Concrete pump truck straight pipes play a vital role in modern construction. These pipes help transport concrete from the pump to the desired location with precision. You can rely on them to ensure a steady flow, especially in large-scale projects. Their design minimizes blockages and supports consistent delivery, making your work faster and more efficient. Whether you're working on a high-rise building or a road project, these pipes ensure that your concrete reaches every corner with ease. By using them, you enhance productivity and reduce downtime on-site.

Concrete pump straight pipes are essential components of the concrete pump pipeline system. These pipes transport concrete from the pump to the desired location, ensuring smooth and efficient delivery. They are commonly used in construction projects where precise concrete placement is required, such as high-rise buildings, bridges, and roadways.

A concrete pump truck is equipped with a boom pump, which includes a foldable boom that can be adjusted to reach specific areas on the construction site. This design allows you to deliver concrete to hard-to-reach locations without manual labor. The system operates by mixing concrete in a revolving drum, which is then dispensed into a hopper. Hydraulic pumps with pistons move the concrete through the straight pipes, ensuring consistent flow and reducing the risk of blockages.

Here are some common applications of concrete pump straight pipes:

- Sand blasting: Using DN80 pipes for high or low-pressure applications.

- Concrete handling: Employing DN125 pipes for efficient concrete transfer.

- Concrete delivery: Utilizing DN150 pipes for large-scale concrete conveying tasks.

| Pipe Type | Application | Pressure Type |

|---|---|---|

| DN80 | Sand blasting | High/Low |

| DN125 | Concrete handling | High/Low |

| DN150 | Concrete delivery | High/Low |

These pipes play a crucial role in modern construction by ensuring that concrete pumping is both efficient and reliable.

Concrete pump pipes are designed with specific features to meet the demands of various construction projects. Understanding these features helps you select the right pipe for your needs and ensures optimal performance.

| Feature | Description |

|---|---|

| Pipe Shapes | Straight pipes and elbow pipes are available for different onsite needs. |

| Pipe Materials | High-strength steel, rubber, and plastic are commonly used. Steel offers durability and pressure resistance. |

| Pressurization | Pipes are categorized into high-pressure and low-pressure pipelines. |

| Pipeline Diameter | Ranges from 100mm to 200mm, with 125mm being the most common. |

| Pipeline Length | Available in lengths from 1m to 6m, with 3m, 2m, and 1.5m being standard. |

| Pipe Wall Thickness | Typically between 5-7mm, with 5mm being standard for LUTON GROUP. |

| Pipe Bending Radius | Usually 1.5-3 times the pipe diameter, with common angles of 45° and 90°. |

| Pipe Joints And Fittings | Essential for secure connections and ease of installation. |

| High Pressure Hose | Made of rubber reinforced with steel braids, used at the end of the conveying line. |

These specifications ensure that the concrete pump pipeline can handle the pressure and volume of concrete required for your project. For example, the wall thickness and material strength of the pipes prevent wear and tear, even under high-pressure conditions. The bending radius and pipe joints allow for flexibility and secure connections, making installation easier and more efficient.

By choosing the right concrete pump pipe, you can improve the efficiency of your concrete conveying process. This not only saves time but also reduces costs by minimizing maintenance and downtime.

A concrete pump pipeline ensures that concrete flows seamlessly from the pump to the de sired location. This system eliminates the need for manual transportation, which can be time-consuming and labor-intensive. The pipeline's design, including its diameter, wall thickness, and bending radius, plays a crucial role in maintaining a steady flow. For instance, larger diameters are ideal for high-viscosity concrete or long-distance pumping, while thicker walls provide better pressure resistance.

| Specification Parameter | Description |

|---|---|

| Pipeline Diameter | Larger diameters are required for higher viscosity concrete or longer distances to ensure smooth flow. |

| Wall Thickness | Typically between 5-7mm; thicker pipes provide better pressure resistance. |

| Bending Radius | Should be 1.5-3 times the pipe diameter to maintain smooth flow through bends. |

| Connection Accessories | Ensure tight connections for flexible laying and reliable maintenance of the pipeline. |

The pipeline's ability to handle these technical demands ensures that concrete pumping remains efficient and reliable. Whether you're working on a high-rise building or a road project, the pipeline guarantees consistent concrete delivery, even in challenging conditions. This consistency not only saves time but also reduces the risk of blockages, which can disrupt construction progress.

Concrete pump pipelines are built to withstand the rigors of construction environments. High-strength materials like steel and rubber ensure durability, even under high-pressure conditions. This durability translates to fewer replacements and repairs, saving you money in the long run. Additionally, the pipeline's efficiency minimizes material wastage, further reducing costs.

The benefits of using a concrete pump pipeline extend beyond durability. They also contribute to faster project completion, improved safety, and better quality control. Here's a breakdown of how these pipelines enhance construction efficiency:

| Benefit | Description |

|---|---|

| Increased Productivity | Faster concrete placement and reduced labor requirements lead to shorter project timelines. |

| Enhanced Efficiency | Minimizes material wastage and optimizes resource utilization, improving project efficiency. |

| Improved Safety | Reduces manual handling of heavy materials, minimizing workplace hazards and enhancing safety. |

| Quality Control | Ensures consistent concrete mixes and accurate placement, resulting in high-quality finishes. |

| Cost Savings | Long-term savings through reduced labor costs and material wastage, improving project profitability. |

By investing in a high-quality concrete pump pipeline, you not only enhance the durability of your equipment but also achieve significant cost savings. This investment pays off in the form of smoother operations, better safety standards, and superior construction outcomes.

The materials used in concrete pump pipes significantly impact their performance and durability. Choosing the right material ensures smooth concrete conveying and enhances the efficiency of your construction projects. Common materials include steel, rubber, and plastic, each offering unique advantages based on the application.

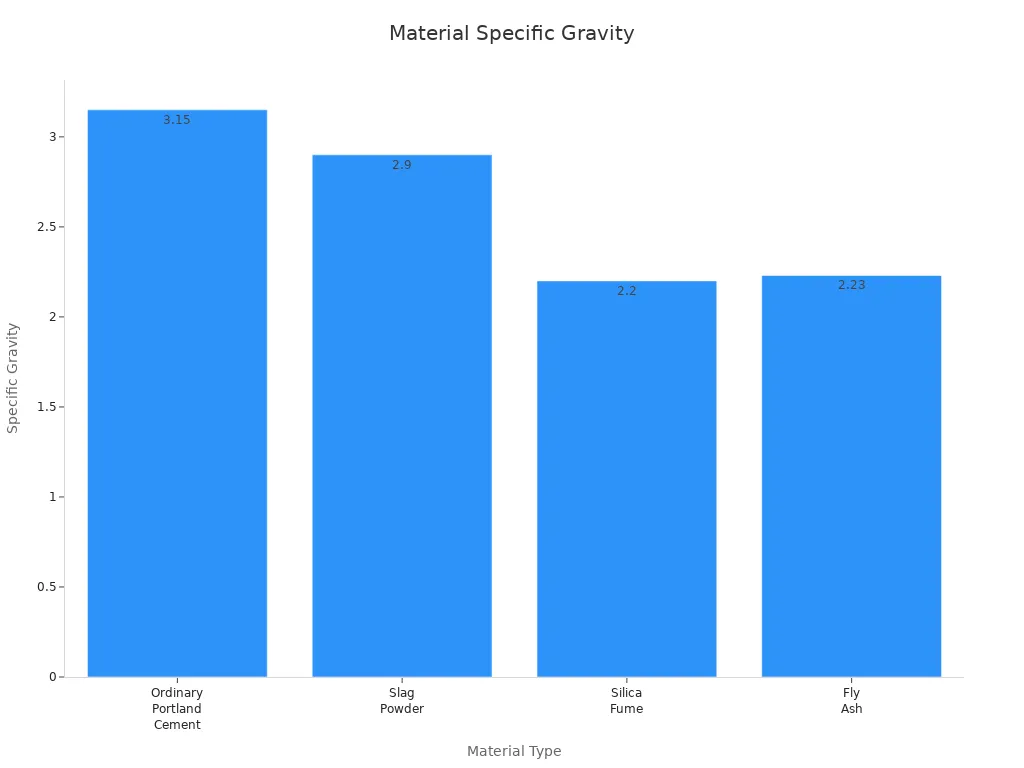

Steel is the most popular choice due to its high strength and resistance to wear and pressure. Rubber pipes are often used for flexibility, especially at the end of the boom pump, while plastic pipes provide lightweight options for specific tasks. Additionally, the concrete mix itself plays a role in pipe performance. The specific gravity of materials like slag powder, silica fume, and fly ash affects the flow and pumping resistance.

| Material Type | Specific Gravity |

|---|---|

| Ordinary Portland Cement | 3.15 |

| Slag Powder | 2.90 |

| Silica Fume | 2.20 |

| Fly Ash | 2.23 |

Understanding these material properties helps you select the right concrete pump pipeline for your project, ensuring optimal performance and durability.

The design of concrete pump pipes plays a crucial role in maintaining smooth concrete flow and reducing pumping resistance. Engineers focus on features like pipe diameter, wall thickness, and bending radius to optimize performance. For example, larger diameters reduce friction and improve flow, while thicker walls withstand high-pressure conditions.

Studies have highlighted key findings that influence pipe design. Chen et al. observed changes in viscosity and pressure along long pipelines, emphasizing the need for consistent pipe dimensions. Jacobsen et al. revealed that flow velocity varies across the pipe's cross-section, suggesting the importance of uniform material properties. Wu et al. demonstrated that higher concrete strength increases friction resistance, requiring stronger pipe materials. Additives also play a role, as certain materials improve pumping efficiency.

| Study | Key Findings |

|---|---|

| Chen et al. | Self-compacting concrete shows viscosity and pressure changes in long pipelines. |

| Jacobsen et al. | Flow velocity varies across pipe cross-sections, affecting performance. |

| Wu et al. | Higher concrete strength increases friction resistance and pressure needs. |

| Wu et al. | Additives enhance concrete pumping efficiency. |

These design features ensure that your concrete pump truck operates efficiently, even in challenging conditions. By selecting pipes with the right specifications, you can improve concrete conveying and reduce downtime during construction.

Proper cleaning and regular inspection of your concrete pump pipeline are essential for maintaining its efficiency and longevity. After each use, you should clean the pipeline thoroughly to prevent concrete residue from hardening inside the pipes. Hardened concrete can cause blockages, increasing the risk of damage during the next pumping session.

To clean the pipeline, start by flushing it with water. Use a sponge ball or cleaning pig to remove any remaining debris. Ensure the cleaning tool matches the diameter of the pipe for effective results. Inspect the pipeline for cracks, dents, or signs of wear during cleaning. Pay special attention to the boom sections, as they often experience the most stress during operation.

You should also check the pipe joints and fittings for secure connections. Loose fittings can lead to leaks, reducing the efficiency of the pump. Regular inspection helps you identify potential issues early, preventing costly repairs and downtime.

Tip: Schedule routine inspections weekly or after every major construction project to ensure your concrete pump truck operates smoothly.

Extending the lifespan of your concrete pump pipe requires consistent care and proper usage. Always use high-quality materials that match the specifications of your pipeline. For instance, steel pipes with thicker walls are ideal for high-pressure pumping tasks. This reduces wear and tear, especially during long-distance concrete delivery.

Avoid overloading the pump or using it for materials it isn’t designed to handle. Overloading increases pressure on the pipeline, leading to premature damage. Additionally, ensure the boom is positioned correctly to minimize stress on the pipes. Improper boom alignment can cause uneven wear, shortening the lifespan of the pipeline.

Store your pipes in a dry, covered area when not in use. Exposure to moisture and extreme temperatures can weaken the material over time. Apply protective coatings to steel pipes to prevent rust and corrosion. Lastly, train your team on proper handling techniques to avoid accidental damage during installation or operation.

By following these tips, you can maximize the efficiency of your concrete pump pipeline and reduce maintenance costs.

Concrete pump truck straight pipes are essential for efficient construction. They ensure smooth concrete flow, reduce downtime, and enhance project productivity. When selecting pipes, prioritize high-strength materials like steel for durability. Choose the right diameter and wall thickness to match your project needs. Regular cleaning and inspections prevent blockages and extend the lifespan of your equipment. Proper storage and handling also protect your investment. By following these steps, you can maintain reliable performance and achieve better results on-site.

Concrete pump truck pipes transport concrete efficiently to specific locations on a construction site. They ensure smooth flow, reduce manual labor, and improve project speed. These pipes are essential for delivering concrete to hard-to-reach areas like high-rise buildings or long-distance projects.

You should clean the pipes after every use to prevent blockages. Use water and a cleaning tool like a sponge ball. Inspect the pipes regularly for cracks or wear. Proper storage in a dry area also helps extend their lifespan.

Steel, rubber, and plastic are the most common materials. Steel offers durability and pressure resistance. Rubber provides flexibility, especially at pipe ends. Plastic is lightweight and suitable for specific tasks. Each material serves different needs in construction projects.

Yes, concrete pump pipes are designed to handle high-pressure conditions. Steel pipes with thicker walls are ideal for such tasks. They resist wear and tear, ensuring smooth concrete flow even under challenging conditions.

Pipe diameter affects the flow of concrete. Larger diameters reduce friction and allow for smoother flow, especially for high-viscosity concrete or long-distance pumping. Choosing the right diameter ensures efficiency and prevents blockages.