Machinery efficiency depends on the durability of its components. Wear parts endure constant stress during operation, which can lead to breakdowns if left unchecked. You can avoid costly interruptions by adopting effective wear parts solutions. These strategies help maintain equipment performance, reduce repair costs, and extend the lifespan of vital parts. Proactively managing wear parts ensures smoother operations and minimizes unexpected downtime.

Tip: Regular inspections and upgrades can prevent small issues from turning into expensive repairs.

High-quality replacement parts are components designed to match or exceed the standards of original equipment. These parts, often referred to as OEM (Original Equipment Manufacturer) parts, ensure reliability and performance. Manufacturers create them with precision to meet strict industry standards, such as IATF 16949 for quality management in the automotive sector. They are especially critical in applications like air and gas flow control, where even minor deviations can impact performance.

Using high-quality replacement parts directly improves machinery performance. These parts fit perfectly, reducing the risk of malfunctions. For example, genuine spare parts ensure optimal performance and longevity by maintaining the original specifications of your equipment. They also minimize wear and tear, which helps your machinery operate smoothly for longer periods. Additionally, fast response times and priority shipping for these parts reduce downtime, keeping your operations running efficiently.

Investing in high-quality replacement parts offers several advantages:

- Reliability: These parts are built to last, reducing the frequency of replacements.

- Cost Efficiency: Discounts on spare parts are often available with service plans, saving you money in the long run.

- Global Standards Compliance: Certifications like AEC-Q100 and AEC-Q200 ensure that components can withstand rigorous testing.

- Industry Growth: The global automotive aftermarket industry, valued at USD 468.91 billion in 2024, is projected to grow steadily, reflecting the increasing adoption of high-quality replacement parts.

By choosing high-quality replacement parts, you can enhance the lifespan of your equipment and reduce operational costs. This approach is one of the most effective wear parts solutions available today.

Preventive maintenance involves scheduled inspections and servicing of wear parts to ensure they remain in optimal condition. Instead of waiting for a failure to occur, you address potential issues before they escalate. This proactive approach includes tasks like cleaning, lubrication, and part replacements. For example, implementing an oil sampling program can help identify early signs of wear, allowing you to take corrective action promptly.

Tip: Regularly updating your maintenance schedule ensures no critical component is overlooked.

Preventive maintenance minimizes wear and tear by addressing factors that accelerate damage. Routine cleaning removes dirt and contaminants that can corrode or weaken parts. Inspections using digital tools detect early signs of deterioration, enabling timely repairs. Replacing parts before they fail prevents damage to surrounding components, which helps maintain the overall integrity of your machinery. This approach not only extends the lifespan of wear parts but also reduces the risk of unexpected breakdowns.

Adopting a preventive maintenance program offers significant long-term benefits. Organizations have reported a 48% reduction in conveyor system incidents and a 24% decrease in downtime. Additionally, over 400 overdue work orders were resolved through proactive maintenance efforts. Financially, this strategy can reduce costs by 12-18% and deliver a 400% return on investment. Every dollar spent on preventive maintenance saves up to five dollars on unforeseen expenses. These savings allow you to allocate resources more effectively and avoid costly capital expenditures.

| Statistic | Value |

|---|---|

| Cost Reduction | 12-18% |

| ROI | 400% |

| Savings per Dollar Invested | Up to $5 |

By implementing preventive maintenance, you can optimize your wear parts solutions, reduce operational costs, and ensure your machinery operates efficiently for years to come.

Advanced coating and material technologies involve innovative methods and materials designed to enhance the durability and performance of wear parts. These technologies include techniques like self-healing coatings, electroplating, and chemical vapor deposition. For example, self-healing coatings repair minor damages automatically, reducing maintenance needs. Similarly, electroplating applies a hard metal layer over softer materials, significantly improving wear resistance. The book Advanced Coating Materials provides detailed insights into these technologies, covering their composition, applications, and optimization strategies. These advancements are transforming industries by offering more efficient and cost-effective wear parts solutions.

These technologies protect wear parts from damage caused by friction, corrosion, and extreme conditions. Electroplating, for instance, enhances wear resistance by creating a durable surface layer. This process reduces wear and tear, especially in high-friction environments. Heat-resistant and corrosion-resistant coatings shield parts from harsh conditions, extending their operational life. Targeted applications of these coatings to critical areas optimize performance while minimizing costs. By reducing the frequency of replacements, these technologies ensure your machinery operates efficiently for longer periods.

Advanced coating and material technologies offer significant cost and performance advantages. A comparative study highlights that hybrid cryoMQL methods improve tool life by 30 times compared to traditional flood machining. High-pressure cooling doubles tool life, showcasing the efficiency of these innovations. Additionally, self-healing coatings reduce maintenance costs, while heat-resistant coatings lower replacement expenses. The table below summarizes the benefits of various technologies:

| Technology Type | Benefits | Applications |

|---|---|---|

| Self-Healing Coatings | Enhances durability, reduces maintenance costs | Automotive, aerospace, consumer electronics, construction |

| Antibacterial Coatings | Inhibits microbial growth, ensures cleaner surfaces | Healthcare, public spaces, food industry, HVAC systems |

| Heat-Resistant and Corrosion-Resistant Coatings | Protects against extreme conditions, extends lifespan, reduces costs | Aerospace, automotive, marine, construction, renewable energy systems |

By adopting these advanced technologies, you can achieve better performance and cost savings, making them a vital component of modern wear parts solutions.

Adopting the right wear parts solutions can transform how you manage machinery. High-quality replacement parts ensure reliability, preventive maintenance programs reduce unexpected failures, and advanced coatings extend part lifespan. Proactive management minimizes downtime and improves efficiency.

Predictive maintenance extends equipment life by focusing on worn parts.

It reduces lifecycle costs and avoids expensive replacements.

Long-term evaluations reveal significant monetary benefits.

Take a closer look at your current strategy. By implementing these solutions, you can achieve better performance and long-term savings. Start optimizing your wear parts today!

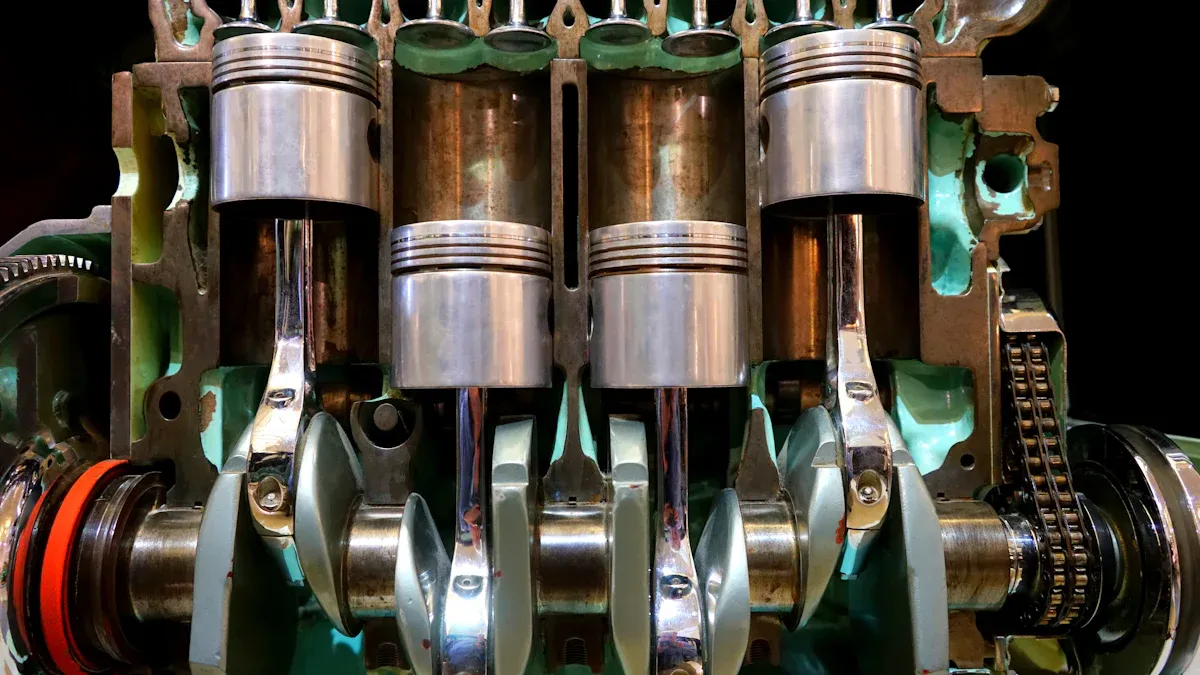

Wear parts are components that experience friction, pressure, or environmental exposure during operation. Over time, these factors cause gradual deterioration. For example, blades, gears, and seals wear out due to constant use. Regular maintenance and high-quality replacements help you manage this inevitable wear.

Replacement frequency depends on usage, material quality, and operating conditions. For heavily used machinery, inspect parts monthly. Follow manufacturer guidelines for specific timelines. Preventive maintenance programs can help you identify when replacements are necessary, avoiding unexpected failures.

Yes, advanced coatings improve durability and reduce maintenance costs. Technologies like self-healing coatings and corrosion-resistant layers extend part lifespan. These innovations save you money by minimizing replacements and downtime, making them a cost-effective solution for long-term performance.

Absolutely! Preventive maintenance reduces unexpected breakdowns and extends equipment life. Studies show it can lower costs by 12-18% and deliver a 400% return on investment. By addressing issues early, you avoid expensive repairs and replacements.

Choose parts that meet or exceed OEM standards. Look for certifications like IATF 16949 or AEC-Q200 to ensure quality. High-quality replacements fit perfectly, enhance performance, and reduce wear. Always source parts from trusted suppliers to maintain reliability.