Machinery in tough environments faces constant challenges from wear and tear. You need solutions that ensure durability and efficiency. China wear-resistant parts deliver exceptional performance in these conditions. Their advanced materials, such as ToughMet alloys, outperform traditional options like steel and bronze. These components extend equipment life and maintenance cycles, even when exposed to harsh elements like silica or coal dust. By reducing damage and downtime, they help you achieve long-term cost savings and reliable operation in demanding industries.

China wear-resistant parts are crafted using cutting-edge materials that ensure exceptional durability. These materials, such as NM450 and Mn13, are engineered to withstand extreme conditions. For example, NM450 offers a tensile strength of at least 1300 MPa and a hardness range of 420-480 HBW, making it ideal for heavy-duty applications like industrial fans and medium trucks. Mn13, on the other hand, provides superior toughness with a tensile strength of 650 MPa, making it a preferred choice for mining equipment.

Here’s a quick comparison of technical specifications for some popular materials:

| Grade | Tensile Strength (MPa) | Elongation (%) | Hardness (HBW) | Wear Resistance | Application |

|---|---|---|---|---|---|

| NM450 | ≥1300 | ≥8 | 420-480 | 2-3 times better than Q345 | Medium and heavy trucks, industrial fans |

| NM400 | - | - | - | - | - |

| Mn13 | ≥650 | - | ≥170 | - | Mining equipment, machinery manufacturing |

These advanced materials not only enhance durability but also reduce the frequency of part replacements, saving you time and money.

The high resistance to abrasion and corrosion is another standout feature of China wear-resistant parts. Testing results reveal that these components perform exceptionally well under both low and high-stress abrasion conditions. For instance, materials like ULTIMET® alloy exhibit a wear rate of 0.45 under three-body abrasion at room temperature, outperforming alternatives like harden ed D-2 tool steel. Additionally, wear rates decrease at higher temperatures, proving their reliability in extreme environments.

This resistance ensures that the parts maintain their integrity even when exposed to harsh elements like coal dust, silica, or corrosive chemicals. By choosing these components, you can significantly reduce equipment wear and extend its operational lifespan.

China wear-resistant parts are not one-size-fits-all. Manufacturers offer extensive customization options to meet the unique demands of various industries. Whether you need components for mining, construction, or power generation, these parts can be tailored in terms of size, shape, and material composition. For example, alumina ceramic parts are widely used in industries requiring high thermal conductivity, as they maintain performan ce at temperatures exceeding 1200°C.

Customization ensures that you get the perfect fit for your machinery, enhancing efficiency and reducing the risk of operational failures. This adaptability makes these parts a versatile solution for businesses worldwide.

China wear-resistant parts significantly extend the lifespan of your machinery. These components are engineered to withstand extreme conditions, reducing wear and tear over time. For example, HCWI liners used in crushers have increased service life by 35%, minimizing replacements and downtime. This durability ensures your equipment rem ains operational for longer periods, allowing you to focus on productivity rather than frequent repairs.

Predictive maintenance strategies further enhance equipment longevity. By forecasting the remaining lifetime of critical components, you can avoid unnecessary replacements and prevent disruptions in your operations. This approach not only save s resources but also ensures your machinery performs optimally throughout its lifecycle.

China wear-resistant parts offer a perfect balance between affordability and quality. Manufacturers use advanced materials like nickel-based alloys to create components that last longer and perform better. For instance, slurry pump impellers made from these alloys have extended operational life by 40%, reducing maintenance expenses.

Here’s a breakdown of the financial benefits:

| Metric | Description |

|---|---|

| Overall Equipment Effectiveness (OEE) | Measures the percentage of time a plant is productive, factoring in performance, quality, and availability. |

| Rate of Return (ROR) | Indicates the profitability of an investment, expressed as a percentage of profit or loss. |

These metrics highlight how investing in wear-resistant parts can improve your financial performance. You gain durable components without compromising on quality, ensuring long-term savings and operational efficiency.

China wear-resistant parts help you minimize maintenance frequency and operational downtime. Modular wear-resistant castings, for instance, reduce maintenance time by 50%, enabling continuous production and improved efficiency. Implementing preventive maintenance plans further reduces downtime by scheduling activities in advance, ensuring your equipment remains available when you need it most.

Tailored maintenance approaches also play a crucial role. By deviating from OEM recommendations and optimizing resource allocation, you can reduce unnecessary maintenance activities. This strategy enhan ces equipment availability and productivity, allowing you to focus on meeting production goals.

Predictive maintenance techniques take this a step further. By predicting the remaining lifetime of components, you avoid unplanned downtimes and critical process disturbances. This proactive approach ensures your operations run smoothly, saving you time and money in t he long run.

Mining and heavy construction demand machinery that can endure extreme conditions. China wear-resistant parts excel in these environments by reducing wear and tear caused by abrasive materials like rocks and minerals. The increasing scale of mining projects has amplified the need for durable components. These parts ensure operational efficiency and minimize downtime, even in the harshest conditions . For example, advanced materials like engineering plastics reduce friction in bearings and gears, maintaining their shape and function over time. This reliability is crucial for heavy-duty applications where equipment failure can lead to costly delays.

In the energy sector, wear-resistant parts play a vital role in maintaining the efficiency of critical equipment. Coatings applied to turbines and generators protect them from wear and corrosion, ensuring long-term reliability. For instance, wear-resistant coatings enhance the durability of bearings and yoke bushings, which are essential for smooth operation. The growing focus on renewable energy sources, such as wind and solar power, has furthe r increased the demand for these components. They withstand challenging conditions, ensuring the longevity of power generation systems while reducing maintenance costs and downtime.

| Product Type | Application | Key Feature |

|---|---|---|

| Wear Products | Bearings, Yoke Bushings | Extreme Wear Resistance |

| Coatings | Turbines, G enerators | Protects from wear and corrosion |

| Materials | Precision Plastics | High durability under extreme condition s |

In manufacturing, wear-resistant parts improve machinery performance and extend its lifespan. Proper lubrication and high-quality materials, such as wear-resistant alloys, prevent excessive wear and tear. Innovations in tribology have also reduced friction, enhancing energy efficiency and productivity. Regular inspections and condition monitoring help identify potential issues early, preventing unexpected failures. By using these parts, you can ensure smooth operation, reduce downtime, and boost overal l productivity. This makes them an essential investment for any manufacturing operation.

Chinese manufacturers dominate the global market for wear-resistant parts due to their competitive pricing and extensive export networks. In 2023, China accounted for 30.71% of the steel wear liners market, driven by rapid industrialization and urbanization. This growth is expected to continue with a compound annual growth rate (CAGR) of 5.3% through 2032. Lower production costs, such as a 10% reduction in natural rubber prices compared to international aver ages, allow manufacturers to offer affordable yet high-quality products.

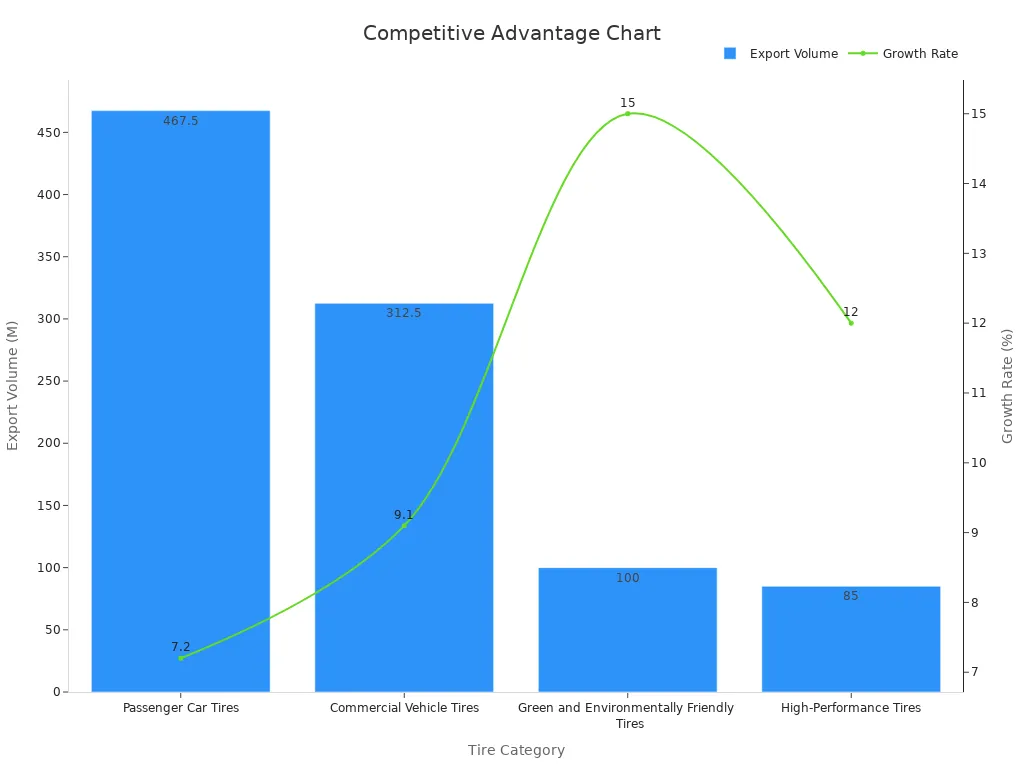

Export data highlights their global reach:

| Tire Category | Export Volume (Units) | Main Export Markets | |

|---|---|---|---|

| Passenger C ar Tires | 467.5 million | 7.2 | North America, EU |

| Commercial Vehicle Tires | 312.5 million | 9.1 | Southeast Asia, Africa |

| Green and Environmentally Friendly Tires | 100 million | 1 5 | Europe, North America |

| High-Performa nce Tires | 85 million | 12 | North America, Japan |

This combination of affordability and global accessibility makes China wear-resistant parts a p referred choice for industries worldwide.

Chinese manufacturers excel in innovation and quality, as reflected in the 2024 Global Innovation Index (GII), where China ranked 11th globally. This achievement highlights their advancements in science and technology, with 26 clusters among the top 100 worldwide. These innovations ensure that wear-resistant parts meet stringent quality standards, making them reliable for demanding applications.

For example, materials like NM450 and Mn13 are engineered t o provide superior durability and resistance. These advancements not only enhance performance but also reduce the frequency of part replacements, saving you time and money.

Customer satisfaction is a priority for Chinese manufacturers. Metrics like Customer Satisfaction Score (CSAT) and Net Promoter Score (NPS) demonstrate their commitment to delivering exceptional service. They also excel in resolving issues effi ciently, with impressive first response times and high ticket resolution rates.

Manufacturers offer extensive customization options to meet your specific needs. Whether you require parts for mining, cons truction, or energy sectors, they can tailor components in terms of size, shape, and material composition. This adaptability ensures that you receive solutions perfectly suited to your machinery, enhancing efficiency and reducing operational risks.

China wear-resistant parts play a vital role in improving the durability and efficiency of machinery across industries. Their advanced materials and innovative designs ensure long-lasting performance. You can rely on these components to reduce costs and enhance productivity. Manufacturers in China offer affordable solutions without compromising quality, making them a trusted choice worldwide. By choosing these parts, you gain access to reliable components that optimize your operations and minimize downtime.

T ip: Partnering with Chinese manufacturers ensures you get high-quality, customized solutions tailored to your needs.

Industries like mining, construction, energy, and manufacturing gain the most from these parts. Their durability and resistance to wear make them ideal for heavy-duty applications, ensuring reliable performance in harsh environments.

These parts last longer due to their advanced materials and design. You replace them less frequently, which lowers maintenance expenses and minimizes downtime, saving you money over time.

Yes, manufacturers offer extensive customization options. You can request specific sizes, shapes, and materials tailored to your machinery and industry requirements, ensuring optimal performance and compatibility.

Materials like NM450, Mn13, and nickel-based alloys are popular. These materials provide high tensile strength, abrasion resistance, and durability, making them suitable for demanding applications.

Chinese manufacturers combine affordability with quality. They use innovative techniques, adhere to global standards, and offer strong customer support. Their competitive pricin g and global reach make them a trusted option worldwide.

Tip: Always consult with manufacturers to ensure the parts meet your specific operational needs.