Mining Machinery Series

Haitian casting mainly provides a variety of highly durable and wear-resistant parts for crushers in mining applications. These wear-resistant parts are mainly suitable for impact crushers, cone crushers, jaw crushers and gyratory crushers. These wear parts are made of high-quality alloys with optimal hardness and strength, which can reduce maintenance requirements, extend equipment life and improve crushing efficiency. Haitian has a professional R&D team and advanced R&D equipment, and can provide wear-resistant parts customization services according to your specific machinery usage needs.

- Impact Crusher Parts

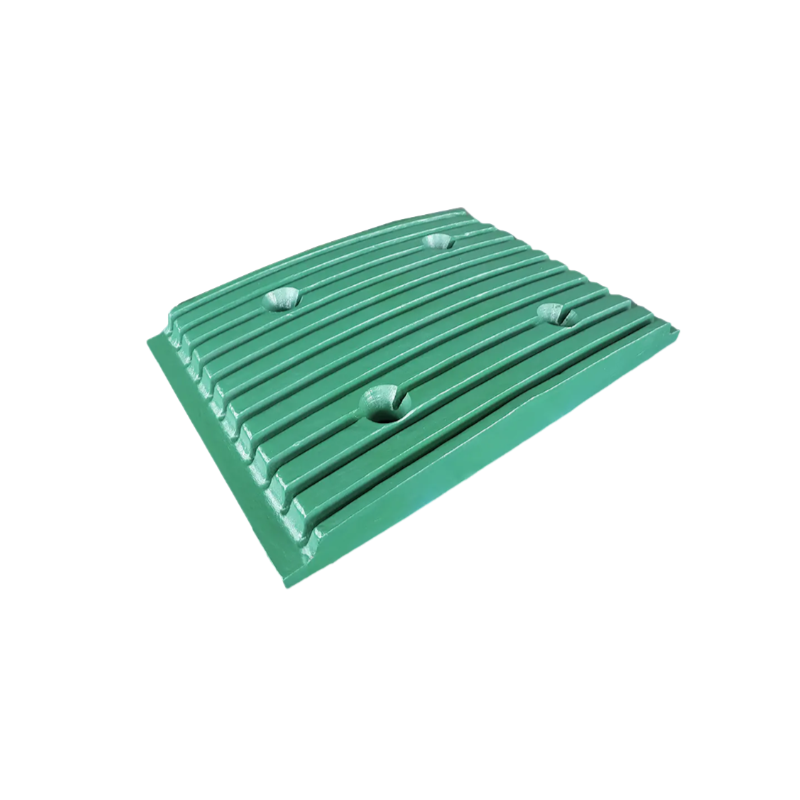

- Cone Crusher Parts

- Jaw Crusher Parts

- Gyratory Crusher Parts

- Sand Making Machine Parts

-

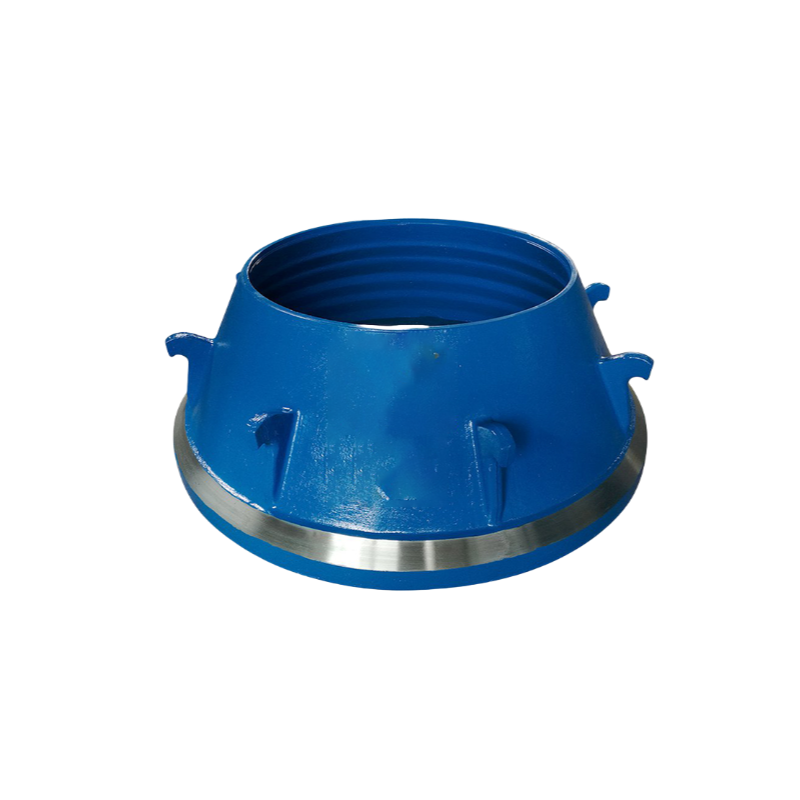

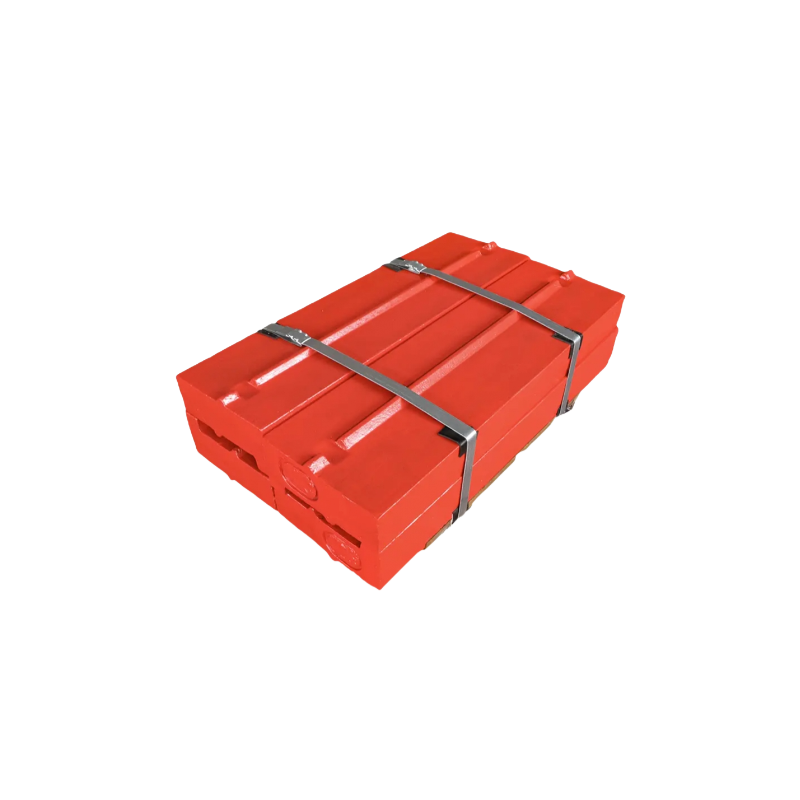

High-Quality Wear-Resistant Cone Crusher Parts

High - quality wear - resistant cone crusher parts are the cornerstone of reliable and efficient con

See More> -

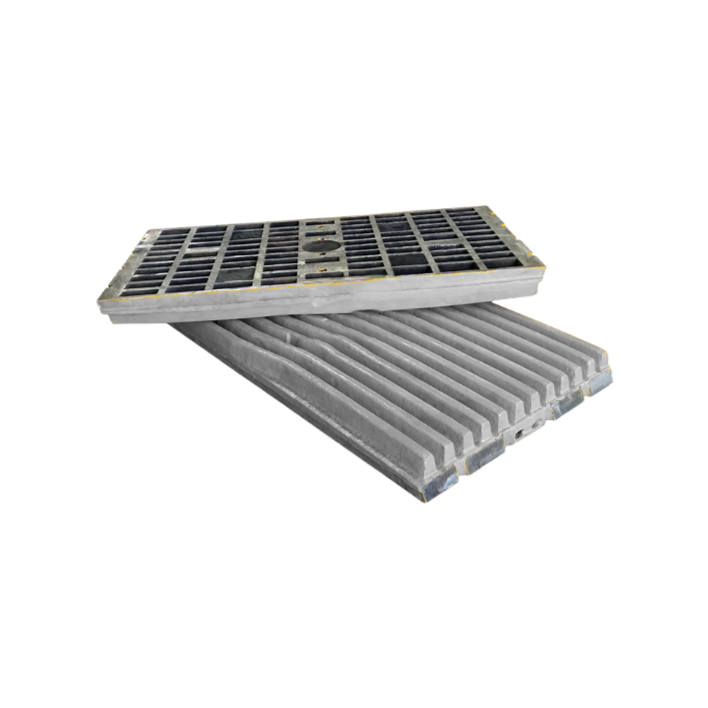

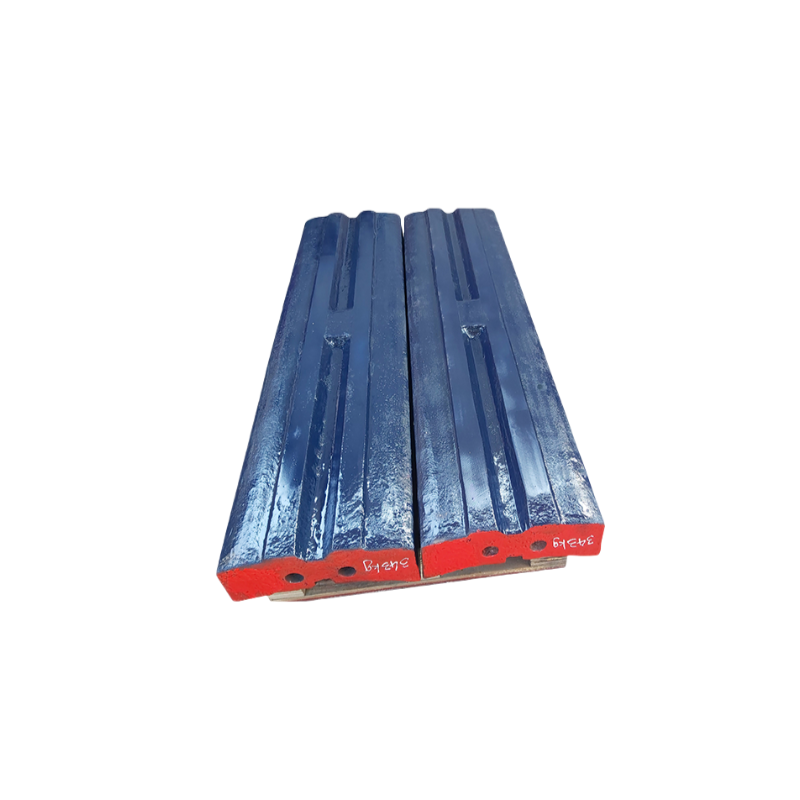

Long Service Life Crusher Jaw Plate

The crusher jaw plate is a critical wear part used in jaw crushers, which are widely utilized in the

See More> -

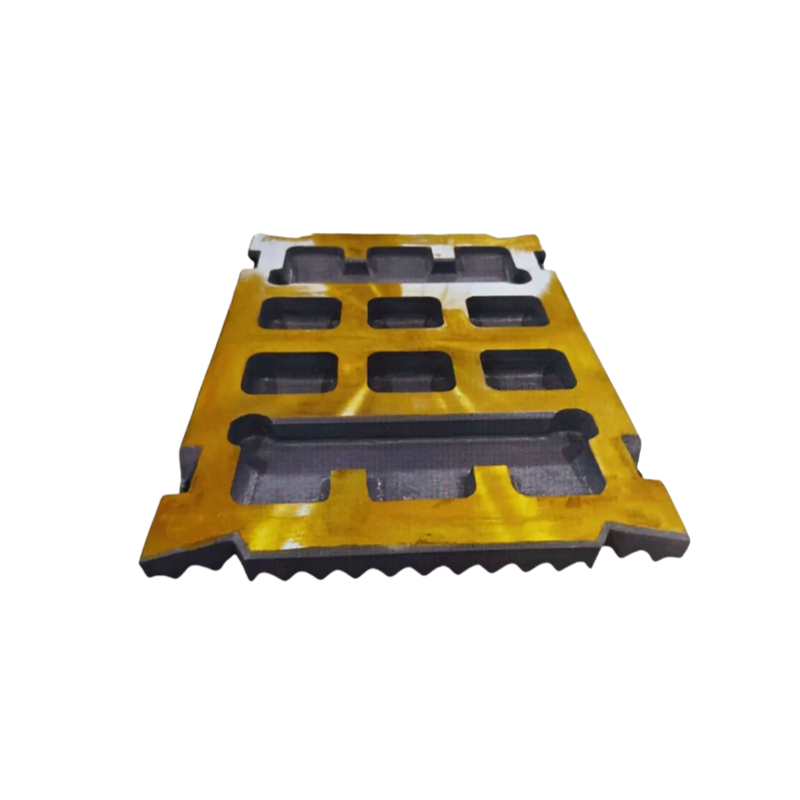

High Quality Wear-Resistant Crusher Jaw Plate

Wear resistance: High-quality Jaw Plates are usually made of wear-resistant materials.

See More> -

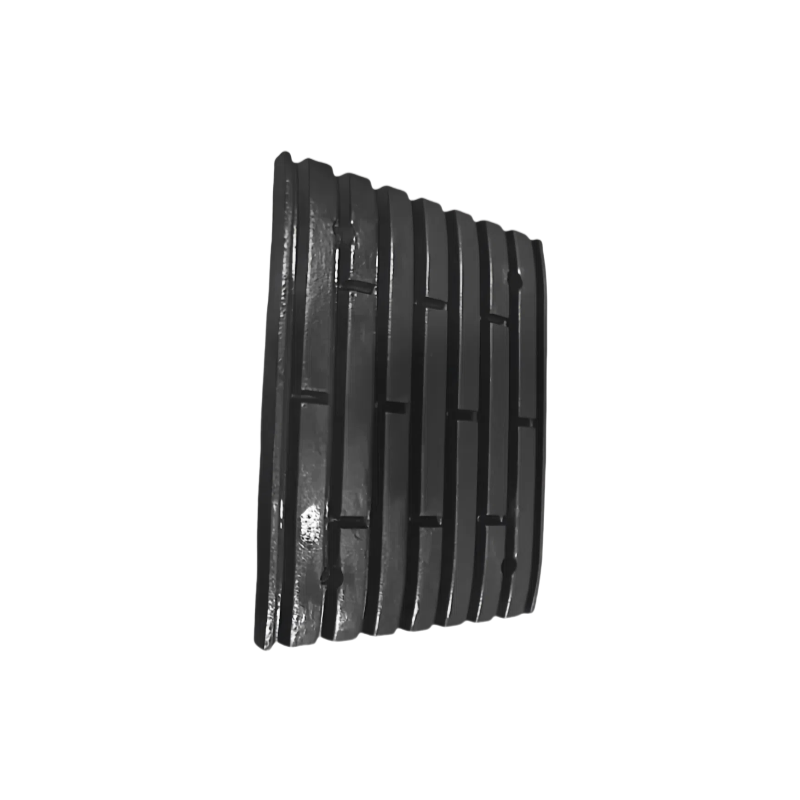

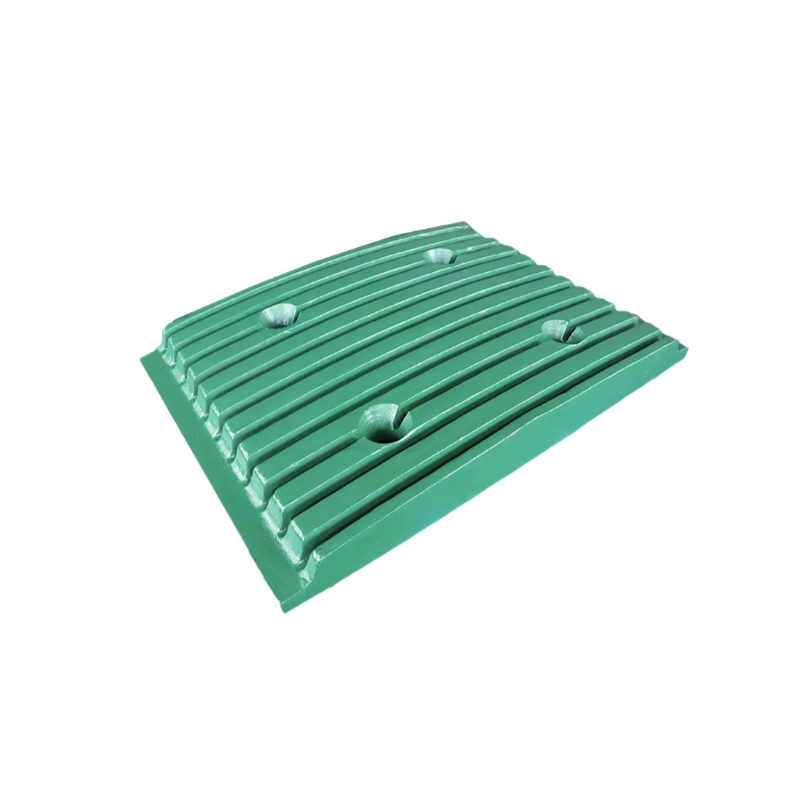

High-quality wear-resistant plates

High - quality wear - resistant plates are a class of materials engineered to withstand extreme abra

See More> -

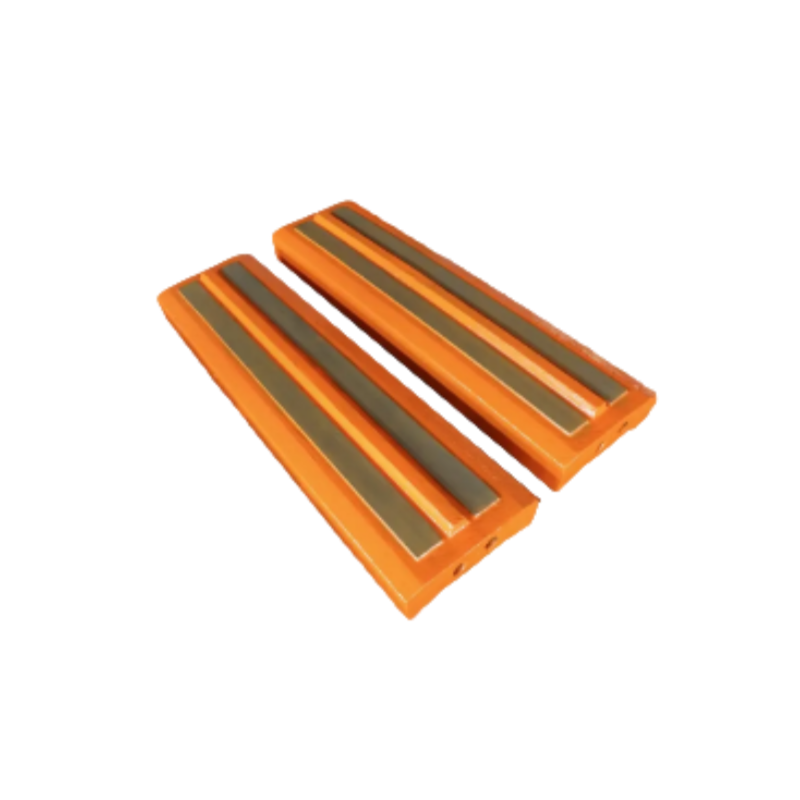

Premium Impact Crusher Blow Bar

A Crusher Blow Bar is a high-impact wear part designed for crushing materials in impact crushers. It

See More> -

Stable Quality Impact Crusher Blow Bar

The blow bar of an impact crusher is a critical component that plays a key role in the crushing proc

See More> -

High-Quality Wear-Resistant Hammer Plate

Resistant hammer plate is a critical component in various industrial machinery, especially in crushe

See More> -

Premium Wear-Resistant Plates

The primary wear parts of jaw crushers include jaw plates, crafted from high manganese steel and ref

See More> -

Long Service Life Impact Crusher Blow Bar

Impact Crusher Parts are crucial components designed to withstand high-impact forces during the crus

See More> -

Hard Alloy Slag Crushing Jaw Crusher

The jaw crusher tooth plate,commonly referred to as the jaw plate,is a critical wear-resistant compo

See More> -

Superior Wear-Resistant Blow bar For Impact Crusher

Blow bar is the core compnent of the impact crusher,directly involved in the third-level crushing of

See More>

Why Choose HAITIAN Mining Wear Parts?

When it comes to mining wear parts, HAITIAN stands out as a trusted global partner, offering superior material technology, precision manufacturing processes, rigorous quality testing, and efficient supply chain management to ensure maximum durability and performance in harsh mining conditions.

1. Advanced Material Technology for Extended Service Life

We utilize high-performance materials such as High Manganese Steel, High Chromium Cast Iron, and Ceramic Composites to cast mining crusher wear parts, ensuring exceptional strength, impact resistance, and wear resistance in extreme operating conditions. This significantly reduces replacement frequency and enhances equipment uptime.

2. Precision Manufacturing for Consistent Quality

HAITIAN employs Resin Sand Casting technology, producing smoother surfaces and more accurate dimensions while minimizing defects like porosity and slag inclusions. Every component meets stringent industrial standards for reliability.

3. Rigorous Quality Testing for Guaranteed Performance

Our fully equipped lab includes:

Tensile testing equipment – Measures material tensile strength

Impact energy testing equipment – Evaluates resistance to shock loads

Brinell hardness testing equipment – Ensures optimal hardness levels

Spectrometer component detection equipment – Precisely analyzes alloy composition

Triangulation Coordinate Measuring Machine – Verifies dimensional accuracy

Every batch undergoes strict inspection to comply with international standards (e.g., ISO, ASTM).

Explore our advanced testing equipment here!

4. Extensive Mold Inventory for Faster Delivery

HAITIAN has a huge inventory of molds, which can quickly match customer needs, shorten delivery cycles, and help mining companies reduce downtime and improve production efficiency.

Mining Wear Part Solution Success Story

HAITIAN's high-chromium alloy vertical mill liners (26% Cr, hardness ≥58 HRC) with precision 3D sand printing (±0.5mm accuracy) solved a US client's extreme wear challenges, delivering consistent, super-wear-resistant liners on schedule and demonstrating our expertise in large-tonnage casting and advanced manufacturing capabilities that earned unanimous customer praise.

If you are interested in our products or have any questions, please feel free to contact us.

We will provide professional consulting services and customized solutions according to your needs.

SEND INQUIRY NOWContact information

Tel: 0555-71661667166199

Tel: 0555-71661667166199

Fax: 0555-6971198

Fax: 0555-6971198

Website: https://www.htwearparts.com

Website: https://www.htwearparts.com

Email: info@mashthi.com

Email: info@mashthi.com

Postal code: 243141

Postal code: 243141

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe VIDEO FREQUENCY

VIDEO FREQUENCY

Tik Tok

Tik Tok