In the competitive world of aggregate production and mining, the "cheapest" spare part often becomes the most expensive mistake. For quarry operators and plant managers, the balance sheet isn't determined by the invoice price of a single set of liners, but by the Total Cost of Ownership (TCO) over a fiscal year.

As a leading jaw crusher plate manufacturer, we have analyzed decades of wear data across diverse geological conditions. The verdict is clear: while Mn13 is affordable, upgrading to Mn18Cr2 or Mn22Cr2 in hard rock applications can yield a 20-30% increase in wear life, fundamentally shifting the ROI equation.

This article moves beyond basic metallurgical definitions to provide a commercial and technical analysis of which material drives real profitability.

To make an informed purchase, one must understand the unique behavior of Hadfield steel (manganese steel). Unlike other wear materials like high-chrome iron (which is simply hard and brittle), manganese steel is austenitic.

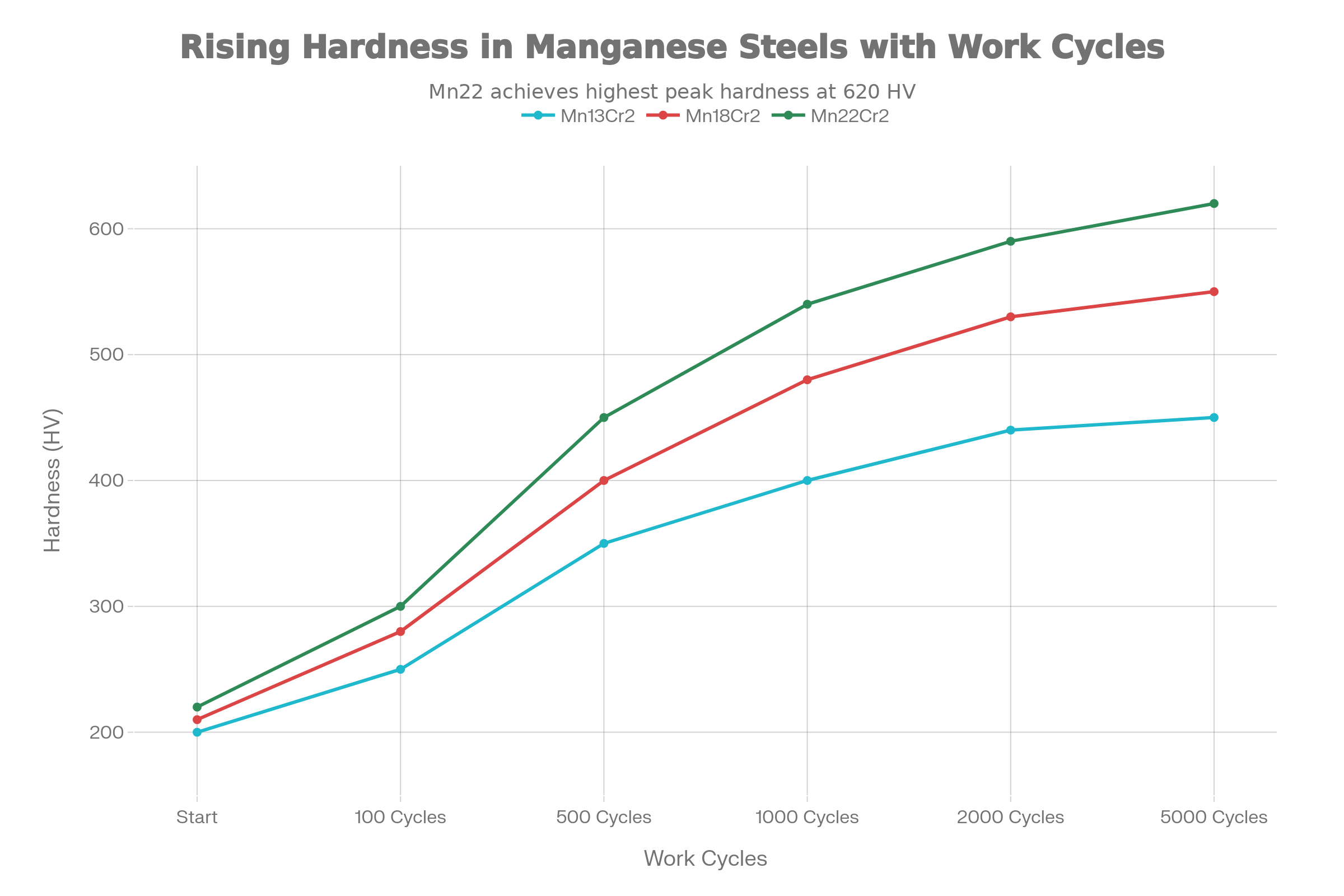

It is soft and ductile in its supplied state (approx. 200-220 HB). However, under impact, the surface layer undergoes a phase transformation, changing its crystalline structure to form a super-hard "skin" (up to 550+ HB), while the core remains ductile to absorb shock.

If your rock isn't hard enough to trigger this "work hardening," you are paying for premium alloy but getting mediocre results. Conversely, if your rock is extremely abrasive and hard, standard Mn13 will wear away before it can sufficiently harden, leading to rapid washout.

Not all manganese plates are created equal. The difference lies in the Carbon-to-Manganese ratio and the addition of Chromium (Cr).

Composition: ~13% Manganese, ~2% Chromium.

Performance: Reliable, tough, and cost-effective.

Best For: Soft to medium-abrasive materials (Limestone, Dolomite, soft Sandstone).

Commercial Reality: This is the "safe" choice. It is rarely the wrong choice, but in hard rock applications, it is inefficient. It wears relatively quickly because it lacks the manganese content to form a deep, ultra-hard wear skin under high stress.

Composition: ~18% Manganese, ~2% Chromium.

Performance: The sweet spot for modern crushing. The extra manganese allows the steel to work-harden faster and deeper.

Best For: Hard and abrasive materials (Granite, Basalt, Quartzite, River Gravel).

Commercial Reality: Mn18Cr2 typically costs 15-20% more than Mn13Cr2. However, in compressive strength tests involving granite (250+ MPa), it consistently delivers 20-40% longer service life. The mathematics of this trade-off is the core of our ROI analysis below.

Composition: ~22% Manganese, ~2% Chromium (often with traces of Molybdenum).

Performance: Extreme hardening capability. Can reach surface hardness levels exceeding 600 HB.

Best For: Extreme impact applications and highly abrasive ores (Iron Ore, Trap Rock, Gold Ore).

Commercial Reality: There is a law of diminishing returns. Mn22 is significantly more expensive and difficult to cast properly. If the impact energy in your crusher isn't high enough (e.g., a small jaw crusher or softer feed), Mn22 will not work-harden and will wear faster than Mn18 due to lower initial abrasion resistance relative to its cost. It requires heavy impact to pay off.

| Feature | Mn13Cr2 (Standard) | Mn18Cr2 (Premium) | Mn22Cr2 (Ultra) |

| Initial Hardness | ~210 HB | ~220 HB | ~230 HB |

| Max Work Hardened | ~450 HB | ~550 HB | ~600+ HB |

| Impact Toughness | High | Very High | Extreme |

| Relative Price | Base (1.0x) | 1.15x - 1.25x | 1.40x - 1.60x |

| Ideal Rock Type | Limestone, Coal | Granite, Basalt | Iron Ore, Taconite |

| Typical Wear Life | 100% (Baseline) | 120% - 140% | 130% - 160% |

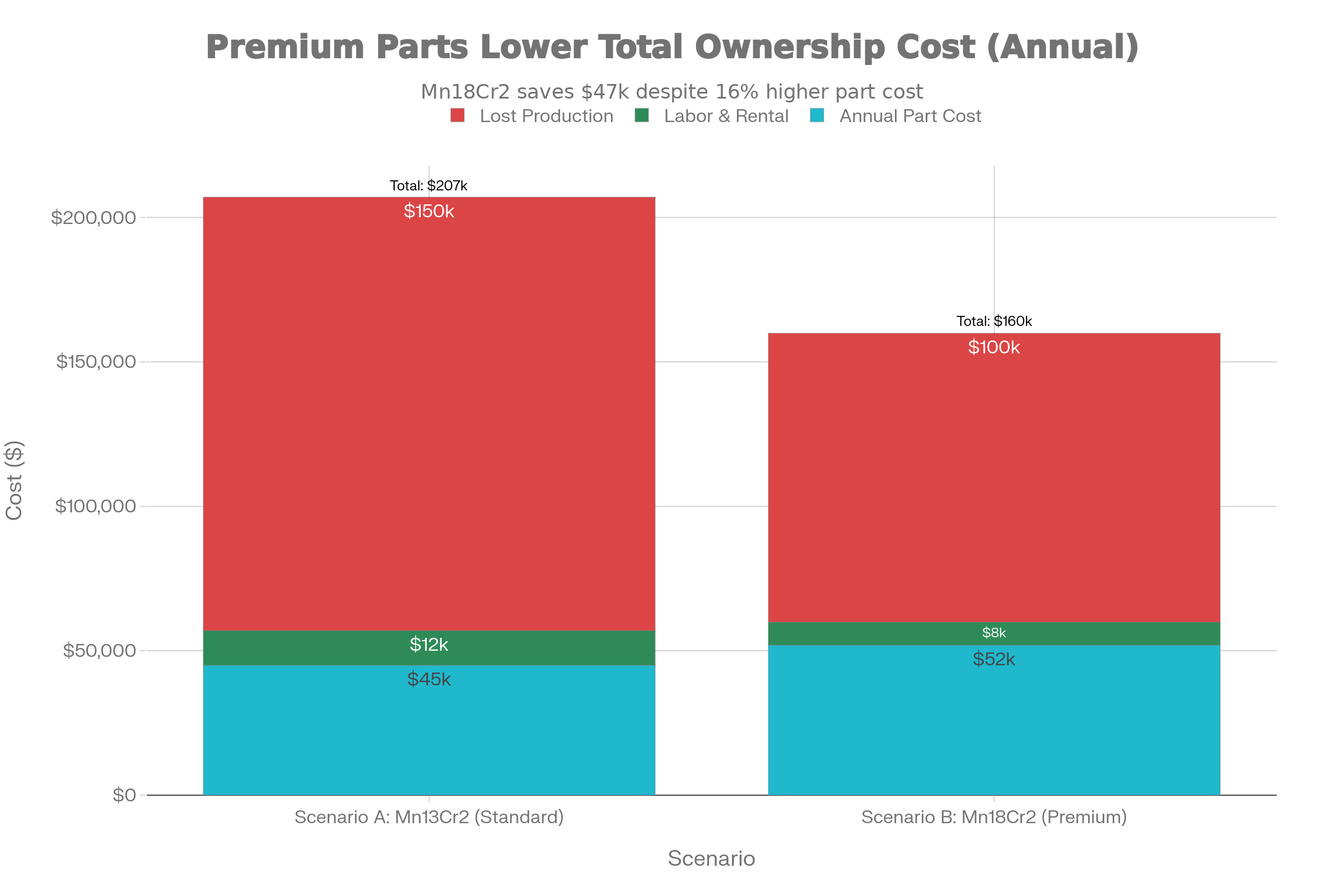

The sticker price of the liner is the smallest component of your crushing costs. To calculate true ROI, we must look at Total Cost of Ownership (TCO).

Downtime Opportunity Cost: A 500 TPH plant selling aggregate at $15/ton loses $7,500 in revenue for every hour the crusher is down.

Crane & Labor: Hiring a crane and maintenance crew for a liner change often costs $3,000 - $5,000 per event.

Safety Risk: Every liner change involves heavy lifting and risk to personnel. Reducing frequency improves safety metrics.

Baseline (Mn13Cr2): Liners last 300 hours.

Upgrade (Mn18Cr2): Liners last 390 hours (+30%).

Price Premium: Mn18 costs 20% more.

| Cost Variable | Scenario A: Mn13Cr2 (Standard) | Scenario B: Mn18Cr2 (High Performance) | Impact |

| Liner Price (Set) | $4,000 | $4,800 | +$800 cost |

| Wear Life (Hours) | 300 Hrs | 390 Hrs | +90 Hrs life |

| Annual Operating Hrs | 2,400 Hrs | 2,400 Hrs | - |

| Changes Needed / Year | 8 Changes | 6.15 (approx 6) | 2 fewer changes |

| Total Parts Cost / Year | $32,000 | $29,538 | Save $2,462 |

| Labor/Crane ($4k/change) | $32,000 | $24,600 | Save $7,400 |

| Downtime Lost Revenue | $480,000 (assuming 80 hrs lost) | $360,000 (assuming 60 hrs lost) | Save $120,000 |

| TOTAL ANNUAL SAVINGS | ~$129,862 |

(Note: Downtime revenue loss is often theoretical if production can be made up, but labor and parts savings are direct cash).

The Conclusion: Even paying 20% more for the Mn18Cr2 liners resulted in a direct cash saving on parts and labor, plus a massive reduction in operational disruption.

Simply specifying "Mn18" on a purchase order does not guarantee results. As a specialized jaw crusher plate manufacturer, we see significant variance in the market. "Cheap" Mn18 often fails to outperform high-quality Mn13. Why?

The Risk: If the manufacturer rushes this process to save energy costs (a common tactic in budget foundries), carbides precipitate in the grain boundaries.

The Result: The steel becomes brittle. Instead of wearing down, the jaw plate cracks or chunks off under impact. You lose 50% of the wear life instantly.

The Risk: If a foundry uses low-grade scrap metal without precise spectral analysis, trace elements like Phosphorus can rise.

The Result: "Short" steel that breaks unexpectedly. At Haitian, we utilize advanced spectrometry to ensure every batch hits the precise Mn18Cr2 specification before pouring.

The Solution: Premium manufacturers use machined back surfaces or advanced casting methods (like V-Process or Lost Foam) to ensure a snug fit. This prevents the plate from cracking due to fatigue stress.

To maximize your ROI, align your material choice with your specific geological reality.

| Rock Type | Compressive Strength (MPa) | Abrasiveness (SiO2) | Recommended Material | Why? |

| Limestone | < 150 MPa | Low (< 5%) | Mn13Cr2 | Sufficient hardness; Mn18 is overkill and won't work-harden fully. |

| Dolomite | 150 - 200 MPa | Medium | Mn13Cr2 / Mn18Cr2 | Transition zone. Test Mn18 if wear life is < 4 weeks. |

| Granite | 200 - 300 MPa | High (> 60%) | Mn18Cr2 | The industry standard for hard rock. Best cost-per-ton balance. |

| Basalt | > 300 MPa | Very High | Mn18Cr2 / Mn22Cr2 | High impact allows Mn22 to shine. |

| River Gravel | Variable | Very High (Silica) | Mn18Cr2 + TIC | Consider TIC (Titanium Carbide) inserts for extreme silica content. |

| Recycling | Mixed (Steel/Concrete) | Variable | Mn18Cr2 | Toughness is key to handle "tramp iron" without cracking. |

For operators facing extreme wear issues where even Mn22 is insufficient, the next step in ROI evolution is Ceramic Composite Technology.

The Benefit: The ceramic resists abrasion while the manganese absorbs impact.

The ROI: These plates can cost 2-3x the price of standard Mn18 but deliver 3-5x the service life.

Ideal For: Fixed jaw plates in applications with extremely abrasive feed but moderate impact energy.

The data is irrefutable: for hard rock applications, adhering to the "cheaper" Mn13Cr2 standard is a false economy. By upgrading to Mn18Cr2, operators typically secure a 20-30% extension in wear life, which translates to weeks of additional production and thousands of dollars in saved maintenance labor annually.

However, material chemistry is only half the battle. The integrity of the casting—determined by the heat treatment and quality control of your jaw crusher plate manufacturer—is what ensures that the theoretical performance becomes a reality in the pit.