekapan loji atau memaksa penutupan separa.

Pasukan perolehan harus mengklasifikasikan item Kategori B mengikut masa petunjuk pembekal, kemudian melaraskan sasaran stok ke atas untuk item masa pendahuluan yang panjang. Galas yang tersedia dalam masa 2 minggu memerlukan kurang inventori sandaran daripada tali pinggang penghantar khusus dengan penghantaran 6 minggu.

Kategori C – Bahan Habis Biasa (50–60% Sasaran Ketersediaan): Pengikat, pengedap, gasket, tali pinggang kecil dan pelincir mewakili item penggunaan tinggi, kos individu yang rendah. Walaupun murah secara individu, menyimpan kuantiti yang berlebihan mengikat modal kerja. Strategi pembelian tepat pada masa atau pukal berfungsi untuk item Kategori C kerana masa pendahuluan yang singkat (biasanya <1 minggu) membolehkan pengisian semula yang cepat.

Pasukan perolehan harus mengira kuantiti pembelian yang optimum mengimbangi diskaun pukal dengan kos penyimpanan inventori. Sistem pesanan semula automatik yang mencetuskan pesanan pembelian apabila stok mencapai ambang yang ditetapkan mengurangkan usaha manual dan mengelakkan kehabisan stok.

Masa pendahuluan yang singkat (< 1 minggu): Stok keselamatan yang lebih rendah mencukupi

Masa pendahuluan sederhana (1–4 minggu): Inventori penimbal sederhana dinasihatkan

Masa pendahuluan yang panjang (> 4 minggu): Stok keselamatan yang banyak atau unit sandaran penting

Menggabungkan pengkategorian ABC dengan klasifikasi masa utama membolehkan pengoptimuman inventori kuantitatif. Komponen kritikal (Kategori A) dengan masa tunggu 8 minggu daripada pembekal tunggal mungkin menjamin 2–3 unit sandaran, manakala komponen sederhana (Kategori B) dengan ketersediaan 2 minggu mungkin memerlukan hanya 1 unit sandaran.

Profesional perolehan mengikuti proses penilaian berstruktur yang mengurangkan berat sebelah dan memastikan perbandingan sistematik merentas calon:

Sebelum menilai pembekal tertentu, pasukan perolehan mesti menentukan keperluan terperinci. Ini termasuk menentukan bahagian yang diperlukan, kuantiti, standard kualiti (pematuhan ASTM/AASHTO), garis masa penghantaran dan pilihan lokasi geografi. Spesifikasi yang diterbitkan dan piawaian kualiti menghapuskan kriteria penilaian yang tidak jelas.

Pemeriksaan awal menghapuskan vendor yang tidak dapat memenuhi keperluan teras. Contohnya termasuk sekatan lokasi geografi (sesetengah kontraktor memilih pembekal domestik), keperluan pensijilan (pematuhan ISO 9001), atau keupayaan khusus (perkhidmatan OEM untuk jenama peralatan tertentu).

Pasukan perolehan mengedarkan RFI yang meminta maklumat terperinci tentang keupayaan pembekal, tahap inventori, pilihan penghantaran, struktur harga dan model perkhidmatan. RFI biasanya meminta salinan pensijilan kualiti, rujukan pelanggan, penyata kewangan (atau pengesahan kelayakan kredit), dan dokumentasi teknikal.

Respons RFI yang berkualiti membezakan vendor yang serius daripada pesaing kasual. Pembekal yang menyediakan senarai inventori terperinci, masa petunjuk yang diterbitkan dan penetapan harga yang telus cemerlang dalam fasa ini. Mereka yang menawarkan jawapan yang samar-samar atau meminta kerahsiaan tentang tawaran standard menandakan potensi cabaran dalam urusan masa hadapan.

Menggunakan rangka kerja penilaian wajaran yang diterangkan sebelum ini, pasukan perolehan menjaringkan vendor calon merentas setiap kriteria. Metrik kuantitatif (masa penghantaran, kuantiti inventori, harga) membolehkan perbandingan langsung, manakala faktor kualitatif (kepakaran teknikal, kualiti perkhidmatan) memerlukan pemarkahan terhadap piawaian yang ditetapkan.

Membangunkan matriks pemarkahan mewujudkan ketelusan, mengurangkan berat sebelah dan menyediakan dokumentasi yang menyokong keputusan pemilihan akhir. Pemarkahan wajaran secara semula jadi menimbulkan pertukaran: contohnya, vendor yang mendapat markah lebih tinggi pada kualiti dan penghantaran mungkin mendapat markah yang lebih rendah pada harga, tetapi jumlah skor wajaran mereka mencerminkan sama ada premium kualiti membenarkan kos yang lebih tinggi.

Untuk perhubungan pembekal yang besar atau jangka panjang, audit kemudahan di tapak menyediakan bukti langsung tentang keupayaan operasi. Pasukan perolehan harus menilai kualiti pembuatan, organisasi inventori, sistem teknologi dan kepakaran tenaga kerja. Panggilan rujukan pelanggan daripada kemudahan yang serupa dengan operasi anda sendiri memberikan cerapan tentang prestasi dunia sebenar.

Semasa semakan rujukan, tanya soalan khusus tentang kebolehpercayaan penghantaran, kualiti sokongan teknikal, kelajuan penyelesaian masalah dan kesaksamaan harga. Rujukan daripada pelanggan yang mengendalikan kilang yang setanding dengan anda memberikan pandangan yang lebih berkaitan daripada testimoni generik.

Memenangi cadangan vendor mara ke fasa rundingan. Pasukan perolehan merundingkan syarat yang merangkumi harga, diskaun volum, syarat pembayaran, jaminan penghantaran dan perjanjian tahap perkhidmatan (SLA). Kontrak berkesan menyatakan:

Spesifikasi bahagian dan piawaian kualiti

Garis masa penghantaran dan pilihan dipercepatkan

Struktur harga dan diskaun

Jaminan ketersediaan inventori

Sokongan teknikal dan ketersediaan perkhidmatan lapangan

Syarat jaminan dan jaminan kualiti

Ulasan perniagaan suku tahunan untuk menilai prestasi

Fasa 6: Pemantauan Prestasi dan Penilaian Semula Berkala

Hubungan pembekal memerlukan pengurusan prestasi yang berterusan. Pasukan perolehan harus menjejaki metrik termasuk peratusan penghantaran tepat pada masa, kelajuan penyelesaian isu kualiti, daya saing harga dan responsif perkhidmatan pelanggan. Ulasan perniagaan suku tahunan dengan pembekal utama mengenal pasti peluang penambahbaikan dan mencegah kemerosotan perkhidmatan.

Penilaian semula kompetitif berkala—setiap 2–3 tahun—memastikan vendor pilihan anda kekal sebagai pilihan yang optimum. Dinamik pasaran, perubahan keupayaan pembekal dan keperluan perniagaan yang berkembang mewajarkan penilaian semula sekali-sekala.

Kemampanan dan Pematuhan Alam Sekitar: Semakin banyak, kontraktor mengutamakan pembekal yang menawarkan komponen mematuhi alam sekitar. Penapis baghouse yang dinaik taraf mengurangkan pelepasan, sistem pelinciran automatik meminimumkan sisa, dan teknologi penunu yang memfokuskan daya tarikan kecekapan bahan api kepada kontraktor yang menghadapi peraturan alam sekitar yang lebih ketat. Pembekal yang melabur dalam proses pembuatan yang mampan meletakkan diri mereka dengan baik dengan pembeli yang mementingkan alam sekitar.

Integrasi Digital dan IoT: Loji asfalt moden menyepadukan penderia IoT dan sistem pemantauan berasaskan awan. Pembekal yang menawarkan alat ganti yang serasi dengan sistem penyelenggaraan ramalan—di mana penderia menjejaki keadaan komponen dan memberi amaran kepada pengendali sebelum kegagalan—memerintahkan penilaian premium. Penyepaduan dengan perisian pengurusan loji membolehkan penyusunan semula alat ganti automatik apabila analitik ramalan meramalkan kegagalan yang akan berlaku.

Penyelesaian Modular dan Retrofit: Daripada penggantian loji lengkap, kontraktor semakin mengejar peningkatan yang disasarkan. Pembekal yang menawarkan komponen modular dan bahagian yang serasi retrofit menangkap permintaan yang semakin meningkat daripada kontraktor dengan peralatan yang sudah tua tetapi masih produktif. Perkhidmatan penyepaduan Stansteel dan kepakaran pengubahsuaian Motion Engineering menunjukkan trend ini.

Penyatuan Rantaian Bekalan: Penggabungan dan pengambilalihan menyatukan pembekal serantau ke dalam platform yang lebih besar. Penggabungan ini membawa manfaat (logistik yang lebih baik, inventori yang lebih luas) dan risiko (potensi jurang perkhidmatan jika penyatuan mengganggu kepakaran setempat). Pasukan perolehan harus memantau aktiviti penyatuan di kalangan pembekal pilihan untuk menjangka perubahan yang berpotensi.

Kos peralatan loji asfalt antara $500,000 (unit mudah alih yang lebih kecil) hingga $4 juta (operasi pegun yang besar). Alat ganti dan penyelenggaraan mewakili 10–15% daripada jumlah kos pemilikan merentas kitaran hayat peralatan. Analisis kos yang canggih memerlukan penilaian jumlah kos pemilikan dan bukannya harga unit sahaja.

Contoh perbandingan harga unit: Pembekal A memetik $15,000 untuk penggantian pelapik dram pengering dengan penghantaran 6 minggu. Pembekal B memetik $14,200 untuk komponen yang sama dengan penghantaran 2 minggu. Pembekal A kelihatan lebih murah sehingga memfaktorkan kos modal kerja dan risiko masa henti. Pada kos modal 10%, tempoh penyimpanan inventori tambahan 4 minggu berharga $600 dalam perbelanjaan pembiayaan. Selain itu, garis masa penghantaran yang lebih pendek daripada Pembekal B mengurangkan inventori sandaran yang diperlukan sebanyak satu unit, menjimatkan tambahan $14,200 dalam modal terikat.

Kesan kualiti pada TCO: Komponen berharga rendah yang gagal sebelum waktunya atau memerlukan penggantian lebih kerap meningkatkan kos seumur hidup. Pembekal premium mewajarkan harga unit yang lebih tinggi melalui ketahanan yang unggul, menghasilkan kekerapan penggantian yang lebih rendah dan jumlah perbelanjaan merentas kitaran hayat peralatan.

Analisis diskaun pukal: Diskaun volum memberi insentif kepada pembelian yang lebih besar tetapi meningkatkan kos penyimpanan inventori. Kuantiti pembelian optimum mengimbangi faedah diskaun terhadap kos pembiayaan dan risiko usang. Pembekal yang menawarkan harga berperingkat (diskaun 10%+ untuk pesanan 3 unit, 15% untuk pesanan 5 unit) mendayakan strategi volum tersuai yang sepadan dengan corak penggunaan organisasi.

Kesusahan kewangan pembekal: Nilaikan kestabilan kewangan pembekal sebelum melakukan hubungan jangka panjang. Minta penyata kewangan atau pengesahan kelayakan kredit. Kepekatan pelanggan yang tinggi (di mana seorang pelanggan mewakili >20% daripada hasil) menunjukkan kerentanan terhadap kehilangan pelanggan. Pembekal dengan pangkalan pelanggan yang pelbagai menunjukkan daya tahan.

Gangguan rantaian bekalan: Kebergantungan satu sumber mewujudkan kerentanan. Untuk komponen kritikal, kenal pasti pembekal alternatif atau kekalkan stok keselamatan yang diperluaskan daripada vendor utama anda. Pembekal global (seperti AIMIX dengan kehadiran di 150+ negara) menunjukkan daya tahan rantaian bekalan berbanding dengan pengendali satu lokasi.

Keusangan teknologi: Pengeluar peralatan secara berkala menghentikan komponen atau mereka bentuk semula mereka. Pembekal yang menawarkan kedua-dua komponen baharu dan terpakai (seperti Bahagian Hotmix) mengurangkan risiko keusangan dengan mendapatkan alat ganti lama untuk peralatan yang akan bersara. Keupayaan pembuatan tersuai Motion Engineering menangani keusangan oleh komponen penggantian kejuruteraan apabila yang asal tidak tersedia.

Isu kualiti dan waranti: Wujudkan jaminan kualiti dan syarat waranti yang jelas dalam kontrak pembekal. Tentukan remedi untuk kecacatan, termasuk garis masa penggantian dan peruntukan kos. Pembekal bersedia menerima liabiliti untuk isu kualiti menunjukkan keyakinan terhadap produk mereka.

Memilih pembekal bahagian loji asfalt yang betul mewakili salah satu keputusan perolehan berimpak tertinggi yang dihadapi oleh pengurus kemudahan dan pasukan perolehan. Tidak seperti pembelian komoditi, keputusan ini secara langsung mempengaruhi masa operasi peralatan, kebolehpercayaan operasi dan kos jangka panjang.

Rangka kerja penilaian vendor yang digariskan dalam panduan ini—kualiti penimbang (20%), penghantaran (20%), kepakaran (15%), penetapan harga (15%), kebolehpercayaan (15%), kestabilan kewangan (10%) dan skalabiliti (5%)—menyediakan metodologi kuantitatif untuk membandingkan calon. Pembekal terkemuka termasuk Bahagian Hotmix (tindak balas kecemasan), Kejuruteraan Gerakan (kepakaran teknikal), Stansteel (perkhidmatan penyepaduan), AIMIX (operasi global) dan Astec Industries (penyelesaian OEM) masing-masing cemerlang dalam dimensi tertentu, memerlukan pasukan pemerolehan menyelaraskan kriteria pemilihan dengan keutamaan organisasi.

Melaksanakan pengurusan inventori alat ganti yang canggih—menggunakan analisis ABC dan klasifikasi masa utama—meminimumkan risiko masa henti sambil mengawal kos pembawaan. Mengikuti proses pemilihan vendor enam fasa berstruktur (definisi keperluan, RFI, pemarkahan, audit, rundingan, pemantauan) mengurangkan berat sebelah, meningkatkan kualiti keputusan dan mencipta dokumentasi yang menyokong keputusan perolehan.

Prestasi loji asfalt anda sangat bergantung pada pembekal yang anda pilih. Laburkan masa dalam penilaian menyeluruh, dan organisasi anda akan merealisasikan pulangan merentas kebolehpercayaan, kos dan kecekapan operasi untuk tahun-tahun akan datang.

4 weeks): Substantial safety stock or backup units essential"}}},"folded":false,"type":"bullet","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","locked":false,"hidden":false,"children":[],"align":""}},"T1o7dVClmoi6wixQLUJckueln9C":{"id":"T1o7dVClmoi6wixQLUJckueln9C","snapshot":{"comments":[],"revisions":[],"hidden":false,"author":"7519687792448929820","children":[],"align":"","type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","locked":false,"text":{"apool":{"numToAttrib":{"0":["author","7519687792448929820"]},"nextNum":1},"initialAttributedTexts":{"attribs":{"0":"*0+8p"},"text":{"0":"Combining ABC categorization with lead time classification enables quantitative inventory optimization. A critical component (Category A) with 8-week lead time from a single supplier might warrant 2–3 backup units, while a moderate component (Category B) with 2-week availability might require just 1 backup unit."}}},"folded":false}},"VxyDdIxWEodkmdxhHuRcVMrknhf":{"id":"VxyDdIxWEodkmdxhHuRcVMrknhf","snapshot":{"children":[],"revisions":[],"locked":false,"author":"7519687792448929820","hidden":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+1e"},"text":{"0":"Vendor Selection Process: A Step-by-Step Framework"}}},"align":"","folded":false,"type":"heading2","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[]}},"FKrud3VN6od2VJxdZWcc2ecknQd":{"id":"FKrud3VN6od2VJxdZWcc2ecknQd","snapshot":{"revisions":[],"locked":false,"hidden":false,"align":"","folded":false,"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"author":"7519687792448929820","children":[],"text":{"initialAttributedTexts":{"attribs":{"0":"*0+3p"},"text":{"0":"Procurement professionals follow structured evaluation processes that reduce bias and ensure systematic comparison across candidates:"}},"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}}}}},"OoYhdmmiIogkTZxEcmycholpnMh":{"id":"OoYhdmmiIogkTZxEcmycholpnMh","snapshot":{"align":"","folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"locked":false,"hidden":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"text":{"0":"Phase 1: Requirements Definition and Initial Screening"},"attribs":{"0":"*0+1i"}}},"type":"text","revisions":[],"author":"7519687792448929820","children":[]}},"QIH2dUDrwofvcex7b9fctLLjnFe":{"id":"QIH2dUDrwofvcex7b9fctLLjnFe","snapshot":{"author":"7519687792448929820","type":"text","comments":[],"locked":false,"hidden":false,"align":"","folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+94"},"text":{"0":"Before evaluating specific suppliers, procurement teams must define detailed requirements. This includes specifying required parts, quantities, quality standards (ASTM/AASHTO compliance), delivery timelines, and geographic location preferences. Published specifications and quality standards eliminate vague evaluation criteria."}}}}},"VL5idfiTOoZxGVxp7zmccHlanwg":{"id":"VL5idfiTOoZxGVxp7zmccHlanwg","snapshot":{"locked":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+81"},"text":{"0":"Initial screening eliminates vendors unable to meet core requirements. Examples include geographic location restrictions (some contractors prefer domestic suppliers), certification requirements (ISO 9001 compliance), or specialized capabilities (OEM service for specific equipment brands)."}}},"align":"","folded":false,"comments":[],"revisions":[],"hidden":false,"author":"7519687792448929820","children":[],"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC"}},"YJyudHyLsoXopIxxzSNczB71nNe":{"id":"YJyudHyLsoXopIxxzSNczB71nNe","snapshot":{"children":[],"text":{"initialAttributedTexts":{"attribs":{"0":"*0+1s"},"text":{"0":"Phase 2: Information Gathering and Request for Information (RFI)"}},"apool":{"numToAttrib":{"0":["author","7519687792448929820"]},"nextNum":1}},"folded":false,"revisions":[],"author":"7519687792448929820","comments":[],"locked":false,"hidden":false,"align":"","type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC"}},"DNMmdjKOYoL00vxvkQac4l1tntD":{"id":"DNMmdjKOYoL00vxvkQac4l1tntD","snapshot":{"revisions":[],"locked":false,"hidden":false,"align":"","folded":false,"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+9a"},"text":{"0":"Procurement teams distribute RFIs requesting detailed information about supplier capabilities, inventory levels, delivery options, pricing structures, and service models. RFIs typically request copies of quality certifications, customer references, financial statements (or creditworthiness verification), and technical documentation."}}},"comments":[],"author":"7519687792448929820"}},"Anl5dsL5CobRDSxgPTMcfCsinDh":{"id":"Anl5dsL5CobRDSxgPTMcfCsinDh","snapshot":{"children":[],"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"locked":false,"hidden":false,"author":"7519687792448929820","type":"text","comments":[],"text":{"initialAttributedTexts":{"attribs":{"0":"*0+8x"},"text":{"0":"Quality RFI responses distinguish serious vendors from casual competitors. Suppliers providing detailed inventory lists, published lead times, and transparent pricing excel in this phase. Those offering vague responses or requesting confidentiality about standard offerings signal potential challenges in future dealings."}},"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}}},"align":"","folded":false}},"RV5ldBAsMo3HUAxLzTXc9MATnDc":{"id":"RV5ldBAsMo3HUAxLzTXc9MATnDc","snapshot":{"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"locked":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+17"},"text":{"0":"Phase 3: Competitive Evaluation and Scoring"}}},"align":"","folded":false,"revisions":[],"hidden":false,"author":"7519687792448929820","children":[]}},"PN5adgk40olbODxN6gRczkc1nGc":{"id":"PN5adgk40olbODxN6gRczkc1nGc","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","children":[],"locked":false,"hidden":false,"author":"7519687792448929820","text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"text":{"0":"Using the weighted evaluation framework described earlier, procurement teams score candidate vendors across each criterion. Quantitative metrics (delivery time, inventory quantity, pricing) enable direct comparison, while qualitative factors (technical expertise, service quality) require scoring against defined standards."},"attribs":{"0":"*0+8z"}}},"align":"","type":"text","comments":[],"revisions":[],"folded":false}},"XaqFdekAeoJ5Z6xL4BxcMKsPnjc":{"id":"XaqFdekAeoJ5Z6xL4BxcMKsPnjc","snapshot":{"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+9x"},"text":{"0":"Developing a scoring matrix creates transparency, reduces bias, and provides documentation supporting final selection decisions. Weighted scoring naturally surfaces trade-offs: for instance, a vendor scoring higher on quality and delivery may score lower on pricing, but their total weighted score reflects whether the quality premium justifies higher cost."}}},"align":"","folded":false,"revisions":[],"locked":false,"hidden":false}},"AALadTRjMocguwxwjPTcjZpankf":{"id":"AALadTRjMocguwxwjPTcjZpankf","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"children":[],"type":"text","hidden":false,"author":"7519687792448929820","text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"text":{"0":"Phase 4: Site Audits and Reference Checks"},"attribs":{"0":"*0+15"}}},"align":"","folded":false,"locked":false}},"I2UsdPep0oAf7exgZbHcEeXqn1g":{"id":"I2UsdPep0oAf7exgZbHcEeXqn1g","snapshot":{"revisions":[],"hidden":false,"children":[],"align":"","folded":false,"text":{"initialAttributedTexts":{"attribs":{"0":"*0+a2"},"text":{"0":"For large or long-term supplier relationships, on-site facility audits provide direct evidence of operational capability. Procurement teams should assess manufacturing quality, inventory organization, technology systems, and workforce expertise. Customer reference calls from facilities similar to your own operation provide insights into real-world performance."}},"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}}},"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"locked":false,"author":"7519687792448929820"}},"UFSldEfhxo14sUxOFzbcsNNancc":{"id":"UFSldEfhxo14sUxOFzbcsNNancc","snapshot":{"locked":false,"hidden":false,"author":"7519687792448929820","children":[],"folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"text":{"apool":{"numToAttrib":{"0":["author","7519687792448929820"]},"nextNum":1},"initialAttributedTexts":{"attribs":{"0":"*0+7j"},"text":{"0":"During reference checks, ask specific questions about delivery reliability, technical support quality, problem resolution speed, and pricing fairness. References from customers operating plants comparable to yours provide more relevant insights than generic testimonials."}}},"align":"","type":"text","comments":[]}},"NzOpd1SUioiMjRxwyBZcjpsTnkb":{"id":"NzOpd1SUioiMjRxwyBZcjpsTnkb","snapshot":{"hidden":false,"author":"7519687792448929820","align":"","locked":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+18"},"text":{"0":"Phase 5: Negotiation and Contract Definition"}}},"folded":false,"type":"text"}},"OnktdAvlyoUOxOxTbkgc1eesnRh":{"id":"OnktdAvlyoUOxOxTbkgc1eesnRh","snapshot":{"folded":false,"comments":[],"hidden":false,"children":[],"align":"","author":"7519687792448929820","text":{"apool":{"numToAttrib":{"0":["author","7519687792448929820"]},"nextNum":1},"initialAttributedTexts":{"text":{"0":"Winning vendor proposals advance to negotiation phase. Procurement teams negotiate terms spanning pricing, volume discounts, payment terms, delivery guarantees, and service level agreements (SLAs). Effective contracts specify:"},"attribs":{"0":"*0+6a"}}},"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"locked":false}},"Y2B8dPl7toc5GixLFIKczW8Fnjf":{"id":"Y2B8dPl7toc5GixLFIKczW8Fnjf","snapshot":{"hidden":false,"author":"7519687792448929820","children":[],"folded":false,"type":"bullet","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"locked":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+15"},"text":{"0":"Part specifications and quality standards"}}},"align":""}},"IefmdzPihoQhVFxxChhcBDD3n3c":{"id":"IefmdzPihoQhVFxxChhcBDD3n3c","snapshot":{"type":"bullet","revisions":[],"locked":false,"align":"","text":{"initialAttributedTexts":{"attribs":{"0":"*0+14"},"text":{"0":"Delivery timelines and expedited options"}},"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}}},"folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"hidden":false,"author":"7519687792448929820","children":[]}},"LPwkditbcoX3tBxmhyhcSEkrnn9":{"id":"LPwkditbcoX3tBxmhyhcSEkrnn9","snapshot":{"children":[],"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","hidden":false,"author":"7519687792448929820","locked":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+u"},"text":{"0":"Pricing and discount structure"}}},"align":"","folded":false,"type":"bullet","comments":[],"revisions":[]}},"AheFdqUZXoIX9TxZ2IGckoWmnkh":{"id":"AheFdqUZXoIX9TxZ2IGckoWmnkh","snapshot":{"type":"bullet","comments":[],"locked":false,"children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+x"},"text":{"0":"Inventory availability guarantees"}}},"folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"hidden":false,"author":"7519687792448929820","align":""}},"Zi0qdLEwSoMZyZx8bWMcBK4NnRc":{"id":"Zi0qdLEwSoMZyZx8bWMcBK4NnRc","snapshot":{"folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"locked":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+1c"},"text":{"0":"Technical support and field service availability"}}},"align":"","type":"bullet","hidden":false,"author":"7519687792448929820","children":[]}},"ToptdFLado6OsgxKVO6czPZTnGc":{"id":"ToptdFLado6OsgxKVO6czPZTnGc","snapshot":{"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"text":{"0":"Warranty terms and quality guarantees"},"attribs":{"0":"*0+11"}}},"folded":false,"comments":[],"locked":false,"revisions":[],"hidden":false,"align":"","type":"bullet","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC"}},"Je3gdi3uGoVSxLx1QM9c1Z3lnvc":{"id":"Je3gdi3uGoVSxLx1QM9c1Z3lnvc","snapshot":{"locked":false,"folded":false,"type":"bullet","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"hidden":false,"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+1c"},"text":{"0":"Quarterly business reviews to assess performance"}}},"align":""}},"IfKRdQkzkoBa2SxeLLQctrCZnWd":{"id":"IfKRdQkzkoBa2SxeLLQctrCZnWd","snapshot":{"folded":false,"type":"text","comments":[],"locked":false,"author":"7519687792448929820","text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+1m"},"text":{"0":"Phase 6: Performance Monitoring and Periodic Re-evaluation"}}},"align":"","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"hidden":false,"children":[]}},"DfJ2dHUQeoIhqoxMATicucCZnqh":{"id":"DfJ2dHUQeoIhqoxMATicucCZnqh","snapshot":{"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+9o"},"text":{"0":"Supplier relationships require ongoing performance management. Procurement teams should track metrics including on-time delivery percentage, quality issue resolution speed, pricing competitiveness, and customer service responsiveness. Quarterly business reviews with key suppliers identify improvement opportunities and prevent service degradation."}}},"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"align":"","folded":false,"comments":[],"locked":false,"hidden":false}},"SjZcdRzfyowjCfx46FIctyWZnUh":{"id":"SjZcdRzfyowjCfx46FIctyWZnUh","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","locked":false,"hidden":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+62"},"text":{"0":"Periodic competitive re-evaluation—every 2–3 years—ensures your selected vendors remain optimal choices. Market dynamics, supplier capability changes, and evolving business requirements justify occasional reassessment."}}},"align":"","folded":false,"type":"text","comments":[],"revisions":[],"author":"7519687792448929820","children":[]}},"ScH2dEB3fo1nBXxFh09coOiQnSf":{"id":"ScH2dEB3fo1nBXxFh09coOiQnSf","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+1u"},"text":{"0":"Industry Insights: Emerging Trends in Asphalt Plant Parts Sourcing"}}},"folded":false,"type":"heading2","revisions":[],"locked":false,"hidden":false,"align":""}},"EjFldErv9o77JyxANh8ciydXnqs":{"id":"EjFldErv9o77JyxANh8ciydXnqs","snapshot":{"type":"text","locked":false,"hidden":false,"author":"7519687792448929820","children":[],"text":{"initialAttributedTexts":{"attribs":{"0":"*0+d3"},"text":{"0":"Sustainability and Environmental Compliance: Increasingly, contractors prioritize suppliers offering environmentally compliant components. Upgraded baghouse filters reduce emissions, automated lubrication systems minimize waste, and burner technology focusing on fuel efficiency appeal to contractors facing stricter environmental regulations. Suppliers investing in sustainable manufacturing processes position themselves favorably with environmentally conscious buyers."}},"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}}},"align":"","folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[]}},"ELl6dnb9sodSHIxqRXacsbtCnht":{"id":"ELl6dnb9sodSHIxqRXacsbtCnht","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+bp"},"text":{"0":"Digital Integration and IoT: Modern asphalt plants integrate IoT sensors and cloud-based monitoring systems. Suppliers offering parts compatible with predictive maintenance systems—where sensors track component condition and alert operators before failure—command premium valuations. Integration with plant management software enables automatic spare parts reordering when predictive analytics forecast imminent failures."}}},"align":"","folded":false,"type":"text","locked":false,"hidden":false}},"NmT3dzTEWoT7vnxxrJdcgUENnmd":{"id":"NmT3dzTEWoT7vnxxrJdcgUENnmd","snapshot":{"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+ac"},"text":{"0":"Modular and Retrofit Solutions: Rather than complete plant replacement, contractors increasingly pursue targeted upgrades. Suppliers offering modular components and retrofit-compatible parts capture growing demand from contractors with aging but still-productive equipment. Stansteel's integration services and Motion Engineering's retrofit expertise exemplify this trend."}}},"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"locked":false,"hidden":false,"type":"text","comments":[],"align":"","folded":false}},"AMHNd4ZjAok15QxUuagcmDjCn8d":{"id":"AMHNd4ZjAok15QxUuagcmDjCn8d","snapshot":{"locked":false,"hidden":false,"children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+ai"},"text":{"0":"Supply Chain Consolidation: Mergers and acquisitions consolidate regional suppliers into larger platforms. This consolidation brings benefits (improved logistics, broader inventory) and risks (potential service gaps if consolidation disrupts localized expertise). Procurement teams should monitor consolidation activity among preferred suppliers to anticipate potential changes."}}},"folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"author":"7519687792448929820","align":"","type":"text"}},"WSA1de7aDoMUAuxxwLLca7Zrnof":{"id":"WSA1de7aDoMUAuxxwLLca7Zrnof","snapshot":{"type":"heading2","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"locked":false,"author":"7519687792448929820","children":[],"revisions":[],"hidden":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+1k"},"text":{"0":"Cost Implications: Understanding Total Cost of Ownership"}}},"align":"","folded":false}},"NYK8dCvB9oUVqSxQ8btcaplnniK":{"id":"NYK8dCvB9oUVqSxQ8btcaplnniK","snapshot":{"children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+8s"},"text":{"0":"Asphalt plant equipment costs range from $500,000 (smaller portable units) to $4 million (large stationary operations). Parts and maintenance represent 10–15% of total ownership costs across equipment lifecycles. Sophisticated cost analysis requires evaluating total cost of ownership rather than unit pricing alone."}}},"folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","locked":false,"revisions":[],"hidden":false,"author":"7519687792448929820","align":"","type":"text","comments":[]}},"QpIldVexooppmcxTeT1csFHjnnh":{"id":"QpIldVexooppmcxTeT1csFHjnnh","snapshot":{"hidden":false,"author":"7519687792448929820","type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+er"},"text":{"0":"Unit pricing comparison example: Supplier A quotes $15,000 for a replacement dryer drum liner with 6-week delivery. Supplier B quotes $14,200 for the same component with 2-week delivery. Supplier A appears cheaper until factoring in working capital costs and downtime risk. At a 10% cost of capital, the extra 4-week inventory carrying period costs $600 in financing expense. Additionally, the shorter delivery timeline from Supplier B reduces required backup inventory by one unit, saving an additional $14,200 in tied-up capital."}}},"align":"","folded":false,"comments":[],"locked":false,"children":[]}},"A3ildoAOyozb0WxFosIcN98Knjf":{"id":"A3ildoAOyozb0WxFosIcN98Knjf","snapshot":{"children":[],"text":{"apool":{"numToAttrib":{"0":["author","7519687792448929820"]},"nextNum":1},"initialAttributedTexts":{"attribs":{"0":"*0+85"},"text":{"0":"Quality impact on TCO: Lower-priced components that fail prematurely or require more frequent replacement increase lifetime costs. Premium suppliers justify higher unit prices through superior durability, resulting in lower replacement frequency and total spending across equipment lifecycles."}}},"align":"","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"hidden":false,"author":"7519687792448929820","folded":false,"type":"text","comments":[],"locked":false}},"ULIzdxC2So1iHLxNKnccJ2jEnGc":{"id":"ULIzdxC2So1iHLxNKnccJ2jEnGc","snapshot":{"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+al"},"text":{"0":"Bulk discount analysis: Volume discounts incentivize larger purchases but increase inventory carrying costs. Optimal purchase quantity balances discount benefits against financing costs and obsolescence risk. Suppliers offering tiered pricing (10%+ discount for 3-unit orders, 15% for 5-unit orders) enable customized volume strategies matching organizational consumption patterns."}}},"align":"","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"children":[],"hidden":false,"author":"7519687792448929820","folded":false,"type":"text","revisions":[],"locked":false}},"UxGJd7aqwofsedxwqI7cfll0nMd":{"id":"UxGJd7aqwofsedxwqI7cfll0nMd","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"children":[],"align":"","type":"heading2","locked":false,"hidden":false,"author":"7519687792448929820","text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+1j"},"text":{"0":"Risk Mitigation: Protecting Against Supplier Disruption"}}},"folded":false,"comments":[]}},"GP39dOOI7oj4YSxcVzice1qXn7d":{"id":"GP39dOOI7oj4YSxcVzice1qXn7d","snapshot":{"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+9z"},"text":{"0":"Supplier financial distress: Evaluate supplier financial stability before committing to long-term relationships. Request financial statements or creditworthiness verification. High customer concentration (where one customer represents >20% of revenue) indicates vulnerability to customer loss. Suppliers with diversified customer bases demonstrate resilience."}}},"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"locked":false,"hidden":false,"comments":[],"author":"7519687792448929820","children":[],"align":"","folded":false}},"WWiVd0S0VoFQpbxTonwcq8aXn0D":{"id":"WWiVd0S0VoFQpbxTonwcq8aXn0D","snapshot":{"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","locked":false,"hidden":false,"children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+91"},"text":{"0":"Supply chain disruption: Single-source dependency creates vulnerability. For critical components, identify alternative suppliers or maintain expanded safety stock from your primary vendor. Global suppliers (like AIMIX with presence in 150+ countries) demonstrate supply chain resilience compared to single-location operators."}}},"align":"","comments":[],"revisions":[],"author":"7519687792448929820","folded":false}},"SvkQdiGMHoRAoWx4MBrcT9rantc":{"id":"SvkQdiGMHoRAoWx4MBrcT9rantc","snapshot":{"type":"text","locked":false,"hidden":false,"children":[],"align":"","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"author":"7519687792448929820","text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"text":{"0":"Technology obsolescence: Equipment manufacturers periodically discontinue components or redesign them. Suppliers offering both new and used components (like Hotmix Parts) mitigate obsolescence risk by sourcing legacy parts for retiring equipment. Motion Engineering's custom manufacturing capability addresses obsolescence by engineering replacement components when originals become unavailable."},"attribs":{"0":"*0+az"}}},"folded":false}},"VTIad9NQtogdNGxLZhycioienxf":{"id":"VTIad9NQtogdNGxLZhycioienxf","snapshot":{"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","revisions":[],"hidden":false,"author":"7519687792448929820","children":[],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"text":{"0":"Quality and warranty issues: Establish clear quality guarantees and warranty terms in supplier contracts. Specify remedies for defects, including replacement timelines and cost allocation. Suppliers willing to accept liability for quality issues demonstrate confidence in their products."},"attribs":{"0":"*0+7z"}}},"align":"","comments":[],"locked":false,"folded":false}},"HuEQdXdVVop6loxyRytcrsgInff":{"id":"HuEQdXdVVop6loxyRytcrsgInff","snapshot":{"locked":false,"author":"7519687792448929820","children":[],"text":{"apool":{"numToAttrib":{"0":["author","7519687792448929820"]},"nextNum":1},"initialAttributedTexts":{"attribs":{"0":"*0+1t"},"text":{"0":"Conclusion: Optimizing Your Asphalt Plant Parts Sourcing Strategy"}}},"align":"","folded":false,"type":"heading2","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","hidden":false,"comments":[],"revisions":[]}},"FZ9SdCuxjoSSHFxbQCCcSqj1nMf":{"id":"FZ9SdCuxjoSSHFxbQCCcSqj1nMf","snapshot":{"type":"text","hidden":false,"author":"7519687792448929820","children":[],"align":"","folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"locked":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+7s"},"text":{"0":"Selecting the right asphalt plant parts suppliers represents one of the highest-impact procurement decisions facility managers and procurement teams face. Unlike commodity purchases, this decision directly influences equipment uptime, operational reliability, and long-term costs."}}}}},"ZfdDdUTTSoYs50xjvdPconZSnMe":{"id":"ZfdDdUTTSoYs50xjvdPconZSnMe","snapshot":{"type":"text","revisions":[],"locked":false,"children":[],"align":"","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"hidden":false,"author":"7519687792448929820","text":{"initialAttributedTexts":{"attribs":{"0":"*0+g5"},"text":{"0":"The vendor evaluation framework outlined in this guide—weighing quality (20%), delivery (20%), expertise (15%), pricing (15%), reliability (15%), financial stability (10%), and scalability (5%)—provides a quantitative methodology for comparing candidates. Leading suppliers including Hotmix Parts (emergency response), Motion Engineering (technical expertise), Stansteel (integration services), AIMIX (global operations), and Astec Industries (OEM solutions) each excel in specific dimensions, requiring procurement teams to align selection criteria with organizational priorities."}},"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}}},"folded":false}},"FfjIdVelqoMbnvxKQz4cqaZDnHc":{"id":"FfjIdVelqoMbnvxKQz4cqaZDnHc","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"hidden":false,"author":"7519687792448929820","children":[],"folded":false,"type":"text","locked":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+b2"},"text":{"0":"Implementing sophisticated spare parts inventory management—using ABC analysis and lead time classifications—minimizes downtime risk while controlling carrying costs. Following a structured six-phase vendor selection process (requirements definition, RFI, scoring, audits, negotiation, monitoring) reduces bias, improves decision quality, and creates documentation supporting procurement decisions."}}},"align":"","revisions":[]}},"NklfdVDwqohZeXxBp9hcdPLOnhc":{"id":"NklfdVDwqohZeXxBp9hcdPLOnhc","snapshot":{"type":"text","author":"7519687792448929820","text":{"initialAttributedTexts":{"text":{"0":"The asphalt manufacturing industry's $36.7 billion market size and the capital-intensive nature of plant equipment justify investment in rigorous supplier evaluation. Procurement teams implementing comprehensive vendor selection frameworks, negotiating favorable contracts, and monitoring ongoing performance secure competitive advantages through superior equipment uptime, optimized procurement costs, and reliable supplier partnerships."},"attribs":{"0":"*0+c6"}},"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}}},"align":"","hidden":false,"children":[],"folded":false,"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"locked":false}},"HAx7dUxonowKLUxsdeFcAJD3n9g":{"id":"HAx7dUxonowKLUxsdeFcAJD3n9g","snapshot":{"type":"text","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","locked":false,"align":"","folded":false,"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+6f"},"text":{"0":"Your asphalt plant's performance depends critically on the suppliers you choose. Invest time in thorough evaluation, and your organization will realize returns across reliability, cost, and operational efficiency for years to come."}}},"comments":[],"revisions":[],"hidden":false,"author":"7519687792448929820","children":[]}},"Qxnyd1zwGo24ZExj0rvckeeLnmM":{"id":"Qxnyd1zwGo24ZExj0rvckeeLnmM","snapshot":{"type":"divider","parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","comments":[],"revisions":[],"locked":false,"hidden":false,"author":"7519687792448929820"}},"I2kKdzdhroKBL9xzUVGcTMhpnpS":{"id":"I2kKdzdhroKBL9xzUVGcTMhpnpS","snapshot":{"parent_id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","locked":false,"text":{"initialAttributedTexts":{"attribs":{"0":"*0+3u*0*1+s"},"text":{"0":"About HTWearParts.com: For more information on asphalt plant maintenance strategies, spare parts sourcing, and equipment solutions, visit https://www.htwearparts.com/"}},"apool":{"numToAttrib":{"0":["author","7519687792448929820"],"1":["link","https%3A%2F%2Fwww.htwearparts.com%2F"]},"nextNum":2}},"align":"","type":"text","revisions":[],"hidden":false,"author":"7519687792448929820","children":[],"folded":false,"comments":[]}},"ZYMQdgyWhoBxZgxLjpHc9oVgnjC":{"id":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","snapshot":{"type":"page","parent_id":"","comments":null,"revisions":null,"locked":false,"author":"7519687792448929820","align":"","hidden":false,"children":["FcvadEZuWoddmSxGTaZc4hn1nXe","XPwidKZ9momY7zxc58JcgbHsnEb","FmetdYdpDoilyCxEeu2c1UnrnKe","YGmkd4DXmofbkFxHFUGcKHbOnId","M2XsdwWbdodnjQxeWDIcZ17VnUd","BiF6d32BiooLk7xbZCdcp16onRf","UzPXdpyPfon2LBxXYI5cwqzDnic","GoGHdu3TioSKWgx4CNYcOfhAnqf","WDuyd3GyCoLdnWxOxHUcNsCTneh","XSPydu2fSorQEsxdVOTcPKw5ncg","DDvOdHsEIonwMpxtid8cI9XmnBa","ImWldNBG1oF2fpxlaSmch0oynxc","XNphdE5fwolTXPxzgc4cUOzEn8e","NuY9dgJYBoN6FZxlbF0cuILmnAh","KgdGdyGFZobrfExlqo9cHVvTnHf","P7hMdLDFRoBvJYxxheucW7UonFb","AhcRdsSeIoIfrnxs6Svc7iF4nyc","Zqwmd6AQGogIcyxf1vDcctWTneg","ZdTGdW76qoBoIdx81OgcFix8n4g","B5y9dCCfNogxLfxR2oxc966Lnmb","Ozv9dhMb1ojT7wxZywHch2TznMh","D6AtdGIVeothWExfS3UcGhSSnLc","WiiHdLRyBolV0exOtxccwn8Snxf","OW4tdZ4ZxoZikJxHcOBcCo5rn6d","LVqqd6vlPorOYMxnvXnczapOnKe","LwoVdoOREocsUYxc4HYcXOEAngZ","EQvFdMWRDo61cCxshQPceSo2nJc","T8ucdK7nKo03JCxlei6cRLoRnSb","MJCqdRLbRolGgWxioedcBCkzn5e","MCY0dbVipodYZIxjyQ4cAmNbnEh","T6nadQdNwoIFY4xMGOLcHtXsnyc","VjpKdJaJaoIXUEx4MW8cM7Pfn8c","E3eOdXML4o2ioCxefotcK4Epnub","ZJ4TdSzJEog61QxCaAScmOMcnWe","ADhsdgkGVo1sgkxkZB6cYQF3n6f","G38Uddw9WoCxWPxlAyKcA7Mvnof","TtYsd0LSgoKtWnxQgdmcahpFnLe","IBWEdIZXJo2O1FxP6NscScu8n2g","NtZudQk8qoQDmIxVS2qchiL0neb","FwtgdbnPboaP0Yx4jiJcckuknwe","XnytdJKA5oJ9XHxjKwec0MfknHe","Q9Z3dch7Xo0oH6x3oR1cUcfpnWg","CYqudEv3lop7UPxN9jsc4xJfncV","Fpw8den7AoPa6lxRvFgcjuveneh","Vv1fd7bv8o7uiexC1FJclsTPnDb","JnQ5d5yQyo6YCTxhdiGcQyNUn8b","TlQVdgAsBopmDvxpuiwcHlxwnSc","ZSz0dfT24oJDhVxGlmOcBv9JnQO","M2ahdNsd2oDlcoxBe0ucVlycnXd","JagBdY61Yoc6f5xbOTEcmlgZnnh","NfwudkcDFoSjApxum8EcA1TanPe","EO9Ld2qVQoaibZxQqcQcM3J0nPh","X3RUdN3fqoBAhaxj5iQcJzyxnab","T1o7dVClmoi6wixQLUJckueln9C","VxyDdIxWEodkmdxhHuRcVMrknhf","FKrud3VN6od2VJxdZWcc2ecknQd","OoYhdmmiIogkTZxEcmycholpnMh","QIH2dUDrwofvcex7b9fctLLjnFe","VL5idfiTOoZxGVxp7zmccHlanwg","YJyudHyLsoXopIxxzSNczB71nNe","DNMmdjKOYoL00vxvkQac4l1tntD","Anl5dsL5CobRDSxgPTMcfCsinDh","RV5ldBAsMo3HUAxLzTXc9MATnDc","PN5adgk40olbODxN6gRczkc1nGc","XaqFdekAeoJ5Z6xL4BxcMKsPnjc","AALadTRjMocguwxwjPTcjZpankf","I2UsdPep0oAf7exgZbHcEeXqn1g","UFSldEfhxo14sUxOFzbcsNNancc","NzOpd1SUioiMjRxwyBZcjpsTnkb","OnktdAvlyoUOxOxTbkgc1eesnRh","Y2B8dPl7toc5GixLFIKczW8Fnjf","IefmdzPihoQhVFxxChhcBDD3n3c","LPwkditbcoX3tBxmhyhcSEkrnn9","AheFdqUZXoIX9TxZ2IGckoWmnkh","Zi0qdLEwSoMZyZx8bWMcBK4NnRc","ToptdFLado6OsgxKVO6czPZTnGc","Je3gdi3uGoVSxLx1QM9c1Z3lnvc","IfKRdQkzkoBa2SxeLLQctrCZnWd","DfJ2dHUQeoIhqoxMATicucCZnqh","SjZcdRzfyowjCfx46FIctyWZnUh","ScH2dEB3fo1nBXxFh09coOiQnSf","EjFldErv9o77JyxANh8ciydXnqs","ELl6dnb9sodSHIxqRXacsbtCnht","NmT3dzTEWoT7vnxxrJdcgUENnmd","AMHNd4ZjAok15QxUuagcmDjCn8d","WSA1de7aDoMUAuxxwLLca7Zrnof","NYK8dCvB9oUVqSxQ8btcaplnniK","QpIldVexooppmcxTeT1csFHjnnh","A3ildoAOyozb0WxFosIcN98Knjf","ULIzdxC2So1iHLxNKnccJ2jEnGc","UxGJd7aqwofsedxwqI7cfll0nMd","GP39dOOI7oj4YSxcVzice1qXn7d","WWiVd0S0VoFQpbxTonwcq8aXn0D","SvkQdiGMHoRAoWx4MBrcT9rantc","VTIad9NQtogdNGxLZhycioienxf","HuEQdXdVVop6loxyRytcrsgInff","FZ9SdCuxjoSSHFxbQCCcSqj1nMf","ZfdDdUTTSoYs50xjvdPconZSnMe","FfjIdVelqoMbnvxKQz4cqaZDnHc","NklfdVDwqohZeXxBp9hcdPLOnhc","HAx7dUxonowKLUxsdeFcAJD3n9g","Qxnyd1zwGo24ZExj0rvckeeLnmM","I2kKdzdhroKBL9xzUVGcTMhpnpS"],"text":{"apool":{"nextNum":1,"numToAttrib":{"0":["author","7519687792448929820"]}},"initialAttributedTexts":{"attribs":{"0":"*0+2r"},"text":{"0":"Choosing the Right Asphalt Plant Parts Supplier: A Comprehensive Vendor Comparison & Sourcing Guide"}}},"doc_info":{"editors":["7519687792448929820","7570895337385410588"],"options":["editors","edit_time"],"deleted_editors":[],"option_modified":null}}}},"payloadMap":{"FcvadEZuWoddmSxGTaZc4hn1nXe":{"level":1},"XPwidKZ9momY7zxc58JcgbHsnEb":{"level":1},"YGmkd4DXmofbkFxHFUGcKHbOnId":{"level":1},"M2XsdwWbdodnjQxeWDIcZ17VnUd":{"level":1},"BiF6d32BiooLk7xbZCdcp16onRf":{"level":1},"GoGHdu3TioSKWgx4CNYcOfhAnqf":{"level":1},"WDuyd3GyCoLdnWxOxHUcNsCTneh":{"level":1},"XSPydu2fSorQEsxdVOTcPKw5ncg":{"level":1},"DDvOdHsEIonwMpxtid8cI9XmnBa":{"level":1},"ImWldNBG1oF2fpxlaSmch0oynxc":{"level":1},"KgdGdyGFZobrfExlqo9cHVvTnHf":{"level":1},"P7hMdLDFRoBvJYxxheucW7UonFb":{"level":1},"AhcRdsSeIoIfrnxs6Svc7iF4nyc":{"level":1},"Zqwmd6AQGogIcyxf1vDcctWTneg":{"level":1},"ZdTGdW76qoBoIdx81OgcFix8n4g":{"level":1},"B5y9dCCfNogxLfxR2oxc966Lnmb":{"level":1},"Ozv9dhMb1ojT7wxZywHch2TznMh":{"level":1},"D6AtdGIVeothWExfS3UcGhSSnLc":{"level":1},"WiiHdLRyBolV0exOtxccwn8Snxf":{"level":1},"OW4tdZ4ZxoZikJxHcOBcCo5rn6d":{"level":1},"LVqqd6vlPorOYMxnvXnczapOnKe":{"level":1},"LwoVdoOREocsUYxc4HYcXOEAngZ":{"level":1},"EQvFdMWRDo61cCxshQPceSo2nJc":{"level":1},"MCY0dbVipodYZIxjyQ4cAmNbnEh":{"level":1},"T6nadQdNwoIFY4xMGOLcHtXsnyc":{"level":1},"VjpKdJaJaoIXUEx4MW8cM7Pfn8c":{"level":1},"E3eOdXML4o2ioCxefotcK4Epnub":{"level":1},"ZJ4TdSzJEog61QxCaAScmOMcnWe":{"level":1},"ADhsdgkGVo1sgkxkZB6cYQF3n6f":{"level":1},"G38Uddw9WoCxWPxlAyKcA7Mvnof":{"level":1},"TtYsd0LSgoKtWnxQgdmcahpFnLe":{"level":1},"IBWEdIZXJo2O1FxP6NscScu8n2g":{"level":1},"NtZudQk8qoQDmIxVS2qchiL0neb":{"level":1},"FwtgdbnPboaP0Yx4jiJcckuknwe":{"level":1},"CYqudEv3lop7UPxN9jsc4xJfncV":{"level":1},"Fpw8den7AoPa6lxRvFgcjuveneh":{"level":1},"Vv1fd7bv8o7uiexC1FJclsTPnDb":{"level":1},"JnQ5d5yQyo6YCTxhdiGcQyNUn8b":{"level":1},"TlQVdgAsBopmDvxpuiwcHlxwnSc":{"level":1},"ZSz0dfT24oJDhVxGlmOcBv9JnQO":{"level":1},"M2ahdNsd2oDlcoxBe0ucVlycnXd":{"level":1},"JagBdY61Yoc6f5xbOTEcmlgZnnh":{"level":1},"T1o7dVClmoi6wixQLUJckueln9C":{"level":1},"FKrud3VN6od2VJxdZWcc2ecknQd":{"level":1},"OoYhdmmiIogkTZxEcmycholpnMh":{"level":1},"QIH2dUDrwofvcex7b9fctLLjnFe":{"level":1},"VL5idfiTOoZxGVxp7zmccHlanwg":{"level":1},"YJyudHyLsoXopIxxzSNczB71nNe":{"level":1},"DNMmdjKOYoL00vxvkQac4l1tntD":{"level":1},"Anl5dsL5CobRDSxgPTMcfCsinDh":{"level":1},"RV5ldBAsMo3HUAxLzTXc9MATnDc":{"level":1},"PN5adgk40olbODxN6gRczkc1nGc":{"level":1},"XaqFdekAeoJ5Z6xL4BxcMKsPnjc":{"level":1},"AALadTRjMocguwxwjPTcjZpankf":{"level":1},"I2UsdPep0oAf7exgZbHcEeXqn1g":{"level":1},"UFSldEfhxo14sUxOFzbcsNNancc":{"level":1},"NzOpd1SUioiMjRxwyBZcjpsTnkb":{"level":1},"OnktdAvlyoUOxOxTbkgc1eesnRh":{"level":1},"IfKRdQkzkoBa2SxeLLQctrCZnWd":{"level":1},"DfJ2dHUQeoIhqoxMATicucCZnqh":{"level":1},"SjZcdRzfyowjCfx46FIctyWZnUh":{"level":1},"EjFldErv9o77JyxANh8ciydXnqs":{"level":1},"ELl6dnb9sodSHIxqRXacsbtCnht":{"level":1},"NmT3dzTEWoT7vnxxrJdcgUENnmd":{"level":1},"AMHNd4ZjAok15QxUuagcmDjCn8d":{"level":1},"NYK8dCvB9oUVqSxQ8btcaplnniK":{"level":1},"QpIldVexooppmcxTeT1csFHjnnh":{"level":1},"A3ildoAOyozb0WxFosIcN98Knjf":{"level":1},"ULIzdxC2So1iHLxNKnccJ2jEnGc":{"level":1},"GP39dOOI7oj4YSxcVzice1qXn7d":{"level":1},"WWiVd0S0VoFQpbxTonwcq8aXn0D":{"level":1},"SvkQdiGMHoRAoWx4MBrcT9rantc":{"level":1},"VTIad9NQtogdNGxLZhycioienxf":{"level":1},"FZ9SdCuxjoSSHFxbQCCcSqj1nMf":{"level":1},"ZfdDdUTTSoYs50xjvdPconZSnMe":{"level":1},"FfjIdVelqoMbnvxKQz4cqaZDnHc":{"level":1},"NklfdVDwqohZeXxBp9hcdPLOnhc":{"level":1},"HAx7dUxonowKLUxsdeFcAJD3n9g":{"level":1},"I2kKdzdhroKBL9xzUVGcTMhpnpS":{"level":1},"lingoClipboardPayload":{"spaceSubExtraInfo":[{"spaceSubId":"XSPydu2fSorQEsxdVOTcPKw5ncg","word":"Maintenance"}],"spaceId":"ZYMQdgyWhoBxZgxLjpHc9oVgnjC","spaceType":1}},"extra":{"channel":"saas","pasteRandomId":"e510c0be-0462-4427-ab57-f16b6daacd5b","mention_page_title":{},"external_mention_url":{},"isEqualBlockSelection":true},"isKeepQuoteContainer":false,"selection":[{"id":1399,"type":"block","recordId":"FcvadEZuWoddmSxGTaZc4hn1nXe"},{"id":1400,"type":"block","recordId":"XPwidKZ9momY7zxc58JcgbHsnEb"},{"id":1402,"type":"block","recordId":"FmetdYdpDoilyCxEeu2c1UnrnKe"},{"id":1403,"type":"block","recordId":"YGmkd4DXmofbkFxHFUGcKHbOnId"},{"id":1404,"type":"block","recordId":"M2XsdwWbdodnjQxeWDIcZ17VnUd"},{"id":1405,"type":"block","recordId":"BiF6d32BiooLk7xbZCdcp16onRf"},{"id":1407,"type":"block","recordId":"UzPXdpyPfon2LBxXYI5cwqzDnic"},{"id":1408,"type":"block","recordId":"GoGHdu3TioSKWgx4CNYcOfhAnqf"},{"id":1409,"type":"block","recordId":"WDuyd3GyCoLdnWxOxHUcNsCTneh"},{"id":1410,"type":"block","recordId":"XSPydu2fSorQEsxdVOTcPKw5ncg"},{"id":1411,"type":"block","recordId":"DDvOdHsEIonwMpxtid8cI9XmnBa"},{"id":1412,"type":"block","recordId":"ImWldNBG1oF2fpxlaSmch0oynxc"},{"id":1414,"type":"block","recordId":"XNphdE5fwolTXPxzgc4cUOzEn8e"},{"id":1415,"type":"block","recordId":"NuY9dgJYBoN6FZxlbF0cuILmnAh"},{"id":1416,"type":"block","recordId":"KgdGdyGFZobrfExlqo9cHVvTnHf"},{"id":1417,"type":"block","recordId":"P7hMdLDFRoBvJYxxheucW7UonFb"},{"id":1418,"type":"block","recordId":"AhcRdsSeIoIfrnxs6Svc7iF4nyc"},{"id":1419,"type":"block","recordId":"Zqwmd6AQGogIcyxf1vDcctWTneg"},{"id":1420,"type":"block","recordId":"ZdTGdW76qoBoIdx81OgcFix8n4g"},{"id":1421,"type":"block","recordId":"B5y9dCCfNogxLfxR2oxc966Lnmb"},{"id":1422,"type":"block","recordId":"Ozv9dhMb1ojT7wxZywHch2TznMh"},{"id":1423,"type":"block","recordId":"D6AtdGIVeothWExfS3UcGhSSnLc"},{"id":1424,"type":"block","recordId":"WiiHdLRyBolV0exOtxccwn8Snxf"},{"id":1425,"type":"block","recordId":"OW4tdZ4ZxoZikJxHcOBcCo5rn6d"},{"id":1426,"type":"block","recordId":"LVqqd6vlPorOYMxnvXnczapOnKe"},{"id":1427,"type":"block","recordId":"LwoVdoOREocsUYxc4HYcXOEAngZ"},{"id":1428,"type":"block","recordId":"EQvFdMWRDo61cCxshQPceSo2nJc"},{"id":1430,"type":"block","recordId":"T8ucdK7nKo03JCxlei6cRLoRnSb"},{"id":1431,"type":"block","recordId":"MJCqdRLbRolGgWxioedcBCkzn5e"},{"id":1432,"type":"block","recordId":"MCY0dbVipodYZIxjyQ4cAmNbnEh"},{"id":1433,"type":"block","recordId":"T6nadQdNwoIFY4xMGOLcHtXsnyc"},{"id":1434,"type":"block","recordId":"VjpKdJaJaoIXUEx4MW8cM7Pfn8c"},{"id":1435,"type":"block","recordId":"E3eOdXML4o2ioCxefotcK4Epnub"},{"id":1436,"type":"block","recordId":"ZJ4TdSzJEog61QxCaAScmOMcnWe"},{"id":1437,"type":"block","recordId":"ADhsdgkGVo1sgkxkZB6cYQF3n6f"},{"id":1438,"type":"block","recordId":"G38Uddw9WoCxWPxlAyKcA7Mvnof"},{"id":1439,"type":"block","recordId":"TtYsd0LSgoKtWnxQgdmcahpFnLe"},{"id":1440,"type":"block","recordId":"IBWEdIZXJo2O1FxP6NscScu8n2g"},{"id":1441,"type":"block","recordId":"NtZudQk8qoQDmIxVS2qchiL0neb"},{"id":1442,"type":"block","recordId":"FwtgdbnPboaP0Yx4jiJcckuknwe"},{"id":1444,"type":"block","recordId":"XnytdJKA5oJ9XHxjKwec0MfknHe"},{"id":1445,"type":"block","recordId":"Q9Z3dch7Xo0oH6x3oR1cUcfpnWg"},{"id":1446,"type":"block","recordId":"CYqudEv3lop7UPxN9jsc4xJfncV"},{"id":1447,"type":"block","recordId":"Fpw8den7AoPa6lxRvFgcjuveneh"},{"id":1448,"type":"block","recordId":"Vv1fd7bv8o7uiexC1FJclsTPnDb"},{"id":1449,"type":"block","recordId":"JnQ5d5yQyo6YCTxhdiGcQyNUn8b"},{"id":1450,"type":"block","recordId":"TlQVdgAsBopmDvxpuiwcHlxwnSc"},{"id":1451,"type":"block","recordId":"ZSz0dfT24oJDhVxGlmOcBv9JnQO"},{"id":1452,"type":"block","recordId":"M2ahdNsd2oDlcoxBe0ucVlycnXd"},{"id":1453,"type":"block","recordId":"JagBdY61Yoc6f5xbOTEcmlgZnnh"},{"id":1454,"type":"block","recordId":"NfwudkcDFoSjApxum8EcA1TanPe"},{"id":1455,"type":"block","recordId":"EO9Ld2qVQoaibZxQqcQcM3J0nPh"},{"id":1456,"type":"block","recordId":"X3RUdN3fqoBAhaxj5iQcJzyxnab"},{"id":1457,"type":"block","recordId":"T1o7dVClmoi6wixQLUJckueln9C"},{"id":1459,"type":"block","recordId":"VxyDdIxWEodkmdxhHuRcVMrknhf"},{"id":1460,"type":"block","recordId":"FKrud3VN6od2VJxdZWcc2ecknQd"},{"id":1461,"type":"block","recordId":"OoYhdmmiIogkTZxEcmycholpnMh"},{"id":1462,"type":"block","recordId":"QIH2dUDrwofvcex7b9fctLLjnFe"},{"id":1463,"type":"block","recordId":"VL5idfiTOoZxGVxp7zmccHlanwg"},{"id":1464,"type":"block","recordId":"YJyudHyLsoXopIxxzSNczB71nNe"},{"id":1465,"type":"block","recordId":"DNMmdjKOYoL00vxvkQac4l1tntD"},{"id":1466,"type":"block","recordId":"Anl5dsL5CobRDSxgPTMcfCsinDh"},{"id":1467,"type":"block","recordId":"RV5ldBAsMo3HUAxLzTXc9MATnDc"},{"id":1468,"type":"block","recordId":"PN5adgk40olbODxN6gRczkc1nGc"},{"id":1469,"type":"block","recordId":"XaqFdekAeoJ5Z6xL4BxcMKsPnjc"},{"id":1470,"type":"block","recordId":"AALadTRjMocguwxwjPTcjZpankf"},{"id":1471,"type":"block","recordId":"I2UsdPep0oAf7exgZbHcEeXqn1g"},{"id":1472,"type":"block","recordId":"UFSldEfhxo14sUxOFzbcsNNancc"},{"id":1473,"type":"block","recordId":"NzOpd1SUioiMjRxwyBZcjpsTnkb"},{"id":1474,"type":"block","recordId":"OnktdAvlyoUOxOxTbkgc1eesnRh"},{"id":1475,"type":"block","recordId":"Y2B8dPl7toc5GixLFIKczW8Fnjf"},{"id":1476,"type":"block","recordId":"IefmdzPihoQhVFxxChhcBDD3n3c"},{"id":1477,"type":"block","recordId":"LPwkditbcoX3tBxmhyhcSEkrnn9"},{"id":1478,"type":"block","recordId":"AheFdqUZXoIX9TxZ2IGckoWmnkh"},{"id":1479,"type":"block","recordId":"Zi0qdLEwSoMZyZx8bWMcBK4NnRc"},{"id":1480,"type":"block","recordId":"ToptdFLado6OsgxKVO6czPZTnGc"},{"id":1481,"type":"block","recordId":"Je3gdi3uGoVSxLx1QM9c1Z3lnvc"},{"id":1482,"type":"block","recordId":"IfKRdQkzkoBa2SxeLLQctrCZnWd"},{"id":1483,"type":"block","recordId":"DfJ2dHUQeoIhqoxMATicucCZnqh"},{"id":1484,"type":"block","recordId":"SjZcdRzfyowjCfx46FIctyWZnUh"},{"id":1486,"type":"block","recordId":"ScH2dEB3fo1nBXxFh09coOiQnSf"},{"id":1487,"type":"block","recordId":"EjFldErv9o77JyxANh8ciydXnqs"},{"id":1488,"type":"block","recordId":"ELl6dnb9sodSHIxqRXacsbtCnht"},{"id":1489,"type":"block","recordId":"NmT3dzTEWoT7vnxxrJdcgUENnmd"},{"id":1490,"type":"block","recordId":"AMHNd4ZjAok15QxUuagcmDjCn8d"},{"id":1492,"type":"block","recordId":"WSA1de7aDoMUAuxxwLLca7Zrnof"},{"id":1493,"type":"block","recordId":"NYK8dCvB9oUVqSxQ8btcaplnniK"},{"id":1494,"type":"block","recordId":"QpIldVexooppmcxTeT1csFHjnnh"},{"id":1495,"type":"block","recordId":"A3ildoAOyozb0WxFosIcN98Knjf"},{"id":1496,"type":"block","recordId":"ULIzdxC2So1iHLxNKnccJ2jEnGc"},{"id":1498,"type":"block","recordId":"UxGJd7aqwofsedxwqI7cfll0nMd"},{"id":1499,"type":"block","recordId":"GP39dOOI7oj4YSxcVzice1qXn7d"},{"id":1500,"type":"block","recordId":"WWiVd0S0VoFQpbxTonwcq8aXn0D"},{"id":1501,"type":"block","recordId":"SvkQdiGMHoRAoWx4MBrcT9rantc"},{"id":1502,"type":"block","recordId":"VTIad9NQtogdNGxLZhycioienxf"},{"id":1504,"type":"block","recordId":"HuEQdXdVVop6loxyRytcrsgInff"},{"id":1505,"type":"block","recordId":"FZ9SdCuxjoSSHFxbQCCcSqj1nMf"},{"id":1506,"type":"block","recordId":"ZfdDdUTTSoYs50xjvdPconZSnMe"},{"id":1507,"type":"block","recordId":"FfjIdVelqoMbnvxKQz4cqaZDnHc"},{"id":1508,"type":"block","recordId":"NklfdVDwqohZeXxBp9hcdPLOnhc"},{"id":1509,"type":"block","recordId":"HAx7dUxonowKLUxsdeFcAJD3n9g"},{"id":1510,"type":"block","recordId":"Qxnyd1zwGo24ZExj0rvckeeLnmM"},{"id":1511,"type":"block","recordId":"I2kKdzdhroKBL9xzUVGcTMhpnpS"}],"pasteFlag":"4272581d-f9d8-4e90-86db-20546b494809"}" data-lark-record-format="docx/record" class="lark-record-clipboard">