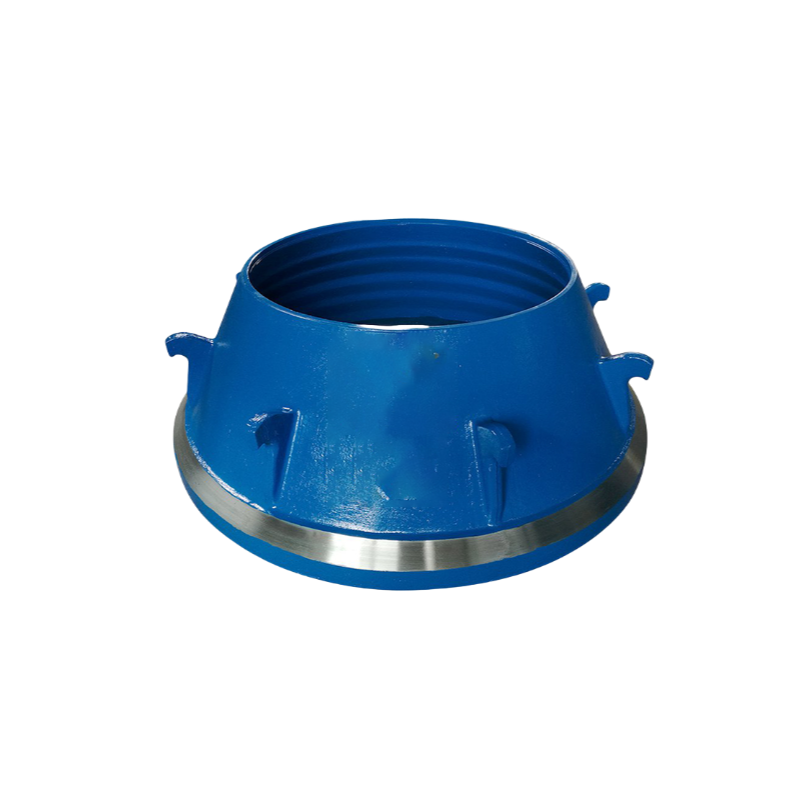

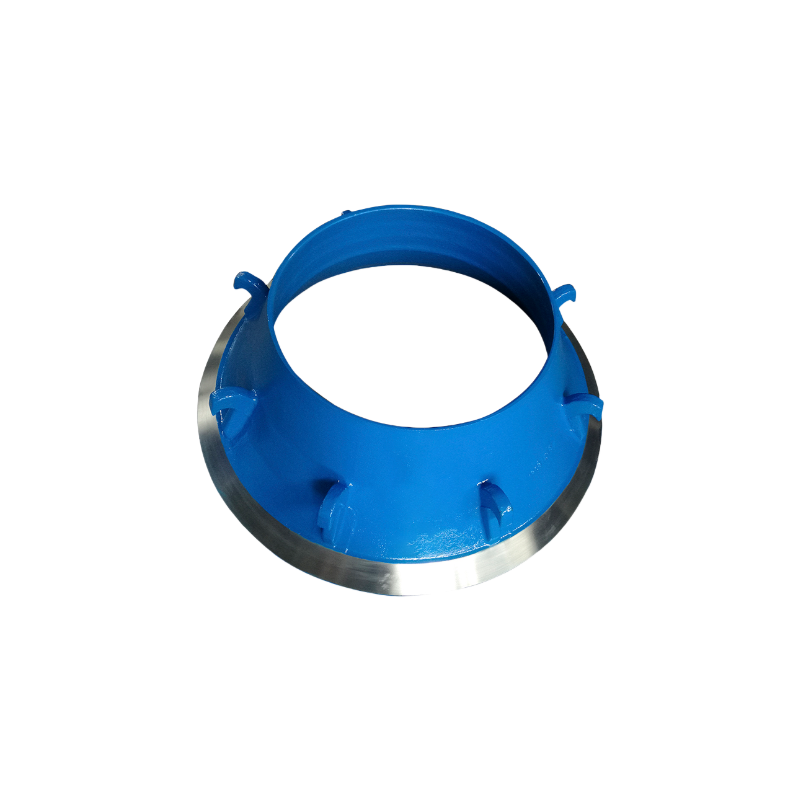

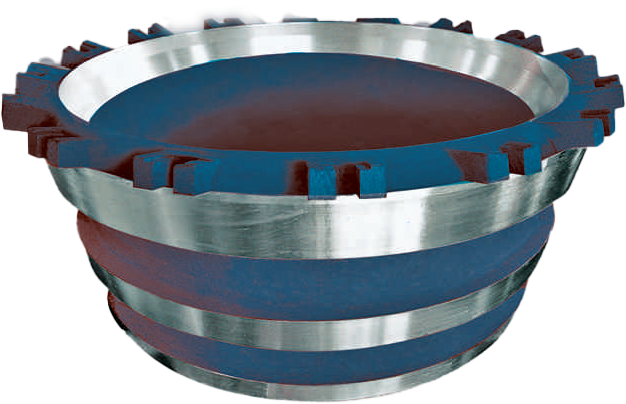

High-Quality Cone crusher Bowl Liner

Material:Mn13Cr2 Mn18Cr2 Mn21Cr2

Application:Cone Crusher

Process:Resin Sand

Features:Wear Resistance, Strength and Toughness, Design Optimization, High Appearance Quality, 20% Longer Service Life Than Counterpart,Easy to Replace, Processing Accuracy, Comprehensive Testing, Competitive Products, Environmental Friendlly.

- Product Description

- Product Specifications

- Product Advantages

- More Details

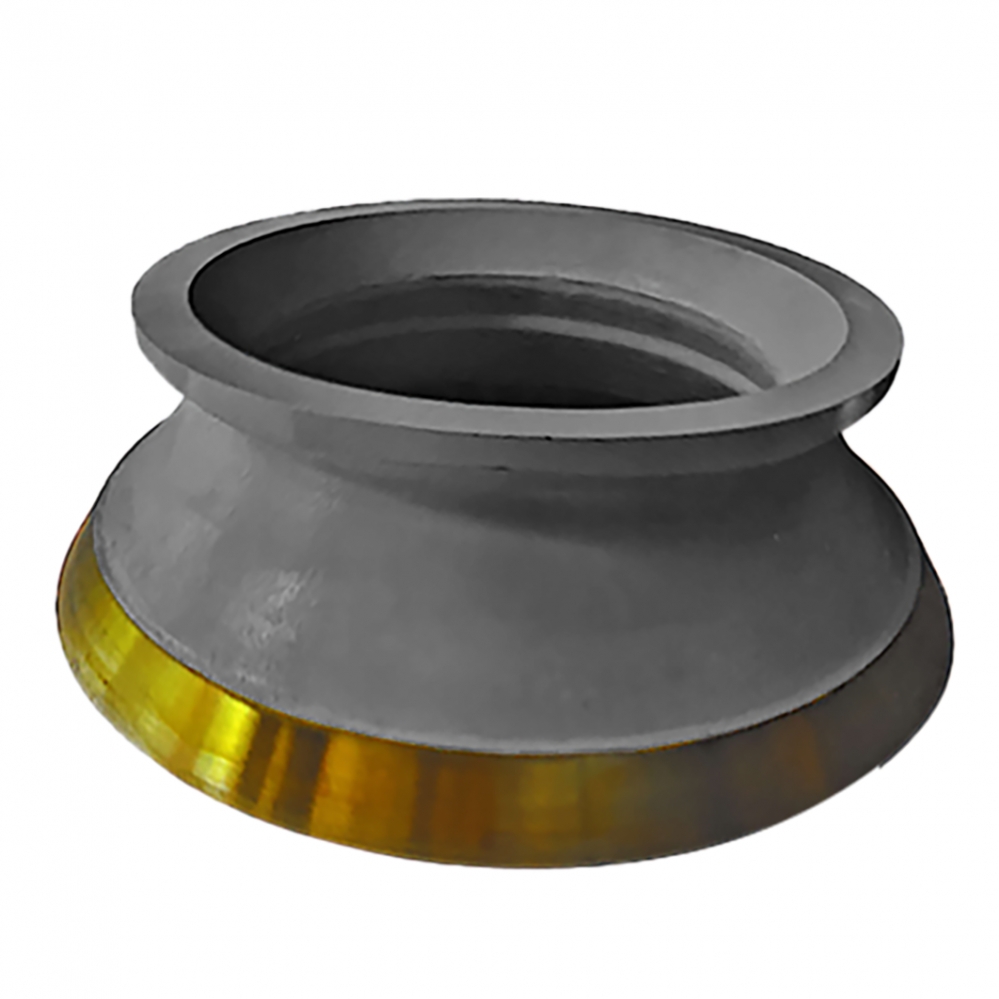

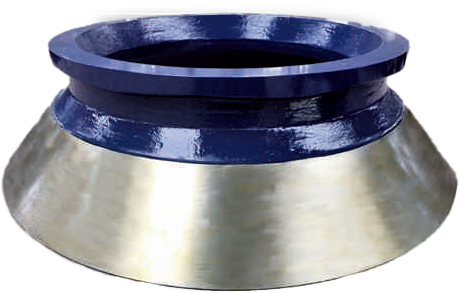

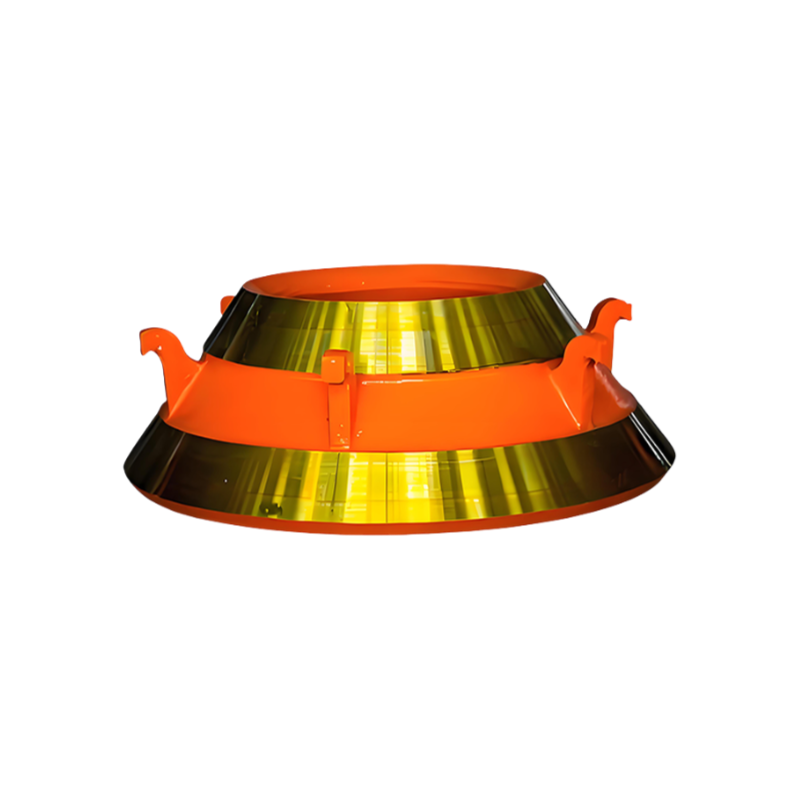

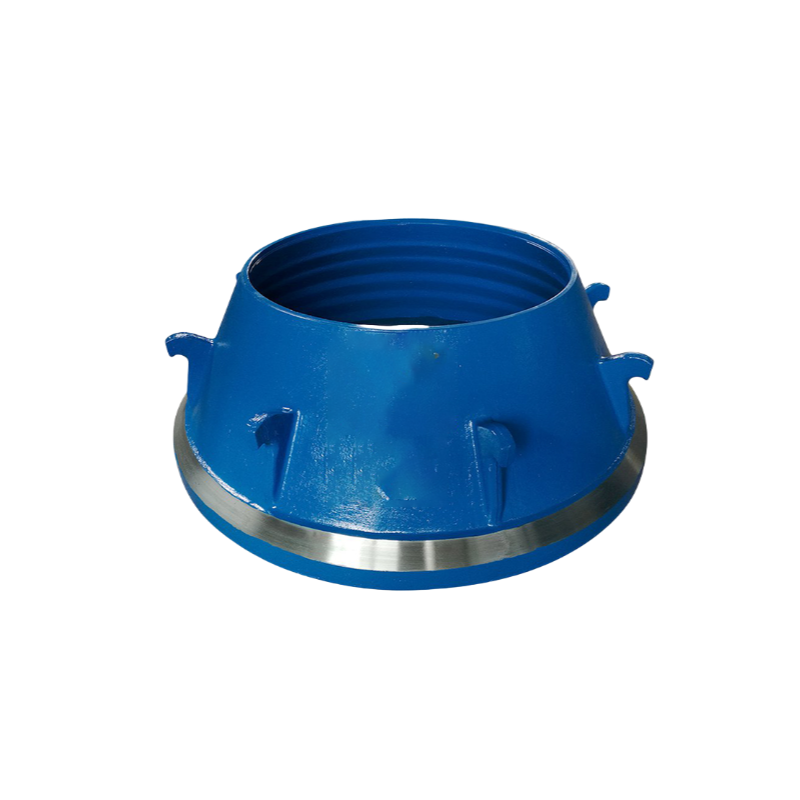

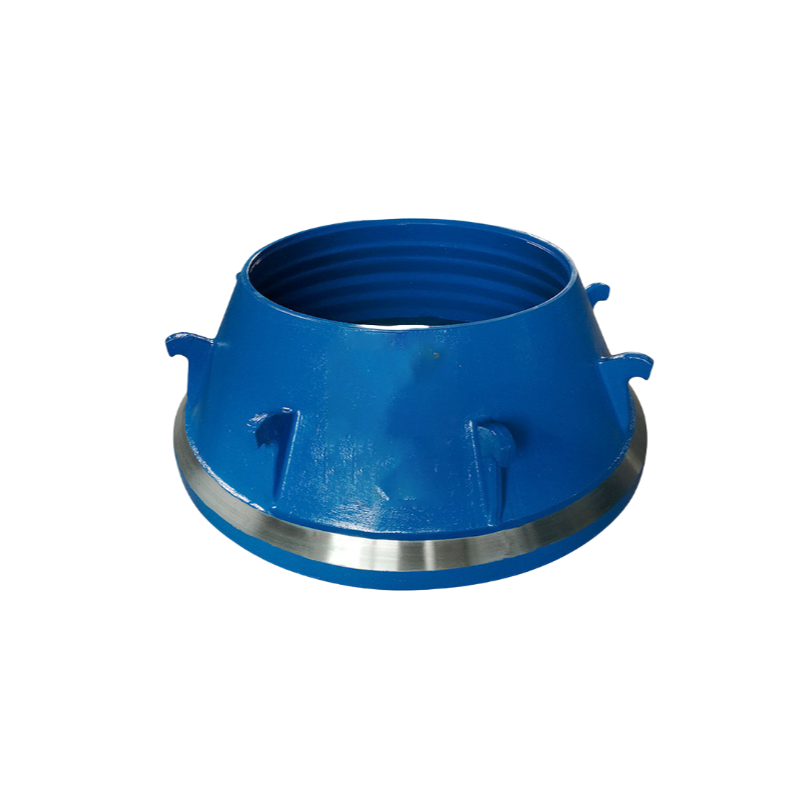

Cone Crusher Wear Parts--Mantle and Concave

Cone crushers are widely used for crushing hard and medium-hard materials such as granite,basalt,ironore,and limestone. Haitian specializes in manufacturing high-performance wear parts for cone crushers,including the mantle(moving cone) and concave(fixed cone), which maintain stable and efficient crushing performance under harsh working conditions.

our cone crushere wear parts are engineered with structural and material optimizations based on crusher mechanics,offering excellent wear resistance and impact strength.

Made from high-strength manganese steel, the parts undergo advancced smelting processes,precision castig cintrol, and strict heat treatment, ensuring euperior mechanical strength and long service life even under heavy lodas. With optimized chamber design and lamination crushing technology, Haitian parts are dimensionally accurate and highly compatible,working seamlessly with the crusher to deliver better particle shape, stable output, and reduced engergy consumption,helping customers increase productivity and lower operating costs.

We offer customized wear parts based on customer-supplied drawings,samples,or equipment models,or equipment models.Full quality inspection reports and technical support are available,making Haitian your trusted partner in the filed od cone crusher wear solutions.

Product Specifications

| Product Name | Service Life | Product accuracy | Delivery Time | Model | Spray Painting | Inspection |

| Cone Liner | 3-6 moths | Metallographic grade: 1-2 Inclusion grade 1A | 45 Days | Major Brand All Series | √ | 100% Inspection Inspection Report |

PRODUCT ADVANTAGES

-

HIGH ASSEMBLY PRECISION

Haitian always adhere to efficient operation and ensure strict control of every link. 3D sand printing equipment can be used, with high product assembly accuracy and fast sample supply cycle. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

Haitian castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.With drawing numbers,Haitian can supply nearly 90% of wear-resistant parts for mining crushing equipment from major brands.

-

LONG SERVICE LIFE

Haitian cone liner uses advanced molten iron smelting with digital raw material control to ensure high purity and consistent quality. Combined with optimized casting, strict heat treatment, and rigorous inspections, each part delivers reliable performance, durability, and stable quality for demanding mining and crushing environments.

-

STABLE QUALITY

Haitian apply full-process quality control, from raw material sourcing to final inspection.

Each product undergoes strict testing, including spectrometric analysis, hardness testing, ultrasonic flaw detection, and metallographic inspection.With stable quality and reliable performance, Haitian parts deliver excellent wear resistance and strength, helping customers reduce downtime and maintenance costs in demanding mining environments.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok