Solving High-Load Continuous Operation Challenges: Custom Grinding Ball Case for Vertical Grinding Mills

Project Overview

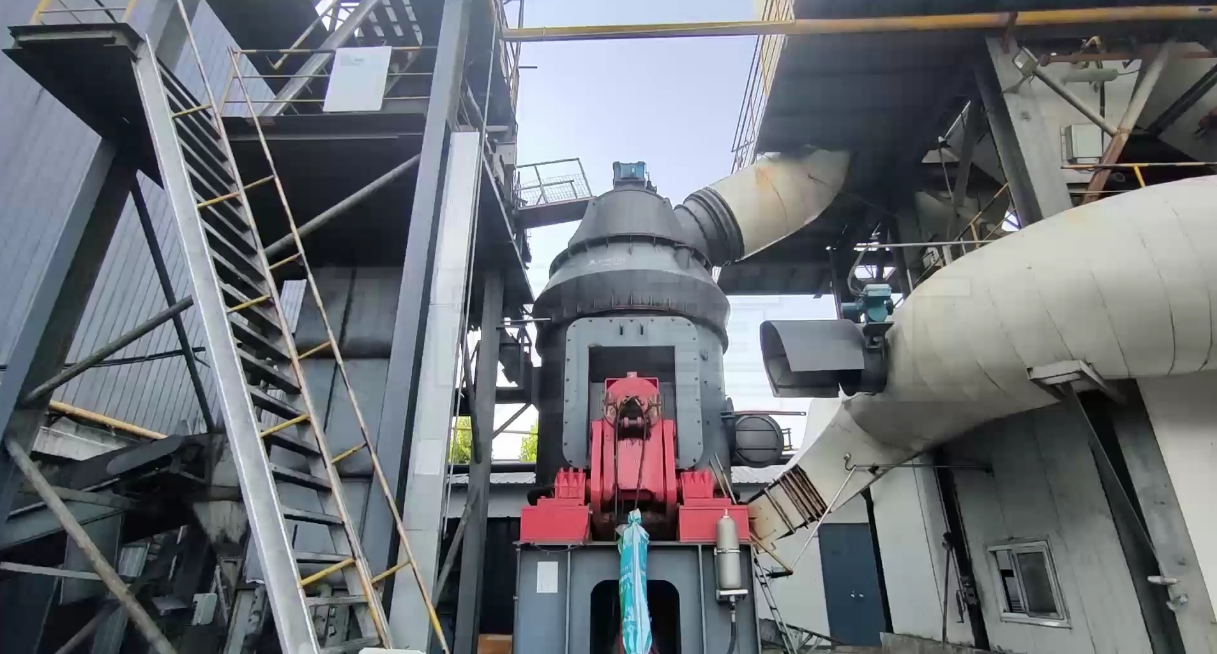

A domestic industrial customer operates an EM80-5115 vertical grinding mill in its production line for continuous material grinding. Due to long-term high-load and non-stop operation, the customer placed exceptionally high requirements on the grinding components—particularly the grinding balls, which play a critical role in system stability and product consistency.

During previous operation, the existing grinding balls showed several performance limitations, including insufficient geometric stability, uneven wear, and limited resistance to foreign object impact. These issues negatively affected operational safety, grinding efficiency, and product quality consistency.

As a result, the customer commissioned us to develop a high-reliability, high-consistency customized grinding ball solution specifically designed for the EM80-5115 vertical grinding mill.

Application Challenges in High-Load Vertical Grinding Mills

Long-term continuous operation under heavy load

High demand for geometric accuracy and structural safety

Uneven wear causing system imbalance

Risk of damage from unexpected foreign materials

Requirement for stable grinding efficiency and consistent particle size

Customized Grinding Ball Solution Design

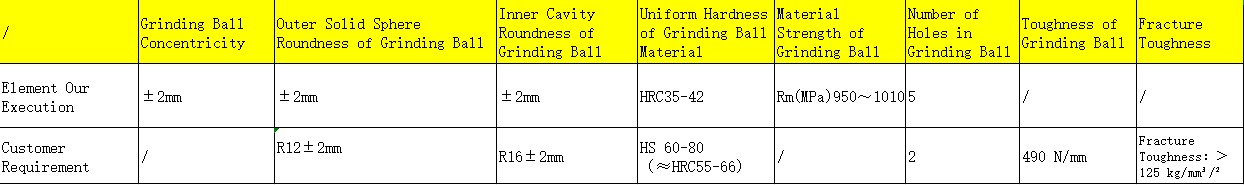

Overall Geometric Accuracy Control

Instead of focusing only on local radius tolerances, our solution emphasizes overall geometric accuracy, which is more suitable for large hollow grinding balls operating under heavy loads.

Grinding ball concentricity: ±2 mm

Outer sphere roundness: ±2 mm

Inner cavity roundness: ±2 mm

This approach ensures uniform load distribution during rotation, significantly reducing stress concentration and improving long-term operational stability.

Hollow Structure and Process Hole Optimization

Hollow spherical grinding ball design

Five uniformly distributed process holes

Stress-relieved and structurally verified hole positions

This design:

Enhances vibration absorption during foreign object impact

Prevents stress concentration around hole areas

Improves overall structural safety for continuous operation

Grinding Ball Technical Parameters Comparison

Grinding Ball Material Composition and Design Philosophy

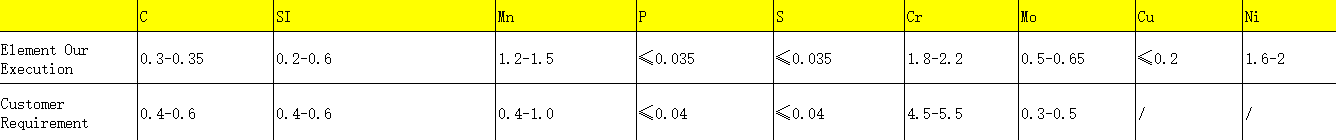

Chemical Composition (wt.%)

Instead of pursuing excessively high initial hardness, we adopted a Cr–Ni–Mo alloy system with moderate base hardness and excellent work-hardening characteristics.

* Base hardness: HRC 35–42

* Work-hardened surface layer: HRC 48–55

* mproved toughness and crack resistance

* Enhanced safety for thick-section hollow grinding balls

Operating Performance and Test Results

Grinding Conditions

Material: Calcined petroleum coke

Feed size: 0–6 mm

Bulk density: 0.65–0.75 t/m³

Grindability (HGI): 37–42

Moisture: ≤0.5%

Performance Results

Stable throughput: 20 t/h

<0.075 mm particle content: 65 ±5%

Grinding fineness meets DIN 52098

Moisture meets DIN 51718

Noise level ≤ 85 dB(A) at 1 m (DIN 45635)

Service Life, Safety and Maintenance-Free Performance

Capable of crushing foreign objects without shutdown

Vibration absorbed by spring frame system

No cracking, breakage, or spalling down to Ø ≤950 mm

No damage to other grinding components

Uniform wear across all grinding balls

Throughout the entire service life, the grinding balls require no maintenance and no adjustment, enabling truly maintenance-free operation.

Project Conclusion

This customized grinding ball solution successfully enabled:

Long-term stable operation of the EM80-5115 vertical grinding mill

Improved grinding efficiency and product consistency

Extended grinding ball service life

Reduced overall operating and maintenance costs

The project demonstrates our strong capabilities in custom grinding ball design, material engineering, and large-scale vertical mill applications.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok