Maintaining wear parts in stabilized soil mixing plants plays a vital role in keeping your equipment efficient and reliable. Ignoring this maintenance can lead to reduced productivity, costly repairs, or even sudden equipment failure. Studies reveal that proactive care prevents breakdowns, improves reliability, and minimizes long-term costs. For example, regular inspections and timely repairs can delay expensive replacements by addressing minor issues like rust and leaks. By prioritizing upkeep, you ensure consistent performance, energy efficiency, and extended equipment lifespan. A small effort today can save you from major disruptions tomorrow.

Wear parts are components in machinery that experience gradual degradation due to regular use. In stabilized soil mixing plants, these parts include blades, paddles, and liners. They come into direct contact with abrasive materials like soil, stones, and moisture. Over time, this contact causes wear and tear, reducing their efficiency. You can think of wear parts as the "working hands" of your equipment, constantly exposed to tough conditions.

Wear parts play a critical role in the operation of stabilized soil mixing plants. They ensure the proper blending of soil, water, and stabilizing agents to create a uniform mixture. Blades and paddles, for instance, churn and mix the materials, while liners protect the internal surfaces of the equipment from damage. Without these parts functioning correctly, the mixing process becomes inefficient, leading to inconsistent results. By maintaining these components, you ensure the plant operates smoothly and produces high-quality mixtures.

Several factors accelerate the wear and tear of components in stabilized soil mixing plants:

- The interaction between machinery and soil often leads to friction and wear.

- Abrasive wear is a major cause of damage, especially when soil contains rough particles like stones.

- Soil texture and moisture content also play a role. For example, dry soil with high stone content increases abrasion, while moist soil can reduce wear.

- Surface characteristics of the parts, such as roughness and hardness, influence their resistance to damage.

Understanding these factors helps you take preventive measures, such as choosing high-quality materials and monitoring soil conditions, to extend the lifespan of your equipment.

Neglecting wear parts maintenance directly impacts the efficiency of your stabilized soil mixing plant. Worn-out components like blades and paddles lose their ability to mix materials effectively. This results in uneven mixtures, which compromise the quality of the final product. For instance, if the blades are dull or damaged, they cannot churn the soil and stabilizing agents properly. This inefficiency forces the equipment to work harder, consuming more energy and increasing operational costs.

Tip: Regularly inspect wear parts to ensure they perform at their best. A small effort in maintenance can prevent significant losses in productivity.

Ignoring maintenance often leads to minor issues escalating into major problems. A damaged liner, for example, can expose the internal surfaces of your equipment to abrasive materials. Over time, this causes extensive damage, requiring costly repairs or even full replacements.

A U.S. manufacturer of automotive parts faced severe breakdowns due to neglected maintenance.

This oversight caused prolonged downtime, reduced productivity, and dissatisfied customers.

The case highlights how delaying maintenance can lead to unexpected failures and financial losses.

By addressing wear and tear early, you avoid expensive repairs and extend the lifespan of your equipment. Preventive care always costs less than emergency fixes.

Neglecting wear parts maintenance increases the likelihood of equipment failure, which poses serious safety risks. Malfunctioning machinery can lead to accidents, injuries, or even fatalities. For example, the inadequate maintenance of a soil screener once resulted in a tragic loss of life and heavy penalties for the responsible company.

Regular maintenance checks are essential to prevent malfunctions.

Servicing ensures that all components function safely and efficiently.

Research shows that predictive and preventive maintenance strategies significantly reduce downtime and severe asset damage.

By prioritizing maintenance, you not only protect your equipment but also safeguard the well-being of your team. A well-maintained stabilized soil mixing plant operates smoothly and minimizes risks.

Regular inspections are the cornerstone of wear parts maintenance. By monitoring the condition of components like blades, paddles, and liners, you can identify early signs of wear and address them before they escalate. Inspections optimize equipment performance and safety, reducing unplanned downtime that can lead to financial losses.

Structured maintenance programs enhance reliability and prevent equipment failures.

Proactive approaches, such as condition-based and predictive maintenance, improve equipment reliability.

Reliable machinery minimizes downtime, boosting productivity and saving costs.

For example, Outotec Equipment Inspection services provide valuable data and recommendations that improve decision-making and operational efficiency. KCGM reported significant improvements in equipment reliability after implementing these inspections.

Cleaning and lubrication are essential for maintaining wear parts in stabilized soil mixing plants. Proper cleaning removes abrasive particles that accelerate wear, while lubrication reduces friction and prevents corrosion. These techniques extend the lifespan of components and ensure smooth operation.

| Method | Description |

|---|---|

| PQ Index | Measures magnetizable iron particles, indicating wear severity. |

| AES Iron Content | Assesses iron particles in grease to identify wear types. |

| FTIR Spectroscopy | Analyzes molecular changes in lubricants to detect degradation. |

| Water Content Measurement | Determines water levels in grease, which can lead to corrosion. |

For instance, a high PQ index (over 500) signals acute wear, while a low PQ index (under 50) indicates corrosion. Regular lubrication based on these measurements prevents damage and ensures optimal performance.

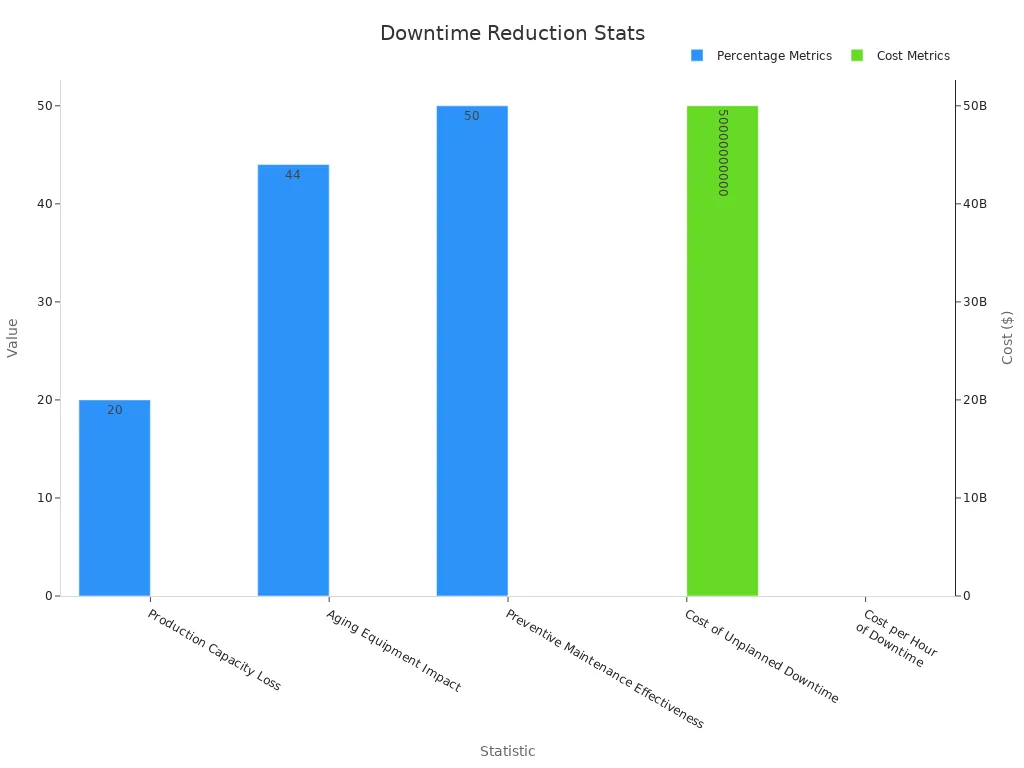

Replacing worn parts promptly prevents equipment failure and reduces downtime. Delaying replacement can lead to severe consequences, including reduced production capacity and increased costs. Studies show that poor maintenance can reduce production capacity by up to 20%, while unplanned downtime costs manufacturers $50 billion annually.

Preventive maintenance strategies, such as timely replacement, significantly reduce downtime. Aging equipment often causes unplanned downtime, but replacing worn parts ensures your stabilized soil mixing plant operates efficiently.

High-quality materials ensure the durability and efficiency of wear parts in your stabilized soil mixing plant. Components made from premium materials resist abrasion and corrosion better than cheaper alternatives. For example, hardened steel or carbide materials can withstand the constant friction and impact caused by mixing soil and stabilizing agents. Using substandard materials may save money initially, but they wear out faster, leading to frequent replacements and higher long-term costs. Investing in superior materials guarantees consistent performance and reduces the risk of unexpected breakdowns.

Finding reliable and durable wear parts requires careful evaluation. Look for components with proven durability and compatibility with your equipment. Check for certifications like ISO, which indicate strict quality control during manufacturing. Wear parts with these certifications often last up to 30% longer than uncertified options. Additionally, consider the balance between cost and durability. While cheaper parts may seem appealing, they often lead to more frequent replacements and increased downtime. Prioritize parts that offer a longer lifecycle and better value over time.

Partnering with trusted suppliers ensures you receive high-quality wear parts and reliable support. Established suppliers often have a proven track record of delivering durable components. They also provide consistent quality, minimizing variations that can affect performance. Trusted suppliers understand the importance of reducing downtime and offer parts designed to maximize productivity. According to industry data, equipment downtime caused by inadequate wear parts can lead to significant productivity losses. By working with reputable suppliers, you gain access to wear parts that balance cost and durability, ensuring your stabilized soil mixing plant operates efficiently.

| Evidence Type | Details |

|---|---|

| Cost vs. Durability | End-user industries prioritize the balance between cost and durability when selecting suppliers. |

| Impact of Downtime | Equipment downtime due to inadequate wear parts can lead to significant productivity losses. |

| Lifecycle Cost Analysis | High-quality wear parts can last up to 30% longer than cheaper alternatives, reducing overall costs. |

| Quality Certifications | Suppliers with ISO certifications ensure consistent quality control, minimizing durability variations. |

| Supplier Relationships | Established suppliers with proven track records are often preferred, even at higher price points. |

Choosing the right supplier not only improves the performance of your equipment but also reduces long-term costs. A trusted partner helps you maintain the efficiency and reliability of your stabilized soil mixing plant.

Maintaining wear parts in stabilized soil mixing plants ensures efficiency and prevents costly breakdowns. Neglecting this care can lead to unplanned downtime, which costs industries billions annually. Predictive maintenance saves up to 40% compared to reactive approaches, making it a smart investment.

| Statistic | Implication |

|---|---|

| Running equipment to failure costs up to 10x more than regular maintenance. | Regular care reduces financial strain and extends equipment life. |

| Every $1 of deferred maintenance quadruples to $4 in renewal costs. | Timely upkeep avoids expensive replacements. |

Invest in high-quality wear parts and adopt proactive maintenance to protect your equipment and your bottom line.

Wear parts are components like blades and liners that experience wear during operation. They ensure your equipment mixes soil efficiently. Without proper maintenance, these parts lose effectiveness, leading to poor performance and costly repairs.

Inspect wear parts weekly or after every major project. Regular checks help you spot damage early and prevent equipment failure. Consistent monitoring ensures your stabilized soil mixing plant operates smoothly.

Yes! Cleaning removes abrasive particles, while lubrication reduces friction and prevents rust. These practices keep wear parts functional longer and improve equipment efficiency. Neglecting them accelerates wear and tear.

Choose wear parts made from durable materials like hardened steel or carbide. Look for certifications like ISO to ensure quality. Reliable parts last longer, reduce downtime, and save money in the long run.

Trusted suppliers provide durable wear parts and consistent quality. They help you avoid downtime caused by substandard components. A reliable supplier ensures your equipment performs efficiently and minimizes unexpected costs.