Jaw crushers are one of the most commonly used pieces of equipment in the mining, quarrying, and recycling industries. At the heart of every jaw crusher lies a critical component: the jaw plate. Understanding jaw plates—their function, material composition, wear patterns, and maintenance—can significantly improve crusher performance and reduce downtime.

This complete guide provides 10 essential facts that every operator, plant manager, and maintenance engineer should know about jaw plates.

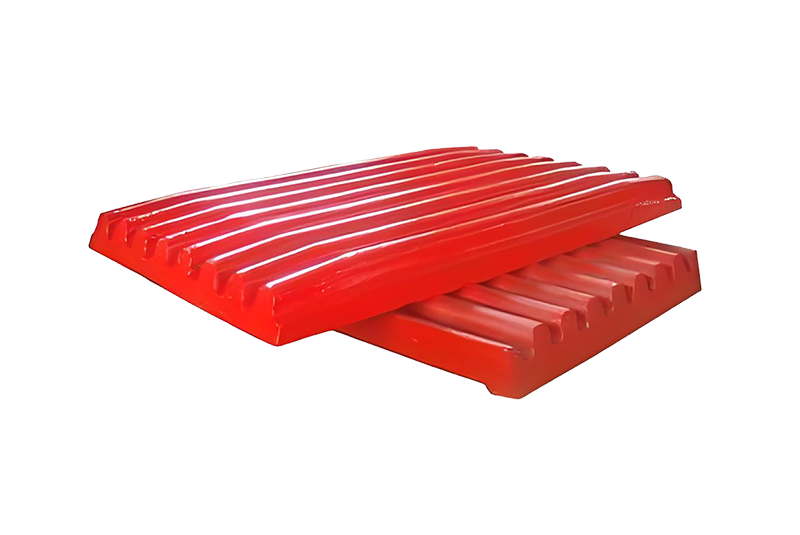

Jaw plates are the replaceable steel plates that line the inside of the crushing chamber in a jaw crusher. There are typically two plates:

Fixed Jaw Plate: Mounted to the frame and remains stationary.

Movable Jaw Plate: Mounted to the swing jaw and moves in a back-and-forth motion.

Together, these plates crush raw material through compressive force. When the swing jaw moves toward the fixed jaw, the material is crushed; as it retracts, the crushed material falls down for further processing or discharge.

There are several jaw plate profiles designed for different crushing applications:

Flat/Smooth Jaw Plates: Ideal for primary crushing of soft to medium-hard rock.

Toothed or Corrugated Jaw Plates: Increase grip and are better for harder rock or recycling applications.

Heavy-Duty Jaw Plates: Thicker and stronger for extended wear life in demanding applications.

Custom Profiles Jaw Plates: Many manufacturers offer customized profiles for specific feed characteristics or product sizing goals.

The selection of profile affects the crusher’s throughput, particle size distribution, and wear behavior.

The performance and durability of jaw plates depend heavily on the materials used in their manufacture. The most common materials include:

High Manganese Steel (Mn13, Mn18, Mn22)

Excellent work-hardening properties

Suitable for high-impact environments

Chrome-Manganese Alloy Steel

Improved abrasion resistance over standard manganese

Composite and Ceramic Inserts

Enhanced wear resistance for extreme applications

Ideal for fine crushing and extended life applications

Material selection must balance toughness (resistance to breakage) with hardness (resistance to abrasion).

Jaw plates wear due to continuous contact with abrasive material. The wear occurs primarily in three forms:

Abrasive Wear: Caused by the friction between the rock and the jaw surface.

Impact Wear: Results from the crushing blow during operation.

Fatigue Cracking: Long-term use can cause microcracks that propagate over time.

Common wear patterns include:

Scalloping: Uneven wear caused by irregular feed.

Pitting: Localized spots of intense wear.

Cracking: A sign of structural failure or improper material choice.

Understanding wear patterns helps in diagnosing operational issues and extending jaw plate life.

Knowing when to replace jaw plates prevents production losses and possible damage to the crusher:

Decreased Throughput: A clear sign that crushing efficiency has dropped.

Poor Product Shape: Resulting from inconsistent nip angles.

Excessive Vibration or Noise: May signal plate cracking or loosening.

Visual Inspection: Deep grooves, cracks, or exposed base metal indicate replacement is needed.

It’s vital to follow the manufacturer’s wear limit guidelines to avoid operational risks.

Operators can significantly improve the life of jaw plates through proper practices:

Use Correct Feed Size: Oversized rocks cause premature wear and potential damage.

Ensure Even Material Distribution: Prevents localized wear.

Rotate or Flip Jaw Plates: Distributes wear evenly across the surface.

Install Protective Liners: Side liners and cheek plates help protect surrounding components.

Lubricate Toggle Bearings and Maintain Proper Tension: Reduces mechanical stress.

Preventive maintenance is far more cost-effective than reactive replacement.

Different applications require different jaw plate characteristics:

Quarrying: Typically uses thicker plates with deep profiles for tough materials.

Mining: Requires wear-resistant materials and heavy-duty designs.

Recycling: Often needs aggressive tooth profiles for gripping irregular materials like concrete and rebar.

Demolition: Requires balance between impact toughness and surface hardness.

Factors such as feed size, compressive strength, and production targets should guide plate selection.

There are benefits and risks to both OEM (Original Equipment Manufacturer) and aftermarket jaw plates:

OEM Pros: Guaranteed fit, engineering quality, brand trust.

OEM Cons: Often more expensive, limited customization.

Aftermarket Pros: Cost-effective, variety of material choices, custom profiles.

Aftermarket Cons: Quality varies—must choose a reputable supplier.

It’s essential to ensure that aftermarket jaw plates meet the same (or better) metallurgical and dimensional standards as OEM wear parts.

Proper installation ensures both safety and efficiency:

Clean Contact Surfaces: Avoid improper seating and misalignment.

Use Correct Torque Specifications: Prevents loosening and uneven wear.

Inspect Jaw Dies Frequently: Check for signs of wear or movement.

Replace in Pairs: To maintain balanced crushing force.

Use Locking Wedges and Shims: For secure positioning.

A proactive maintenance schedule maximizes uptime and component lifespan.

Avoiding these common pitfalls can save time and money:

Using Incorrect Jaw Plate for the Application

Ignoring Manufacturer Guidelines

Running Plates Past Wear Limit

Feeding Oversized or Unsorted Material

Failing to Rotate Plates Regularly

Choosing the right jaw plate and maintaining it properly is just as important as selecting the right crusher.

Jaw plates are more than just spare parts—they are fundamental to the efficiency, productivity, and lifespan of your jaw crusher. From material selection and installation to wear monitoring and replacement, understanding the critical aspects of jaw plate management can lead to better crushing results and lower operational costs.

HAITIAN HEAVY INDUSTRY is a trusted name in high-quality casting and wear-resistant parts for crushers. Our HAITIAN CASTING jaw plates are engineered for strength, precision, and durability, ensuring reliable performance in the toughest mining and quarrying conditions. Choose HAITIAN for solutions that work as hard as your machinery does.