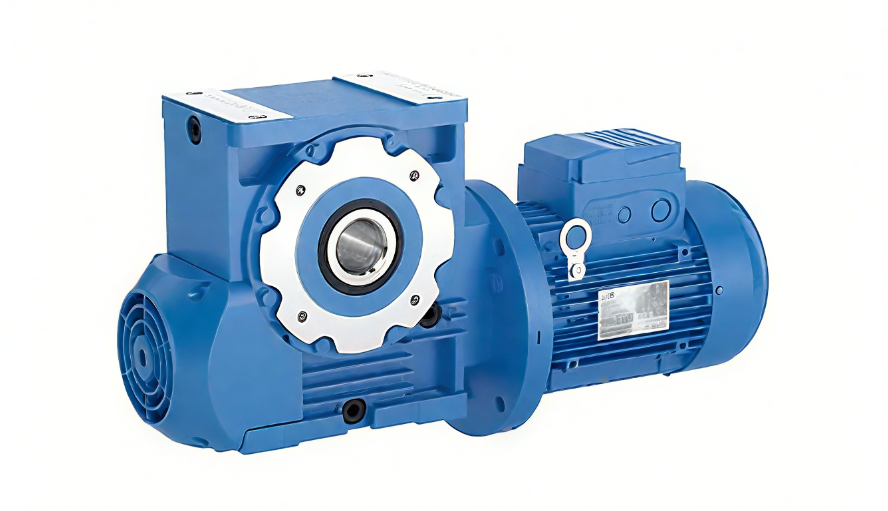

Custom Worm Gear Case for Italian Client

Client Pain Points

The Italian mining equipment client’s traditional worm gear shafts suffered from insufficient hardness and poor wear resistance. Under high-load and abrasive mining conditions, the worm surface wore rapidly, causing frequent equipment failures and downtime, significantly reducing production efficiency. Additionally, frequent part replacements led to soaring maintenance costs, affecting overall profitability. The client urgently required a custom worm gear solution with superior wear resistance, high hardness, and adaptability to harsh mining environments.

Haitian’s Solution

Haitian Heavy Industry chose GX280Cr20 high chromium cast iron material in compliance with DIN 1695 W7 standard. The material contains 1.9–2.2% carbon and 18–22% chromium, undergoing rigorous quenching and tempering processes to achieve hardness above 58 HRC. This high chromium wear-resistant cast iron dramatically enhances the worm gear shaft’s surface hardness and abrasion resistance while improving corrosion resistance, ensuring stable performance in dusty, humid, and high-temperature mining environments.

Furthermore, our engineering team optimized the worm tooth profile to reduce stress concentration on the gear surface and improve torque transmission efficiency, effectively extending product service life and enhancing overall machine reliability. High-precision sand casting technology was employed to ensure dimensional accuracy and surface finish, meeting the stringent requirements of heavy-duty mining equipment.

Production & Delivery

Lead Time: 45 days from order confirmation

Payment Terms: 30% prepaid after PO confirmation, 70% before shipment

Process: Sand casting → precision machining → quenching and tempering → rigorous quality inspection → packaging and delivery

Quality Control: Multiple nondestructive testing methods to ensure no cracks or porosity; uniform hardness meeting design standards

Client Feedback

After installation, the client reported that the worm gear shaft’s service life extended by over 50%, greatly improving equipment operational stability and reducing unexpected downtime caused by part wear. Long-term maintenance costs dropped significantly, leading to improved production efficiency and profitability. The client highly praised Haitian Heavy Industry’s professional custom manufacturing and prompt delivery, and has placed multiple repeat orders for the same specification. They plan further cooperation to develop more wear-resistant transmission components.

Application & Market Value

This high chromium custom worm gear is widely applied in mining machinery, aggregate crushing equipment, and other heavy-duty transmission fields, especially suited for continuous operation under harsh conditions. By enhancing wear resistance and corrosion protection of critical transmission parts, it significantly improves overall equipment efficiency and lifespan, delivering substantial economic benefits and market competitiveness for mining clients.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok