Mounted close to the drum wall

Prevent dead zones and propel material toward the center

Positioned near the drum axis

Promote vertical circulation for thorough mixing

Arranged in a helical configuration

Provide continuous axial flow, ideal for high-slump or self-compacting mixes

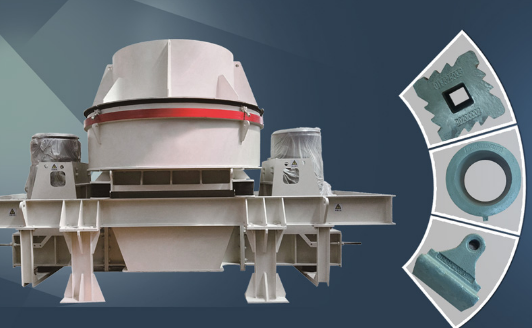

Chromium content: 24–28%

Hardness: 60–64 HRC after quenching and tempering

Microstructure: M7C3 carbides in a resilient matrix ensure up to 50,000 m³ of concrete throughput before replacement

Exceptional surface finish and dimensional accuracy (±0.3 mm)

Ideal for complex spiral geometries

High throughput: 350 molds per shift

Consistent mold quality minimizes porosity and inclusions

Critical sealing surfaces machined to ±0.1 mm

Coordinate metrology (CMM) verifies blade profile

Dynamic balance testing reduces vibration and motor strain

Spiral pitch refined to 30°–35° for optimal flow energy

Thickness tapering: 8 mm leading edge for abrasion zones, tapering to 5 mm at heel for weight control

Anti-adhesion grooves: Surface micro-grooves reduce concrete buildup, ensuring uninterrupted mixing

Enhanced Mix Uniformity: Improved circulation yields up to 15% better homogeneity

Energy Savings: Optimized blade angles cut motor power draw by 8–10%

Extended Service Life: High-chromium blades last 40% longer than standard designs

Rapid Maintenance: Modular attachment points allow blade swaps in under two hours

Smart Blades with integrated wear sensors for predictive maintenance

Ceramic-Composite Coatings to further boost abrasion resistance

Lightweight Alloy Structures combining aluminum cores with wear-resistant liners