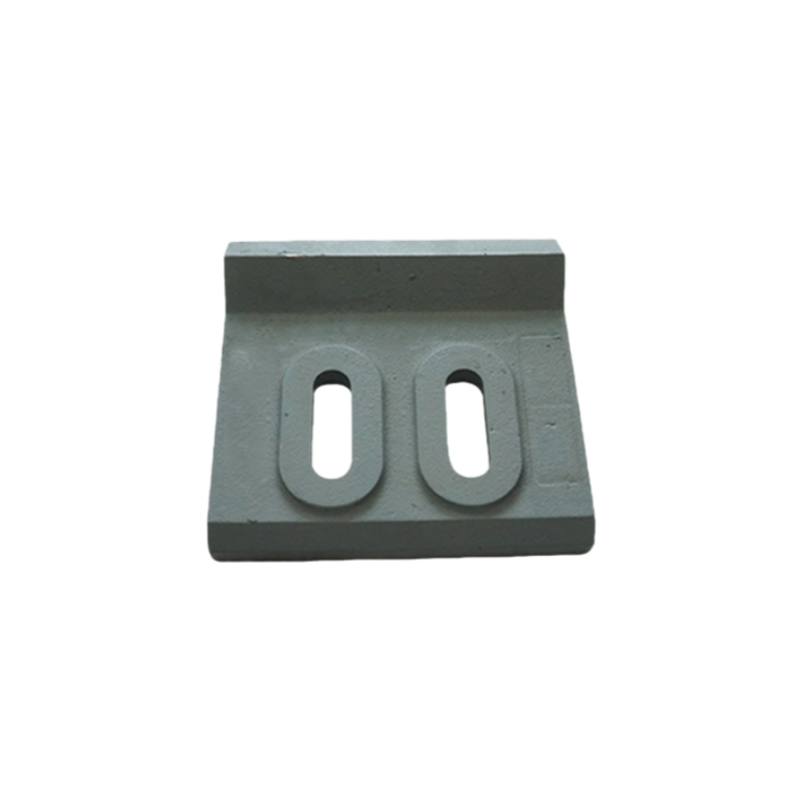

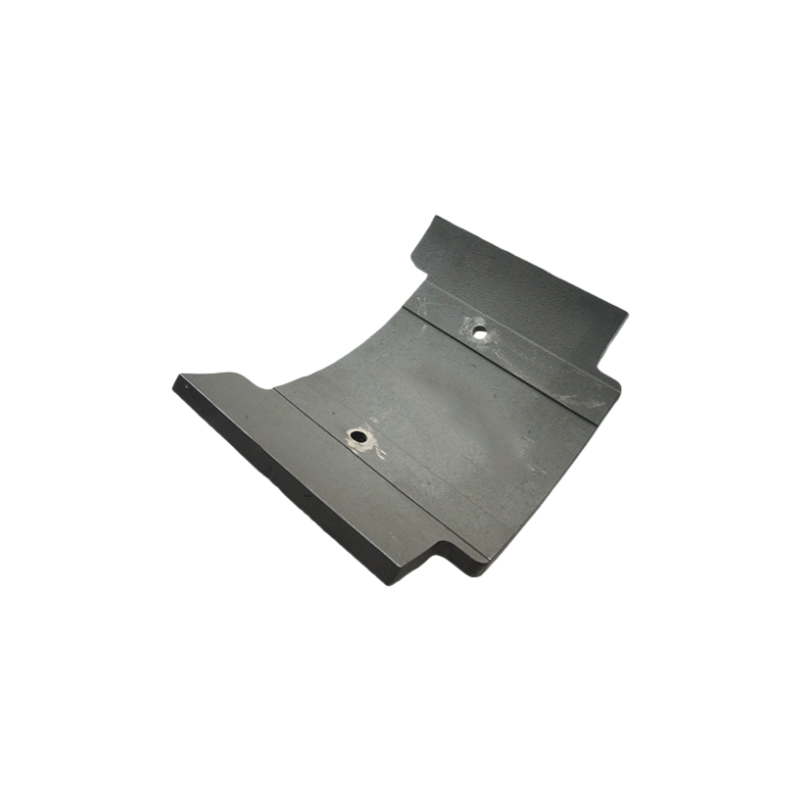

Spiral Blade-Asphalt Mixing Plant

Material:High Chromium Cast Iron

Application:Asphalt Mixing Plant

Process:DISA Vertical Line

Features:Conveying and Mixing Functions,High Wear Resistance,Design Fexibility,High Efficiency,High Temperature Resistance,Easy Maintenance.

- Product Description

- Product Specifications

- Product Advantages

- More Details

The spiral blades can effectively mix asphalt and aggregate to ensure the uniformity of the mixture. This is crucial to the quality of the final paved road surface, as a uniform mixture can ensure that the paved road surface is smooth and consistent, avoiding unevenness or falling off.

The spiral blades are responsible for conveying the mixture from the hopper to the paving parts of the paver. Efficient conveying can ensure the continuous operation of the paver and reduce the fluctuation of the material volume in the hopper, thereby improving work efficiency and production capacity. Through uniform conveying and mixing, the spiral blades help to achieve precise material laying, which is of great significance for ensuring construction quality, improving pavement durability and extending the service life of the road. The ability to complete the mixing of asphalt and aggregate in a short time reduces the pretreatment time and improves the overall construction speed and production efficiency. Highly wear-resistant materials and reasonably designed spiral blades reduce the failure rate and maintenance frequency, and reduce the cost of maintenance and replacement. This is of great significance for long-term operation and management. Uniform conveying and mixing can reduce unexpected failures during operation and ensure the smooth progress of the construction process, thereby improving overall construction safety. The design can adapt to different types of asphalt mixtures and construction environments, and has strong adaptability, which enables the paver to play a role in various road construction projects.

Product Specifications

| Product Name | Material | Weight(kg) | Service Life | Precision | Delivery Time | Model | Spray Painting | Inspection |

| spiral blade | HP-4s | 3.6 | 100,000batches | CT9 | 7-10/15-20days | all series | √ | 100% Inspection |

PRODUCT ADVANTAGES

-

HIGH ASSEMBLY PRECISION

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

LONG SERVICE LIFE

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

STABLE QUALITY

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok