Mill wear parts play a critical role in keeping your milling equipment running smoothly. High-quality components reduce wear and tear, which helps avoid costly repairs and downtime. Studies show that tools with optimized geometry, like T6, experience less wear and stress, improving performance and energy efficiency. On the other hand, low-quality materials often lead to frequent breakdowns and production delays, harming productivity. By investing in durable wear parts, you can enhance operational efficiency and save on long-term costs.

Mill wear parts are essential for keeping your equipment operational. When wear parts are in good condition, they ensure consistent machine availability, allowing you to meet production targets without interruptions. Regular inspections help catch issues early, preventing small problems from escalating into major breakdowns. Techniques like vibration analysis and thermal imaging provide real-time insights into wear part performance, helping you avoid unexpected failures. Predictive maintenance strategies, such as AI-driven data monitoring, further enhance machine availability by identifying potential issues before they disrupt operations.

A historical review of maintenance practices highlights the benefits of proactive strategies:

- Inspections reduce unplanned stoppages and mitigate risks.

- Predictive maintenance ensures higher equipment availability by addressing problems early.

- Audit packages optimize production assets and lower costs per ton.

By prioritizing wear part care, you can maximize machine uptime and maintain a steady workflow.

Unplanned downtime can have severe financial consequences for milling operations. Large manufacturing plants lose an average of 323 production hours annually, costing up to $532,000 per hour, according to industry reports. This amounts to a staggering $172 million in annual losses per plant. For smaller operations, downtime costs can still reach $125,000 per hour, with outages occurring monthly. Deferred maintenance often leads to costly repairs, as minor issues grow into major failures.

A reactive approach, such as run-to-failure maintenance, results in frequent disruptions and strains your budget. Proactive measures, including routine wear part replacement, reduce these risks. Regular servicing extends the lifespan of your equipment, minimizes repair costs, and ensures uninterrupted production. By investing in high-quality mill wear parts and maintaining them properly, you can avoid the financial burden of unexpected downtime.

Preventative maintenance is key to extending the lifespan of mill wear parts. Regular checks help identify wear and tear patterns, allowing you to address issues before they lead to equipment failure. Keeping detailed maintenance records aids in predicting when parts need servicing, ensuring your machinery operates efficiently. Historical data also provides valuable insights into performance trends, helping you plan future maintenance effectively.

Preventative measures offer several benefits:

- They reduce downtime by catching problems early.

- They save costs by avoiding major repairs and replacements.

- They improve safety by minimizing the risk of accidents.

Well-maintained wear parts not only enhance productivity but also contribute to the overall durability of your equipment. By adopting a preventative maintenance approach, you can maximize the value of your mill wear parts and ensure long-term operational success.

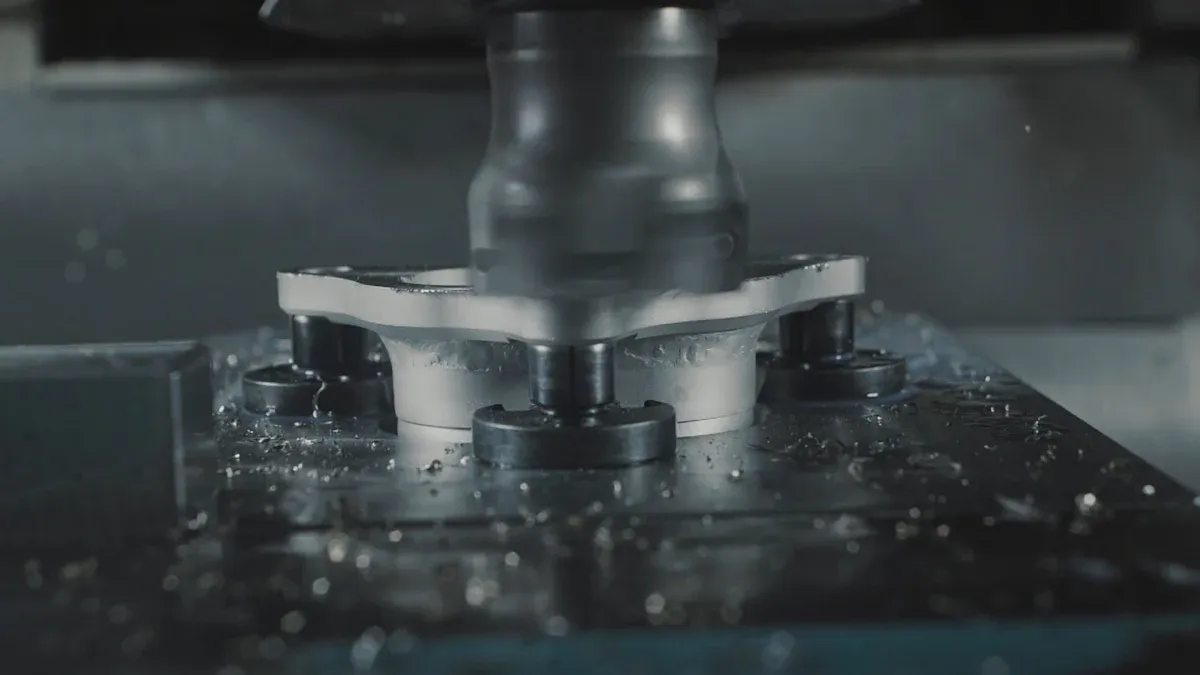

The quality of mill wear parts directly impacts the efficiency of your milling operations. High-quality wear parts improve grinding performance by reducing friction and wear, which allows your equipment to operate at optimal levels. When wear parts are designed with precision, they enhance the grinding process, leading to finer and more consistent output.

Upgrades and rebuilds of wear parts can significantly boost efficiency. These processes extend the life of your equipment and reduce energy consumption. For example, audits of grinding mills often reveal opportunities to optimize performance by replacing outdated or worn components. By investing in superior wear parts, you can achieve greater productivity while lowering operational costs.

Choosing the right materials for mill wear parts is essential for maximizing their performance and durability. Materials like tungsten carbide and high-chromium steel offer excellent resistance to wear and tear. These materials withstand the harsh conditions of milling operations, ensuring that your equipment remains reliable over time.

When selecting materials, consider the specific needs of your operation. For instance, if your mill processes abrasive materials, you should prioritize wear parts made from highly durable alloys. Manufacturers often provide detailed specifications for their products, helping you make informed decisions. By selecting the best materials, you can reduce the frequency of replacements and improve the overall efficiency of your milling equipment.

Real-world examples highlight the benefits of upgrading mill wear parts. Companies that invest in advanced materials and designs often see significant improvements in efficiency and equipment lifespan.

| Source | Evidence |

|---|---|

| Element Six | Upgraded tungsten carbide supermaterials enhance wear resistance, increasing lifespan and operational efficiency. |

| Metso | Codelco Andina increased Symons crusher availability by 23% through upgrades. |

These examples demonstrate how high-quality wear parts can transform milling operations. By adopting similar strategies, you can achieve better results and reduce downtime in your facility.

Investing in durable wear parts can lead to significant long-term savings. High-quality components last longer, reducing the frequency of replacements and minimizing maintenance costs. For example, Company XYZ, a manufacturing firm, faced high expenses due to poor spare parts management. By analyzing their inventory and partnering with reliable suppliers, they streamlined their processes and reduced costs. A proactive maintenance program further lowered emergency repair expenses, demonstrating how durable wear parts contribute to financial efficiency.

Durable parts also improve equipment reliability, which helps you avoid costly downtime. When your machinery operates smoothly, you can maintain consistent production levels and meet customer demands without interruptions. Over time, these savings add up, making durable wear parts a smart investment for any operation.

Low-quality components may seem cost-effective initially, but they often come with hidden ex penses. These include frequent repairs, higher energy consumption, and reduced equipment lifespan. Owning a CNC milling machine, for instance, involves costs like tooling, software updates, and operator training. Poor-quality parts exacerbate these expenses by requiring more frequent maintenance and updates.

| Hidden Costs of Poor Quality | Description |

|---|---|

| Potential lost sales | Missed opportunities due to inadequate quality. |

| Costs of redesign | Expenses from modifying products to fix issues. |

| Scrap not reported | Waste that is not accounted for in financial records. |

| Management time demands | Time spent resolving quality-related problems. |

Understanding these hidden costs is crucial. By prioritizing high-quality components, you can reduce waste, improve efficiency, and save money in the long run.

Replacing wear parts strategically can help you save money while maintaining equipment performance. Start by evaluating the warranty period of your parts. If a part is still under warranty, repairs may be more cost-effective than replacement. Compare the costs of repair versus replacement to ensure you make the best financial decision.

Consider asset lifecycle management to plan for long-term maintenance and operational costs. Minimizing downtime is also essential. Assess how long your equipment will be out of service and schedule replacements during planned maintenance periods. Finally, prioritize safety. Frequent breakdowns can pose risks, so addressing wear part issues promptly is critical.

Data shows that repairing or re-engineering components can save up to 50% compared to buying new parts. By carefully evaluating your options, you can reduce expenses and keep your operations running smoothly.

Proper care of wear parts directly impacts the durability of your equipment. When you maintain these components, you reduce wear and tear, ensuring smoother operations and fewer breakdowns. Comprehensive maintenance practices, such as regular inspections and proper calibration, play a vital role in extending equipment lifespan.

Routine maintenance minimizes downtime and lowers repair costs.

Preventive care, including cleaning and timely part replacement, keeps equipment running efficiently.

A well-documented maintenance plan helps you avoid risks associated with improper operation.

By building a comprehensive inventory and maintenance schedule, you can ensure your equipment remains in optimal condition. Proactive care not only enhances durability but also improves accuracy and reliability in your operations.

Adopting effective maintenance practices can significantly extend the life of your wear parts. Predictive maintenance techniques, such as advanced monitoring systems, allow you to track performance and identify potential issues before they escalate. Following a structured checklist for regular inspections, cleaning, and lubrication ensures consistent performance.

Conduct regular inspections to detect wear and misalignments early.

Use surface treatments and repairs to address common issues and prolong tool life.

Recondition worn parts to restore their functionality and reduce replacement costs.

These practices not only extend the lifespan of wear parts but also improve the overall efficiency of your equipment. A proactive approach to maintenance saves time and money while ensuring uninterrupted operations.

Knowing when to replace wear parts is crucial for maintaining equipment performance. Sensor data and operational metrics provide valuable insights into the condition of your machinery. Predictive maintenance systems forecast when parts need attention, allowing you to schedule replacements proactively.

| Metric Type | Description |

|---|---|

| Predictive Maintenance | Utilizes sensor data to forecast when maintenance is needed, allowing for proactive scheduling. |

| Condition-Based Maintenance | Monitors equipment condition to optimize maintenance schedules and minimize unnecessary interventions. |

| Improved Asset Tracking | Tracks performance and maintenance history to inform decisions on repairs or replacements. |

Additionally, tracking metrics like Mean Time Between Failures (MTBF) helps you evaluate the effectiveness of your maintenance strategy. By replacing wear parts at the right time, you can prevent costly breakdowns and maintain consistent productivity.

Mill wear parts are essential for keeping your equipment efficient and reliable. Regular maintenance and high-quality components reduce wear and tear, ensuring consistent performance. Preventive maintenance may require an initial investment, but it saves money by extending equipment lifespan and minimizing downtime. Addressing wear early prevents costly replacements and maximizes your return on investment. By prioritizing durable wear parts, you can maintain steady production schedules and achieve long-term success.

Investing in reliable wear parts is not just a cost-saving measure—it’s a strategy for operational excellence.

Mill wear parts are components in milling equipment that experience wear during operation. These include grinding plates, hammers, and liners. They ensure smooth functioning by reducing friction and wear, which helps maintain efficiency and prolong equipment life.

Replacement frequency depends on usage, material processed, and maintenance. Regular inspections help identify wear patterns. For optimal performance, follow the manufacturer’s guidelines and replace parts before significant wear impacts efficiency.

Material selection affects durability and performance. High-quality materials like tungsten carbide or high-chromium steel resist wear better. Choosing the right material ensures longer part life, reduces replacements, and improves milling efficiency.

Yes, preventative maintenance reduces downtime and avoids costly repairs. Regular checks catch issues early, extending the lifespan of wear parts. This proactive approach minimizes unexpected expenses and ensures consistent production.

Monitor performance metrics like Mean Time Between Failures (MTBF). Use predictive maintenance tools to track wear. Replace parts showing significant wear or reduced efficiency to prevent equipment damage and maintain productivity.

Tip: Keep detailed maintenance records to predict replacement needs accurately.