Ceramic Composite Solutions

Process development process:

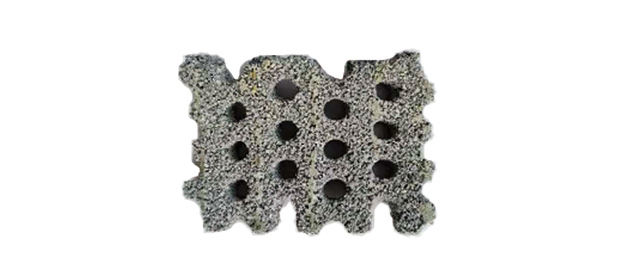

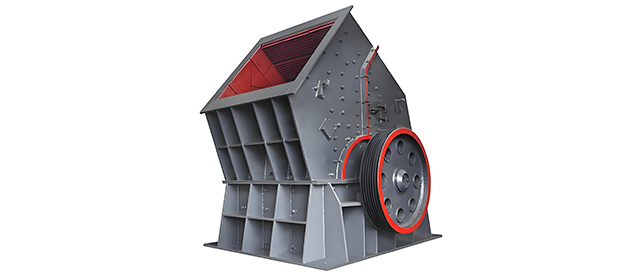

Demand analysis and material selection: The team first evaluated the working conditions of the crusher in mining, analyzed the hardness of the ore, the impact force during the crushing process, and the wear characteristics. In order to cope with these harsh working conditions, high-chromium cast iron was selected as the base material, with its high hardness and wear resistance as its advantages. At the same time, the design of embedded ceramic particles further enhances the wear resistance of the hammer.

Composite material design: During the design process, engineers combined the excellent mechanical properties of high-chromium cast iron with the extremely high wear resistance of ceramic particles. Through computer simulation and experimental testing, the distribution and embedding of ceramic particles were optimized to ensure uniform distribution of impact and wear parts during crushing operations and improve overall service life.

Manufacturing process development: During the production process, advanced composite casting technology is used to embed ceramic particles into a high-chromium cast iron matrix. The casting process strictly controls the temperature and cooling rate to avoid thermal cracks and ensure good bonding between the ceramic particles and the metal matrix. In addition, the blow bars are also subjected to high-temperature tempering treatment to optimize the material's microstructure and mechanical properties.

strict performance testing was carried out, including wear resistance testing, impact resistance testing, fatigue testing and practical application testing under simulated mining conditions. Test results show that the wear resistance of this ceramic blow hammer is significantly improved under high-intensity use conditions, and its service life is more than 100% longer than that of traditional high-chromium cast iron blow bars. Based on test feedback, the team fine-tuned the production process to ensure stability and consistency in mass production.

Application and customer feedback:

After this ceramic blow hammer was put into the mining crusher, customer feedback showed that the blow hammer showed excellent wear resistance when processing hard ores, significantly reducing equipment downtime and replacement frequency. Mine mining efficiency has been improved and operating costs have been significantly reduced.

Results and advantages:

By combining the advantages of high-chromium cast iron and ceramic particles, your company has successfully developed a high-performance ceramic blow bar for mining crushers. This product demonstrates excellent wear resistance and impact resistance under extreme working conditions, greatly extending its service life while improving the overall efficiency of mining. This case demonstrates your company's innovative capabilities and technological advantages in developing high-performance industrial application materials.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok