Cone crushers are essential pieces of machinery used in the mining and construction industries. They are designed to crush rocks and other materials into smaller, manageable pieces, making them vital for producing aggregates used in building roads, bridges, and other infrastructure projects. Understanding the main parts of a cone crusher is crucial for anyone involved in maintaining and operating these machines. In this article, we will break down the primary components of a cone crusher and their importance in ensuring smooth operation and efficiency.

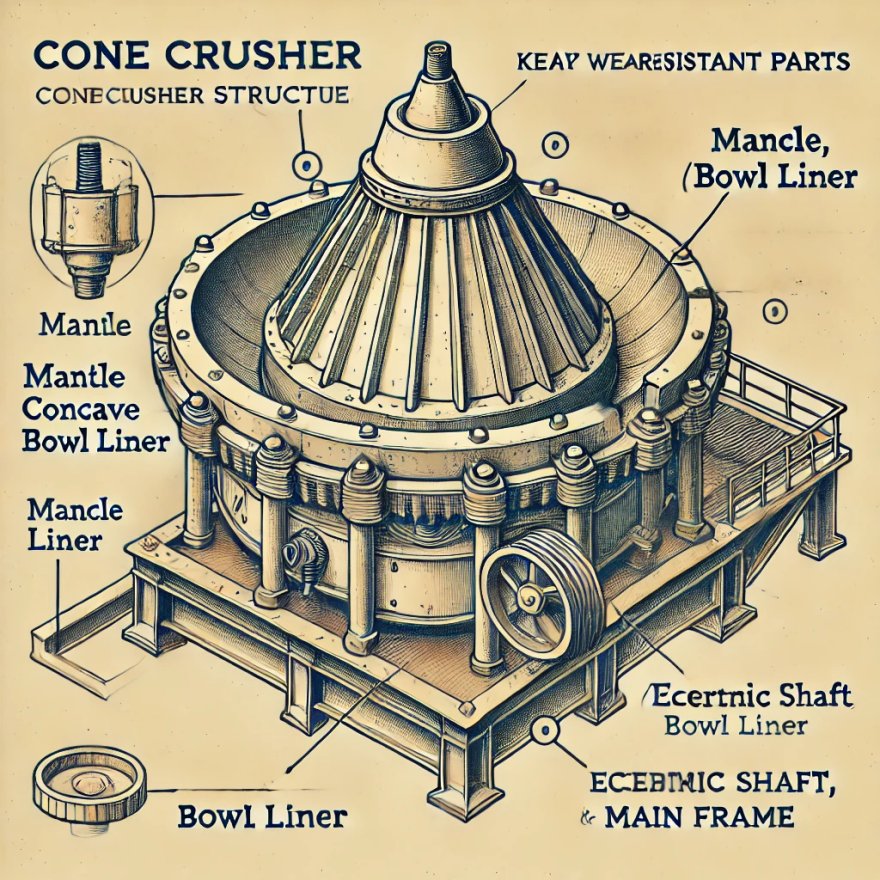

Cone crushers operate on a basic principle: they crush materials between two surfaces—one that is stationary (the concave or bowl liner) and one that moves (the mantle). As materials are fed into the crusher, the moving mantle presses the material against the stationary bowl liner, exerting high pressure and breaking the rocks into smaller pieces. The gap between the mantle and the bowl liner determines the size of the final product. These machines rely heavily on wear-resistant parts to maintain their efficiency and extend their service life.

Frame: The frame is the primary structure that supports all other components of the cone crusher. It is built to be strong and durable, as it absorbs vibrations and impacts that occur during the crushing process. A well-designed frame ensures the crusher operates smoothly and withstands heavy loads.

Mantle: The mantle is the moving part of the cone crusher that rotates around the central axis. Its job is to press the material against the stationary concave, crushing it. Since the mantle is in constant contact with hard materials, it is subject to heavy wear. That’s why high-quality, wear-resistant materials are essential for the mantle. Regular inspection and timely replacement of the cone crusher mantle are important to keep the crusher working efficiently.

Concave (Bowl Liner) : The concave, also known as the bowl liner, is the stationary part of the crusher that works with the mantle to crush materials. Like the mantle, the cone crusher concave is subject to high wear and must be made from durable materials to resist damage from the constant pressure and friction. Replacing worn concave liners is a key part of regular crusher maintenance.

Eccentric Shaft: The eccentric shaft is responsible for driving the gyratory motion of the mantle. It works in tandem with the main shaft and the eccentric bushing to create the oscillating movement necessary to crush materials. Precision engineering is critical for the eccentric shaft, as smooth operation ensures consistent performance and prevents unnecessary wear on other components.

Main Shaft: The main shaft supports the mantle and is connected to the eccentric shaft. It is a vital component that ensures the mantle rotates in alignment with the rest of the crusher. Any misalignment or damage to the main shaft can cause a significant drop in performance and potentially lead to major breakdowns.

Adjustment Ring and Clamping: The adjustment ring allows operators to control the crusher’s closed-side setting (CSS), which determines the size of the output material. The clamping system holds the adjustment ring securely in place. Proper adjustment is crucial for maintaining the desired product size and ensuring consistent crushing efficiency. Regular checks of the adjustment ring and clamping system are necessary to keep the crusher operating smoothly.

Drive System (Motor & Transmission): The drive system powers the cone crusher, providing the energy needed to move the eccentric shaft and mantle. A reliable motor and transmission are essential for consistent crusher performance. A well-maintained drive system ensures that the crusher can handle heavy loads without stalling or slowing down.

Feed Hopper: The feed hopper is where materials are loaded into the crusher. An optimally designed feed hopper ensures a steady flow of material into the crusher without blockages, which is critical for maintaining consistent operation. A well-maintained feed system reduces downtime and keeps the crusher working at full capacity.

The mantle and bowl liner are the two most critical wear parts in a cone crusher. These parts are constantly exposed to the abrasive action of the material being crushed. Selecting high-quality, wear-resistant materials for these components is essential for maximizing their lifespan and reducing the frequency of replacements.

At Haitian, we specialize in providing premium wear-resistant parts that are designed to extend the life of your equipment. Whether you're operating a cone crusher in a concrete mixing plant, a mine, or an asphalt production facility, Haitian's high-performance wear parts ensure your crusher remains efficient and cost-effective.

Proper maintenance is key to maximizing the life of cone crusher parts and ensuring smooth, efficient operation:

Inspect regularly: Frequent inspections of wear parts like the mantle, concave, and eccentric shaft can help detect early signs of wear and prevent unexpected breakdowns.

Replace wear parts on time: Worn parts should be replaced before they fail completely to avoid costly damage to other components.

Lubricate properly: Regular lubrication of moving parts, such as the main and eccentric shafts, helps reduce friction and prevent excessive wear.

Check alignment: Ensure the main shaft and other key components are correctly aligned to maintain the crusher's balance and performance.

Using Haitian’s durable cone crusher wear parts reduces maintenance frequency, improves uptime, and lowers operational costs, making your cone crusher more reliable in the long run.

In conclusion, cone crushers are complex machines with many critical components that work together to break down materials. Understanding the main parts of a cone crusher, such as the frame, mantle, concave, eccentric shaft, and drive system, is essential for maintaining and optimizing the machine’s performance. Regular maintenance and timely replacement of wear parts can significantly extend the life of your crusher and improve its efficiency.

At Haitian, we provide top-quality wear-resistant parts for cone crushers and other industrial equipment. If you’re looking to maximize the lifespan and performance of your machinery, contact us today to learn more about our range of wear parts and how they can benefit your operation.