Keeping your asphalt paver in top shape is critical for smooth paving. Did you know advanced screeds can improve smoothness by 10% and ensure better thermal consistency with an average lot temperature of 267°F? Regularly inspecting parts like screed plates and augers ensures your paver performs efficiently and reliably every time.

Screed plates are the unsung heroes of your asphalt paver. They’re responsible for leveling the asphalt and creating that smooth, even surface you see on freshly paved roads. Without well-maintained screed plates, achieving a consistent finish becomes nearly impossible.

In paving operations, screed plates work in tandem with other components to ensure the asphalt is laid at the correct thickness and elevation. Research shows that screed plates play a critical role in leveling the material to its final height, ensuring a smooth and uniform surface. This not only improves the quality of the paving but also boosts productivity by r educing the need for rework.

If you notice uneven surfaces or inconsistent thickness in your paving, it might be time to inspect your screed plates. Regular maintenance can help you avoid costly delays and keep your asphalt paver running smoothly.

Augers are like the arms of your asphalt paver, distributing material evenly across the width of the paving area. They ensure that the asphalt is spread uniformly, preventing segregation and maintaining consistency.

In slipform paving, augers play a vital role by moving the material in front of the screed plate. This process minimizes segregation and ensures the asphalt is evenly distributed before leveling. Together with the screed plate, augers enhance both the qual ity of the paving and the overall efficiency of the operation.

Keep an eye out for signs of wear, such as uneven material distribution or reduced efficiency. Replacing worn augers promptly can save you time and money in the lon g run.

Conveyor chains and bars are the lifeline of your asphalt paver’s material flow system. They transport the asphalt from the hopper to the augers, ensuring a steady supply of material for paving.

When these components wear out, you might notice interruptions in material flow or uneven distribution. This can lead to delays and affect the quality of your paving. Regular inspection and lubrication can help extend their lifespan and keep your paver operating efficiently.

Track pads provide the traction your asphalt paver needs to move across the job site. They’re designed to withstand the weight of the machine and the harsh conditions of paving environments.

Damaged or worn track pads can reduce mobility and even cause damage to the underlying surface. If you notice cracks, excessive wear, or reduced traction, it’s time to replace them. Choosing high-quality track pads can improve your paver’s performance and reduce downtime.

End gates are essential for controlling the edges of the asphalt layer. They prevent material from spilling over the sides and help create clean, straight edges.

Worn or damaged end gates can lead to uneven edges and wasted material. Regularly inspecting and replacing them ensures your paving projects maintain a prof essional finish.

Bearings and rollers keep your asphalt paver’s moving parts running smoothly. They reduce friction and support the machine’s opera tional stability.

When bearings or rollers wear out, you might hear unusual noises or notice reduced efficiency. Regular lubri cation and timely replacement can prevent these issues and keep your paver in top condition.

Screed plates are the backbone of your asphalt paver’s ability to create smooth, even layers. They ensure the asphalt is laid at the correct thickness and height. Without them, achieving a professional finish would be nearly impossible.

When you’re paving, screed plates help maintain consistency across the surface. They level the material and eliminate irregularities, giving roads that polished look. If you’ve ever driven on a freshly paved road and admired its smoothness, you’v e seen screed plates in action.

To keep them working efficiently, inspect them regularly. Worn screed plates c an lead to uneven surfaces, which might require costly rework.

Augers are the workhorses of your asphalt paver. They distribute material evenly across the paving width, ensuring no area is left underfilled or overfilled. This prevents segregation and keeps the asphalt consisten t.

Different auger systems offer varying levels of control:

| Auger System Type | Description | Efficiency Highlight |

|---|---|---|

| Single Auger | One central auger ru nning down the center of the screed | Basic control o ver material flow |

| Dual Auger | Two auger s along the edges of the screed | Better control and precise adjustments for material distribution |

You can also fine-tune auger performance by:

- Adjusting conveyor speed

- Modifying auger height

- Changing auger angle

By keeping your augers in good shape, you’ll ensure your paving projects stay efficient and high-quality.

Conveyor chains are vital for moving asphalt from the hopper to the augers. They maintain a steady material flow, which is crucial for consistent paving.

The feeder system design often includes 14-inch diameter augers. These ensure material flows smoothly across the screed, whether you’re working on narrow or wide paving widths. The confined auger chamber also keeps the material mov ing, preventing stagnation.

If you notice interruptions in material flow, it’s time to ch eck your conveyor chains. Regular maintenance, like lubrication, can keep them running smoothly and avoid delays.

Track pads give your asphalt paver the traction it needs to move across different surfaces. They’re designed to handle the machine’s weight while protecting the underlying pavement.

Rubber or polyurethane track pads improve traction and reduce the risk of slipping, even on wet or uneven surfaces. They also minimize damage to the roadway, making them essential for maintaining both mobility and surface integrity.

If your track pads show cracks or excessive wear, replace them promptly. This will keep your paver moving efficiently and prevent unnecessary d owntime.

End gates play a key role in controlling the edges of your asphalt layer. They prevent material from spilling over and help create clean, straight edges.

When end gates wear out, you might notice uneven edges or wasted material. Replacing them ensures your paving projects maintain a professional finish. Regular inspections can help you catch wear early and avoid costly mistakes.

Bearings and rollers keep your asphalt paver’s moving parts running smoothly. They reduce friction and support the machine’s overall stability.

When bearings or rollers wear out, you might hear strange noises or notice reduced efficiency. Regular lubrication can prevent these issues. If you spot signs of wear, replace them to avoid fu rther damage and keep your paver operating at its best.

Screed plates wear down over time due to constant contact with hot asphalt. You might notice uneven paving or inconsistent thickness in the asphalt layer. These are clear signs the screed plates need attention. Regularly inspect them for scratches, warping, or thinning. If you see any of these, it’s time to replace them. Keeping screed plates in good condition ensures yo ur asphalt paver delivers smooth and even results.

Worn augers can cause uneven material distribution. If you spot areas where asphalt isn’t spread evenly, the augers might be the culprit. Look for signs like bent blades or reduced efficiency during operation. Replacing damaged augers promptly will save you from costly delays and ensure consistent paving quality.

Conveyor chains are vital for moving asphalt through the paver. When they wear out, you may notice interruptions in material flow or hear unusual noises. Check for rust, loose links, or visible damage. Regular lubrication helps, but if wear persists, replace the chains to avoid breakdowns.

Track pads endure heavy loads and rough surfaces. Cracks, excessive wear, or reduced traction are signs they need replacing. Damaged track pads can affect your paver’s mobility and even damage the surface you’re working on. Inspect them often to keep your machine moving smoot hly.

End gates control the edges of the asphalt layer. Worn end gates can lead to uneven edges or wasted material. If you notice material spilling over or jagged edges, it’s time for a replacement. Regular checks will help you maintain clean, pro fessional paving results.

Bearings and rollers keep your asphalt paver running smoothly. Strange noises, increased friction, or reduced efficiency are signs of wear. Lubricate them regularly and replace them when needed. This will prevent further damage and keep your paver operating efficiently.

Keeping your asphalt paver clean and well-inspected is one of the easiest ways to extend the life of its wear parts. Dirt, debris, and asphalt buildup can cause unnecessary wear and tear. Regular cleaning prevents harmful particulates from accumulating, which can reduce efficiency. < /p>

Make it a habit to inspect your paver after every use. Look for signs of wear, such as scratches, cracks, or thinning on parts like screed plates and augers. Detailed maintenance records can help you track inspections and replacements. These records also allow you to iden tify potential issues before they lead to costly failures.

Tip: A quick post-job cleaning and inspection can save you hours of downtime later.

Lubrication is essential for keeping moving parts like bearings, rollers, and conveyor chains running smoothly. Without proper lubrication, friction increases, leading to faster wear and potential breakdow ns. Always use the manufacturer-recommended lubricants and apply them at the intervals specified in your equipment manual.

Pro Tip: Over-lubricating can be just as harmful as under-lubricating. Stick to the recommended amounts to avoid attracting dirt and debris.

Storing spare parts correc

tly ensures they’re ready when you need them. Improper storage can lead to contamination or damage, reducing their effectiveness. Follow these best practices:

- Use a compliance management system to monitor storage conditions.

- Conduct regular inventory audits to ensure parts are in good co

ndition.

- Keep hazardous or restricted parts separate to prevent contamination.

Proper storage not only protects your investment but also ensures your paver stays operational during critical projects.

A solid preventative maintenance schedule can save you from unexpected breakdowns. Track your equipment’s usage with daily reports of productive and downtime hours. Us e this data to plan maintenance activities effectively.

Develop maintenance sheets based on th e manufacturer’s recommendations for each part. During plant walkthroughs, document the condition of your equipment to identify necessary repairs. Technology can also help. Real-time performance monitoring systems optimize maintenance schedules and reduce downtime.

Did you know? Preventative maintenance can increase your paver’s lifespan and improve safety on the job site.

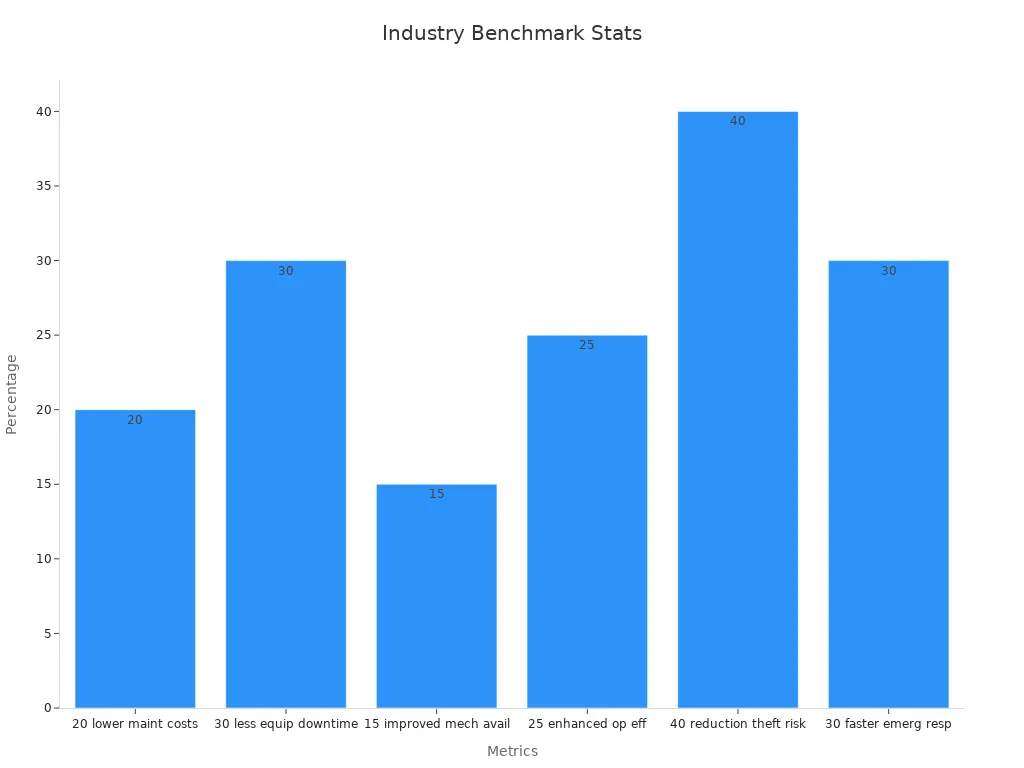

The quality of your wear parts directly impacts your asphalt paver’s performance. Partnering with reliable suppliers ensures you get durable, high-quality parts. Industry benchmarks show that using quality parts can reduce maintenance costs by 20% and equipment downtime by 3 0%.

Here’s a quick look at how reliable suppliers can benefit your operations:

Investing in quality parts and reliable suppliers pays off in the long run. It keeps your pro jects on track and your equipment in top shape.

Taking care of your asphalt paver’s wear parts isn’t just about avoiding downtime—it’s about keeping your projects running smoothly and saving money. Regular maintenance and timely replacements make a big difference. When you prioritize wear part care, you extend your equipment’s life and improve its performanc e.

Worn screed plates cause uneven asphalt layers and inconsistent thickness. This leads to rework, delays, and higher costs. Regular inspections help you avoid these issues.

Inspect wear parts after every job. Frequent checks catch early signs of wear, saving you from unexpected breakdowns and costly repairs.

Tip: Keep a maintenance log to track inspections and replacements. It helps yo u stay organized and proactive.

Generic parts may save money upfront but often wear out faster. OEM parts ensure better performance, durability, and compatibility with your asphalt paver.

Emoji Reminder: 🛠️ Always prioritize quality over cost for long-term savings!

| Impact on Operations | |

|---|---|

| Reduces overall operational expenses | |

| 30% less equipment downtime | Increases productivity and efficiency |

| 15% improved machinery availability | Enhances project timelines and reliability |

| 25% enhanced operational efficiency | Optimizes resource utilization |

| 40% reduction in equipment theft risk | Protects investment in machinery< /tr> |

| 30% faster emergency response times | Minimizes downtime during critical failures |