The jaw crusher plate is the most frequently replaced wear component in any crushing operation. Poor selection leads to accelerated wear, excessive downtime, reduced productivity, and ultimately, higher total cost of ownership. Conversely, strategic plate selection extends service life by 30–50%, improves product quality, and demonstrates why finding a reliable and cost-effective jaw crusher plate manufacturer requires an understanding of technical specifications beyond unit price alone.

Every jaw crusher operates with a paired system of jaw plates that work in concert to break material:

Positioned vertically on the stationary jaw

Remain immobile during operation

Act as the anvil against which material is compressed

Typically experience lower stress concentrations than moving plates

Can be designed with different material compositions to optimize lifetime

Attached to the reciprocating jaw mechanism

Move back and forth through 20–30° angles

Deliver dynamic compressive force against the fixed jaw

Experience higher impact stresses and wear rates

Often require more frequent replacement than fixed plates

| Alloy Type | Manganese Content | Hardness Range (BHN) | Best For |

| Mn13Cr2 | 13% manganese, 2% chromium | 230 BHN (initial) → 400 BHN (work-hardened) | Soft materials (limestone, coal), low AI materials |

| Mn18Cr2 | 18% manganese, 2% chromium | 240 BHN (initial) → 420 BHN (work-hardened) | Most stone types, standard quarry applications, medium AI |

| Mn22Cr2 | 22% manganese, 2% chromium | 250 BHN (initial) → 450 BHN (work-hardened) | Extremely hard, abrasive materials (granite, basalt, taconite) |

High manganese steel exhibits austenitic properties, meaning it hardens progressively under impact stress rather than becoming brittle. This work-hardening capability represents the fundamental advantage of quality manganese steel—as crushing pressures compress the material surface, hardness increases from initial BHN 230 to operational hardness of 400+ BHN, creating a self-protective layer that extends service life.

Premium cheap jaw crusher plate manufacturers enhance base manganese compositions by adding chromium, molybdenum, tungsten, or titanium. These alloy modifications improve:

Impact toughness during hard rock crushing

Resistance to thermal cycling stress

Durability in abrasive material applications

Work-hardening rate under operational pressures

Selecting the correct alloy requires understanding your feed material's Abrasion Index (AI), a scientific metric indicating how aggressively material particles wear down crushing surfaces.

| Classification | AI Range | French Abrasiveness (G/Ton) | Example Materials |

| Non-Abrasive | 0.0–0.1 | 0–100 | Clay, soft limestone, coal |

| Slightly Abrasive | 0.1–0.4 | 100–600 | Soft limestone, gypsum, shale |

| Medium Abrasive | 0.4–0.6 | 600–1,200 | Most common aggregates, river stone |

| Abrasive | 0.6–0.8 | 1,200–1,700 | Granite, basalt, ironstone |

| Very Abrasive | 0.8+ | 1,700+ | Quartzite, taconite, recycled concrete |

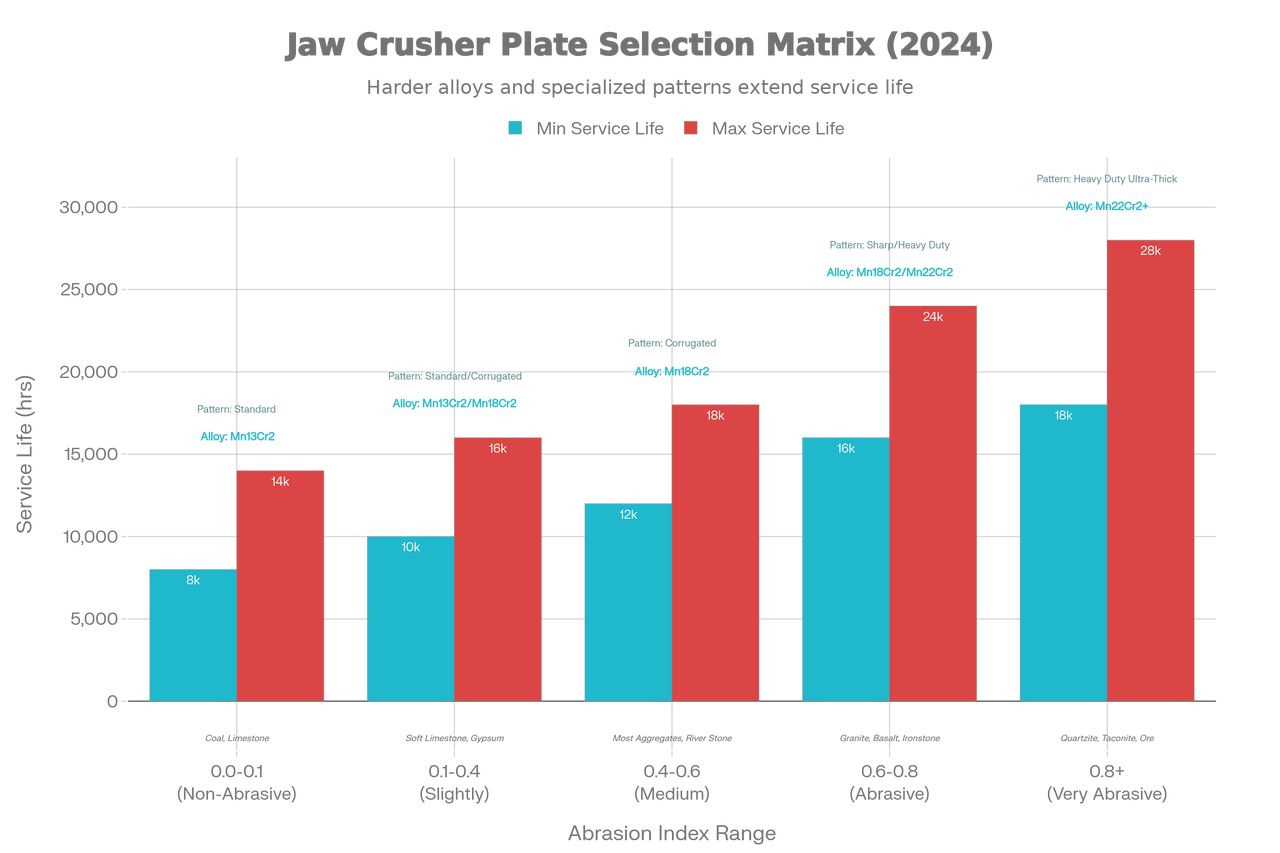

Recommended Alloy: Mn13Cr2, standard teeth or wide tooth design. Rationale: Lower abrasion indexes don't require maximum hardness; Mn13Cr2 provides cost efficiency while delivering adequate wear resistance for low-stress applications. Expected service life: 8,000–12,000 operating hours.

Recommended Alloy: Mn18Cr2 (standard specification), corrugated or coarse corrugated design. Rationale: Mn18Cr2 represents the industry-standard sweet spot, balancing toughness and hardness for 80% of global crushing operations. Superior work-hardening capability extends plate lifetime while maintaining competitive pricing. Expected service life: 12,000–18,000 operating hours.

Recommended Alloy: Mn18Cr2 or Mn22Cr2, sharp teeth or heavy-duty design. Rationale: Hard rock abrasion accelerates surface wear; premium alloys with enhanced chromium content resist particle embedding and maintain crushing efficiency longer. Expected service life: 15,000–22,000 operating hours.

Recommended Alloy: Mn22Cr2 or specialized ultra-thick configurations, heavy-duty ultra-thick (UT) profiles. Rationale: Extremely abrasive materials demand maximum hardness and thickness; ultra-thick configurations reduce replacement frequency from every 6–8 months to 12–15 months, offsetting premium pricing through extended operational periods. Expected service life: 18,000–28,000+ operating hours.

Jaw Crusher Plate Selection Matrix: Matching Abrasion Index to Alloy, Tooth Pattern, and Service Life

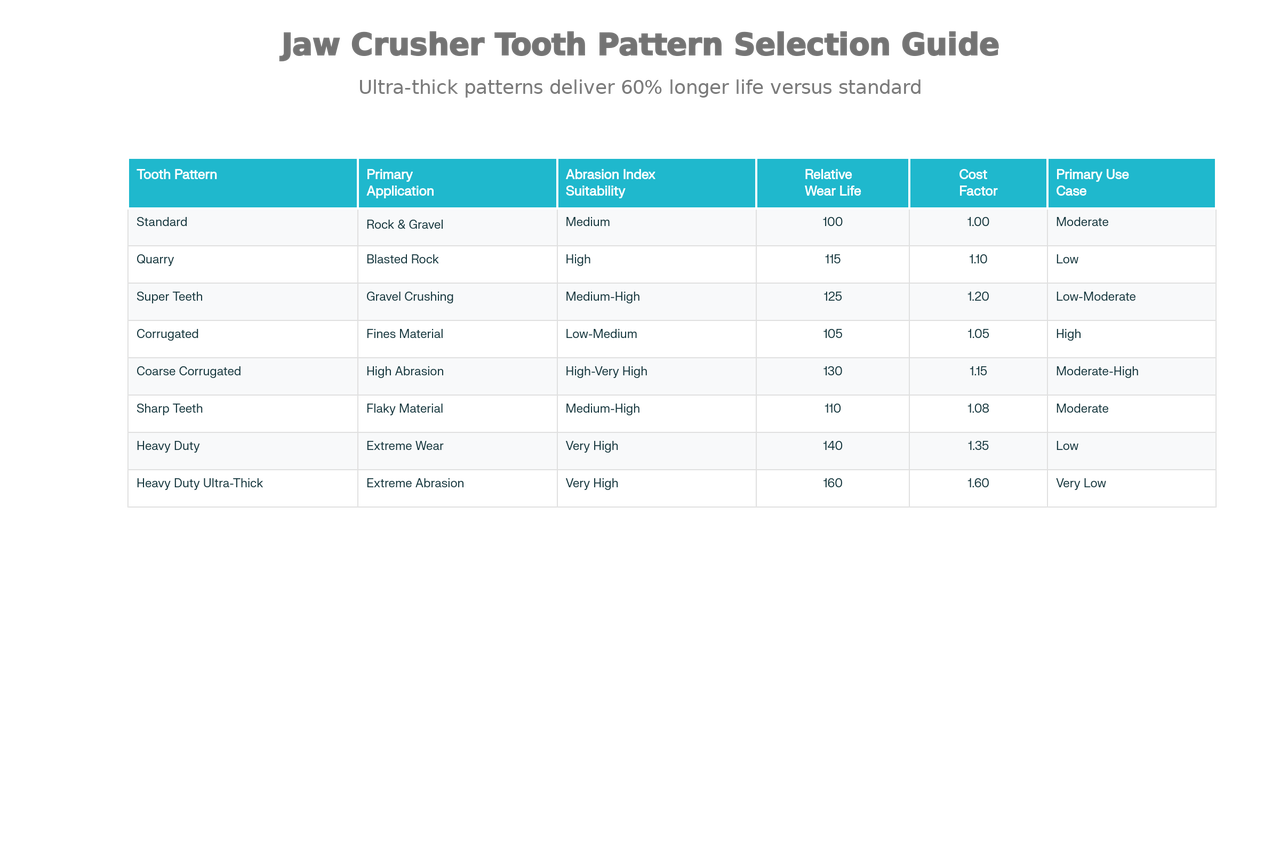

Jaw plate tooth patterns directly influence material grip, fines generation, crushing efficiency, and wear distribution. Selecting the wrong profile causes slabby products (flat fragments unsuitable for concrete), excessive fines dust, or rapid tooth wear.

Design characteristics: Balanced tooth height with moderate spacing

Best for: General rock and gravel crushing applications

Performance profile: Wear life, power requirements, and crushing stresses in good balance

Advantages: Excellent fines removal, reduced slabby product generation, typical factory installation

Industry adoption: Most common profile for mid-sized operations

Caution: Lower performance with heavily abrasive materials

Design characteristics: Flat tooth profile, maximized surface area

Best for: Blasted rock quarries, abrasive materials

Performance profile: Extended lifetime with more wearable manganese steel

Advantages: Flat profile distributes crushing force across larger area, reducing point stress concentrations

Disadvantages: Higher power requirements, increased stress on crusher frame, less favorable for fines removal

Industry adoption: Preferred by large-scale quarry operators processing granite, granite-gneiss

Design characteristics: Larger mass, specially engineered tooth geometry

Best for: Gravel crushing, general applications requiring long wear life

Performance profile: Extended lifetime through enhanced mass and special design

Advantages: Material flows efficiently through large grooves without wearing tooth edges, balanced fines removal

Ideal for: Recycling facilities processing aggregate materials

Limitation: Not suitable for extremely hard rock applications

Design characteristics: Grooved surface with shallow corrugation pattern

Best for: Materials with fine content, small Closed Side Setting (CSS) requirements

Performance profile: Good wear resistance, excellent top-size control

Advantages: Fines flow smoothly through grooves preventing compaction and packing

Use case: Secondary crushing where uniform particle sizing matters

Limitation: Reduced lifetime in highly abrasive applications

Design characteristics: Deeper groove patterns with aggressive corrugation

Best for: Highly abrasive feed materials, large CSS settings

Performance profile: Optimized for maximum abrasion resistance

Advantages: Deep grooves prevent material bridging, material flows freely despite fines

Industry adoption: Mandatory for recycling operations processing concrete/asphalt

Performance metrics: Can increase lifespan by 20–30% versus standard teeth in high-AI applications

Design characteristics: Aggressive pointed geometry for enhanced grip

Best for: Flaky, angular, or smooth feed materials prone to slipping

Performance profile: Superior gripping ability with excellent top-size control

Advantages: Aggressive contact prevents material rotation and sliding

Use case: Recycling facilities processing flat materials (concrete slabs, asphalt chunks)

Caution: Only suitable when AI is moderate; not recommended for extreme abrasion

Design characteristics: Thicker, reinforced tooth structure with increased height

Best for: Extremely abrasive materials, long-term durability requirements

Performance profile: Maximized wear life through enhanced mass and structural strength

Advantages: 30% thicker design extends replacement intervals significantly

Industry adoption: Preferred for continuous high-volume operations in remote locations

Lifetime expectation: 40–50% longer than standard teeth

Design characteristics: Fixed jaw plate with 30mm additional thickness

Best for: Very abrasive materials when combined with CC moving plate

Performance profile: Exceptional wear life in extreme conditions

Special feature: Reserved exclusively for fixed jaw plates to maximize lower-jaw durability

Industry adoption: Premium specification for Sandvik CJ815 and similar large crushers

Cost-benefit analysis: Premium pricing offset by 12+ month extension of replacement intervals

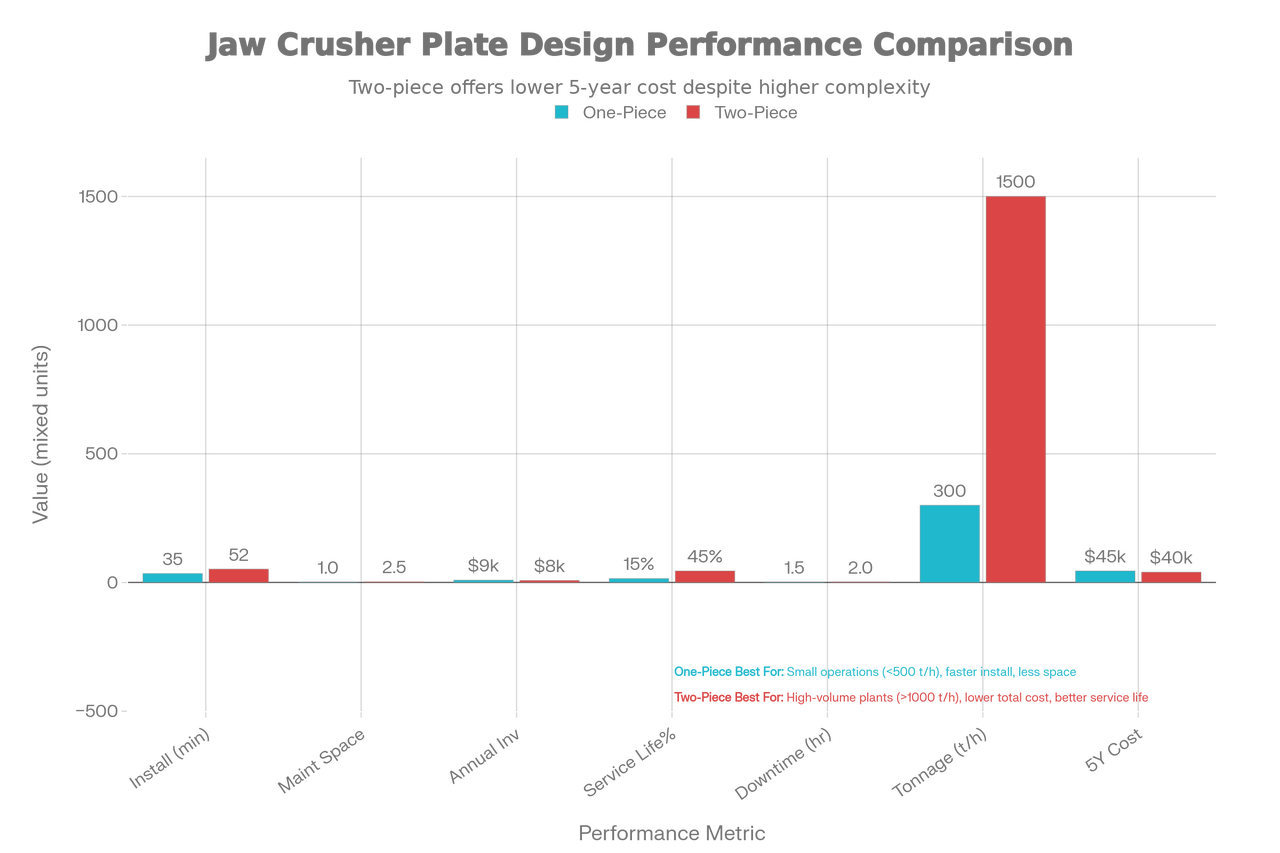

Monolithic construction combining upper and lower plate sections

Can be rotated 180° to extend useful life

Simpler design with fewer replacement components required

Lower manufacturing complexity (more cost-effective to produce)

Easier bolt assembly with fewer fastening points

Faster jaw plate replacement—critical for mobile crusher operations with limited space

Eliminates requirement for center wedges and secondary support components

Straightforward installation process suitable for limited-access maintenance areas

Ideal for smaller to mid-sized crushers with balanced wear patterns

Lower inventory requirements (one plate type vs. multiple sections)

Optimal for materials with uniform abrasion characteristics

Best for operations crushing 8,000–12,000 hours annually

Suitable when wear patterns remain symmetric throughout operational life

Performance rotation strategy: Rotate 180° when lower third exhibits 30% wear

15–25% lower manufacturing cost vs. two-piece equivalent

Reduced inventory carrying costs

Lower replacement parts investment

Ideal for budget-conscious cheap jaw crusher plate manufacturers targeting cost-sensitive operations

Cannot independently replace worn upper vs. lower sections

Less optimal for extreme high-tonnage operations

May require replacement before full theoretical service life exhaustion

Not recommended for highly asymmetric wear environments

Modular construction with independent upper and lower sections

Each section bolts separately to crusher jaw structure

More complex manufacturing requiring precision alignment

Higher manufacturing cost but superior operational flexibility

Each worn section replaces independently (30–40% cost reduction per replacement cycle)

Worn upper section repositions downward where maximum abrasion occurs

Fresh plates install at upper crushing chamber where wear rates lower

Implements strategic rotation extending theoretical service life 40–50%

Ideal for large-capacity operations with high-tonnage throughput

Optimized for high-volume operations (15,000+ annual operating hours)

Accommodates asymmetric wear patterns common in large crushers

Extends overall plate lifetime through strategic component reuse

Rotation strategy: Lower section >50% worn → swap top and bottom dies

20–30% higher initial purchase price

30–50% reduction in cost-per-replacement cycle through section reuse

Lower total cost of ownership for high-throughput operations (3+ years)

Reduced manganese steel consumption (environmental sustainability benefit)

Standard for crushers exceeding 500 ton/hour capacity

Mandatory for mining operations processing taconite or ultra-abrasive ores

Preferred by large aggregate producers targeting cost optimization

| Evaluation Criteria | One-Piece Design | Two-Piece Design |

| Installation Speed | 30–40 minutes | 45–60 minutes |

| Maintenance Space Requirements | Minimal (mobile-friendly) | Standard to large |

| Replacement Cost (per event) | $4,500–$8,000 | $3,500–$6,500 |

| Service Life Extension Potential | 0–20% (through rotation) | 40–50% (through strategic reuse) |

| Downtime per Replacement | 1–2 hours | 1.5–2.5 hours |

| Optimal Application Tonnage | <500 ton/hour | >500 ton/hour |

| Manufacturing Complexity | Low | High |

| Inventory Management | Simple | Complex (multiple SKUs) |

Offers seven distinct tooth patterns with up to three alloy options (M1, M2, M8)

Fixed plate-moving plate combinations engineered for specific models

CJ815 (JM1513) recommendation: Heavy Duty Ultra-Thick (UT) fixed + Coarse Corrugated (CC) moving

Alloy selection: M9 for extended wear life in high-tonnage quarries

Dimension precision required: ±2mm tolerance mandatory

Complex tooth pattern library with model-specific compatibility

Pre-engineered plate sets for different product gradation requirements

Requires verification against crusher serial number for optimal fit

Cheek plates and deflector components integrate with jaw plate assemblies

Offers toggle-dependent designs where jaw plate selection drives overall crusher geometry

Three-piece toggle construction requires coordinated plate specification

Custom designs available for retrofit applications

Jaw plates labeled "universal" typically fit crushers following standard design patterns

Even minor differences in hole placement or alloy composition affect installation

Dimension verification against machine specifications remains essential

True compatibility assessed case-by-case despite "universal" marketing claims

Before ordering from any cheap jaw crusher plate manufacturer, confirm:

Verify exact model designation (e.g., Sandvik CJ815 vs. CJ412)

Confirm manufacturing year (alloy specifications evolved over decades)

Document serial number for traceability

Jaw opening width (defines maximum jaw plate width)

Plate height and thickness specifications

Bolt hole pattern and spacing (±2mm tolerance critical)

Wedge system type (if applicable)

Current alloy composition (Mn13, Mn18, Mn22)

Historical alloy preference for your specific feed material

ISO certification and quality standards documentation

Feed material type and abrasion index

Current tonnage throughput

Closed side setting (CSS) range

Annual operating hours projection

Request dimensional drawings with tolerance specifications

Confirm 100% inspection verification before shipment

Verify fit guarantee or replacement policy

Document customer references with identical crusher models

Alloy: Mn13Cr2

Tooth Pattern: Standard teeth or wide tooth

Design: One-piece (cost-efficient, straightforward replacement)

Fixed/Moving: Standard specifications sufficient

Rationale: Limestone crushing represents the lowest-stress application. Lower manganese content reduces manufacturing cost while delivering adequate wear resistance. Standard tooth geometry prevents fines compaction in the high-fines-content feed characteristic of limestone operations.

Service life: 10,000–14,000 operating hours

Replacement frequency: Every 12–18 months (typical throughput)

Annual jaw plate investment: $6,000–$12,000

Alloy: Mn18Cr2 (standard) or Mn22Cr2 (premium specification)

Tooth Pattern: Sharp teeth or heavy-duty pattern

Design: Two-piece (maximize service life extension through rotation)

Fixed/Moving: Heavy-duty ultra-thick fixed + coarse corrugated moving

Rationale: Granite and basalt crushing demands premium material specifications and strategic design. Work-hardening manganese content (18–22%) resists particle embedding common in abrasive rock. Two-piece architecture enables strategic rotation extending plate lifetime 40–50%.

Service life: 16,000–24,000 operating hours (two-piece rotation strategy)

Replacement frequency: Every 18–24 months

Annual jaw plate investment: $18,000–$28,000

ROI: Premium pricing offset by 50% extension in operational periods

Alloy: Mn22Cr2 (abrasion-resistant specification)

Tooth Pattern: Coarse corrugated or anti-slab design

Design: Two-piece (essential for high-throughput continuous operations)

Fixed/Moving: Heavy-duty ultra-thick fixed + sharp or aggressive moving

Rationale: Recycled concrete and asphalt represent extreme-abrasion applications combining hard embedded aggregates with embedded rebar/steel reinforcement. Aggressive tooth patterns (coarse corrugated, sharp) maintain material grip despite slick surfaces and irregular shapes. Ultra-thick configurations tolerate extreme wear rates.

Service life: 14,000–20,000 operating hours

Replacement frequency: Every 12–16 months (continuous operation model)

Annual jaw plate investment: $24,000–$35,000+

Downtime reduction: Strategic two-piece rotation minimizes crusher idle time

Alloy: Mn22Cr2 with advanced chromium enhancement

Tooth Pattern: Heavy-duty ultra-thick (UT) fixed only

Design: Two-piece (mandatory for 24/7 continuous mining operations)

Fixed/Moving: Ultra-thick fixed (30mm additional thickness) + coarse corrugated moving

Performance Expectations:

Service life: 18,000–28,000+ operating hours (through strategic rotation)

Replacement frequency: Every 24–36 months (extended interval critical for remote mining)

Annual jaw plate investment: $32,000–$48,000

Strategic value: Extended intervals minimize mining operation disruption

Visually inspect jaw plate surfaces for visible cracking or spalling

Verify all bolts remain tight (vibration gradually loosens fasteners)

Check for material bridging or packing within crushing chamber

Clean debris accumulation from tooth grooves

Measure jaw plate wear depth at three locations (upper, middle, lower)

Document wear progression rate (millimeters per operating hour)

Inspect bolt heads and threads for corrosion or degradation

Lubricate toggle joint assemblies per manufacturer specifications

Calculate projected service life based on observed wear rates

Procure replacement plates in advance (lead time planning)

Schedule rotation or replacement during planned maintenance windows

Adjust crusher operating parameters if wear accelerates unexpectedly

Remove jaw plates and inspect internal jaw structure for cracks

Clean all mounting surfaces to manufacturer specifications

Verify jaw alignment within tolerance parameters

Document all maintenance activities for equipment history records

Fixed jaw plate: Rotate 180° when lower third exhibits 30% wear

Moving jaw plate: Rotate when asymmetric center wear becomes noticeable

Timing frequency: Typically every 4–8 months depending on material and tonnage

Lower section rotation trigger: >50% worn lower section

Strategic repositioning: Move work-hardened upper plate downward where maximum abrasion occurs

Install new/less-worn plates at upper chamber (lower stress environment)

Rotation frequency: Every 6–12 months depending on application intensity

Shut down crusher and verify electrical system de-energization

Allow cooling period (2–4 hours for heat dissipation)

Remove safety guards and access covers

Loosen and remove mounting bolts (cap nuts simplify removal process)

Support jaw plates with hydraulic jacks to prevent unexpected dropping

Document wear pattern photography for wear analysis

Rotate or reposition plates according to strategy

Install bolts hand-tight first, then torque to specification

Test crusher briefly before resuming full production

One-piece plate lifecycle: 1 full replacement per ~12 months = $6,000–$12,000 annually

Two-piece plate with rotation strategy: 1 lower replacement + reposition upper = $3,500–$7,000 every 6–12 months, net 30–50% savings

ISO 9001:2008 quality management certification (mandatory minimum)

GMP (Good Manufacturing Practice) compliance documentation

ISO 14001 environmental management certification

ISO 45001 occupational health and safety certification

ASTM or equivalent material testing standards

Advanced casting technology (3D sand printing reduces development cycles to 2 weeks)

Complete process automation from raw material through final inspection

100% final inspection coverage rate before shipment

In-house alloy composition laboratory for quality verification

Heat treatment capability (quenching, tempering for hardness optimization)

Professional technical team (minimum 12 engineers recommended)

Documented collaboration with university research institutions

Active participation in national casting standards development

Demonstrated innovation in specialized alloy formulations

Custom design capability for non-standard crusher models

Minimum 80,000 tons annual production capacity (ensures supply security)

Average delivery cycle < 14 days (logistics efficiency)

Flexibility to accommodate rush orders

Global logistics network for international shipment

Consistent on-time delivery documentation (>95% target)

24/7 technical support availability

Responsive engineering team for application consultation

Detailed technical documentation in multiple languages

Customer training programs on proper installation/maintenance

Warranty coverage specifics and replacement policies

Established relationships with major industry customers

Recommended: Mid-tier Chinese manufacturers emphasizing cost efficiency

Focus: Mn13Cr2, one-piece designs, standard tooth patterns

Advantage: 30–40% cost reduction vs. premium suppliers

Consideration: Verify dimensional accuracy through 100% inspection guarantee

Recommended: Established regional suppliers with proven track records

Focus: Mn18Cr2, balanced quality/cost positioning

Advantage: Local technical support, faster delivery, reasonable pricing

Consideration: Request customer references from similar-tonnage operations

Recommended: Premium suppliers with mining-specific certifications

Focus: Mn22Cr2, custom designs, two-piece configurations

Advantage: Dedicated account management, customized solutions, strategic partnership

Consideration: Long-term volume agreements reduce per-unit costs

35,000 square meter facility with 98.36-acre complex

80,000 tons annual production capacity

236 employees with specialized technical expertise

ISO 9001 certification with 100% final inspection coverage

13 invention patents + 45 utility model patents (documented innovation)

DISA vertical casting lines with advanced automation

3D sand mold printing (2-week product development cycles)

Complete quality control: raw material through shipment

Comprehensive mining machinery wear parts including jaw crusher plates

Concrete plant components

Metallurgical industry products

Asphalt machinery components

Automated intelligent production systems (ERP, MES, OA, CRM integration)

Professional inspection and final quality control personnel

100% final inspection coverage rate

Traceability documentation for batch accountability

"National Outstanding Intelligent Manufacturing Scenario" award

"Anhui Province Intelligent Factory" designation

"Specialized new 'little giant'" recognition

"National Intellectual Property Advantage Enterprise" certification

This profile demonstrates the characteristics distinguishing premium cheap jaw crusher plate manufacturers: documented quality systems, production capacity, technical expertise, and measurable industry recognition—not merely price positioning.

Consult geological surveys or material testing labs for Abrasion Index determination

Cross-reference material type against industry classification tables

Account for seasonal variations (moisture content affects abrasiveness)

Project annual tonnage throughput

Verify exact crusher model, serial number, and manufacturing year

Obtain manufacturer technical drawings with tolerance specifications

Confirm mounting system (bolt-on vs. wedge-style)

Document current jaw plate specifications if replacing existing plates

Select appropriate alloy (Mn13, Mn18, Mn22) based on abrasion index

Choose tooth pattern optimized for feed material characteristics

Determine design architecture (one-piece vs. two-piece) based on tonnage

Project replacement frequency and inventory planning

Verify quality certifications and standards compliance

Request dimensional verification guarantee

Collect customer references processing identical materials

Compare pricing across 3–5 qualified suppliers

Evaluate technical support availability and responsiveness

Calculate cost per ton of material processed

Project service life extension from premium vs. budget specifications

Evaluate downtime costs associated with replacement frequency

Assess impact on product quality and market value

Consider environmental sustainability factors (manganese consumption)

Selecting a cheap jaw crusher plate manufacturer represents a critical operational decision extending far beyond simple price shopping. The optimal choice balances:

Technical compatibility with your specific crusher model

Material specification aligned to feed material abrasion characteristics

Design configuration matching operational throughput and flexibility requirements

Supplier reliability ensuring quality assurance and technical support

Total cost of ownership incorporating service life, downtime, and productivity impacts

By implementing the systematic evaluation framework presented throughout this guide—from abrasion index classification through supplier qualification—you'll move beyond bottom-line pricing toward strategic sourcing that delivers measurable operational value, extended equipment lifespan, and superior profitability.

The decision to invest premium specifications or pursue budget efficiency ultimately reflects your operational priorities: continuous maximum-capacity production favors premium two-piece configurations and Mn22Cr2 alloys; periodic or seasonal operations permit one-piece designs with standard Mn13–Mn18 compositions. Neither approach is inherently superior—but the intentional selection methodology matters absolutely.