Concrete pump elbow pipes are among the highest-wear components in concrete pumping systems. Compared with straight pipes, elbows are exposed to stronger centrifugal forces, high-pressure impact, and continuous abrasion from coarse aggregates. Their performance directly affects pumping efficiency, equipment downtime, and total lifecycle cost.

As global construction projects move toward higher output, longer pumping distances, and more abrasive concrete mixes, traditional elbow pipe designs have reached their limits. This has driven a clear technological evolution—from single-layer steel pipes to advanced composite structures.

Ma’anshan Haitian Heavy Industry Technology Co., Ltd. is the first manufacturer in China to successfully mass-produce concrete pump elbow pipes with a dual-layer inner liner structure, setting a new benchmark for wear-resistant pump components.

When concrete flows through an elbow, centrifugal force pushes coarse aggregates toward the outer curvature of the bend. This creates localized high-pressure abrasion zones, leading to uneven wear and premature failure if material performance is insufficient.

This wear mechanism explains why elbow pipes typically fail several times faster than straight pipes—and why advanced material selection and structural design are essential.

In the early development of concrete pump trucks, elbow pipes were commonly manufactured from single-layer high manganese steel, valued for its toughness and forming capability.

Advantages

Good impact resistance

Mature manufacturing process

Suitable for low to medium pumping intensity

Limitations

Rapid wear under high-pressure, high-output pumping

Short service life in abrasive concrete conditions

Frequent replacement increases downtime and maintenance costs

As pumping demands increased, the limitations of single-layer designs became increasingly evident.

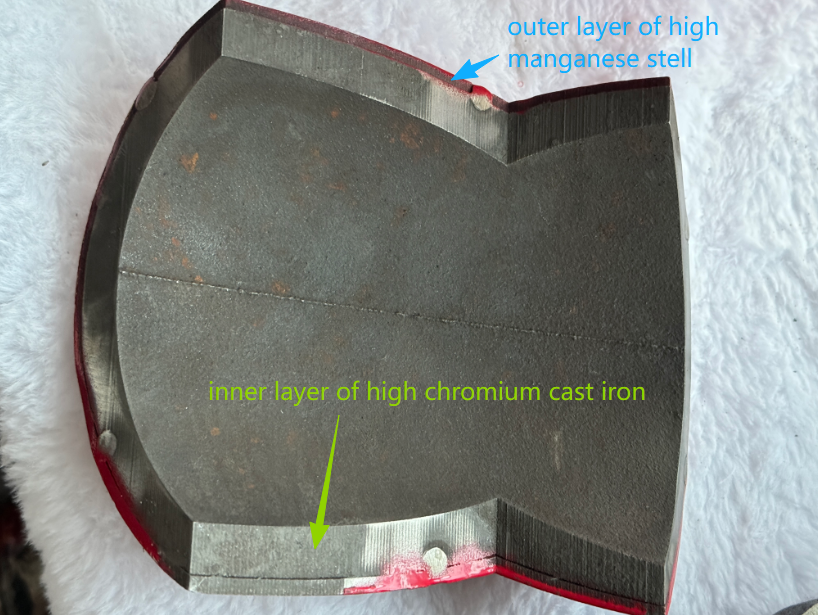

Building on years of wear-material research and extensive jobsite feedback, Haitian Heavy Industry pioneered dual-layer inner liner elbow pipe technology in China.

Instead of relying on a single material to balance toughness and wear resistance, this design separates functions:

Structural strength is provided by the outer layer

Abrasion resistance is handled by the inner liner

This system-level approach fundamentally improves durability and operational reliability.

The outer pipe layer is manufactured from Q235 or Q345 steel, selected for its excellent ductility and forming properties:

Ideal for complex elbow geometries

Strong resistance to pressure and impact

Ensures overall structural stability during high-pressure pumping

The inner liner—directly in contact with concrete—is made from high chromium cast iron, delivering exceptional abrasion resistance:

Extremely high hardness

Chromium carbide (Cr₇C₃) microstructure

Up to 5× longer service life than ordinary steel

3–5× longer than conventional alloy steel

High chromium cast iron is widely recognized by global concrete pump manufacturers as one of the most effective materials for abrasive pumping conditions.

Through laboratory testing and long-term field validation, Haitian’s dual-layer composite elbow pipes have demonstrated:

Service life exceeding +60,000 cubic meters

More uniform wear distribution

Reduced risk of sudden leakage or burst failure

These results are based on real operating conditions, not theoretical simulations.

Elbow pipe service life depends not only on material selection, but also on design parameters such as:

Pump model and output pressure

Elbow radius and bending angle

Concrete mix design and aggregate size

Haitian Heavy Industry customizes inner liner thickness and wear grade according to specific working conditions, helping customers achieve the lowest cost per cubic meter pumped.

First manufacturer in China to mass-produce dual-layer inner liner concrete pump elbow pipes

Strong expertise in wear-resistant materials and casting technology

Proven performance in high-pressure, high-abrasion environments

Flexible customization for global concrete pump brands

The evolution from single-layer high manganese steel to dual-layer composite elbow pipes represents a major advancement in concrete pump wear technology.

As a technology-driven manufacturer, Ma’anshan Haitian Heavy Industry Technology Co., Ltd. continues to innovate in materials, structure, and manufacturing processes—delivering longer-lasting, more reliable concrete pump wear parts to customers worldwide.

Wear resistance is proven in real working conditions—not on paper.

The service life of a dual-layer concrete pump elbow pipe largely depends on pumping pressure, concrete mix, and working conditions. Under typical high-abrasion applications, Haitian Heavy Industry’s dual-layer composite elbow pipes have been field-tested to exceed 60,000 cubic meters of concrete, significantly outperforming traditional single-layer steel elbow pipes.

Concrete pump elbow pipes wear faster because centrifugal force pushes coarse aggregates toward the outer wall of the bend. This creates localized high-pressure abrasion zones, leading to accelerated and uneven wear. Without sufficient wear-resistant materials, elbow pipes will fail much earlier than straight pipes.

High chromium cast iron contains a high volume of chromium carbides (Cr₇C₃), which provide exceptional resistance to sliding and impact abrasion. Compared with ordinary steel, high chromium cast iron offers up to 5 times longer service life, and 3–5 times longer life than conventional alloy steel, making it ideal for abrasive concrete pumping conditions.

Single-layer elbow pipes rely on one material to balance toughness and wear resistance, which limits performance under severe conditions. Dual-layer elbow pipes separate these functions: the outer layer provides structural strength and formability, while the inner liner focuses on wear resistance. This design significantly improves durability and reduces replacement frequency.

Yes. Haitian Heavy Industry customizes concrete pump elbow pipes based on pump model, pumping pressure, elbow angle, and concrete mix design. Inner liner thickness and wear grade can be adjusted to match specific working conditions, helping customers achieve the lowest cost per cubic meter pumped.