Customer Success Story: Customized high precision and durable mixing arms and liners for D&G Machinery

🔍 Client Background

D&G Machinery is a renowned manufacturer of high-performance asphalt mixing plants, serving clients across Europe, Asia, and the Middle East. With a strong reputation for precision engineering and reliability, D&G requires core wear parts that meet rigorous standards for strength, wear resistance, and dimensional accuracy—especially in high-load components like mixer arms and liner plates.

🧩 Project Scope & Challenges

D&G approached HT Wear Parts with two key demands:

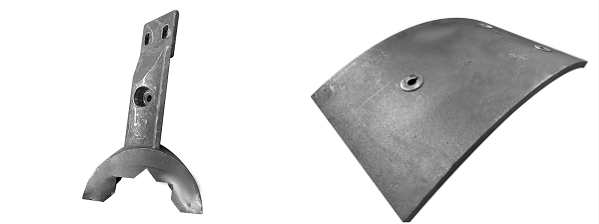

Mixer Arm: Required high-strength, complex-shaped arms with excellent impact resistance and structural balance for long-hour operation.

Liner Plate: Required high-hardness wear-resistant liners suitable for abrasive materials and high-temperature environments.

The client emphasized rapid prototyping, dimensional accuracy, and long-term performance as critical project goals.

⚙️ Our Engineering Solution

✔ Product 1: Mixer Arm

Material: ZG310-570 high-strength cast steel

Initial Sampling: 3D printed prototype for structural and dynamic balance verification

Production Method: Lost Foam Casting (消失模工艺), enabling precise shaping of complex geometries

Post-Processing: CNC machining and heat treatment to ensure dimensional integrity and strength

✔ Product 2: Liner Plate

Material: High Chromium Cast Iron

Sample Delivery: 3D printed sample for fitment testing and visual inspection

Production Method: DISA automatic vertical molding line for consistent thickness and precision

Heat Treatment: Multi-stage hardening process to reach HRC 60+ surface hardness

🧪 Client Validation & Results

After installation and real-world operation, the results were impressive:

Mixer Arm: Maintained structural integrity after over 200 hours of continuous mixing. No deformation or balance issues were reported.

Liner Plate: Demonstrated160% longer lifespan compared to previous models, with zero early wear failures even in abrasive mix environments.

D&G approved both components for ongoing supply and officially listed HT Wear Parts as a trusted wear parts supplier for their core equipment.

⭐ Key Highlights

Rapid 3D printing accelerated prototyping and reduced development cycles by 40%.

Advanced casting techniques ensured uniform quality and reliable performance.

Custom solutions met the client’s precise application needs and enhanced equipment lifecycle.

📞 Looking for custom wear parts like D&G Machinery?

Contact us today to discuss your requirements or request a free consultation.

👉 Get a Quote | 📧 info@htwearparts.com

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok