Durable jaw plates are vital for the efficiency of industrial crushers. When jaw plates wear out quickly, crusher performance drops, leading to higher operational costs. For instance, a fixed jaw plate's service life can decrease from 150 days to 63 days, reducing ore processing from 750,000 tons to 420,000 tons. This can result in an annual economic loss of 160,000 yuan due to increased replacement costs and downtime.

Optimized casting techniques play a crucial role in overcoming these challenges. By improving wear resistance, they reduce the frequency of replacements and enhance crushing efficiency. These advancements not only save energy but also significantly lower long-term costs. You can see how investing in high-quality jaw plate casting benefits crusher operations and boosts overall productivity.

High manganese steel stands out as a superior material for crusher jaw plates due to its unique properties. This steel, often referred to as Hadfield steel, contains 11% to 14% manganese and 1.1% to 1.4% carbon. These elements contribute to its exceptional strength and durability.

One of its most remarkable features is its work-hardening ability. When subjected to impact, the surface of the steel hardens significantly, reaching a maximum hardness of 550 BHN (Brinell Hardness Number). This property ensures that the jaw plate becomes tougher with use, making it ideal for heavy-duty applications. Additionally, high manganese steel exhibits excellent impact resistance, allowing it to withstand constant crushing forces without fracturing.

The material's wear resistance is another critical advantage. Studies show that high manganese steel can last up to ten times longer than mild steel under similar impact conditions. Its yield strength of approximately 66,000 PSI and ultimate tensile strength of about 107,000 PSI further highlight its robustness.

| Property | Description |

|---|---|

| Work-hardening ability | Develops a hardened surface under impact, increasing strength and durability. |

| Impact resistance | Withstands constant impact, making it suitable for crushers. |

| Wear resistance | Lasts significantly longer than mild steel in high-impact environments. |

| Yield strength | Approximately 66,000 PSI. |

| Ultimate tensile strength | About 107,000 PSI. |

| Surface hardness | Can reach up to 550 BHN under impact. |

Using high manganese crusher jaw plates offers several benefits that directly impact the efficiency and longevity of your crusher.

Enhanced Durability: The work-hardening property ensures that the jaw plate becomes harder and more resistant to wear over time.

Reduced Maintenance: Crushers equipped with high manganese steel jaw plates require less frequent replacements, saving you time and money.

Improved Performance: The material's ability to endure high stress and impact ensures consistent crushing performance, even under demanding conditions.

Minimized Downtime: With longer-lasting jaw plates, you can maintain uninterrupted operations, leading to higher productivity.

Users have reported significant improvements in operational efficiency after switching to high manganese steel. For instance:

- Maintenance frequency decreased, resulting in smoother operations.

- Operational hours increased, reducing downtime and ensuring consistent output.

While high manganese steel remains the gold standard for crusher jaw plates, alternative materials are gaining attention for specific applications.

Martensitic Steel: Known for its high strength and moderate wear resistance, martensitic steel is suitable for applications requiring a balance between toughness and hardness.

EN31 Steel: This material offers greater strength compared to martensitic steel, making it a viable option for swing jaw plates.

E Glass/Epoxy Composite: Research highlights the potential of this composite material as a lightweight and durable alternative to manganese steel.

| Study Title | Focus | Findings |

|---|---|---|

| Material Selection for Crusher Jaw in a Jaw Crusher Equipment | Comparison of composite materials with manganese steel | E glass/epoxy composite shows promise as a replacement for manganese steel. |

| Design and Analysis of Swing Jaw Plates of Jaw Crusher | Comparison of martensitic steel and EN31 steel | EN31 steel demonstrates greater strength for swing jaw plates. |

| A Review on Study of Jaw Plates of Jaw Crusher | Kinematic & dynamic analysis of swing jaw plates | Identifies areas for further improvement in jaw plate design. |

When selecting an alternative material, consider the specific requirements of your crushing plant. Consulting experts and choosing products from reputable manufacturers can help you make an informed decision.

The casting process plays a critical role in determining the durability and performance of a crusher's jaw plate. By optimizing each stage of the process, you can en sure that the jaw plates meet the highest standards of quality and wear resistance.

Smelting and alloy preparation form the foundation of the casting process. During this stage, raw materials are melted and combined to create the desired alloy composition. For jaw plates, high manganese steel is often the preferred choice due to its exceptional strength and wear resistance.

To achieve optimal results, you must carefully control the smelting temperature and composition. Techniques like Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) help monitor the thermal properties of the alloy. These methods ensure that the alloy remains stable and free from impurities during the smelting process.

| Technique | Description |

|---|---|

| Differential Scanning Calorimetry (DSC) | Measures heat flow to determine thermal stability and specific heat capacity. |

| Thermogravimetric Analysis (TGA) | Tracks mass changes in the alloy to study reactions at high temperatures. |

| Thermal Mechanical Analysis (TMA) | Analyzes dimensional changes to calculate thermal expansion coefficients. |

Industry reports highlight the effectiveness of advanced smelting techniques. For example, wireless sensing technology improves casting quality by monitoring the alloy's properties in real time. This approach reduces defects and enhances the overall durability of the jaw plate.

| Aspect | Description |

|---|---|

| Casting Technique | Sand casting combined with additive manufacturing enables complex geometries. |

| Improvement Method | Wireless sensing monitors and improves casting quality. |

| Outcome | Enhanced product quality and fewer defects. |

The mold des ign and pattern manufacturing stage determines the shape and dimensions of the jaw plate. A well-designed mold ensures that the casting process produces jaw plates with precise dimensions and minimal defects.

You can use sand casting, which is a popular method for creating molds. This technique involves packing sand around a pattern to form the mold cavity. Additive manufacturing, such as 3D printing, has revolutionized this process by enabling the creation of complex geometries with high accuracy.

Patterns must be carefully crafted to account for shrinkage during solidification. By using advanced simulation tools, you can predict and prevent common issues like microporosity and warping. Reports like "Development of New Feeding Distance Rules" emphasize the importance of simulation in improving mold design.

| Report Title | Year | Focus |

|---|---|---|

| Development of a Methodology to Predict and Prevent Leaks | 2001 | Addresses microporosity in steel castings. |

| Development of New Feeding Distance Rules | 2004 | Uses casting simulation for improved feeding strategies. |

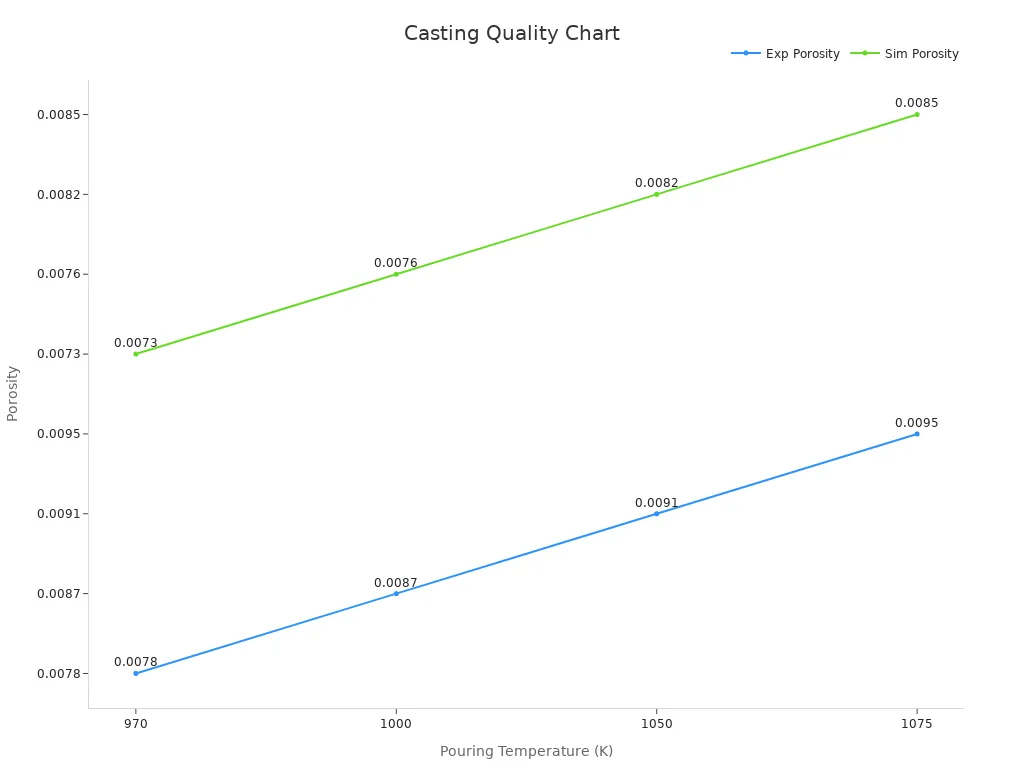

Pouring and solidification are the final steps in the casting process. These stages determine the internal structure and mechanical properties of the jaw plate.

To minimize defects, you must carefully control the pouring temperature and velocity. Experimental data shows that maintaining a pouring velocity of around 500 mm/s results in high-quality castings with minimal porosity.

| Pouring Temperature (K) | Experimental Porosity | Simulation Porosity |

|---|---|---|

| 970 | 0.0078 | 0.0073 |

| 1000 | 0.0087 | 0.0076 |

| 1050 | 0.0091 | 0.0082 |

| 1075 | 0.0095 | 0.0085 |

Temperature tracking and carbon content analysis are essential for ensuring consistent solidification. These metrics help you monitor the cooling process and predict the alloy's final properties.

| Metric | Importance |

|---|---|

| Temperature Tracking | Ensures consistent solidification and prevents defects. |

| Carbon Content | Predicts graphite formation and overall alloy properties. |

| Carbon Equivalency | Assesses the impact of additives on the alloy's characteristics. |

| Silicon Levels | Influences melt fluidity and reduces erosion of ceramic materials. |

By optimizing pouring and solidification techniques, you can produce jaw plates with superior wear resistance and structural integrity.

Heat treatment is essential for enhancing the durability and performance of crusher jaw plates. By optimizing processes like quenching, tempering, and stress relieving, you can significantly improve the wear resistance and structural integrity of these critical components.

Quenching and tempering are vital steps in heat treatment. Quenching involves rapidly cooling the jaw plate after heating it to a specific temperature. This process increases hardness and wear resistance. Tempering follows quenching and involves reheating the plate to a lower temperature. This step reduces brittleness while maintaining strength.

To optimize these processes, industries rely on computer modeling and thermal simulations. These tools help you achieve precise control over heat transfer and mechanical properties. For example:

| Evidence Type | Description |

|---|---|

| Heat Treatment Process | Computer modeling and simulation optimize quenching and tempering techniques. |

| Thermal Models | Accurate thermal models ensure desired mechanical properties. |

| Data Utilization | Simulation data exceeds physical testing data, improving process efficiency. |

By using these advanced techniques, you can ensure that the jaw plate achieves the perfect balance of hardness and toughness.

Stress relieving is another critical heat treatment process. It involves heating the jaw plate to a moderate temperature and then cooling it slowly. This process removes residual stresses that develop during casting and machining. Eliminating these stresses prevents cracking and distortion during operation.

Stress relieving also enhances the structural integrity of the plate. With fewer internal stresses, the jaw plate can withstand heavy loads and impacts without failure. This step is particularly important for crushers operating in demanding environments.

The microstructure of the jaw plate plays a significant role in its wear resistance. Heat treatment processes like gas nitriding can refine the microstructure, leading to improved performance. Studies show that nitrided specimens experience less weight loss compared to untreated ones. Additionally:

Maximum surface microhardness occurs in samples nitrided for 24 hours, indicating superior wear resistance.

Wear debris analysis reveals the presence of iron nitrides, which enhance the diffusion layer's durability.

| Evidence Description | Findings |

|---|---|

| SEM observations of worn surfaces | Delamination indicates weak adhesion due to porosity and low ductility. |

| Wear mechanisms under load | Adhesion and abrasion dominate at low loads; oxidation occurs at high loads. |

| Wear debris composition | Iron nitrides contribute to wear resistance. |

By refining the microstructure, you can extend the lifespan of the jaw plate and reduce maintenance costs. These enhancements ensure that your crusher operates efficiently, even under extreme conditions.

Modern casting technologies have revolutionized the production of jaw plates for crushers. Techniques like sand casting combined with additive manufacturing allow you to create complex geometries with precision. These advancements ensure that the jaw plate fits perfectly into the crusher, reducing wear and improving efficiency.

Automation plays a key role in enhancing casting processes. AI and IoT systems monitor production parameters in real time, enabling predictive maintenance and process optimization. For example, sensors track temperature and composition during smelting, ensuring the molten metal meets specifications. This reduces defects and improves the overall quality of the jaw plate.

Another innovation is the use of simulation tools to predict casting outcomes. These tools help you identify potential issues like shrinkage or porosity before production begins. By addressing these problems early, you can produce jaw plates with superior durability and performance.

Quality control ensures that every jaw plate meets high standards of durability and wear resistance. Advanced techniques like spectroscopy and inclusion analysis verify the metal's composition during smelting. Dimensional criteria are checked using modern gauging appliances like coordinate measuring machines (CMM).

Continuous monitoring systems apply statistical tests to production data, creating feedback loops that flag issues. This approach prevents widespread defects and ensures consistent quality. Key performance indicators (KPIs) track defect rates and efficiency, helping you set realistic targets for improvement.

| Measurement Type | Description |

|---|---|

| Dimensional Criteria | Patterns are gauged for dimensional features using modern gauging appliances like CMM. |

| Surface Condition | Inspection of the wax pattern's surface for imperfections to prevent flaws in the final casting. |

| Shell Integrity Testing | Visual and non-destructive testing to detect defects in the ceramic shell. |

| Metal Quality Control | Spectroscopy and inclusion analysis ensure the molten metal meets required specifications. |

| Post-Casting Inspection | Dimensional and surface testing, along with mechanical tests, verify the quality of the end product. |

| Advanced Automation Techniques | Use of AI and IoT for predictive mainten ance and process optimization to enhance quality control. |

Regular checks on critical dimensions help monitor potential drift due to pattern wear. Mechanical properties like hardness, tensile strength, and ductility are essential for assessing casting quality. These checks ensure that the jaw plate can withstand stress and wear during crusher operations.

Casting defects can compromise the performance of jaw plates. Issues like porosity, shrinkage, and warping often arise during production. You can address these problems by optimizing pouring temperature and velocity. Experimental data shows that maintaining a pouring velocity of around 500 mm/s minimizes porosity.

Real-time data analytics enable prompt adjustments to production parameters, preventing defects before they occur. Continuous monitoring systems flag issues as they arise, ensuring consistent quality. Benchmarking defect rates against KPIs helps you identify areas for improvement.

Common Defects and Solutions:

Porosity: Controlled pouring temperature reduces air pockets.

Shrinkage: Simulation tools predict and prevent shrinkage during solidification.

Warping: Stress-relieving heat treatments enhance structural integrity.

By addressing these defects, you can produce jaw plates that last longer and perform better in crushers. These improvements reduce downtime and maintenance costs, boosting overall efficiency.

Selecting the right materials, refining casting processes, and applying precise heat treatments are essential for producing durable jaw plates. These steps ensure that your crusher operates efficiently, reducing wear and extending the lifespan of critical parts. For example, adopting advanced casting techniques like modular wear-resistant castings has reduced maintenance time by 50% in conveyor systems, demonstrating the potential for significant operational improvements.

Innovative casting methods also address the limitations of traditional approaches, meeting the growing demand for precision and reliability in extreme conditions. By investing in these advancements, you can minimize downtime, improve crusher performance, and achieve long-lasting wear parts. A comprehensive evaluation of costs and benefits, including extended service life and reduced operational expenses, further supports the shift toward modern casting technologies.

Embrace these innovations to enhance your crusher's efficiency and ensure your jaw plates deliver unmatched durability.

High manganese steel offers exceptional durability due to its work-hardening ability. The surface hardens under impact, increasing wear resistance. This material also withstands heavy loads and impacts, making it perfect for crushers in demanding environments.

Heat treatment enhances the jaw plate structure by increasing hardness and reducing brittleness. Processes like quenching and tempering refine the microstructure, improving wear resistance and extending the lifespan of jaw crusher wear parts.

Common defects include porosity, shrinkage, and warping. These issues arise during the casting process. Optimizing pouring temperature and velocity, along with stress-relieving heat treatments, helps prevent these problems and ensures high-quality jaw plates.

Yes, materials like martensitic steel and EN31 steel offer specific advantages. Martensitic steel balances toughness and hardness, while EN31 provides higher strength. However, high manganese steel remains the preferred choice for most crushers due to its superior wear resistance.

Modern casting technologies, such as additive manufacturing and simulation tools, improve precision and reduce defects. These innovations ensure the jaw plate structure fits perfectly into the crusher, enhancing efficiency and durability.