The concave mantle plays a vital role in the performance of a cone crusher. It directly influences how efficiently materials are crushed, impacting both productivity and profitability. By optimizing the mantle, you can achieve significant improvements in crushing efficiency. For example:

Energy consumption can drop by up to 30%, reducing operational costs.

Wear parts last two to four times longer, minimizing replacements.

Fewer production stops enhance safety and profitability.

These benefits not only improve output quality but also lower maintenance demands, ensuring your crusher operates at peak performance.

The concave mantle is a critical component of a cone crusher. It works by compressing and crushing materials between the mantle and the concaves. As the mantle rotates, it creates a gyratory motion that applies pressure to the material, breaking it into smaller pieces. This process ensures that the material is reduced to the desired size before being discharged.

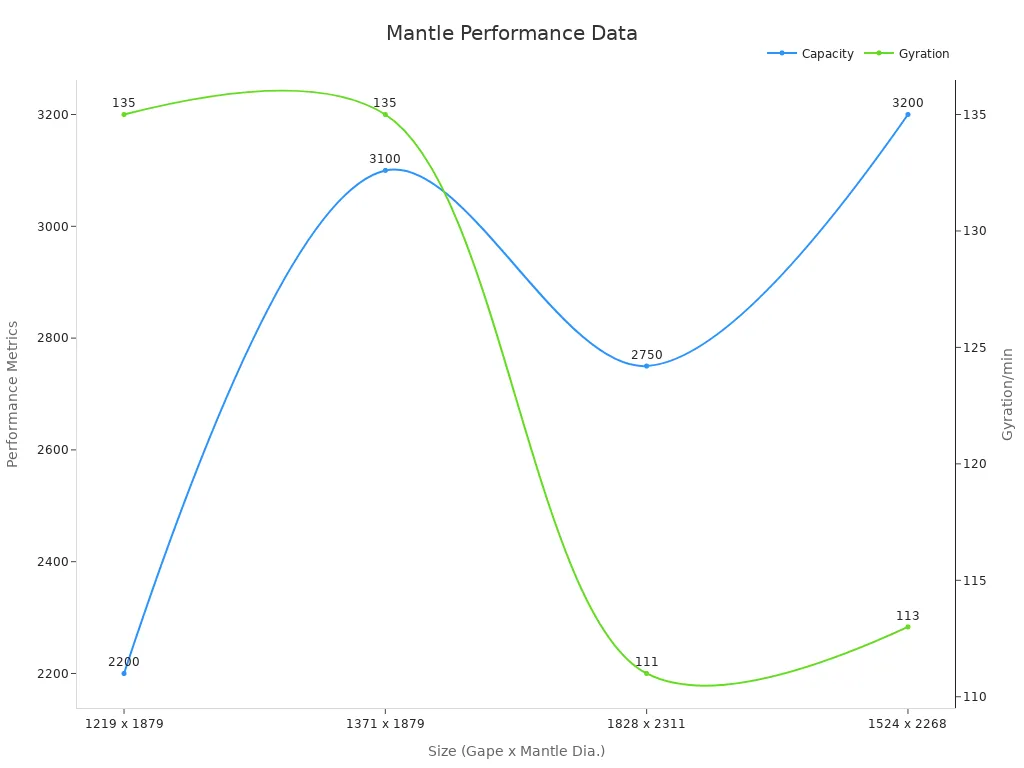

The efficiency of this process depends on several factors, including the size of the mantle, the gap between the mantle and concaves, and the speed of gyration. For example, a crusher with a mantle diameter of 1524 mm and a gyration speed of 113 rpm can achieve a capacity of up to 3,200 tons per hour.

The concave mantle directly impacts the performance of your cone crusher. It determines the throughput, product size, and energy consumption. Using the correct crushing chamber ensures optimal productivity and extends the life of the liners.

Performance metrics like throughput and product size help you monitor the crusher's efficiency. A well-maintained mantle can save up to 30% in energy costs and increase throughput by 70% compared to older models. The table below highlights some key specifications:

| Specification | Value |

|---|---|

| Crushing Capacity | 100 – 1500 short ton/hour |

| Energy Savings | Up to 30% |

| Increase in Throughput | 70% compared to older models |

| Increase in Installed Power | Up to 50% |

| Set Under | As high as 92% |

Improper operation and maintenance can lead to accelerated wear of the concave mantle and liners. This reduces the crusher's efficiency and increases downtime. Poor-quality materials used in liners can also result in faster wear, especially when processing hard materials.

Frequent damage to components not only shortens the machine's lifespan but also causes operational failures. To avoid these issues, ensure proper installation and regular maintenance of the mantle and concaves. This will help maintain consistent performance and reduce unexpected breakdowns.

Proper feed distribution is essential for maintaining uniform wear on the concave mantle and ensuring the efficiency of your cone crusher. When the feed material is unevenly distributed, it causes localized wear on the mantle and concaves. This not only reduces the lifespan of these components but also impacts the crusher's performance.

To achieve proper feed distribution:

- Ensure consistent material flow: Use a feeder or conveyor system that delivers material evenly across the crushing chamber.

- Avoid overloading one side: Uneven loading can lead to imbalanced wear and reduced crushing efficiency.

- Monitor feed size: Oversized materials can cause blockages and uneven wear. Use pre-screening equipment to remove large particles before they enter the crusher.

By maintaining uniform wear, you can extend the life of the mantle and concaves, reduce downtime, and improve overall productivity.

Choosing the correct concave mantle design is critical for optimizing your cone crusher's performance. Different applications require specific designs to handle varying material properties and operating conditions.

Columbia Steel's wear studies provide valuable insights into selecting the most suitable wear parts. These studies analyze real-world data to recommend designs that enhance production and minimize downtime. For example, laser scanning technology identifies high-wear areas, allowing you to make informed decisions about replacement parts.

Key factors to consider when selecting a mantle design include:

| Factor | Description |

|---|---|

| Feed Size | Accurate measurement of raw materials entering the chamber is crucial for optimization. |

| Eccentric Throw | The greater the throw, the more the mantle moves away from its axis, affecting output and wear. |

| Closed Side Setting | Balancing CSS with feed size and eccentric throw is necessary for achieving desired product output. |

| Wear Distribution | An optimal setup results in evenly distributed wear along the mantle and concave, extending lifespan. |

By tailoring the mantle design to your specific application, you can achieve better crushing efficiency, reduce energy consumption, and extend the life of your crusher components.

Proper installation and alignment of the mantle are crucial for maintaining the efficiency and safety of your cone crusher. Misalignment can lead to uneven wear, reduced performance, and potential damage to the crusher.

Follow these steps to ensure correct installation:

1. Inspect the components: Before installation, check the mantle and concaves for any defects or damage.

2. Align the mantle accurately: Use alignment tools to position the mantle correctly within the crushing chamber.

3. Secure the mantle firmly: Tighten all bolts and fasteners to prevent movement during operation.

4. Test the setup: Run the crusher at low speed to verify that the mantle and concaves are aligned and functioning properly.

Regularly inspecting and maintaining the alignment of the mantle will help you avoid costly repairs and ensure consistent performance.

Adjusting the settings of your cone crusher is one of the most effective ways to improve its efficiency. These settings control how the machine processes material, influencing factors like throughput, product size, and energy consumption. By fine-tuning these parameters, you can achieve better performance and reduce operational costs.

Several settings play a critical role in maximizing the efficiency of your cone crusher. These include:

Closed Side Setting (CSS): This determines the smallest gap between the mantle and concave. A smaller CSS produces finer material, while a larger CSS increases throughput. Adjusting this setting helps you balance product size and production rate.

Eccentric Throw: This refers to the distance the mantle moves during each gyration. A higher throw increases crushing force, which is ideal for harder materials. However, it may also lead to faster wear.

Rotational Speed: The speed at which the mantle rotates affects the crushing action. Optimal speeds enhance material breakage and improve efficiency.

When you adjust the settings correctly, you can unlock several benefits:

Increased production capacity without compromising product quality.

Reduced energy consumption, leading to lower operational costs.

Extended lifespan of wear parts due to balanced crushing forces.

For example, upgrades to Linwood’s crushing circuit have shown significant improvements. The site now produces more material while maintaining high product quality. Maintenance costs have decreased, and plant safety has improved.

To maximize efficiency, follow these tips when adjusting your crusher settings:

Monitor Material Properties: Understand the hardness and abrasiveness of the material you are processing. Adjust the settings to match these properties for optimal performance.

Use Real-Time Data: Modern cone crushers often come with monitoring systems that provide real-time data on performance metrics. Use this data to make informed adjustments.

Test and Optimize: After making adjustments, test the crusher's performance. Fine-tune the settings until you achieve the desired balance between throughput and product size.

Studies have shown that the optimal parameter set for cone crushers includes specific angles and rotational speeds. These adjustments enhance crushing efficiency and increase the maximum crushing force, resulting in better overall performance.

By taking the time to adjust your crusher settings, you can ensure that your machine operates at peak efficiency. This not only improves productivity but also reduces wear and tear, saving you time and money in the long run.

Recognizing wear on the concave mantle early can save you from costly repairs and unexpected downtime. Worn-out cone crusher liners often show visible signs, such as uneven surfaces, cracks, or thinning in specific areas. These signs indicate that the mantle is no longer performing efficiently.

You should also monitor the crusher's performance. A sudden drop in throughput or an increase in energy consumption often signals excessive wear. Vibrations or unusual noises during operation may also point to issues with the mantle or concave liner. Regular visual inspections and performance tracking can help you detect these problems before they escalate.

By identifying wear early, you can plan maintenance activities and avoid unplanned shutdowns. This proactive approach ensures your crusher continues to operate efficiently.

Replacing the concave mantle at the right time is crucial for maintaining the efficiency of your cone crusher. Delaying replacement can lead to reduced performance, increased energy consumption, and potential damage to other components.

The timing of replacement depends on the wear rate, which varies based on factors like material hardness and operating conditions. Regular inspections will help you determine when the mantle has reached its wear limit. For example, if you notice uneven wear patterns or significant thinning, it's time to replace the mantle.

When replacing the mantle, follow these steps:

1. Prepare the equipment: Shut down the crusher and ensure all safety protocols are in place.

2. Remove the worn mantle: Use appropriate tools to detach the old mantle carefully.

3. Install the new mantle: Align it properly within the crushing chamber and secure it firmly.

4. Test the setup: Run the crusher at low speed to ensure the new mantle is functioning correctly.

The table below highlights how timely replacements can reduce downtime and improve efficiency:

| Mine Name | Original Downtime | Reduced Downtime | Reduction in Hours |

|---|---|---|---|

| Los Bronces | 100 hours | 56 hours | 44 hours |

| Boliden Kevitsa | 48 hours | 24 hours | 24 hours |

| Milpillas | 6 months | 2 years | N/A |

| Terrafame | N/A | 5 days more uptime | N/A |

Replacing the mantle on time not only minimizes downtime but also ensures consistent performance and extends the life of your cone crusher.

Preventative maintenance is key to extending the lifespan of your cone crusher liners. Regular inspections and consistent monitoring of the crusher's performance are essential. These practices help you identify minor issues before they become major problems.

Here are some effective preventative measures:

- Conduct regular visual inspections to detect wear or damage early.

- Use detailed inspection checklists to ensure no component is overlooked.

- Monitor the crusher's performance metrics, such as throughput and energy consumption, to identify inefficiencies.

By following these steps, you can reduce repair costs and improve operational efficiency. Consistent maintenance also ensures your crusher operates at peak performance, maximizing the lifespan of the concave liner and other components.

Tip: High-quality replacement parts play a significant role in preventative maintenance. Investing in durable materials reduces wear and extends the life of your cone crusher liners.

Using high-quality replacement parts for your cone crusher liners is essential for maintaining optimal performance and reducing long-term costs. Inferior parts may seem like a cost-saving option initially, but they often lead to frequent breakdowns, reduced efficiency, and higher maintenance expenses. Investing in durable, well-designed components ensures your crusher operates smoothly and consistently.

Enhanced Durability

High-quality parts are made from superior materials that resist wear and tear. For example, premium concave liners last longer, even when processing abrasive materials. This durability reduces the frequency of replacements, saving you time and money.

Improved Crusher Performance

Precision-engineered parts fit perfectly within your crusher, ensuring seamless operation. Poorly fitting components can cause misalignment, leading to uneven wear and reduced efficiency. With high-quality parts, you can maintain consistent performance and achieve better crushing results.

Reduced Downtime

Reliable replacement parts minimize unexpected failures. When your crusher operates without interruptions, you can meet production targets and avoid costly delays. For instance, a well-maintained mantle paired with quality liners ensures smooth material flow and consistent output.

Lower Operational Costs

While high-quality parts may have a higher upfront cost, they significantly reduce long-term expenses. Durable components lower energy consumption and maintenance needs, making them a cost-effective choice over time.

Choosing the right replacement parts requires careful consideration. Look for manufacturers with a proven track record of producing durable and efficient components. Pay attention to the following factors:

Material Composition: Opt for parts made from high-grade alloys or materials designed to withstand the specific condition s of your operation.

Compatibility: Ensure the replacement parts match your crusher's specifications. Incorrect parts can lead to operational issues.

Manufacturer Reputation: Choose suppliers known for their quality and reliability. Reading reviews and seeking recommendations can help you make an informed decision.

Tip: Always consult your equipment's manual or contact the manufacturer for guidance on selecting the best replacement parts.

Using high-quality replacement parts not only improves the immediate performance of your cone crusher but also extends its overall lifespan. Consistent use of durable components reduces wear on other parts of the machine, preventing costly repairs. Additionally, it enhances safety by minimizing the risk of sudden failures during operation.

By prioritizing quality, you ensure that your crusher remains a reliable asset in your production process. This approach not only boosts efficiency but also maximizes your return on investment.

The material properties of the concave mantle significantly affect its performance in a cone crusher. Hardness and abrasiveness play a crucial role in determining wear resistance. Materials with higher hardness levels, such as cemented carbide (WC-10Co), exhibit superior durability under abrasive conditions. This ensures the concaves last longer, even when processing tough materials.

Studies show that adding elements like Cu or SiC to alloys improves both hardness and wear resistance. For example, in tests involving Al-4 wt% Mg alloy, these additions enhanced the material's ability to withstand abrasive forces. Similarly, microstructure and microhardness directly correlate with wear resistance, emphasizing the importance of selecting the right material for your crusher's concave mantle.

By choosing materials optimized for hardness and abrasiveness, you can reduce wear, extend the lifespan of your cone crusher, and maintain consistent performance.

Operating conditions directly influence the wear patterns on the concave mantle. Balanced impact loads result in minimal wear, as seen in the inlet section of the crusher. However, areas exposed to large impact loads, such as the middle section, experience higher wear rates.

The table below highlights how wear patterns vary across different sections of the crusher:

| Section | Description of Wear Patterns | Impact Load Characteristics |

|---|---|---|

| k to h | Minimal wear due to balanced impact load | Inlet section with vertical liner curve |

| h to c | Gradual increase in wear, highest at point c | Large impact load from ore, decreasing load towards point h |

| c to a | Non-gradual wear, increasing gap leads to adjustments | Continuous adjustment of moving cone to maintain product quality |

To minimize wear, you should monitor operating conditions closely. Regular adjustments to the moving cone and proper maintenance of the concaves can help maintain optimal performance and reduce downtime.

Feed size and material distribution significantly impact the efficiency of your cone crusher. Larger feed sizes require more energy to crush, reducing overall efficiency. Research shows that variations in feed size can alter crushing performance. For instance, Deniz's study on coal feed size demonstrated that smaller, uniform feed sizes improve efficiency and reduce energy consumption.

Material distribution also plays a key role. Uneven distribution causes localized wear on the concaves, leading to reduced performance and frequent maintenance. Pre-screening materials to ensure uniform feed size and distribution can help you avoid these issues.

The Bond Work Index provides a theoretical framework for understanding the relationship between feed size and efficiency. It highlights how smaller feed sizes reduce the energy required for crushing, improving overall performance. By optimizing feed size and distribution, you can enhance your crusher's efficiency and extend the life of its components.

The concave mantle plays a vital role in improving the efficiency of your cone crusher. By optimizing its design and maintaining it properly, you can achieve better performance, reduce downtime, and lower operational costs. Regular inspections and timely replacements ensure consistent output and extend the lifespan of your crusher.

Applying the actionable tips shared in this blog can lead to significant benefits:

- Improved energy efficiency

- Reduced downtime

- Increased availability

For example, case studies highlight the advantages of optimization:

| Case Study | Benefit Description |

|---|---|

| TPI Polene cement plant | Reduced costs and CO2 emissions through innovative solutions. |

| Norsk Stein | Saved 500 MWh per year with optimized energy costs. |

| Codelco Andina | Increased crusher availability by 23%. |

By implementing these strategies, you can maximize the potential of your cone crusher and ensure long-term success.

The concave mantle compresses and crushes materials within the cone crusher. It works with the mantle to break down materials into smaller sizes, ensuring efficient processing and desired output.

You should inspect the concave mantle regularly, ideally during scheduled maintenance. Frequent checks help identify wear early, preventing unexpected downtime and maintaining optimal performance.

Yes, improper feed size can reduce efficiency. Oversized materials may cause blockages, while uneven distribution leads to localized wear. Pre-screening materials ensures consistent feed size and better performance.

High-grade alloys, such as those with added elements like SiC or Cu, are ideal. These materials resist wear and extend the lifespan of the concave mantle, even under abrasive conditions.

Proper alignment ensures even wear and prevents damage to the crusher. Misalignment can lead to reduced efficiency, uneven material processing, and increased maintenance needs.