You rely on paving equipment to deliver consistent, high-quality results. Paver wear parts play a critical role in maintaining this efficiency. By reducing wear and tear, these components enhance durability and minimize the need for frequent repairs. Jon Anderson from Caterpillar emphasizes that proper maintenance and operator training significantly improve machine performance, reducing wear and fuel consumption. Advanced technologies, like Astec Digital’s telematics systems, further optimize resource allocation and decision-making. With high-quality wear parts, you can extend equipment lifespan, reduce downtime, and achieve long-term savings.

Paver wear parts are specialized components designed to withstand the intense wear and tear that paving equipment endures during operation. These parts protect critical machinery from damage caused by friction, impact, and abrasion. By acting as a shield, they help maintain the integrity of your equipment and ensure consistent performance. Whether you’re working on asphalt or concrete surfaces, wear parts play a vital role in keeping your machines running smoothly.

Several types of wear parts are commonly used in paving equipment. Screed plates, augers, and conveyor chains are essential for distributing and leveling materials. Wear-resistant cutting edges and carbide tips enhance the durability of tools used for precise cutting and shaping. Rollers and track pads ensure smooth movement while reducing surface damage. Each type of wear part is tailored to specific functions, making it easier for you to achieve optimal results in your paving projects.

Wear parts are more than just protective components; they actively enhance the performance of your paving equipment. For example, features like dual carbide rings prevent body wear and maximize the use of carbide tips, extending tool life. Strategically placed additional carbide rings reduce premature wear and tool failure. Maintaining puller groove performance ensures easy removal and minimizes wear on washers and blocks throughout the tool's life.

| Feature | Benefit |

|---|---|

| Dual carbide rings | Prevents body wear and maximizes carbide tip use, extending tool life. |

| Additional carbide ring location | Strategically placed to prevent body wash, reducing premature wear and tool failure. |

| Maintains puller groove performance | Ensures easy removal and reduces wear on washer and block throughout the tool's life. |

By incorporating these advanced features, paver wear parts improve efficiency, reduce downtime, and help you complete projects faster.

Paver wear parts significantly improve the performance of your paving equipment. High-quality components reduce friction and wear, allowing machines to operate more smoothly and efficiently. For instance, screed plates and augers ensure even material distribution, which leads to a more uniform surface finish. This precision minimizes the need for rework, saving you time and resources.

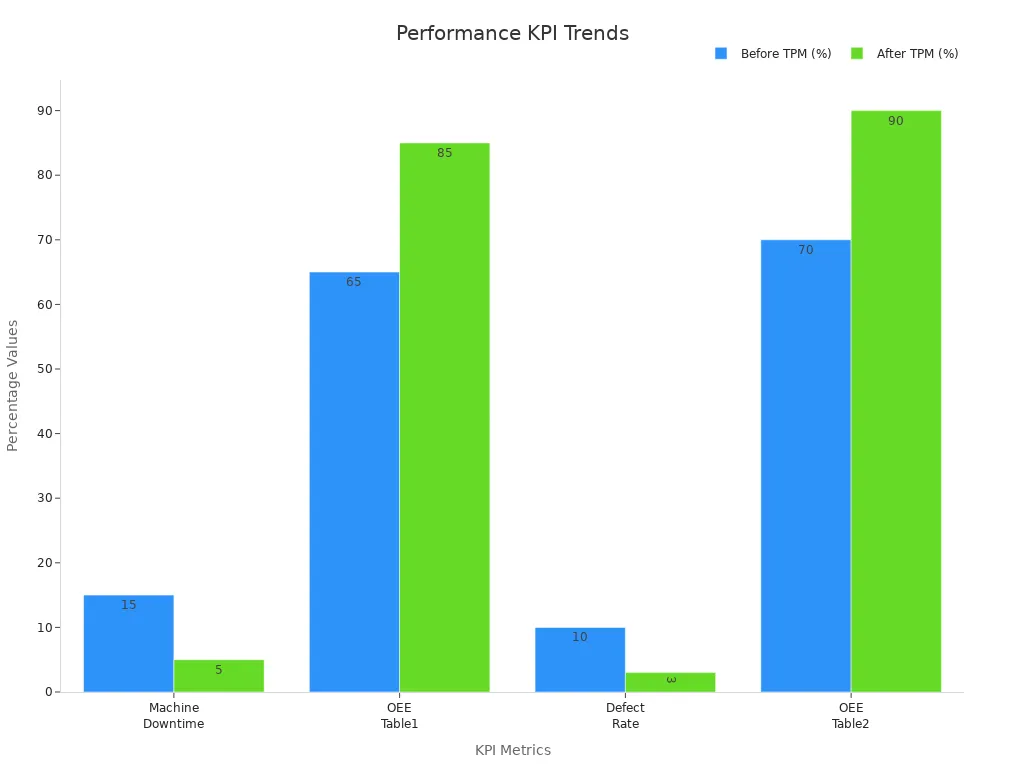

Quantifiable improvements in machine performance highlight the value of wear parts. A study comparing key performance indicators (KPIs) before and after implementing wear parts shows remarkable results:

| KPI | Before Wear Parts | After Wear Parts |

|---|---|---|

| Machine Downtime | 15% | 5% |

| Overall Equipment Effectiveness (OEE) | 65% | 85% |

| Maintenance Costs | $500,000 | $300,000 |

These improvements demonstrate how wear parts enhance productivity while reducing operational costs.

Using durable paver wear parts extends the lifespan of your equipment. These components act as a protective barrier, shielding critical machinery from damage caused by abrasion and impact. By reducing wear and tear, you can avoid premature equipment failure and costly replacements.

Field data supports this claim. Thin overlays, for example, typically last between 7 and 12 years when wear parts are used effectively. Performance indicators such as rutting, cracking, and roughness remain within acceptable limits, ensuring long-term reliability. The International Roughness Index (IRI) for treated surfaces stays below 1.5 m/km even after six years, showcasing the durability of wear parts.

| Findings | Description |

|---|---|

| Life Expectancy | Thin overlays last between 7 and 12 years. |

| Performance Indicators | Evaluated through rutting, cracking, and roughness. |

| Roughness Maintenance | IRI below 1.5 m/km even after 6 years. |

| Deterioration Reduction | Up to 84% decrease in progression compared to untreated sections. |

By investing in high-quality wear parts, you ensure that your equipment remains operational for years, reducing the need for frequent replacements.

Downtime can disrupt your projects and increase costs. Paver wear parts help you minimize these interruptions by improving equipment reliability. Predictive maintenance (PdM) strategies, enabled by durable wear parts, allow you to identify potential failures early. This proactive approach prevents unplanned breakdowns and ensures consistent operation.

Key benefits of using wear parts include:

- Early detection of issues through predictive maintenance.

- Increased plant availability and process stability.

- Reduced maintenance costs by avoiding unplanned repairs.

- Maximized utilization of wear parts, saving material and labor costs.

By reducing downtime, you can complete projects on schedule and improve overall productivity. Reliable equipment also enhances your reputation, as clients value timely and efficient work.

High-quality wear parts reduce the frequency of repairs and replacements, saving you significant costs over time. These components are designed to withstand harsh conditions, minimizing the risk of unexpected failures. Preventive maintenance becomes more effective when paired with durable wear parts, as it helps you address potential issues before they escalate.

| Main tenance Type | Benefits | Cost Implications |

|---|---|---|

| Preventive Maintenance (PM) | Reduces downtime, extends equipment lifespan | Additional cost if applied excessively |

| Corrective Maintenance (CM) | Addresses defects, reduces rework | Higher downtime costs, longer execution time |

By focusing on preventive maintenance and using reliable wear parts, you can avoid the high costs associated with corrective maintenance. This approach not only saves money but also ensures your equipment operates efficiently for longer periods.

Investing in high-quality wear parts directly impacts your productivity. These components enhance machine performance, allowing you to complete projects faster and with greater precision. As equipment utilization increases, you unlock hidden capacity, enabling your machines to produce more efficiently.

Improved wear parts reduce maintenance interruptions, keeping your projects on schedule.

Enhanced equipment performance leads to higher output and better quality results.

Monitoring equipment performance through production data helps optimize productivity.

For example, replacing worn-out parts with high-quality alternatives minimizes delays caused by breakdowns. This proactive approach ensures your team can focus on completing tasks rather than addressing unexpected issues. A safer working environment is another benefit, as reliable components reduce the likelihood of accidents caused by equipment failure.

Durable wear parts offer sustained financial advantages by reducing operational costs and extending equipment lifespan. Long-term durability tests, such as accelerated aging and freeze-thaw cycles, confirm the reliability of these components under various conditions. These tests highlight the importance of investing in materials that perform well over time.

A study on paver block production emphasizes the need for long-term durability tests to assess material performance in different environments. This analysis confirms the cost benefits of using durable components, as they reduce the need for frequent replacements and repairs.

By choosing high-quality wear parts, you make a smart investment that pays off in the long run. Reduced maintenance costs, improved productivity, and extended equipment life all contribute to significant savings over time.

Choosing wear parts with high material quality ensures better performance and longevity. You should evaluate the durability, strength, and resilience of the materials used. Look for components that comply with industry standards and regulatory requirements. This guarantees that the parts can withstand the harsh conditions of paving operations.

Technical evaluations can help you assess material quality effectively. Key factors to consider include:

- Dimensional stability

- Tensile and tearing strength

- Abrasion resistance

- Seam and pocket strength

- Bursting strength

- Appearance evaluation

- Colorfastness

These evaluations provide insights into how well the materials will perform under stress. By focusing on these aspects, you can select wear parts that offer maximum durability and reliability for your equipment.

Not all wear parts fit every machine. Ensuring compatibility with your equipment model is essential for seamless operation. You should check the specifications of your paving equipment and compare them with the dimensions and features of the wear parts. This step prevents installation issues and ensures optimal performance.

Manufacturers often provide compatibility charts or guidelines to help you make the right choice. If you’re unsure, consult with the supplier or manufacturer directly. Using incompatible parts can lead to inefficiencies, increased wear, and even equipment damage. Taking the time to verify compatibility saves you from costly mistakes and ensures your equipment operates smoothly.

The reputation of the supplier plays a critical role in the quality of wear parts you receive. Research shows that poor supplier practices can lead to negative outcomes, such as regulatory fines and damage to your brand’s reputation. For instance, a 2016 investigation revealed unethical practices in supply chains, resulting in customer protests and loss of trust.

To avoid such risks, evaluate potential suppliers based on their reputation and ethical practices. Look for customer reviews and testimonials to gauge their reliability. A supplier with positive feedback and a strong track record is more likely to provide high-quality, durable wear parts. By choosing a reputable supplier, you reduce risks and ensure consistent performance for your paving equipment.

When choosing paver wear parts, balancing the initial cost with long-term value is essential. While cheaper components may seem appealing, they often lead to higher expenses over time due to frequent replacements and repairs. Investing in high-quality wear parts ensures better durability and performance, saving you money in the long run.

Life-Cycle Cost Analysis (LCCA) is a valuable tool for evaluating the economic efficiency of wear parts. This method considers all future costs, such as maintenance and replacements, and calculates their timing. By using LCCA, you can identify the best value option that delivers reliable performance at the lowest overall cost. For example, durable wear parts may have a higher upfront price, but their extended lifespan reduces the need for frequent replacements, lowering your total expenses over time.

Another useful approach is the Total Cost of Ownership (TCO). This analysis estimates all costs associated with owning wear parts, including purchase, maintenance, and operational expenses. By inflating future costs or calculating their net present value, TCO provides a clear picture of the financial impact of your choices. It helps you make informed decisions that align with your budget and operational goals.

💡 Tip: Consider both LCCA and TCO when selecting wear parts. These methods help you avoid short-term savings that lead to long-term losses.

By focusing on long-term value rather than just the initial cost, you can maximize the efficiency and reliability of your paving equipment. This approach not only saves money but also ensures smoother operations and fewer disruptions to your projects.

Paver wear parts are essential for improving the efficiency and reliability of your paving equipment. By investing in high-quality components, you reduce downtime, enhance performance, and save costs over time. These parts also contribute to long-term operational success by extending equipment lifespan and ensuring compliance with environmental standards.

| Benefit/Cost Saving | Description |

|---|---|

| Lower Operating Costs | Electric pavers have reduced dependency on fossil fuels, leading to lower operational expenses. |

| Reduced Maintenance | Fewer moving parts and no oil changes result in less downtime and lower labor costs. |

| Long-term Investment Benefits | Electric pavers have a longer lifespan due to robust mechanical systems, enhancing ROI. |

| Compliance with Emission Regulations | Investing in electric pavers ensures adherence to tightening environmental regulations. |

| Incentives and Rebates | Financial incentives for using eco-friendly machinery improve the overall return on investment. |

| Enhanced Efficiency | Modern pavers streamline the paving process, saving time and resources. |

| Environmental Sustainability | Zero-emission operation reduces the carbon footprint of construction projects. |

By selecting the right paver wear parts, you ensure your equipment o perates at peak efficiency while achieving significant cost savings. This investment not only supports your immediate project goals but also secures long-term success for your operations.

Look for uneven paving, increased machine vibration, or visible wear on components like screed plates and augers. These signs indicate reduced efficiency and potential damage to your equipment. Replacing worn parts promptly prevents costly repairs and downtime.

Inspect wear parts after every major project or at least monthly during heavy use. Regular checks help you identify wear early, ensuring consistent performance and avoiding unexpected failures.

Yes, low-quality parts wear out faster and fail to protect critical components. This can lead to increased friction, overheating, and equipment breakdowns. Investing in high-quality wear parts ensures better protection and longer equipment life.

No, wear parts must match your equipment model. Using incompatible parts can cause inefficiencies and damage. Always check manufacturer specifications or consult your supplier to ensure proper fit and performance.

Durable wear parts reduce repair and replacement costs. They also minimize downtime and improve machine efficiency, allowing you to complete projects faster. Over time, these benefits outweigh the initial investment, saving you money.

💡 Tip: Keep a maintenance log to track wear part inspections and replacements. This helps you plan ahead and avoid unexpected issues.