Asphalt Machinery Series

Asphalt mixing plants are subject to severe wear due to mixing highly abrasive aggregates at high temperatures. Haitian manufactures wear parts for asphalt machinery used in the asphalt mixing and paving industries that are both wear-resistant and impact-resistant. Each component is customized to the customer's specifications or unique requirements. These asphalt wear parts are made of highly wear-resistant, high-toughness, corrosion-resistant and high-temperature resistant materials, specially designed to handle the abrasive and high-temperature conditions in the asphalt mixing and paving process.

-

High Temperature Resistance Plate

The High Temperature Resistance Plate is designed for asphalt, concrete, and heavy-duty industrial e

See More> -

Good Strength Lining Plate

The Good Strength Lining Plate is a high-performance, wear-resistant component designed for asphalt

See More> -

Strong Wear Resistance Lining Plate

The Strong Wear Resistance Lining Plate provides exceptional durability and abrasion resistance for

See More> -

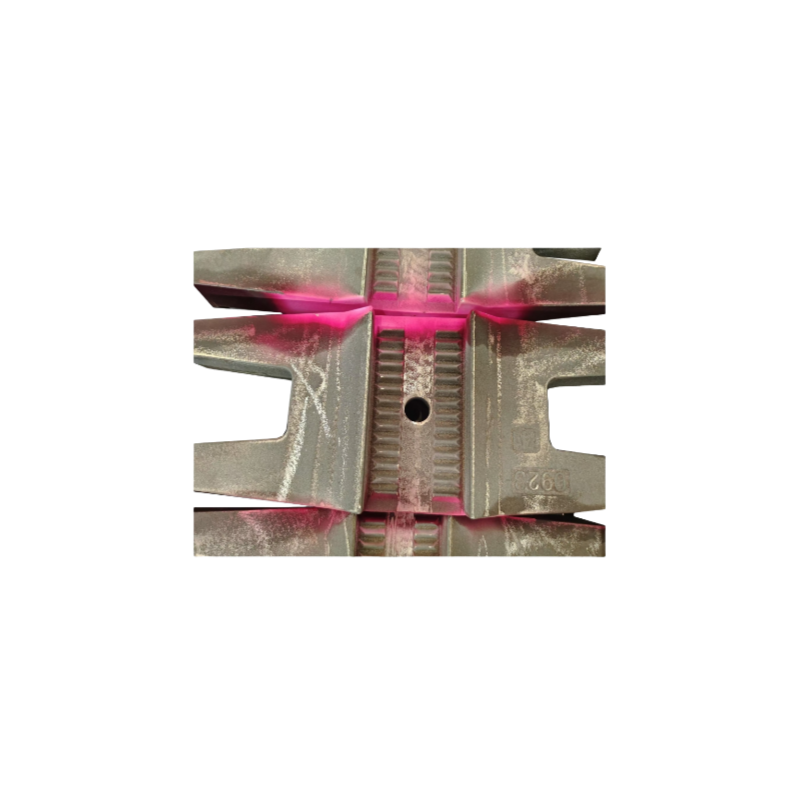

Asphalt Machinery Series

The spiral blade is designed to ensure that the asphalt mixture can be smoothly transported from the

See More>

Wear Parts Supply

Asphalt plant wear parts: seals, scrapers, liners, mixing arms, spiral blades, etc.

Asphalt pavers wear parts: spiral blades.

Why Choose HAITIAN Asphalt Plant Wear Parts?

At HAITIAN, we specialize in high-performance wear parts for asphalt plants, designed to withstand extreme abrasion, heat, and heavy-duty operation. Here’s why global customers trust us for their wear part solutions:

1. Decades of Foundry Expertise

With extensive experience in handling highly abrasive materials (concrete, coal, minerals) and high-temperature environments (steel foundries, coal-fired plants), we engineer wear parts that last longer under harsh asphalt plant conditions, reducing downtime and replacement costs.

2. Advanced Material Solutions

We offer a range of premium wear-resistant materials, including:

Heat-resistant steel (for thermal fatigue resistance)

Alloy cast steel (balanced strength & toughness)

High-chrome iron (HRC 58-62 for severe abrasion)

Each material is selected based on your specific operating conditions.

3. Precision Manufacturing Processes

Lost Foam Casting: Produces complex geometries with smooth surfaces, minimizing machining needs.

DISA Line (Green Sand): Ensures high-volume consistency and dimensional accuracy (±0.5mm).

4. Rigorous Quality Control

Every batch undergoes:

Hardness testing (Brinell/Rockwell)

Chemical composition analysis (spectrometer)

Dimensional checks (CMM)

Non-destructive testing (PT/UT)

5. Large Mold Inventory = Faster Delivery

Our extensive mold library allows rapid production of common wear parts (mixer blades, liner plates), cutting lead times by 30-50%.

Upgrade your asphalt plant’s durability – Contact HAITIAN today!

Asphalt Plant Wear Solutions – Customized for Your Challenges

At HAITIAN Casting, we understand the extreme conditions your asphalt plant faces daily: high abrasion, thermal cycling, and impact loads that cause premature wear and costly downtime. Our solutions are engineered to extend component life, reduce maintenance, and maximize production efficiency.

Asphalt Plant Wear Parts Success Story

HAITIAN developed high-chrome iron (KmTBCr26) spiral blades for Astec/ROADTEC's asphalt mixing and paving equipment, withstanding 400°C heat and extreme abrasion. Using Danish DISA precision casting, the blades enhanced wear resistance and mixing efficiency, earning client acclaim and establishing long-term partnership.

If you are interested in our products or have any questions, please feel free to contact us.

We will provide professional consulting services and customized solutions according to your needs.

SEND INQUIRY NOWContact information

Tel: 0555-71661667166199

Tel: 0555-71661667166199

Fax: 0555-6971198

Fax: 0555-6971198

Website: https://www.htwearparts.com

Website: https://www.htwearparts.com

Email: info@mashthi.com

Email: info@mashthi.com

Postal code: 243141

Postal code: 243141

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe VIDEO FREQUENCY

VIDEO FREQUENCY

Tik Tok

Tik Tok