When it comes to crushing operations, jaw crushers are at the heart of the process. And the jaw plates—the components that do the actual crushing—play a critical role in determining your crusher's performance. Selecting the right jaw plates can dramatically affect your machine’s efficiency, wear life, and overall operational costs. This guide walks you through everything you need to know to choose the best jaw plates for your application.

Jaw plates are the wear components mounted on the fixed and moving jaws of a jaw crusher. As the two jaws move back and forth, they apply pressure to the material, breaking it down into smaller pieces. The condition and design of these plates influence the output size, throughput, and wear rate of your crusher.

There are several types of jaw plate profiles and styles, each suited for different materials and operating conditions:

Flat / Smooth Jaw Plates

Ideal for soft, non-abrasive materials. They provide consistent particle shape but may lack grip for harder rocks.

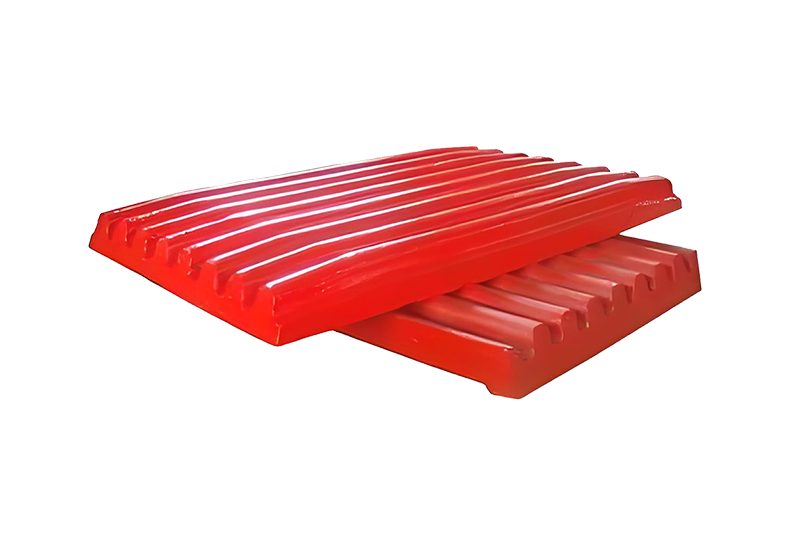

Toothed / Corrugated Jaw Plates

Feature ridges that enhance grip and crushing efficiency for harder, more abrasive materials.

Heavy-Duty Jaw Plates

Thicker and more robust, designed for high-impact, heavy-duty applications where durability is key.

Jaw plates are typically made from high manganese steel, but the exact grade can vary:

Mn13 jaw plates (13% Manganese):

Basic grade with decent toughness and wear resistance for general use.

Mn18 jaw plates (18% Manganese):

A popular option that offers better wear resistance and work hardening.

Mn22 jaw plates (21-22% Manganese):

Best for very abrasive applications. High toughness and wear resistance, but requires good crushing force to activate work-hardening.

Alloy Steel or Bimetallic Plates:

These combine different materials for customized performance, often used in specialized or high-wear environments.

Choosing the right material is essential to balance impact toughness, wear resistance, and lifespan.

1. Material Being Crushed

Different materials have varying hardness, abrasiveness, and moisture content:

Soft or non-abrasive materials (e.g., limestone) may require smooth or lower-grade manganese plates.

Hard, abrasive rocks (e.g., granite, basalt) demand higher manganese content and aggressive tooth profiles.

2. Feed Size and Gradation

Larger feed requires plates with more depth and grip, while uniform, smaller feed sizes can use flatter profiles.

3. Crusher Type and Settings

Not all jaw plates are compatible with every machine. Consider your crusher's design, settings, and stroke behavior when choosing plates.

4. Desired Output Size

Finer output requires jaw plates with tighter nip angles and optimized tooth designs.

5. Operating Conditions

Wet, sticky, or extreme temperature environments may require specially coated or alloyed jaw plates.

Here’s a quick reference for matching jaw plates to typical crushing jobs:

Application | Recommended Jaw Plate | Manganese Grade |

Concrete & Demolition Waste | Toothed or bimetallic | Mn18 or Mn22 |

Hard Rock (Granite, Quartz) | Deep-toothed profile | Mn18 or Mn22 |

Soft Rock (Limestone, Coal) | Smooth or standard tooth | Mn13 or Mn18 |

Recycling (Mixed Materials) | Reinforced heavy-duty | Mn18 with alloy backing |

Noticing any of these issues? It may be time to reconsider your jaw plate selection:

Rapid or uneven wear

Increased downtime and maintenance

Poor product shape and sizing

Higher energy consumption

Breakage or cracking of plates

Monitor Wear: Regularly inspect jaw plates for signs of wear and fatigue.

Rotate When Needed: Flipping or rotating plates helps maintain even wear and extend life.

Proper Installation: Misalignment or loose bolts can cause uneven wear and reduce performance.

Buy Quality Parts: Partner with a trusted supplier to ensure consistent material quality and proper fit.

Choosing the right jaw plates is not just about durability—it’s about optimizing your entire crushing operation. The right jaw plate can boost production, reduce downtime, and save money over the long term. Always match your jaw plate profile and material to your application for the best results.

If you're unsure, consult your crusher manufacturer or a wear parts expert to help tailor the best solution for your needs.

Haitian Heavy Industry, also known as Haitian Casting, is a renowned leader in producing high-performance crusher wear parts. With years of expertise in the industry, Haitian Heavy Industry provides custom jaw plates that are engineered for maximum efficiency and longevity. Their advanced manufacturing processes and commitment to using premium materials ensure that every jaw plate delivers exceptional wear resistance and improved crusher performance. Whether you are in mining, construction, or aggregate processing, Haitian Heavy Industry is your reliable source for durable and cost-effective wear parts solutions.

Q: Can I mix different jaw plate designs on the same crusher?

A: No. Mixing profiles can lead to uneven wear and mechanical imbalance, reducing crusher performance.

Q: How often should I replace jaw plates?

A: It depends on the application, but plates should be replaced once wear reduces crushing efficiency or compromises safety.

Q: What’s the most durable jaw plate material?

A: For extremely abrasive applications, Mn22 or bimetallic options offer the best durability, but require proper crushing force.