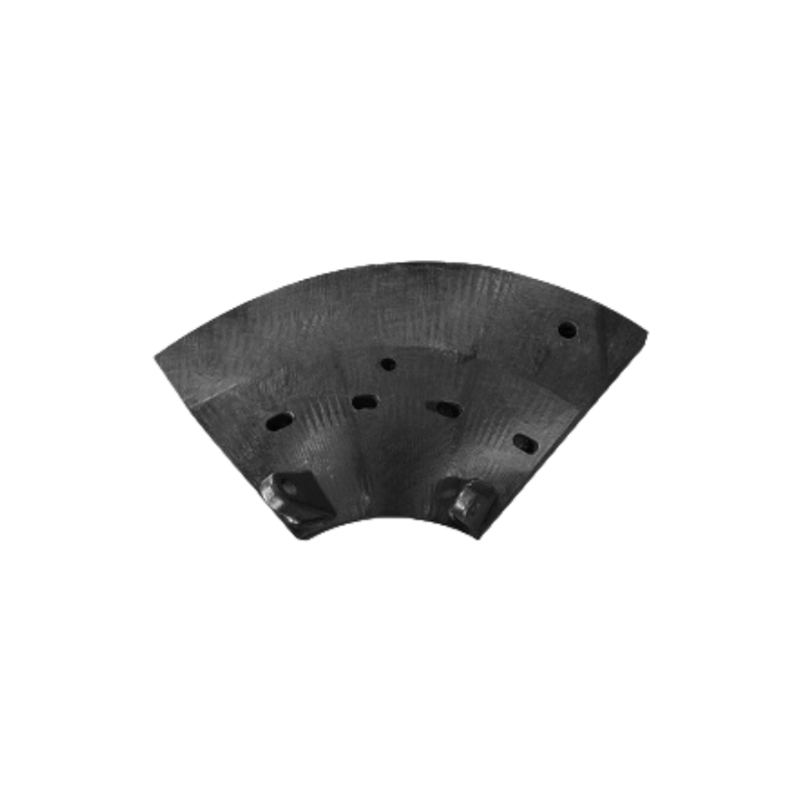

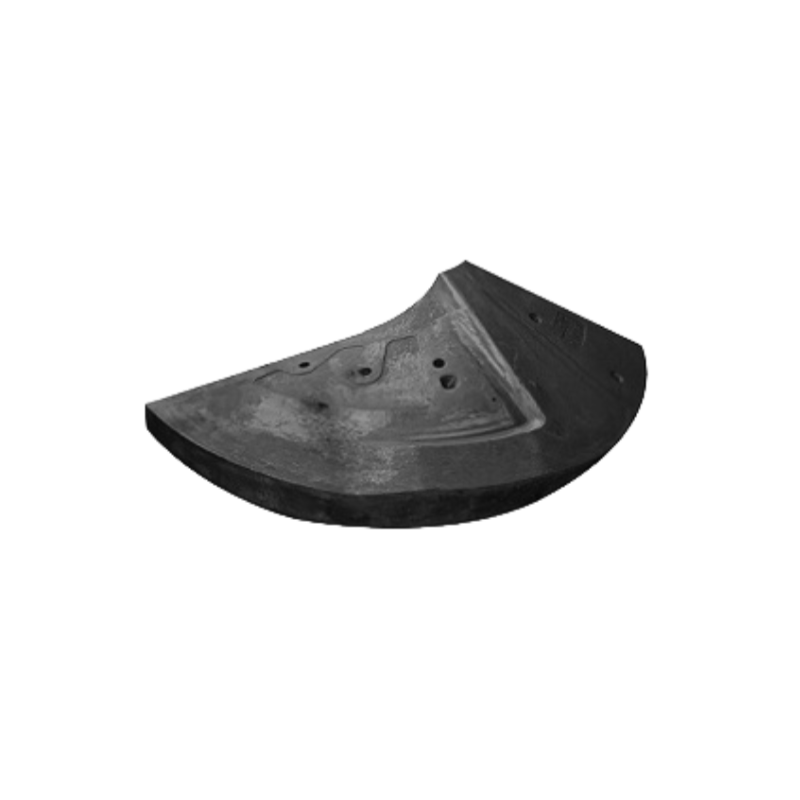

gyratory crusher lining plate

Material: High chromium

Application: Mining、Quarrying、Heavy aggregate industries

Process: 3D-printed Sand Cores,Resin Sand;

Features:High-Chromium Alloy Material, Extended Service Life, strong wear resistance, optimized structure, easy maintenance, long service life, suitable for a variety of working conditions.

- Product Description

- Product Specifications

- Product Advantages

- More Details

Our gyratory crusher liners are engineered for demanding applications in mining and quarrying operations. Made from high chromium cast iron, they offer exceptional wear resistance and impact strength, ensuring reliable performance even under the harshest working conditions.

Field data from mines in South Africa, Chile, and other regions show that our liners deliver over 20% longer service life compared to similar products on the market—significantly reducing replacement frequency and lowering operational costs.

Each liner is produced through precision casting and CNC machining, ensuring tight tolerances and a perfect fit with most major crusher brands. We offer full compatibility across all models and series, along with customization services tailored to specific requirements.

A complete quality inspection report is provided with every order, including chemical composition, hardness, and dimensional accuracy—guaranteeing full traceability and quality assurance from factory to field.

Product Specifications

| Product Name | Hardness | Delivery Time | Model | Spray Painting | Inspection |

|---|---|---|---|---|---|

gyratory crusher lining plate | ≥60HRc | CT10 | 45 Days | Major Brand All Series | 100% Inspection Inspection Report |

PRODUCT ADVANTAGES

-

✅ High Chromium Material

Our wear parts are made from premium high chromium cast iron, specifically engineered to withstand abrasive and high-impact applications. This material ensures long-term durability even under heavy-load operations, reducing downtime and maximizing equipment lifespan.

-

✅ 20% Longer Service Life

Tested and validated in real mining environments across countries such as Chile, South Africa, and Kazakhstan, our products consistently outperform standard components—delivering at least 20% longer service life. This translates to fewer replacements, lower maintenance costs, and improved operational efficiency.

-

✅ Precision Machining

Each part is produced through precision casting and CNC machining, ensuring tight dimensional tolerances. This allows for seamless integration with most major equipment brands, faster installation, and stable high-speed performance in daily operations.

-

✅ Adapted for Harsh Environments

Designed to perform in extreme environments, our components maintain structural integrity and wear resistance even under high-temperature and high-abrasion ore conditions. Ideal for heavy-duty mining, asphalt, concrete, and metallurgical applications.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok