In the world of crushing and mining, the choice of materials for crusher liners can significantly affect operational costs, efficiency, and equipment lifespan. Crusher liners are essential components in crushing equipment, protecting the machinery from excessive wear and tear while improving performance. Two popular options are Manganese Steel liners and High Chrome liners. Each has distinct advantages and disadvantages based on the specific needs of your operation. This article will compare Manganese Steel and High Chrome liners to help you determine which one offers the best return on investment (ROI).

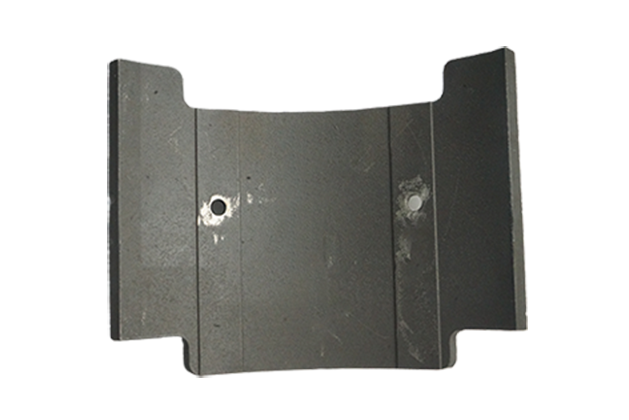

Crusher liners are the wear-resistant parts inside crushers that come into direct contact with the material being crushed. These liners absorb impact forces and prevent damage to the crusher's internal components. As they undergo constant wear during the crushing process, choosing the right material for the liners is crucial for minimizing downtime, optimizing performance, and lowering overall maintenance costs.

There are several types of crusher liners, with Manganese Steel and High Chrome being two of the most common materials. Each material is designed to withstand different types of crushing forces and abrasive conditions.

Manganese Steel is widely known for its excellent toughness, high impact resistance, and superior wear properties. It is often used in jaw crushers, cone crushers, and impact crushers for primary and secondary crushing applications.

Composed primarily of 12% to 14% manganese and 0.8% to 1.2% carbon, making it highly resistant to cracking and wear.

The material hardens under high impact, which increases its resistance to wear over time.

Best suited for applications where materials are not too abrasive but are prone to high impact.

Typically used in primary crushing where the material size is large and irregular.

Excellent resistance to impact and high shock loads: Manganese steel is ideal for tough materials such as ores and hard rock.

Self-hardening properties: The steel increases in hardness with use, prolonging the lifespan of the liners.

Good ductility: Manganese steel can absorb shock without breaking, making it durable in high-impact applications.

Lower abrasion resistance: Manganese steel is not as effective in highly abrasive environments, leading to faster wear under such conditions.

Frequent maintenance: Though durable, manganese liners require regular inspection and maintenance to ensure peak performance.

High Chrome liners are composed of a high-chromium alloy, typically containing 18% to 30% chromium and 1% to 2% carbon, which provides superior abrasion resistance. These liners are most often used in secondary and tertiary crushers, particularly when dealing with highly abrasive materials.

High content of chromium gives these liners excellent hardness, making them ideal for materials that are particularly abrasive.

Designed to maintain a high level of wear resistance without hardening over time.

Excellent for crushing hard and abrasive materials such as sand, gravel, and crushed stone.

Primarily used in secondary and tertiary crushing stages where materials have already been partially reduced in size.

Superior abrasion resistance: High chrome liners are highly effective in processing materials that have sharp edges and high abrasiveness.

Extended wear life: High chrome liners tend to last longer in abrasive environments, reducing the need for frequent replacements.

High hardness: Excellent for crushing applications that involve high wear rates.

Less impact resistance: High chrome liners can be more brittle and less capable of handling high-impact applications compared to manganese steel.

Not suitable for tough materials: These liners may crack or fail under impact from large, tough materials.

When it comes to choosing between Manganese Steel and High Chrome crusher liners, the decision largely depends on the specific needs of your operation. Let's break down the comparison:

Manganese Steel excels in handling impact forces but may wear faster in abrasive environments.

High Chrome liners perform better in abrasive conditions, offering superior wear resistance in crushing environments with sharp-edged materials.

Manganese Steel has a long lifespan due to its self-hardening properties, making it ideal for primary crushing applications.

High Chrome liners last longer in environments where abrasive materials are crushed, but they may need to be replaced sooner if subjected to heavy impacts.

Manganese Steel requires more frequent maintenance and inspection, but its longevity in high-impact conditions often justifies the cost.

High Chrome liners require less maintenance but are more expensive to replace when they do wear out.

Manganese Steel is preferred for softer, tougher materials that undergo high-impact forces.

High Chrome excels in crushing harder, more abrasive materials but struggles with larger, tough materials that generate high impact.

Manganese Steel may have a lower initial cost but may incur higher long-term costs due to more frequent maintenance and replacement.

High Chrome may come with a higher initial investment but could offer a better ROI over time if your operation involves abrasive materials that lead to faster wear on manganese liners.

To determine which option provides the best ROI, consider the following:

Type of Material Processed: If your operation primarily involves abrasive materials (e.g., sand, gravel, crushed stone), High Chrome liners are a better choice due to their superior abrasion resistance and longer lifespan.

Crushing Stage: For primary crushing, where larger and tougher materials are processed, Manganese Steel liners offer better impact resistance and self-hardening properties, providing a better ROI.

Maintenance and Downtime: If minimizing downtime is a priority, High Chrome liners may be the better option due to their longer wear life in abrasive applications.

Ultimately, the best choice depends on your specific operational needs. A balanced approach, where both materials are used in the right stages of crushing, could provide optimal ROI.

Both Manganese Steel and High Chrome crusher liners have their advantages and are suited to different types of crushing conditions. Manganese steel liners are ideal for high-impact, primary crushing applications, while high chrome liners excel in abrasive, secondary crushing conditions. By analyzing the specific needs of your operation, you can make an informed decision that minimizes downtime, reduces maintenance costs, and enhances the overall performance of your crushers.

At Haitian Heavy Industry, we offer expert advice on selecting the right crusher liners for your operation. Contact us today to discuss your needs and get the best solution for improved ROI and long-term equipment performance.