Crushing wear parts are vital for the efficiency and durability of machinery used in mining and construction. These components directly impact how well your equipment performs under demanding conditions. Their optimization can lead to measurable benefits:

Enhanced fragmentation from blasting improves crushing efficiency and lowers energy consumption.

High-energy blasting strategies boost productivity and reduce operational costs.

Adjusting blasting parameters minimizes machinery stops, cutting unnecessary expenses.

Numerical data further highlights their importance. At the Milpillas mine in Mexico, optimized wear parts extended concave segment life from six months to two years, eliminating frequent relines. Similarly, Finland’s Terrafame mine gained an additional five days of uptime annually through wear life improvements. These examples underline how crushing wear parts reduce downtime and maximize performance.

Crushing wear parts are components designed to withstand the intense wear and tear caused by crushing abrasive materials like rocks, ores, and minerals. These parts include items such as liners, mantles, and hammers, which come into direct contact with the materials being processed. Their primary purpose is to protect the machinery while ensuring efficient crushing operations. Regular monitoring of wear profiles helps manufacturers develop optimized liners, improving equipment performance and extending part life.

Crushing wear parts play a critical role in the functionality of crushing equipment. They endure constant friction and impact, which makes them essential for maintaining operational efficiency. By using durable and well-designed wear parts, you can reduce downtime and improve the overall productivity of your machinery. For instance, modular rotor and tool systems enhance performance and extend the lifespan of wear parts. Additionally, innovations in shredder wear parts help lower operational costs and improve efficiency. Proper selection and maintenance of these parts can significantly influence the profitability of your operations.

Several types of crushing wear parts are commonly used in the industry, each serving a specific purpose. These include:

Jaw Plates: Found in jaw crushers, they crush materials by applying pressure.

Mantles and Concaves: Used in cone crushers, they help grind materials into smaller sizes.

Blow Bars: Found in impact crushers, they break down materials through high-speed impact.

Liners: Protect the interior of crushers from wear and tear.

Hammers: Used in hammer mills, they crush materials by striking them repeatedly.

Customizable setups based on specific materials can further enhance the performance of these parts. New materials and designs also improve their durability, leading to lower operational costs and reduced downtime.

High-quality crushing wear parts directly impact the performance of your machinery. These components ensure that your equipment operates efficiently, even under extreme conditions. For example, FLSmidth implemented premium wear parts in their systems, which resulted in a 7% increase in throughput. Additionally, a major gold mine optimized its gyratory crusher with advanced wear parts, quadrupling its operating life. These improvements highlight how the right wear parts can boo st productivity and reduce maintenance needs.

When you use durable and well-designed wear parts, your machinery can handle higher workloads without compromising efficiency. This means fewer interruptions and smoother operations, allowing you to meet production targets consistently.

Crushing wear parts play a crucial role in extending the lifespan of your equipment. By using wear-resistant materials, you can protect your machinery from the constant friction and impact caused by crushing abrasive materials. This reduces the risk of damage and ensures your equipment remains functional for longer periods.

The following table illustrates the benefits of using high-quality wear parts:

| Benefit | Description |

|---|---|

| Equipment Lifespan Extension | Use of wear-resistant materials dramatically extends the lifespan of machinery. |

| Reduced Downtime | Innovations minimize breakdowns, leading to less downtime in operations. |

| Lower Replacement Costs | Enhanced durability reduces the frequency and costs associated with part replacements. |

| Improved Operational Efficiency | Advanced materials enhance performance under extreme conditions, maintaining efficiency. |

| Environmental Sustainability | Reduced part replacements lower environmental impact through recycling and extended lifespan. |

By investing in durable crushing wear parts, you not only extend the life of your machinery but also contribute to a more sustainable and cost-effective operation.

Optimal crushing wear parts can significantly lower your operational costs. For instance, Boliden Kylylahti’s concentration plant installed new crushers, which reduced wear parts expenses. Similarly, the C130 jaw crusher and GP330 cone crusher were noted for cutting spare parts costs, a critical factor in improving overall efficiency.

When you reduce the frequency of part replacements, you save money on both materials and labor. Additionally, fewer breakdowns mean less downtime, allowing you to maintain steady production and avoid costly delays. Over time, these savings can add up, making high-quality wear parts a smart investment for any operation.

Durability and wear resistance are critical features of high-quality crushing wear parts. These components must endure constant friction, impact, and abrasion during crushing operations. To evaluate their durability, manufacturers rely on rigorous laboratory tests. For example:

| Test Type | Description |

|---|---|

| Abrasive Wear Tests | Includes dry-sand, rubber-wheel abrasive wear, Taber Abraser, and more. |

| Impact Wear Tests | Includes ball-on-block impact-spalling and ball-on-ball impact-spalling tests. |

| ASTM Standard Tests | Several tests are recognized as ASTM standards, ensuring reliability and consistency in results. |

| Novel Tests | Includes tests like ball-on-ball impact-spalling and high-speed impact-gouging devised by the Bureau. |

These tests ensure that wear parts can withstand extreme conditions, reducing the need for frequent replacements. By choosing parts with proven wear resistance, you can minimize downtime and maintain consistent performance.

The material composition of crushing wear parts directly affects their strength and longevity. High-quality parts are made from materials that resist stress, puncture, and bursting. The following table highlights key factors influencing material performance:

| Factor | Description | Reference |

|---|---|---|

| Tensile Strength | The maximum stress a material can withstand while being stretched or pulled. | Ali et al. (2018) |

| Puncture Strength | The ability of a material to resist penetration by a sharp object. | Chen et al. (2011) |

| Bursting Strength | The ability of a material to withstand pressure without rupturing. | Tabiei & Nilakantan (2008) |

| Weave Structures | Different weaving techniques that affect the overall strength and durability. | Thiruchitrambalam et al. (2020) |

By selecting wear parts with optimal material composition, you ensure that your equipment can handle demanding workloads without compromising efficiency.

The design and compatibility of crushing wear parts significantly influence their performance. Well-designed parts fit seamlessly into your machinery, reducing wear rates and maintenance costs. For instance, high manganese plates are known for their ability to enhance longevity and efficiency. Collaboration between mechanical and operational teams also plays a vital role in optimizing wear part performance. When teams work together, they can identify the best designs for specific applications, leading to reduced maintenance costs and improved operational efficiency.

Choosing wear parts that align with your equipment's specifications ensures smooth operations and maximizes produ ctivity. Always prioritize compatibility to avoid unnecessary wear and tear on your machinery.

Selecting the right crushing wear parts begins with understanding your operational needs. Every operation is unique, and identifying specific requirements ensures optimal performance. Consider the following factors:

Operational Conditions: Evaluate the type of material you process, its feed size, and the desired end product. These details help determine the most suitable wear part design.

Crushing Goals: Define your objectives, such as achieving a specific product size or shape, to align the wear parts with your goals.

Manufacturer Recommendations: Refer to the manufacturer's guidelines for compatible wear part designs. These recommendations often optimize performance and reduce wear.

Defining your top feed size and overall feed gradation is crucial. This step ensures you choose the right liner configuration and feed opening, preventing premature wear and improving efficiency.

To further refine your selection, follow these steps:

1. Define the feed size and specifications upfront.

2. Share operational data with your wear parts supplier.

3. Consider the material's composition, compressive strength, and chemical properties.

Tailoring wear parts to your specific processes and applications can significantly enhance crusher performance. Data gathering, simulations, and expert analysis often lead to custom solutions that maximize efficiency.

The quality of your crushing wear parts depends heavily on the manufacturer. A reliable supplier ensures durability, compatibility, and performance. When evaluating manufacturers, focus on these aspects:

Material Standards: High-quality wear parts use materials that resist stress, abrasion, and impact. Look for certifications or test results that verify material strength.

Production Processes: Advanced manufacturing techniques, such as heat treatment and precision machining, improve wear part durability.

Customer Support: A good manufacturer provides technical support, helping you select the right parts and offering maintenance advice.

Collaborating with a reputable manufacturer ensures you receive wear parts that meet your operational demands. This partnership can also lead to innovations, such as tailor-made solutions designed for your specific equipment.

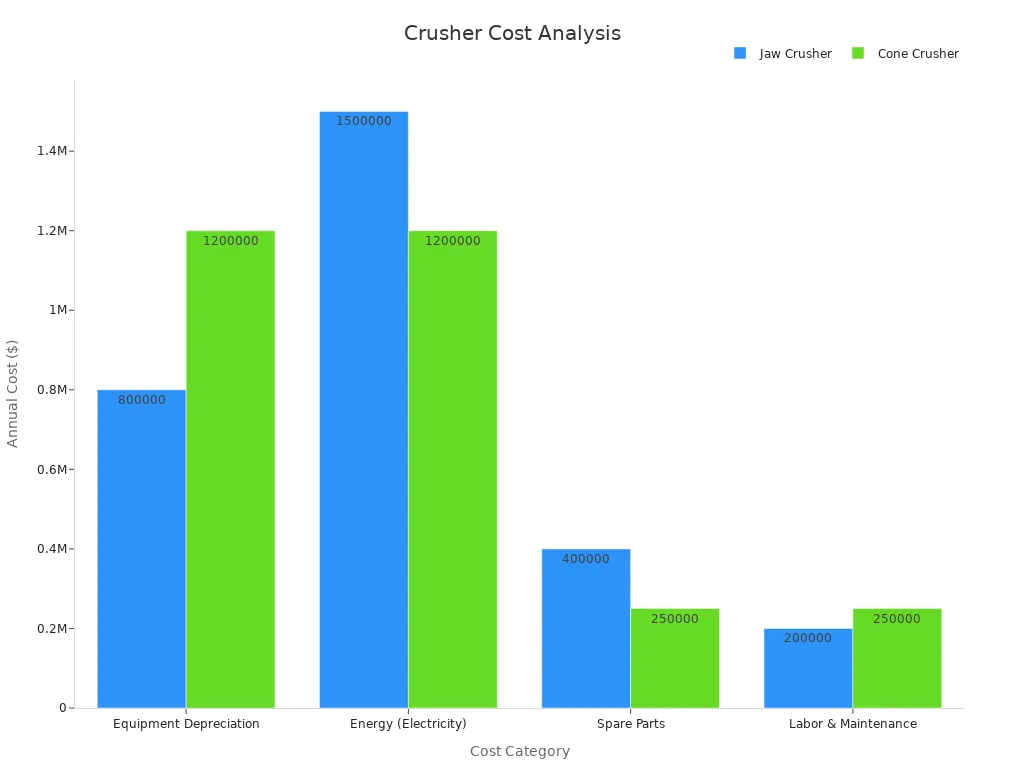

Balancing cost and performance is essential when choosing crushing wear parts. While high-quality parts may have a higher upfront cost, they often reduce long-term expenses by minimizing downtime and replacement frequency. The following table illustrates the annual costs of jaw and cone crushers:

| Cost Category | Jaw Crusher (Annual) | Cone Crusher (Annual) |

|---|---|---|

| Equipment Depreciation | $800,000 | $1,200,000 |

| Energy (Electricity) | $1,500,000 | $1,200,000 |

| Spare Parts | $400,000 | $250,000 |

| Labor & Maintenance | $200,000 | $250,000 |

| Total Cost | $2,900,000 | $2,900,000 |

5-Year TCO: Cone crushers become cost-effective after Year 3 due to lower energy and maintenance costs.

When evaluating costs, consider the total cost of ownership (TCO). This metric includes not only the purchase price but also energy consumption, maintenance, and downtime. Cone crushers, for example, may have higher initial costs but become more economical over time due to their efficiency.

Investing in high-quality wear parts ensures consistent performance and reduces operati onal costs. By balancing cost and performance, you can achieve long-term profitability and operational success.

Regular inspections are essential for maintaining the efficiency of crushing wear parts. These inspections help you identify potential issues before they escalate into costly repairs. For instance, a 1000-hour operating inspection typically takes up to two hours during operation or four to six hours during shutdown. This inspection focuses on reviewing the general condition of equipment, including key wear components, without requiring disassembly. Annual major inspections, on the other hand, involve a more detailed assessment of major components and can take one to two days. These scheduled inspections ensure that wear parts remain in optimal condition, reducing the risk of unexpected downtime.

| Inspection Type | Duration (Operating) | Duration (Shutdown) | Description |

|---|---|---|---|

| 1000-hour Operating inspection | Up to 2 hours | 4-6 hours | General condition review of equipment, including key wear components without disassembly. |

| Wear replacement inspection | N/A | N/A | In-depth inspection during wear replacements, covering bowls, concaves, and other components. |

| Annual major inspection | 1-2 days | N/A | Detailed assessment of major components with measurements, scheduling wear part change-outs. |

Recognizing when to replace crushing wear parts can save you from costly breakdowns. Common signs include visible wear on jaw plates, reduced crushing efficiency, and unusual vibrations or noises during operation. If you notice these issues, it’s time to schedule a replacement. Studies show that effective maintenance practices can significantly reduce downtime. For example, maintenance operations for mining machinery, such as rope shovels, are often completed in under 45 hours, with 80% finalized within a single working shift. This highlights the importance of timely replacements and efficient logistics in minimizing delays.

Following industry-recommended maintenance practices ensures the longevity of your crushing wear parts. Daily inspections should include checking for loose bolts, inspecting jaw plates, and lubricating moving parts. Weekly maintenance involves visual inspections of toggle plates and wear liners. Monthly tasks include detailed checks of mechanical systems and oil levels. An annual overhaul requires disassembling the equipment for a thorough inspection and replacing worn-out parts. These steps not only extend the lifespan of your machinery but also improve operational efficiency.

Daily Inspections: Check for loose bolts, inspect jaw plates, and lubricate moving parts.

Weekly Maintenance: Conduct visual inspections, check toggle plates, and inspect wear liners.

Monthly Maintenance: Perform detailed inspections of mechanical systems and check oil levels.

Annual Overhaul: Disassemble for inspection and replace wear parts.

By adhering to these best practices, you can ensure that your crushing wear parts remain in excellent condition, reducing downtime and operational costs.

Crushing wear parts are vital for keeping your machinery efficient and durable. High-quality components reduce downtime, extend equipment life, and improve overall performance. For example, using medium carbon steel with chromium and silicon adjustments enhances wear resistance and durability. Modern machines with adjustable settings also allow you to fine-tune performance, ensuring energy efficiency and cost savings. Customizing materials for specific applications further boosts performance while reducing wear. By selecting the right parts and maintaining them properly, you can maximize your equipment's potential and achieve long-term operational success.

You might notice reduced crushing efficiency, unusual vibrations, or visible wear on components like jaw plates or liners. These signs indicate that the parts are nearing the end of their lifespan and need replacement to maintain optimal performance.

You should conduct daily visual checks and schedule detailed inspections every 1,000 operating hours. Annual inspections are also essential for assessing major components. Regular inspections help you identify wear early and prevent unexpected downtime.

No, you should avoid using generic parts. Each machine has specific requirements. Using incompatible parts can lead to poor performance, increased wear, and higher operational costs. Always choose parts designed for your equipm ent.

Material composition determines durability and resistance to stress. High-quality materials like manganese steel enhance longevity. Design ensures compatibility with your equipment, reducing wear rates and improving efficiency. Both factors are crucial for optimal performance.

Follow a strict maintenance schedule. Inspect parts regularly, replace them when needed, and use high-quality components. Proper lubrication and avoiding overloading your equipment also help extend the lifespan of wear parts.