HAITIAN CASTING Collaborates with Customers to Develop New Model Accessories

Customer Background

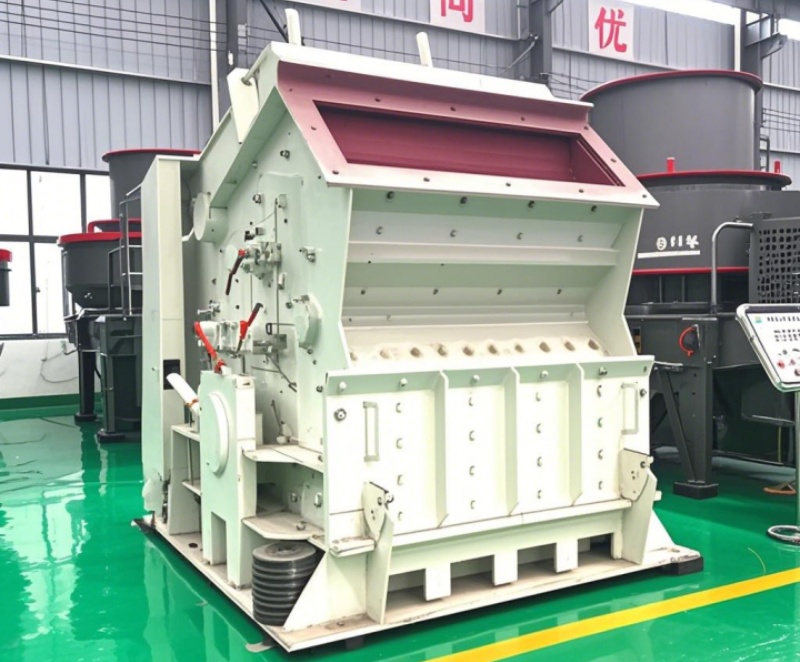

The customer collaborating with Haitian Heavy Industry to develop ceramic plate hammers is JCI, a subsidiary of Astec, a globally leading engineering machinery equipment manufacturer based in the United States. Their products are widely used worldwide.

As market competition intensifies and customer demands for equipment operational efficiency and cost-effectiveness continue to rise, the customer decided to partner with Haitian to further enhance equipment performance. The goal was to develop new model accessories capable of withstanding harsh working environments and meeting ever-increasing productivity requirements.

Product Introduction

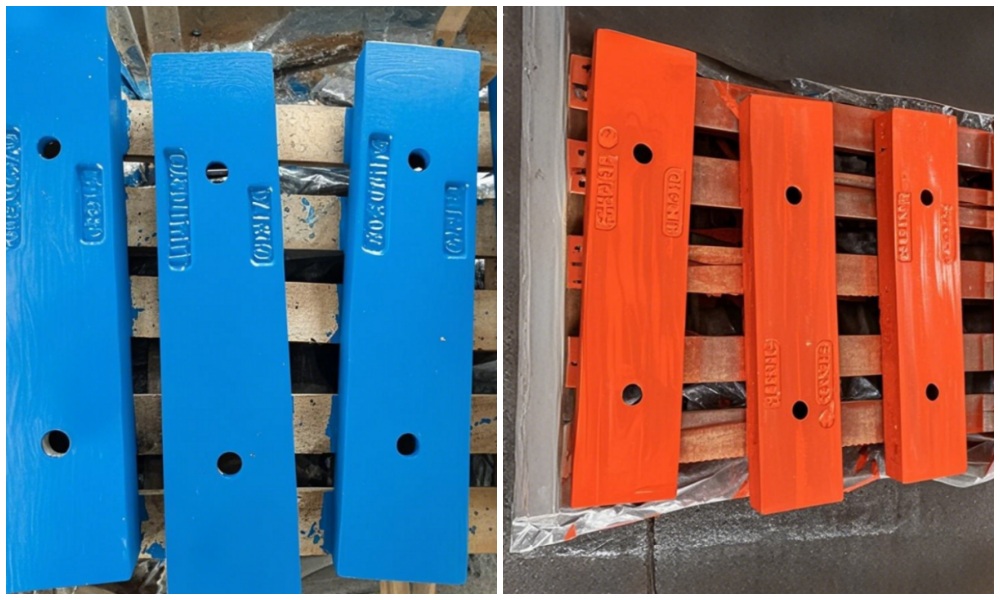

The ceramic plate hammers custom-developed by Haitian Heavy Industry for the customer combine the excellent mechanical properties of high-chromium cast iron with the extreme wear resistance of ceramic particles.

Through computer simulations and experimental testing, engineers optimized the distribution and embedding of ceramic particles to ensure uniform impact and wear distribution during crushing operations, further enhancing the hammer's wear resistance and overall service life.

Production Process

Manufacturing Process Development:

Haitian employs advanced composite casting technology to embed ceramic particles into a high-chromium cast iron matrix. During casting, temperature and cooling rates are strictly controlled to prevent thermal cracks and ensure strong bonding between ceramic particles and the metal matrix.

Additionally, the hammers undergo high-temperature tempering to optimize the material's microstructure and mechanical properties.

Strict Quality Inspection Standards:

The team conducted rigorous performance tests, including wear resistance tests, impact resistance tests, fatigue tests, and real-world application simulations under mining conditions. Based on test feedback, adjustments were made to the production process to ensure stability and consistency in mass production.

Customization

During the collaboration, Haitian implemented several customized adjustments to ensure the ceramic plate hammers perfectly matched the equipment's operational requirements:

Size and Shape Customization:

Haitian tailored the dimensions and shapes of the ceramic plate hammers to fit different models of the customer's mixing station hosts, ensuring perfect compatibility.

Material Optimization:

Based on the working environment of the mixing station hosts, Haitian optimized the ratio of ceramic to cast iron, improving the hammers' wear resistance, high-temperature resistance, and impact toughness.

Results and Feedback

The new ceramic plate hammers addressed the performance limitations of traditional accessories in high-temperature, high-load environments, significantly improving equipment efficiency and service life.

The solution earned high praise from the American customer and established Haitian's reputation for technological innovation in the global market.

Haitian Heavy Industry remains committed to providing innovative, high-efficiency accessory solutions for global customers and driving industry progress.

For customized large-size, high-chromium, high-precision castings, feel free to contact us anytime!

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok