In heavy industries such as casting, mining machinery, and concrete equipment manufacturing, workplace safety is far more than a regulatory obligation—it is the foundation of stable production, employee well-being, and long-term business sustainability. High-load operations, heavy-duty equipment, high-temperature environments, and complex manufacturing workflows inherently involve risks that must be actively managed rather than passively avoided.

With over 21 years of casting expertise, Ma’anshan Haitian Heavy Industry Technology Development Co., Ltd. places safety at the core of its operations. Through regular, structured factory safety drills, Haitian Heavy Industry ensures that every employee is prepared to respond decisively to emergencies—protecting both personnel and production continuity.

Heavy industrial environments face unique safety challenges that require systematic preparation:

Equipment-related risks: Failures in crushers, mixers, grinding mills, or conveyors—often caused by wear, seal failure, or improper operation—can result in severe downtime or injuries.

Harsh production environments: Foundry operations involve molten metal, high temperatures, dust, and industrial gases, increasing risks of burns, respiratory hazards, and chemical exposure.

Complex workflows: Multi-stage processes—from melting and casting to machining, assembly, and warehousing—require precise coordination to prevent safety gaps.

Emergency response limitations: Without regular drills, even well-documented safety procedures may fail under real emergency conditions, escalating minor incidents into major losses.

Safety drills transform written procedures into practical readiness, ensuring that people, equipment, and systems function together effectively under pressure.

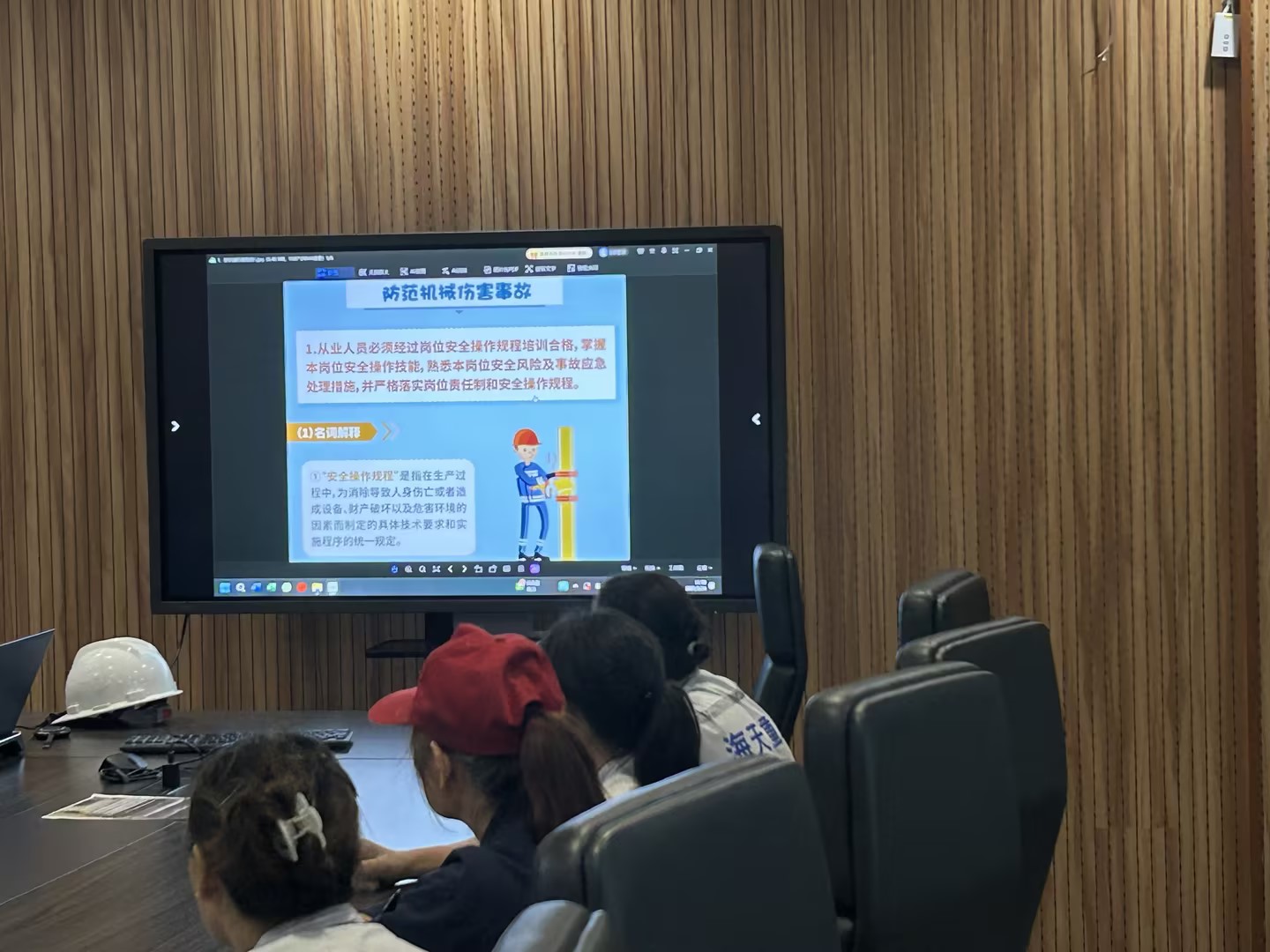

Aligned with ISO 45001 Occupational Health & Safety Management System, Haitian Heavy Industry implements a risk-based, data-driven safety drill system tailored specifically to casting and heavy manufacturing environments.

Annual risk assessments identify high-priority scenarios, including:

Equipment emergency drills: Simulated crusher blockages, mixer seal failures, and conveyor malfunctions, emphasizing safe shutdown and lockout-tagout (LOTO) procedures.

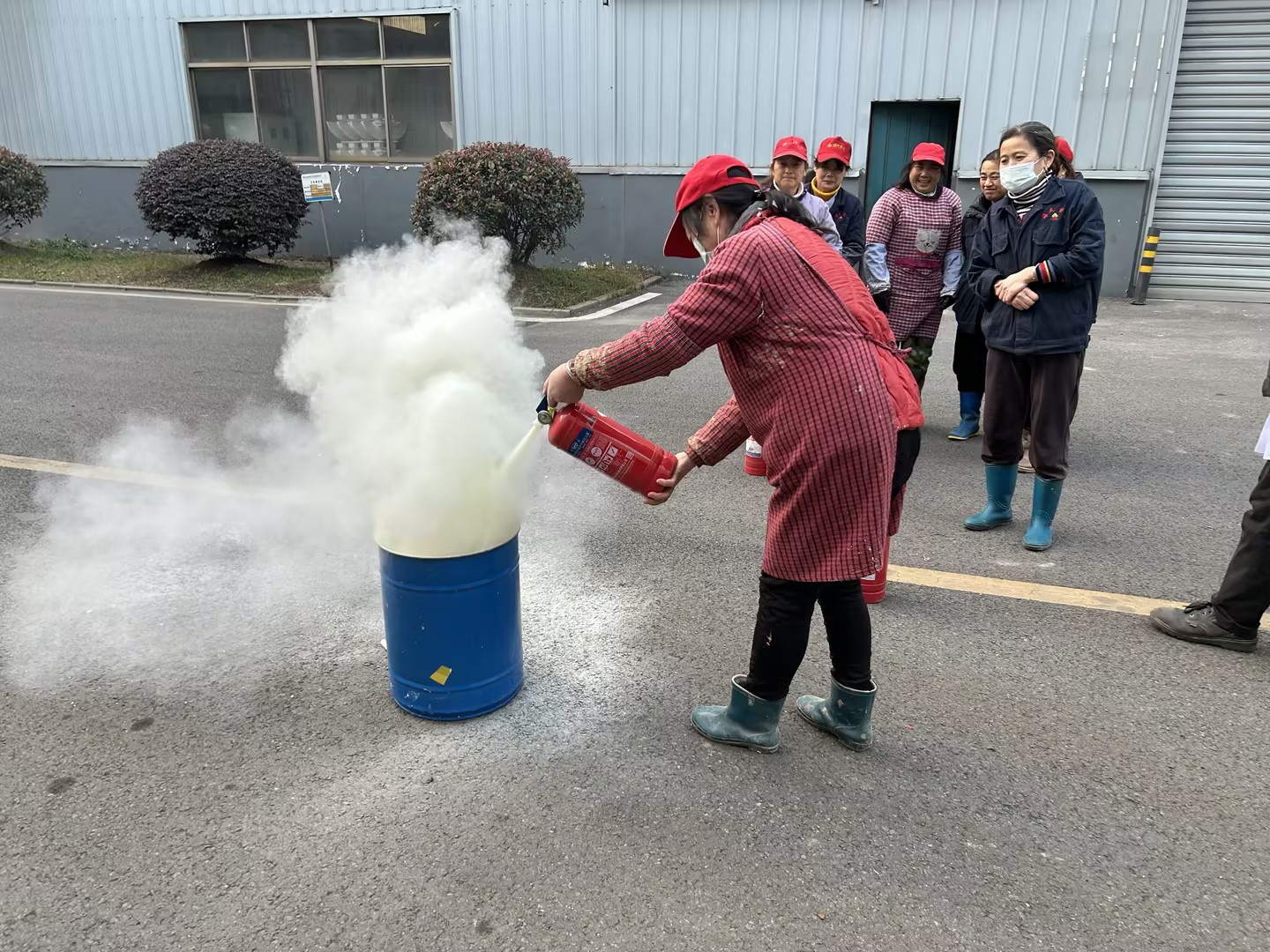

Fire & explosion drills: Focused on foundry risks such as molten metal spills and flammable material ignition.

Hazardous material response drills: Simulated lubricant spills or gas leaks, highlighting containment, PPE usage, and environmental protection.

Medical emergency drills: Practice responses to burns, crush injuries, and coordination with local emergency services.

Effective safety management requires collaboration across departments. Drill participants include:

Production operators

Maintenance and LOTO technicians

Safety officers

Logistics and warehouse teams

Administrative and coordination staff

Each drill follows a standardized process:

Pre-drill briefing – roles, procedures, and objectives clarified

Scenario simulation – realistic emergency initiated without advance notice

Response execution – shutdown, evacuation, first aid, containment

Post-drill review – strengths, gaps, and corrective actions identified

Recognized as a National Outstanding Intelligent Manufacturing Scenario, Haitian Heavy Industry integrates digital tools into safety management:

IoT monitoring systems simulate real-time emergency conditions (temperature, gas levels, equipment status)

MES-based data tracking records response times and compliance metrics

Virtual training modules allow employees to practice emergency responses in 3D simulated environments before on-site drills

After every drill:

Response data is analyzed for efficiency and compliance

Employee feedback is collected to identify practical issues

Safety procedures and training materials are updated accordingly

This ensures the safety system evolves alongside new equipment, expanded capacity, and process upgrades.

Haitian Heavy Industry’s safety program complies with ISO 45001, OSHA guidelines, and local regulations. Our integrated approach is further validated by certifications such as:

Anhui Province Intelligent Factory

National Intellectual Property Advantage Enterprise

40% reduction in workplace incidents over the past decade

Stable 80,000-ton annual production capacity, even during unplanned events

Enhanced trust from global customers including SANY, Zoomlion, XCMG, and Liebherr

A strong internal culture where safety responsibility is shared at every level

In heavy manufacturing, safety is not a cost—it is a strategic investment. Through systematic safety drills, advanced technology, and continuous improvement, Haitian Heavy Industry ensures a safe, resilient, and high-performing manufacturing environment.

As we continue to advance intelligent manufacturing and high-quality casting solutions, we remain committed to setting new benchmarks in industrial safety.