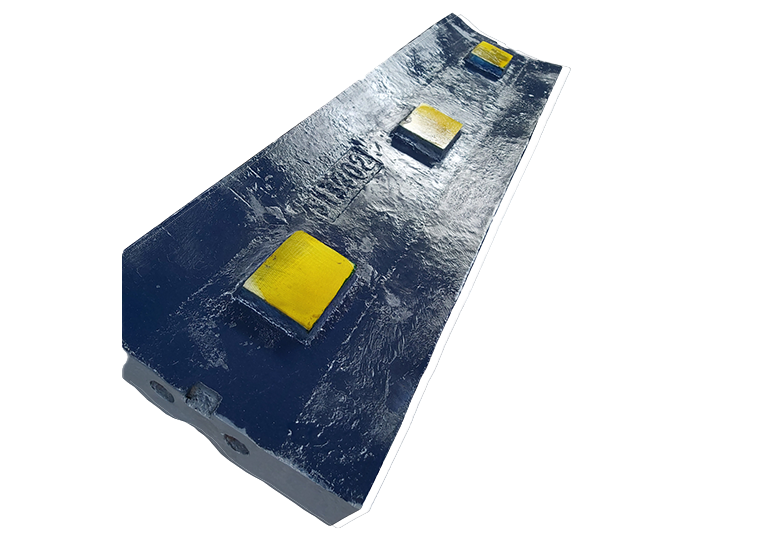

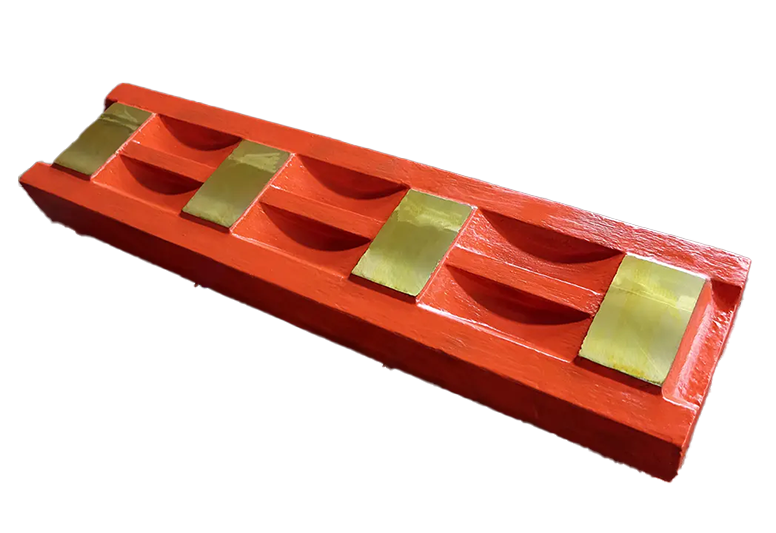

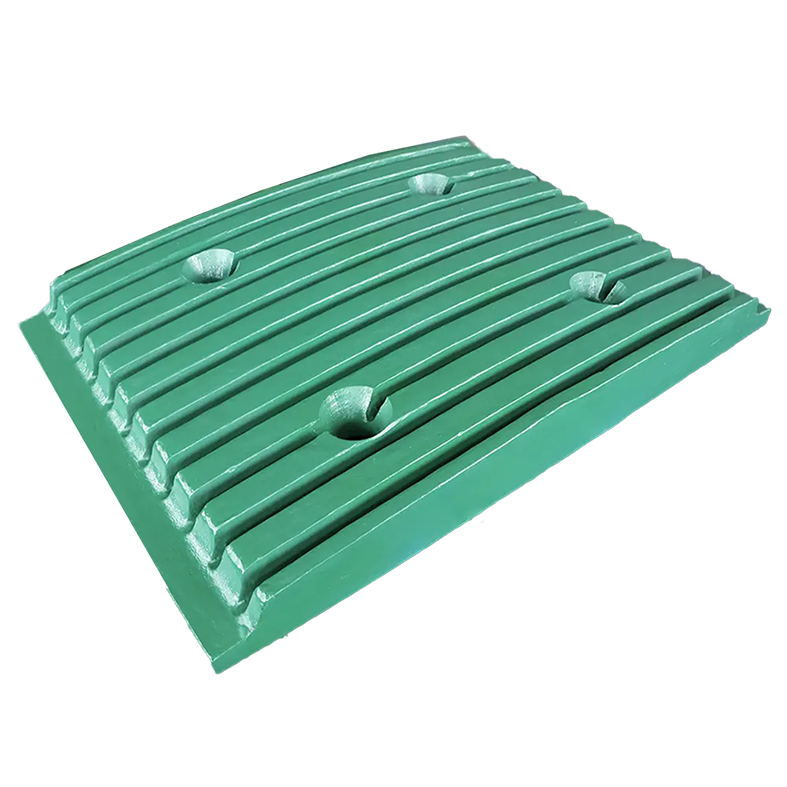

Superior Wear-Resistant Plates for Heavy-Duty Applications

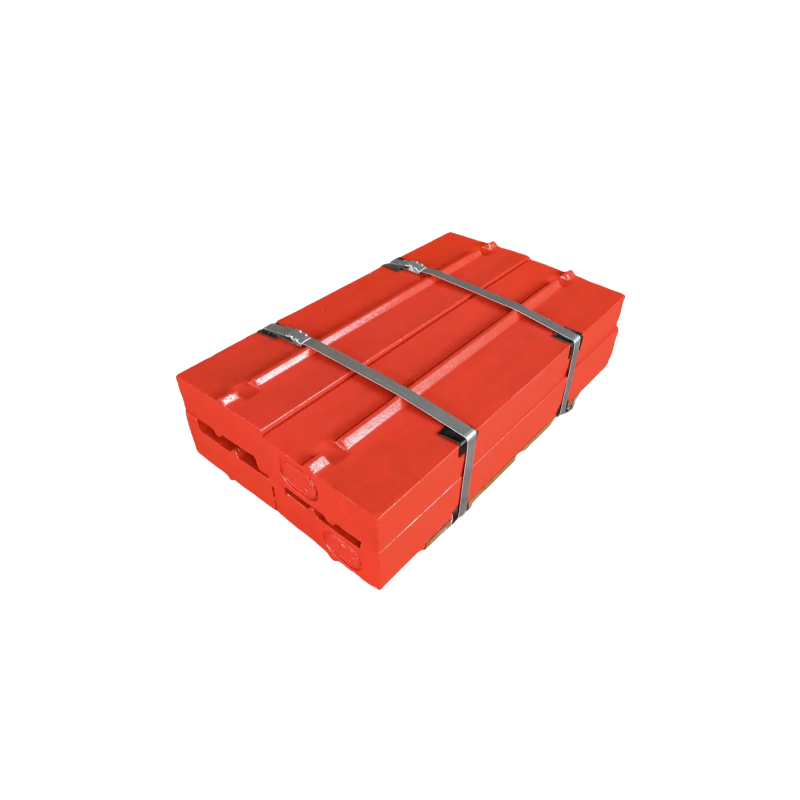

Material:Mn21Cr2 Mn13Cr2 Mn18Cr2

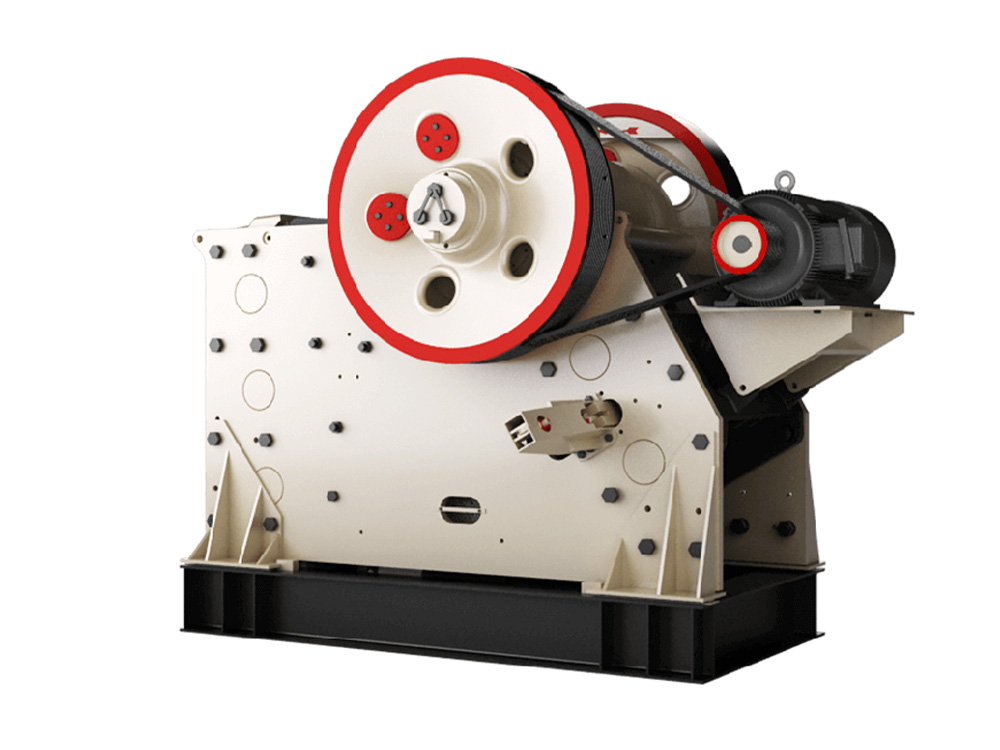

Application:Jaw Crusher

Process:Resin Sand

Features:Wear Resistance,Strength and Toughness,Design Optimization,Corrosion Resistance,Easy to Replace,Processing Accuracy.

- Product Description

- Product Specifications

- Product Advantages

- More Details

High-performance wear-resistant components are widely applied in industries such as mining, construction, concrete and asphalt production, steel manufacturing, and other challenging environments. These components, including crushers, conveyor belts, mixer paddles, excavator buckets, and protective liners, are meticulously engineered to endure extreme abrasion, impact, and wear, greatly enhancing the durability and reliability of machinery.

Crafted from premium alloy steel, these components undergo advanced manufacturing processes such as precision smelting, casting, and heat treatments (e.g., quenching and tempering) to achieve optimal hardness and toughness. This combination ensures that the surface remains highly resistant to wear, while the core maintains flexibility and shock-absorbing capabilities. Furthermore, surface treatments like sandblasting and protective coatings can further enhance corrosion resistance, making them more suitable for use in harsh, corrosive environments.

The key advantages of these wear-resistant components include exceptional hardness, superior wear resistance, and high impact strength, making them perfect for demanding operational conditions. Even under high-pressure and high-temperature situations, they exhibit remarkable durability, reducing maintenance requirements and minimizing equipment downtime. Compared to conventional materials, these components offer a longer service life and provide excellent cost-efficiency, leading to increased productivity and reduced operational costs.

Product Specifications

| Product Name | Material | Weight(kg) | Service Life | Precision | Delivery Time | Model | Spray Painting | Inspection |

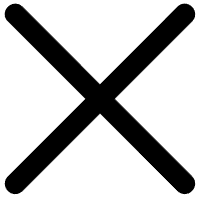

| Jaw Plate | Mn13+Cr2 | 2000 | 3-6 moths | CT9 | 7-10/15-20 Days | All Series | √ | 100% Inspection |

PRODUCT ADVANTAGES

-

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok