Mix Uniformity: Heavier blades generate greater downward force, improving material turnover and reducing dead zones.

Energy Consumption: Excessive blade mass drives up motor load and power draw; underweight blades risk slippage and inconsistent mixing.

Mechanical Stress: Imbalanced or improperly weighted blades accelerate wear on bearings, seals, and drive components.

| Mixer Model | Blade Type | Weight Range (each) |

| Twin-shaft (JS1000) | Side Blade | 28–32 kg |

| Twin-shaft (JS1500) | Spiral Blade | 35–40 kg |

| Planetary (PLD1600) | Center Blade | 22–26 kg |

| Planetary (PLD2400) | Combination Set* | 60–72 kg (set of 2) |

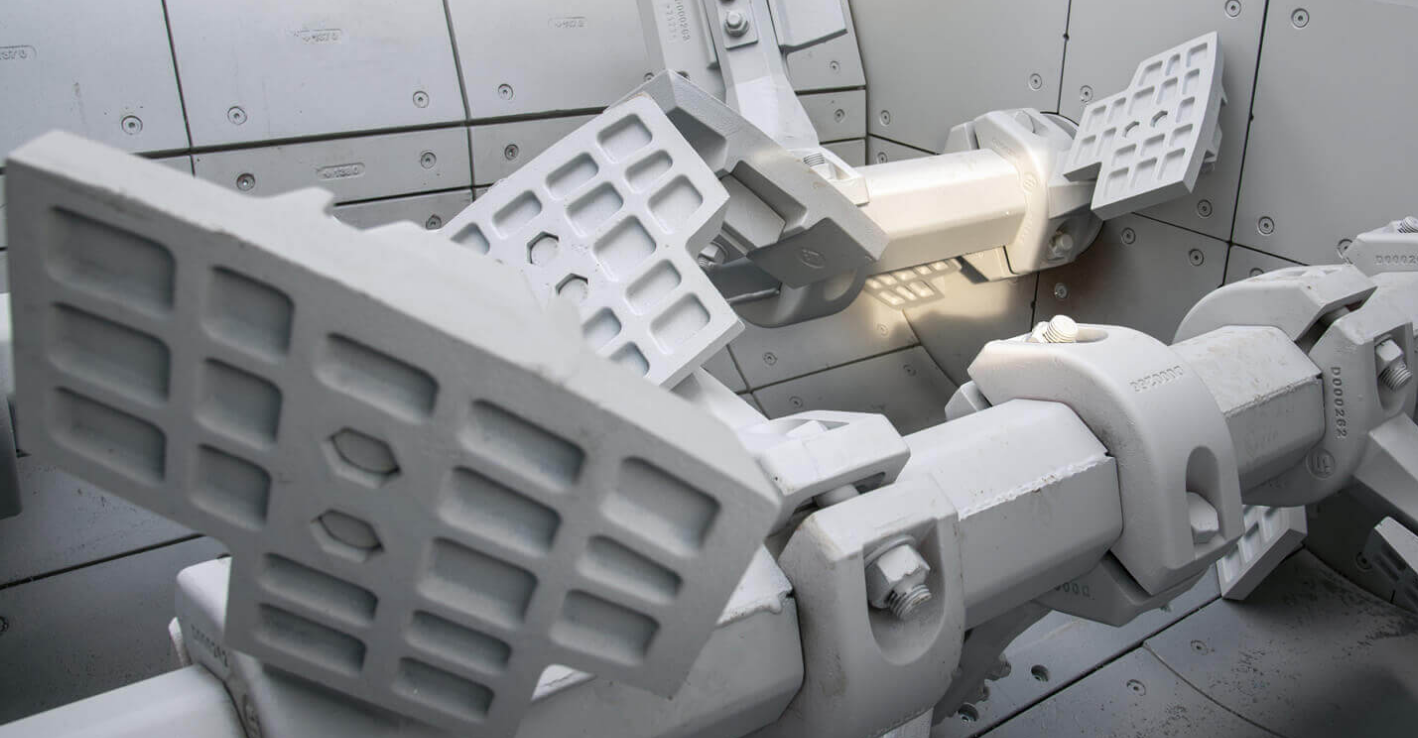

Combination sets include one side plus one central blade tailored to equipment geometry.

Alloy Density: High-chromium alloys exhibit densities of ~7.4 g/cm³—5–10% higher than standard ductile cast iron.

Geometry Optimization: Variable thickness profiles (8 mm at leading edges tapering to 5 mm at heels) reduce unnecessary mass without compromising strength.

Internal Ribbing: Strategic hollow-core and rib structures maintain stiffness while cutting up to 15% of raw material weight.

Automated Sand Molding (DISA Line): Delivers dimensional accuracy of ±0.3 mm, ensuring as-cast weights deviate by no more than ±1.5%.

CNC Machining & Balancing: Machined surfaces and dynamic balancing tests fine-tune each blade’s mass distribution to within ±50 g.

Batch Weighing Control: Every production lot undergoes statistical weight verification; any blade outside tolerance triggers corrective toolpath adjustments.

Stable Torque Profiles: Precisely weighted blades enable predictable motor loading, reducing electrical spikes and mechanical fatigue.

Improved Homogeneity: Controlled mass distribution yields consistent energy transfer to materials, enhancing slump and strength uniformity.

Reduced Downtime: Blades within specification extend bearing and gearbox life by up to 20%, translating to fewer service interruptions.

High-throughput premix plants request heavier spirals for rapid turnover.

Low-energy or solar-powered mixers prefer lighter blades for power constraints.

Mobile compact units require both low weight and high abrasion resistance.