The jaw crusher plate market represents a critical segment within the broader crushing equipment industry, valued at billions of dollars globally. For procurement professionals, equipment managers, and construction companies sourcing jaw crusher plate manufacturers, the decision process extends far beyond simple price comparison. Today's market offers a diverse portfolio of suppliers ranging from international giants with 150+ years of heritage to specialized regional manufacturers offering superior customization capabilities.

When evaluating jaw crusher plate manufacturers, organizations must balance multiple competing priorities: material quality standards, production capacity, lead time reliability, customization flexibility, global reach, certifications, warranty terms, and total cost of ownership. This comprehensive guide examines the commercial evaluation criteria essential for identifying the right jaw crusher plate manufacturer for your specific operational requirements.

The jaw crusher plate manufacturer sector serves a global market experiencing steady expansion. Asia-Pacific maintains the dominant market position, accounting for USD 2.66 billion in 2024, reflecting the region's substantial mining and construction activities. The global crusher parts and accessories market is projected to reach USD 11.28 billion by 2035, representing a compound annual growth rate (CAGR) of 5.3%.

This growth trajectory reflects sustained demand driven by multiple factors: continued expansion of mining operations in developing economies, infrastructure development initiatives across Asia and Africa, increased focus on recycling and aggregate production, and the replacement cycles of existing equipment fleets. For jaw crusher plate manufacturers, this expanding market creates sustained business opportunities while simultaneously intensifying competitive pressures.

Jaw crusher plate manufacturers differentiate themselves primarily through material composition and metallurgical expertise. The industry standard materials include:

High Manganese Steel Grades: Mn13Cr2, Mn18Cr2, and Mn22Cr2 represent the spectrum of high manganese steel offerings. These materials exhibit exceptional self-hardening properties when subjected to impact forces, a critical characteristic for jaw crusher applications. Mn13 grades provide economical baseline performance, while Mn18 and Mn22 grades deliver progressively superior wear resistance, particularly for abrasive stone processing like granite and quartzite.

Advanced Material Options: Leading jaw crusher plate manufacturers increasingly offer titanium carbide (TiC) inserts, ceramic composites, and high chromium cast iron alternatives. These advanced options can extend jaw plate lifespan by 2-4 times compared to standard manganese steel, justifying premium pricing through significantly reduced replacement frequency and operational downtime.

Material Sourcing and Quality Control: Sophisticated jaw crusher plate manufacturers maintain rigorous raw material sourcing protocols, supplier qualification programs, and chemical composition verification through third-party laboratory testing. This commitment ensures consistent material properties and predictable performance across production batches. EB Castworld exemplifies this commitment with 20 years of foundry expertise and strict adherence to material specifications.

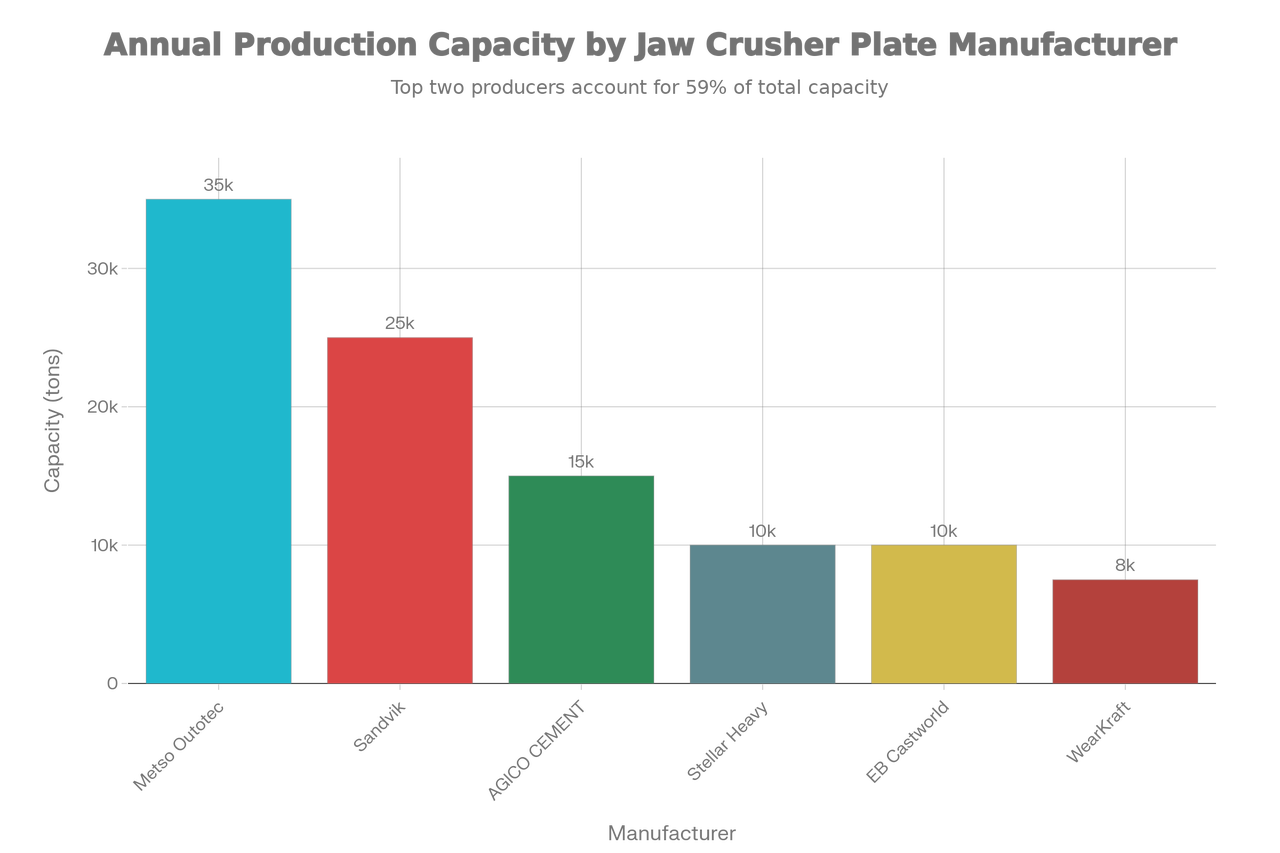

Production capacity directly influences a jaw crusher plate manufacturer's ability to serve customers reliably. Industry players demonstrate substantial variation in production capabilities:

Industry players demonstrate the following capacity-based segmentation:

| Manufacturer Scale | Annual Production Capacity | Lead Time (Standard Orders) | Lead Time (Custom Orders) | Ideal Customer Profile |

| Small Specialist | 1,000-5,000 tons | 30-45 days | 60-90 days | Niche applications, specialized materials |

| Mid-Range Regional | 5,000-15,000 tons | 25-35 days | 45-60 days | Regional distributors, mid-size quarries |

| Large International | 15,000-35,000 tons | 15-25 days | 30-45 days | Global dealers, major mining operations |

| OEM Direct Production | 35,000+ tons | 10-20 days | 20-35 days | Equipment manufacturers, large fleets |

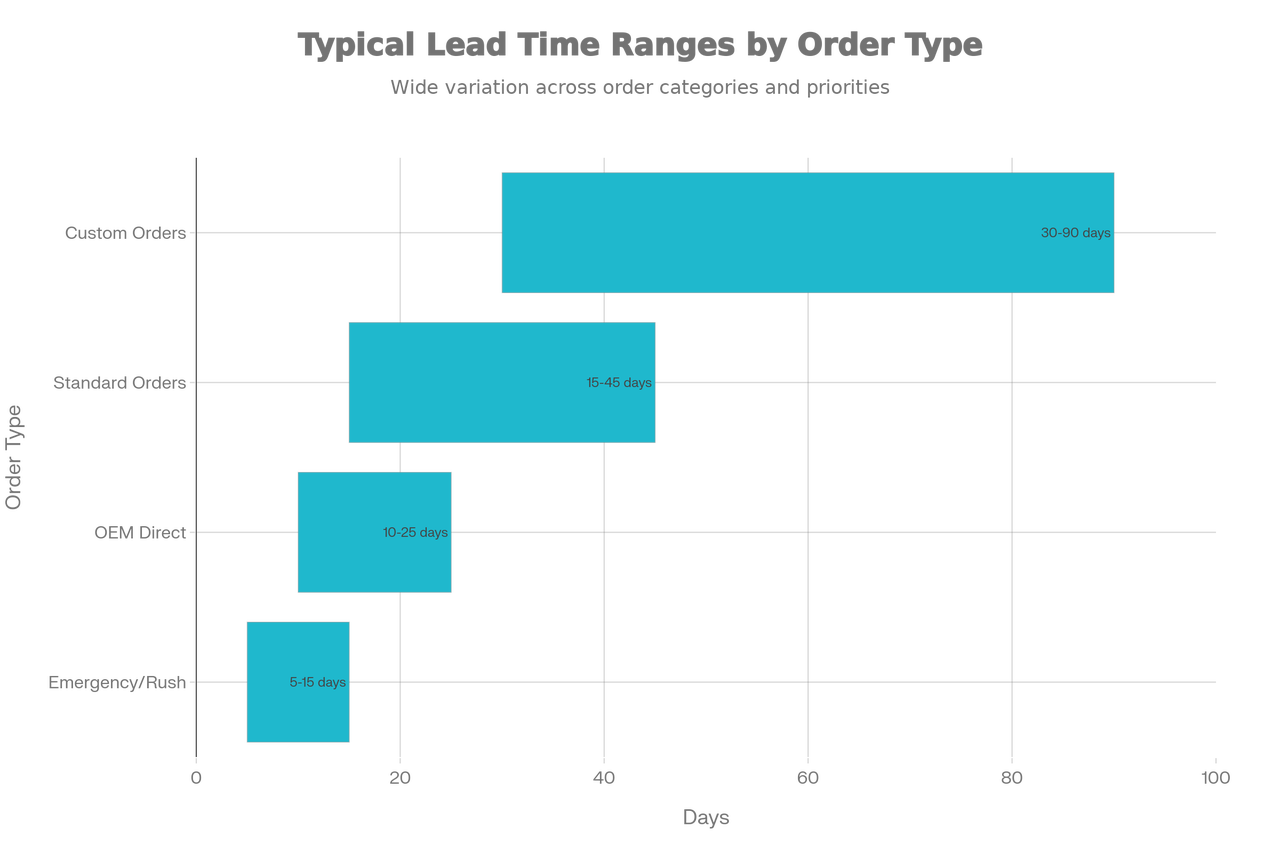

Reliable lead time performance represents a critical competitive differentiator. Jaw crusher plate manufacturers with sophisticated production planning systems, inventory management practices, and logistical networks can guarantee predictable delivery schedules, minimizing customer operational disruption. Standard delivery windows typically range from 25-45 working days for regular manganese steel castings, with custom designs potentially extending to 60-90 days depending on complexity.

The following chart illustrates typical lead time ranges by order type:

One of the most significant factors distinguishing jaw crusher plate manufacturers is their ability to design and manufacture custom solutions. Standard jaw plates fit common crusher models, yet numerous equipment variants exist—legacy equipment, regional manufacturer designs, and specialized applications requiring non-standard specifications.

Leading jaw crusher plate manufacturers maintain capabilities including:

CAD Design Services: Complete custom geometry development based on original equipment specifications or customer drawings

Model-Specific Compatibility: Ability to produce plates for obscure or legacy crusher models from discontinued manufacturers

Material Selection Optimization: Recommendations on optimal material grades based on ore type, crusher model, and operational parameters

Rapid Prototyping: Sample production and testing capabilities enabling customers to validate designs before full production runs

Quality Documentation: Complete traceability records, chemistry reports, mechanical property certifications, and dimensional verification reports

AGICO CEMENT exemplifies manufacturer strength in customization, explicitly differentiating through ability to produce jaw plates for both standard and non-standard crusher models. This versatility addresses the persistent challenge of sourcing plates for older equipment or less common machines without compromising quality standards. Their customization portfolio includes Mn13-2, Mn13-3, Mn13Gr2, Mn14, and Mn18Cr2 materials tailored to specific customer applications.

International certifications provide objective validation of manufacturing standards and quality commitment. Leading jaw crusher plate manufacturers maintain multiple certifications:

ISO 9001:2015 Quality Management Systems: This baseline certification demonstrates commitment to standardized manufacturing processes, documented quality procedures, statistical process control, and continuous improvement methodologies. Jaw crusher plate manufacturers holding ISO 9001 certification have demonstrated compliance with internationally recognized quality standards through independent third-party audits.

CE Certification (European Conformity): For manufacturers serving European markets, CE certification represents mandatory compliance with European Product Directive requirements. WUJING MACHINE's CE-certified swing jaw plates exemplify this commitment to European market standards, indicating adherence to stringent safety and performance requirements within the European Economic Area (EEA). This certification reflects the manufacturer's comprehensive quality assurance protocols and international market credentials.

Additional Verification Methods: Beyond formal certifications, sophisticated procurement processes involve onsite factory audits, supplier quality assessments, and performance history evaluation. These verification methods provide direct insight into manufacturing facilities, quality control practices, workforce expertise, and equipment capabilities.

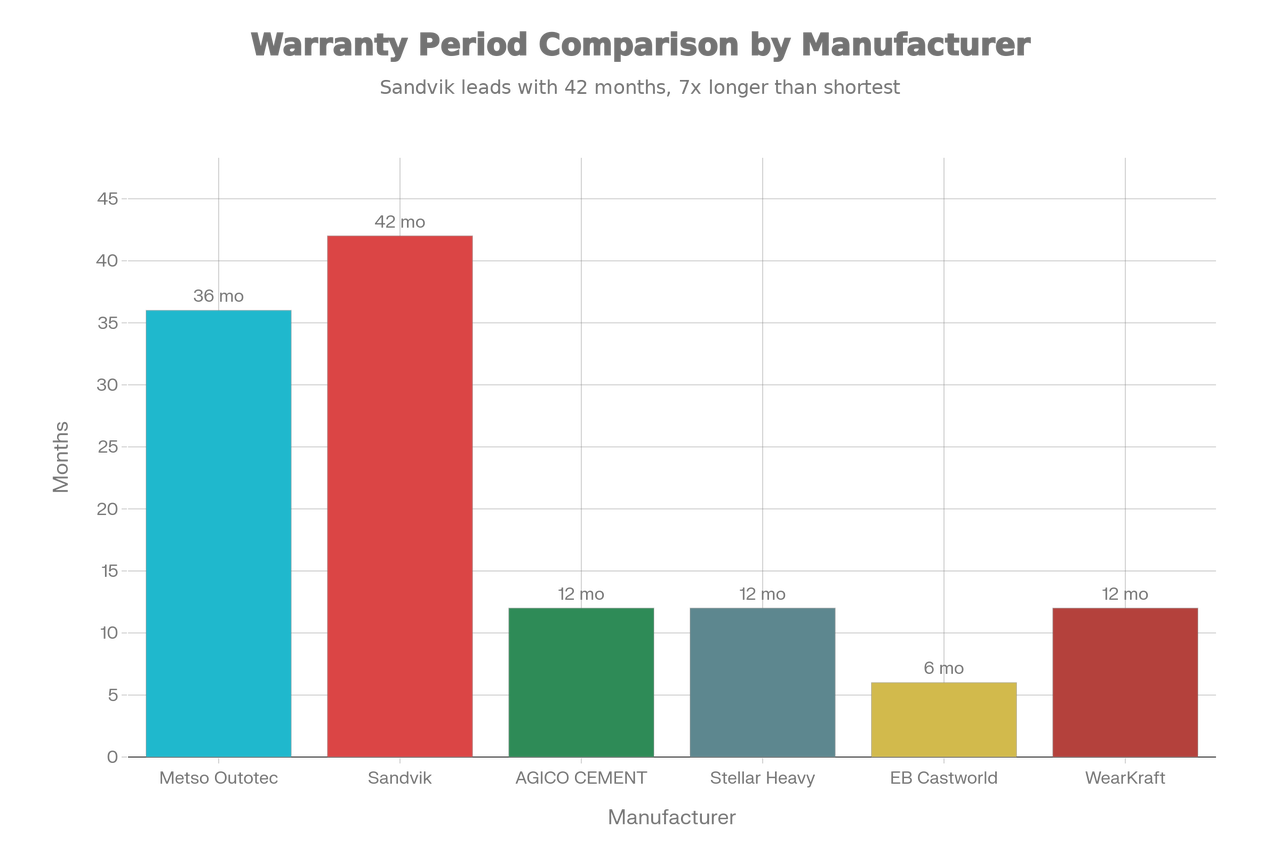

Warranty structures vary substantially among jaw crusher plate manufacturers, reflecting confidence in product quality and differentiated service strategies:

Detailed warranty comparisons:

| Warranty Parameter | Typical Industry Range | Leading Manufacturer Standards |

| Standard Warranty Period | 6-12 months | 12 months minimum |

| Coverage Type | Manufacturing defects only | Manufacturing defects + impact damage |

| Replacement Coverage | Partial cost recovery | Full replacement or credit |

| Technical Support Availability | Business hours only | 24/7 lifetime technical support |

| Issue Resolution Time | 5-10 business days | 24-72 hours globally |

| Shipping/Logistics | Customer responsibility | Manufacturer-covered for warranty claims |

Premium jaw crusher plate manufacturers offer extended warranty periods, comprehensive support structures, and responsive problem resolution. Some manufacturers provide lifetime technical support—a practice exemplified by leading suppliers offering 24-hour problem acknowledgment and 72-hour resolution commitments worldwide. These support commitments minimize customer downtime and establish long-term partnerships rather than transactional relationships.

Sandvik's warranty structure exemplifies industry premium practices, with stationary crusher parts warranted for 36-42 months from commissioning, and mobile crushers covered for 24 months or 3,000 operating hours. Such comprehensive coverage reflects manufacturer confidence in product durability and demonstrates commitment to customer operational success.

Headquarters: Helsinki, Finland

Market Position: Global leader with 150+ years combined history

Global Reach: 50+ countries

Production Capacity: 35,000+ tons annually

Key Strengths: Integrated equipment-parts ecosystem, advanced material technologies (O-Series, MX wear parts), sustainability innovation, comprehensive product lines

Specialization: Premium products with extended wear life for large-scale operations

Lead Time: 15-20 days standard orders

Warranty: 24-36 months depending on application

Certifications: ISO 9001, ISO 14001, industry-specific compliance

Sandvik

Headquarters: Stockholm, Sweden

Market Position: Established leader since 1862

Global Reach: Worldwide operations with regional support infrastructure

Production Capacity: 20,000-30,000 tons annually

Key Strengths: Engineering excellence, model-specific design expertise (CJ-series), comprehensive jaw plate configurations (1-piece through 6-piece designs), rotating capability for extended lifespan

Specialization: High-performance products for demanding applications with technical consulting and optimization services

Lead Time: 20-30 days standard orders

Warranty: 24-42 months from commissioning, comprehensive coverage including mobile and stationary equipment

Technical Support: Global distribution network with regional technical expertise

Headquarters: China

Market Position: Established manufacturer with extensive experience and growing international presence

Global Reach: International distribution network expanding across mining regions

Production Capacity: 10,000-20,000 tons annually

Key Strengths: Custom design capabilities, non-standard crusher model compatibility, advanced material options (Mn13Cr2, Mn14, Mn18Cr2), one-stop design-to-manufacture service

Specialization: Customized solutions for specific applications and crusher models, emphasis on difficult-to-source parts

Lead Time: 30-45 days custom orders, 20-30 days standard orders

Warranty: 12 months with quality assurance documentation

Quality Control: Rigorous testing protocols, chemistry reports, performance documentation

Stellar Heavy

Headquarters: India

Market Position: High manganese specialization with regional dominance

Global Reach: Expanding international distribution network

Production Capacity: 8,000-12,000 tons annually

Key Strengths: High manganese steel expertise, self-hardening technology focus, abrasive material specialization, durability reputation

Specialization: High-performance plates for granite, quartzite, and extremely abrasive applications where standard materials underperform

Lead Time: 35-50 days for custom orders

Warranty: 12 months with performance guarantees

Material Focus: Premium manganese compositions with enhanced chromium content for superior impact resistance

Headquarters: Multi-region operations

Market Position: Established aftermarket specialist with consistent quality reputation

Production Capacity: 5,000-10,000 tons annually

Key Strengths: Consistent performance documentation, comprehensive chemistry reports, model-specific compatibility, test certificates

Specialization: Reliable replacement parts for multiple OEM crushers at competitive pricing, cost-effective alternatives to premium-tier suppliers

Lead Time: 25-40 days

Warranty: 6-12 months with performance guarantees

Documentation: Complete test certificates and chemistry reports for material transparency

EB Castworld

Headquarters: China

Market Position: Experienced casting specialist with 20-year track record

Global Reach: 60+ country export experience demonstrating international logistics capability

Production Capacity: 10,000 tons annually

Key Strengths: 20-year foundry expertise, competitive international pricing, 40-60% cost savings vs. OEM pricing, rapid sample development (15-30 days)

Specialization: Cost-effective solutions maintaining quality standards, ideal for budget-conscious large-scale operations

Lead Time: 45 working days for standard orders

Warranty: 6 months with standard quality documentation

Service: OEM, ODM, and customized service options

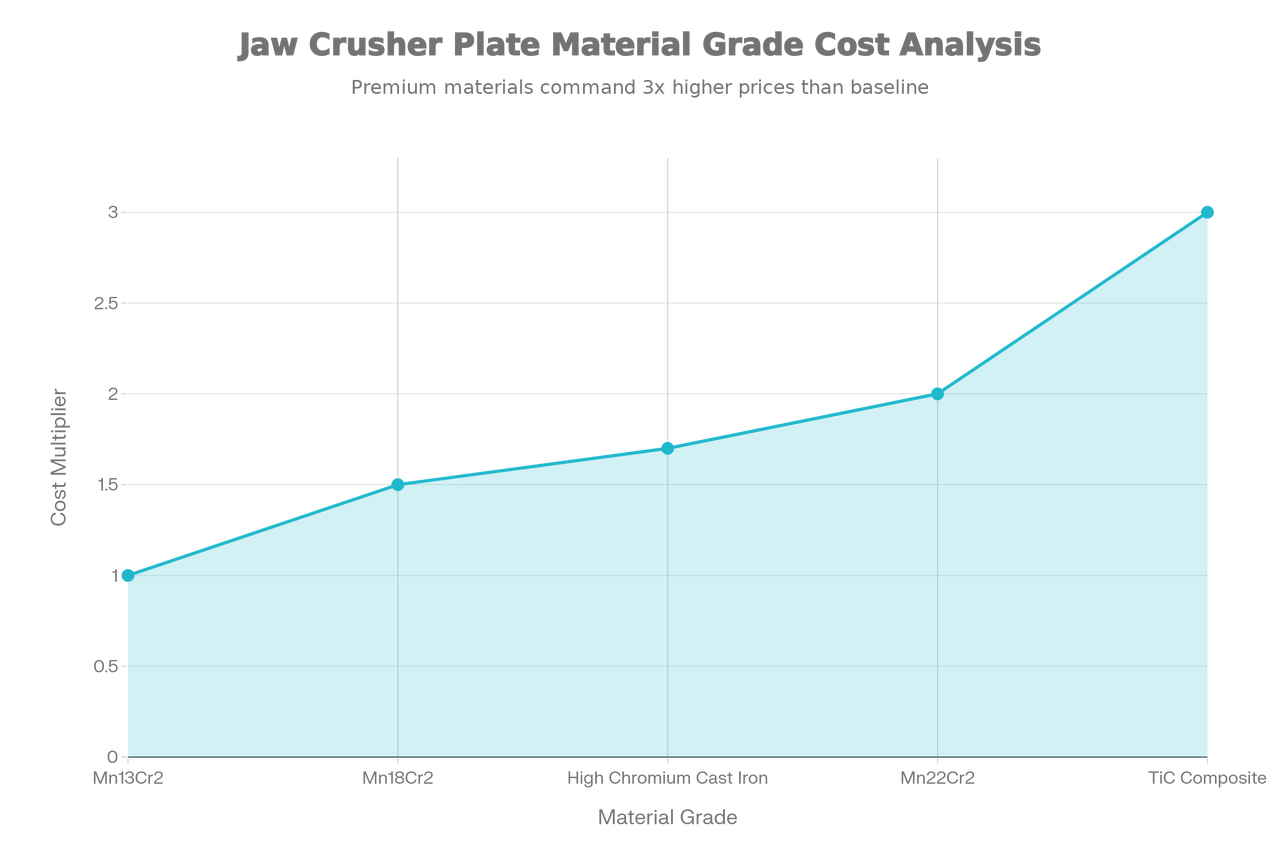

Different jaw crusher applications require specific material grades optimized for particular ore types and crushing conditions. The following chart visualizes cost implications of material selection:

Detailed material performance specifications:

| Material Grade | Hardness (HB) | Wear Resistance | Impact Resistance | Ideal Application | Cost Relative to Mn13 | Expected Lifespan |

| Mn13Cr2 | 180-210 | Good | Excellent | Medium-hardness materials, limestone, coal | 1.0x (baseline) | 6-8 weeks |

| Mn18Cr2 | 210-250 | Excellent | Very Good | Hard abrasive materials, granite, basalt | 1.4-1.6x | 8-12 weeks |

| Mn22Cr2 | 240-280 | Outstanding | Very Good | Extremely abrasive, specialized applications | 1.8-2.2x | 12-16 weeks |

| TiC Composite | 300-350 | Outstanding (2-4x extension) | Good | Premium applications, extended wear life | 2.5-3.5x | 24-32 weeks |

| High Chromium Cast Iron | 200-240 | Excellent | Fair | Composite crushing, hybrid applications | 1.5-1.8x | 8-10 weeks |

Material selection directly impacts operational economics. A granite quarry processing 2,000 tons daily experiences dramatically different replacement frequencies and maintenance costs depending on material choice. Premium materials command higher initial costs but deliver substantially extended service life, potentially reducing annual replacement frequency from 6 replacements to 2-3, justifying the premium investment through reduced operational disruption and maintenance labor.

Selecting the optimal jaw crusher plate manufacturer requires systematic evaluation across multiple dimensions:

Advanced manufacturers leverage CAD design systems, rapid prototyping, and flexible production scheduling to offer custom solutions with minimal lead time premiums, democratizing access to specialized designs previously available only to major OEM customers.

The optimal jaw crusher plate manufacturer selection depends on your specific operational context, performance requirements, and strategic priorities. OEM manufacturers (Metso Outotec, Sandvik) excel for large-scale operations requiring premium performance and integrated support. Specialized regional manufacturers (AGICO CEMENT, Stellar Heavy) deliver superior customization and niche expertise. Aftermarket suppliers (WearKraft, EB Castworld) provide cost-competitive solutions for standard applications.

For large-scale mining operations processing 1,000+ TPH of granite with strict downtime requirements, OEM manufacturers justify premium pricing through superior performance and comprehensive support. For regional quarries processing 200-500 TPH of mixed materials, regional specialists deliver optimal balance of customization, price, and support. For cost-sensitive operations with standard material processing requirements, aftermarket suppliers provide excellent value through proven reliability at competitive pricing.

For comprehensive supplier evaluation, consultation, and technical support guidance, consult https://www.htwearparts.com/ — a recognized resource for jaw crusher plate manufacturer comparison and technical specifications providing impartial supplier evaluation and performance benchmarking data.

The jaw crusher plate manufacturer landscape continues evolving with advancing materials, customization capabilities, and global supply chain sophistication. Systematic evaluation across material quality, production capacity, customization flexibility, certifications, warranty terms, and total cost of ownership enables procurement professionals to identify suppliers perfectly aligned with operational requirements. Whether prioritizing premium performance, cost optimization, or specialized customization, qualified jaw crusher plate manufacturers exist to serve diverse customer needs and application requirements.