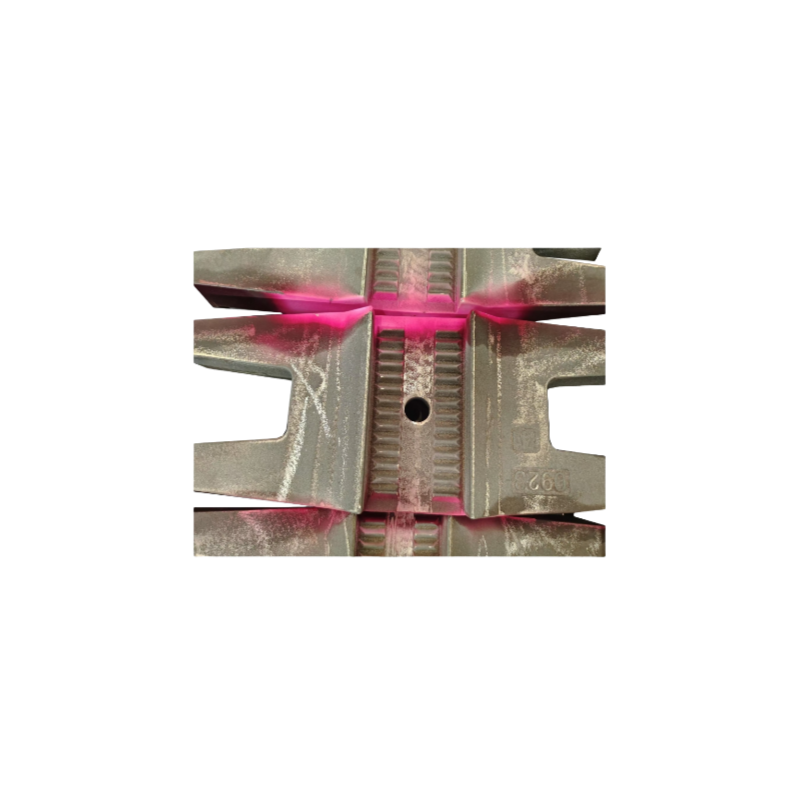

Asphalt Side Lining

Material:W3

Application:Asphalt Side Lining

Process: DISA Vertical Line

Features:Strong Wear Resistance,High Temperature Resistance,High Strength,Good Processing Performace,Corrosion Resistance,Easy to Replace and Maintain,High Efficiency.

- Product Description

- Product Specifications

- Product Advantages

- More Details

Asphalt side lining is a critical feature used in road construction and maintenance, designed to reinforce and protect the edges of pavements by applying a robust asphalt layer. It primarily serves to stabilize the pavement structure and prevent erosion or cracking caused by environmental factors and traffic loads. An effective asphalt side lining design enhances durability and reduces the need for frequent repairs, thereby improving the longevity and cost-efficiency of the roadway. High-quality side lining minimizes damage to adjacent pavement sections by resisting wear and weathering, extending the overall service life of the infrastructure while lowering maintenance costs. Well-implemented side lining reduces the risk of structural failures, such as edge collapse or water infiltration, ensuring safer and more reliable road conditions. By preventing material degradation and loss at the pavement edges, asphalt side lining optimizes resource use and reduces waste, contributing to more sustainable construction practices. The consistency and strength of the side lining directly influence the road’s performance, helping to meet engineering standards and ensure high-quality outcomes. Through its protective and stabilizing functions, asphalt side lining indirectly supports environmental goals by reducing resource consumption and the need for repetitive repairs.

Product Specifications

| Product Name | Material | Weight(kg) | Service Life | Precision | Delivery Time | Model | Spray Painting | Inspection |

| liner | W3 | 17.5 | 100,000batches | CT9 | 7-10/15-20days | all series | 100% Inspection |

PRODUCT ADVANTAGES

-

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok