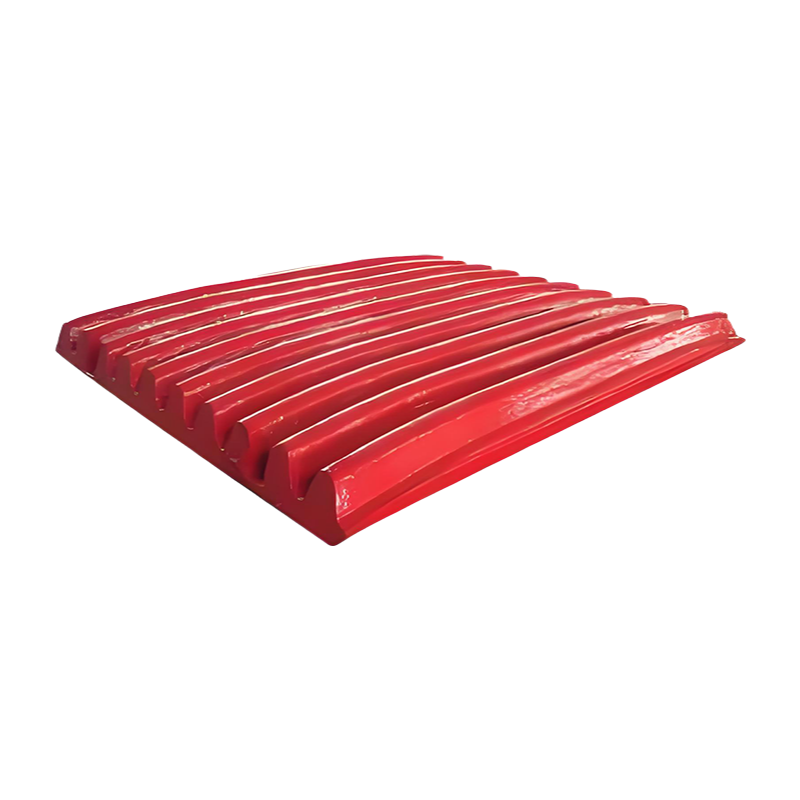

VTM vertical mill liner

Material: 26%High chromium

Application: Mining Machinery

Process: 3D-printed Sand Cores,Resin Sand;

Features:High-chromium content(26%), strong impact resistance, strong wear resistance, optimized structure, easy maintenance, long service life, suitable for a variety of working conditions.

- Product Description

- Product Specifications

- Product Advantages

- More Details

VTM Vertical Mill Liner is a critical wear-resistant component used in fine grinding and regrinding applications in the mining industry. Installed inside VTM vertical mills, the liner is designed to withstand continuous impact, compression, and intense abrasive wear from ore and grinding media, effectively protecting the mill’s internal structure and ensuring stable, long-term operation.

Manufactured from high-performance wear-resistant materials such as high-chromium cast iron and alloy steel, and enhanced through advanced heat treatment processes, VTM vertical mill liners offer excellent wear resistance, strong impact toughness, and precise dimensional control. These advantages significantly extend service life, reduce liner replacement frequency, lower maintenance costs, and improve overall grinding efficiency.

Advanced molten metal smelting technology is applied during production to ensure high material purity and uniform microstructure, resulting in consistent and reliable liner performance. Comprehensive inspection and testing systems provide full quality traceability and detailed inspection reports. Field performance feedback from mining customers in South Africa and Chile shows that Haitian’s VTM vertical mill liners deliver a service life approximately 20% longer than conventional alternatives. In addition, Haitian Heavy Industry supplies a complete range of VTM mill wear parts for various brands and offers customized solutions to ensure optimal compatibility with different equipment and operating conditions.

Product Specifications

| Product Name | Hardness | Product accuracy | Delivery Time | Model | Spray Painting | Inspection |

| Vertical Mill Liner | ≥60HRc | CT10 | 45 Days | Major Brand All Series | √ | 100% Inspection Inspection Report |

PRODUCT ADVANTAGES

-

HIGH ASSEMBLY PRECISION

Haitian always adhere to efficient operation and ensure strict control of every link. 3D sand printing equipment can be used, with high product assembly accuracy and fast sample supply cycle. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

Haitian castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to with stand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.With drawing numbers,Haitian can supply nearly 90% of wear-resistant parts for mining crushing equipment from major brands.

-

LONG SERVICE LIFE

Haitian Grinding liner uses advanced molten iron smelting with digital raw material control to ensure high purity and consistent quality. Combined with optimized casting, strict heat treatment, and rigorous inspections, each parts deliver reliable performance, durability, and stable quality for demanding mining and crushing environments.

-

STABLE QUALITY

Haitian apply full-process quality control, from raw material sourcing to final inspection.

Each product undergoes strict testing, including spectrometric analysis, hardness testing, ultrasonic flaw detection, and metallographic inspection.With stable quality and reliable performance, Haitian Jaw Plates deliver excellent wear resistance and strength, helping customers reduce downtime and maintenance costs in demanding mining environments.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok