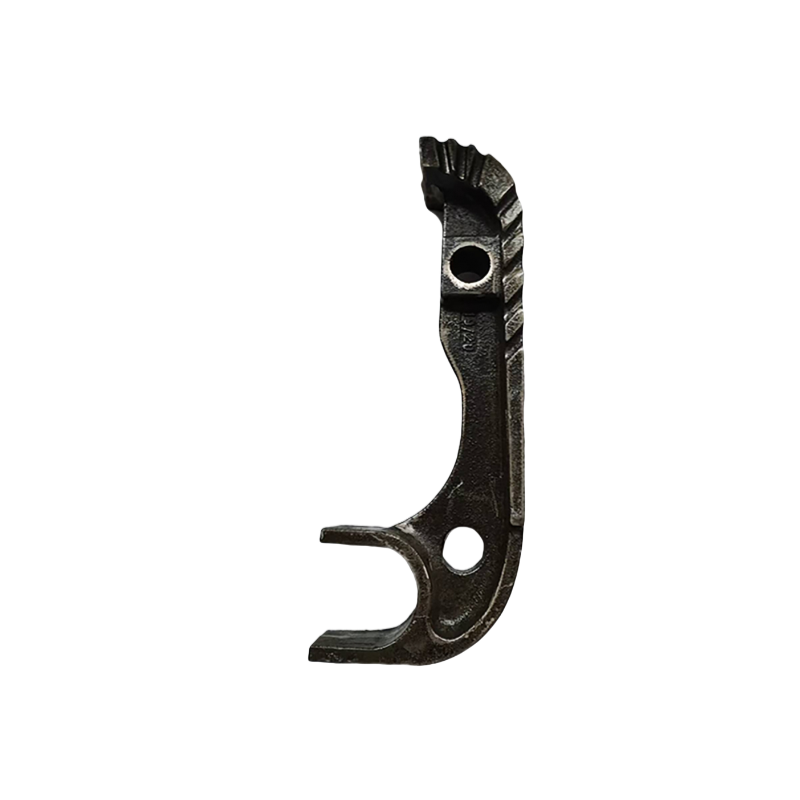

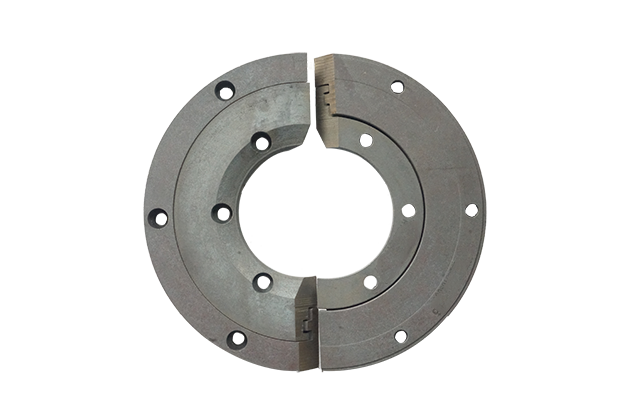

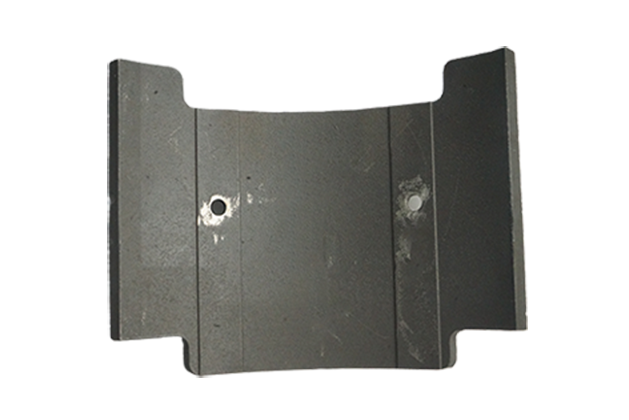

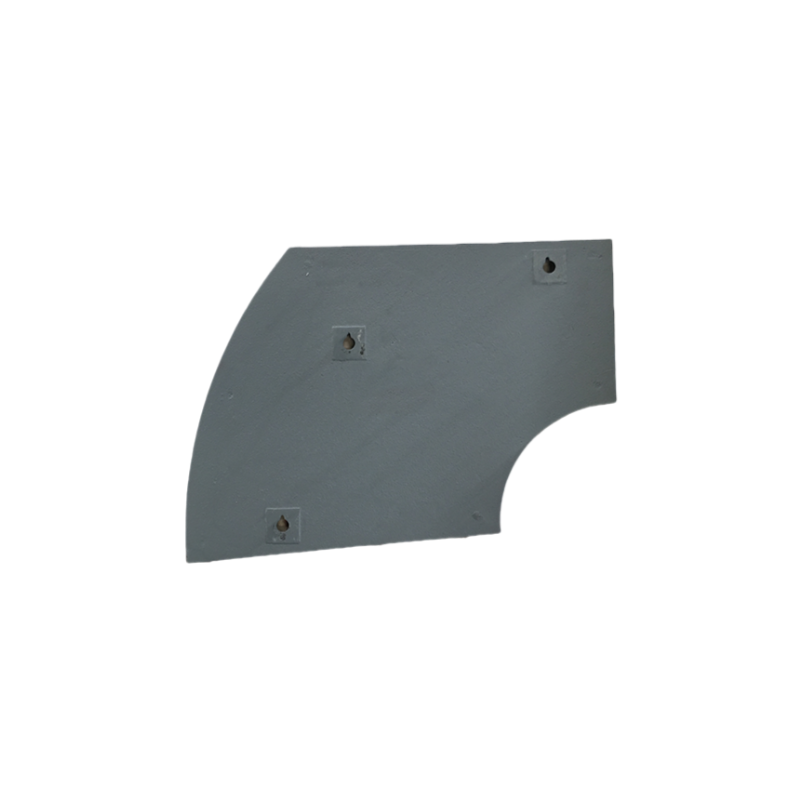

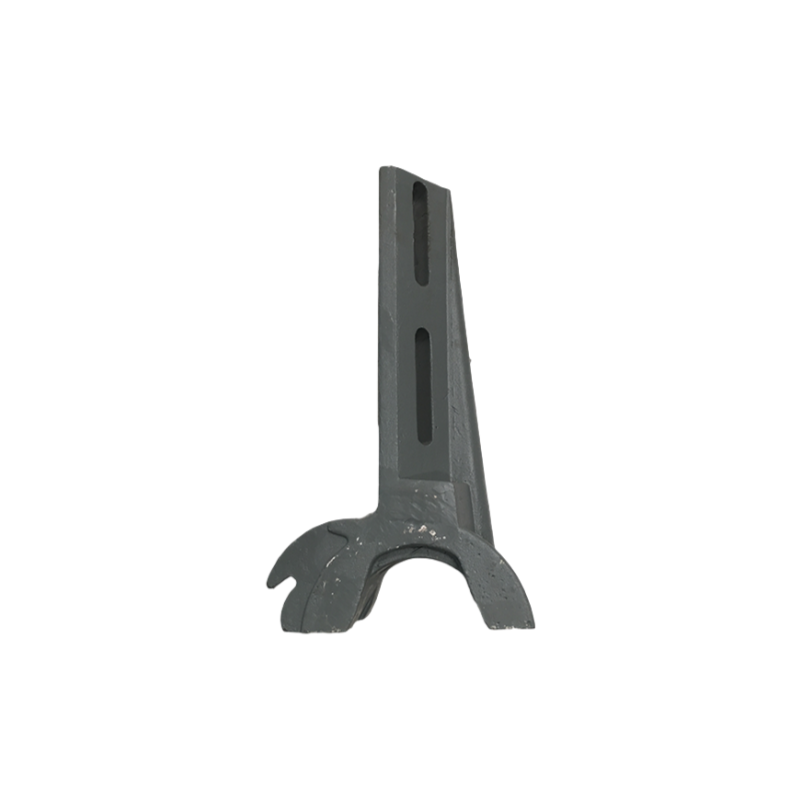

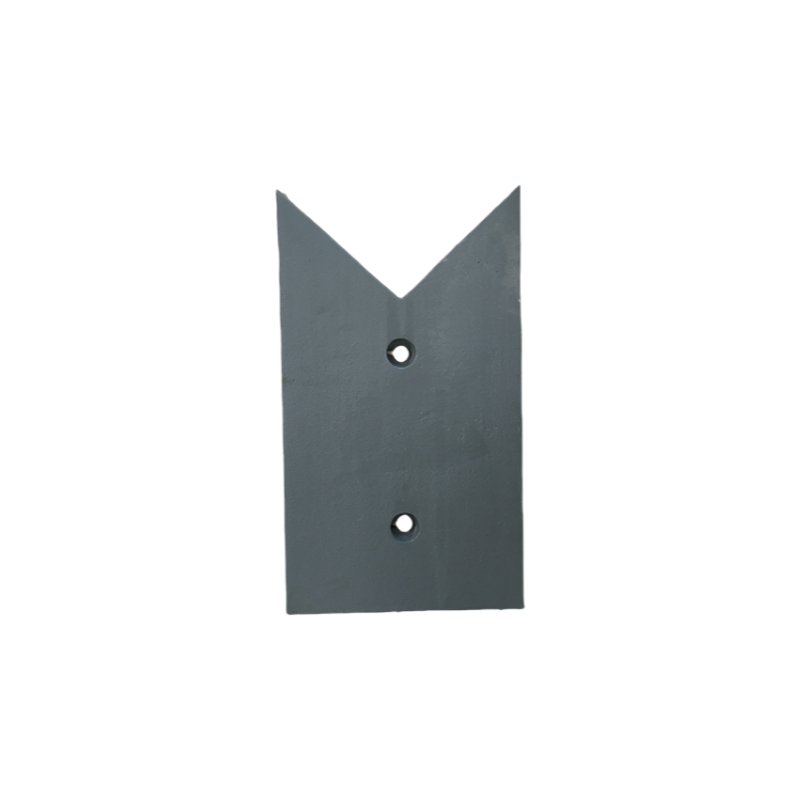

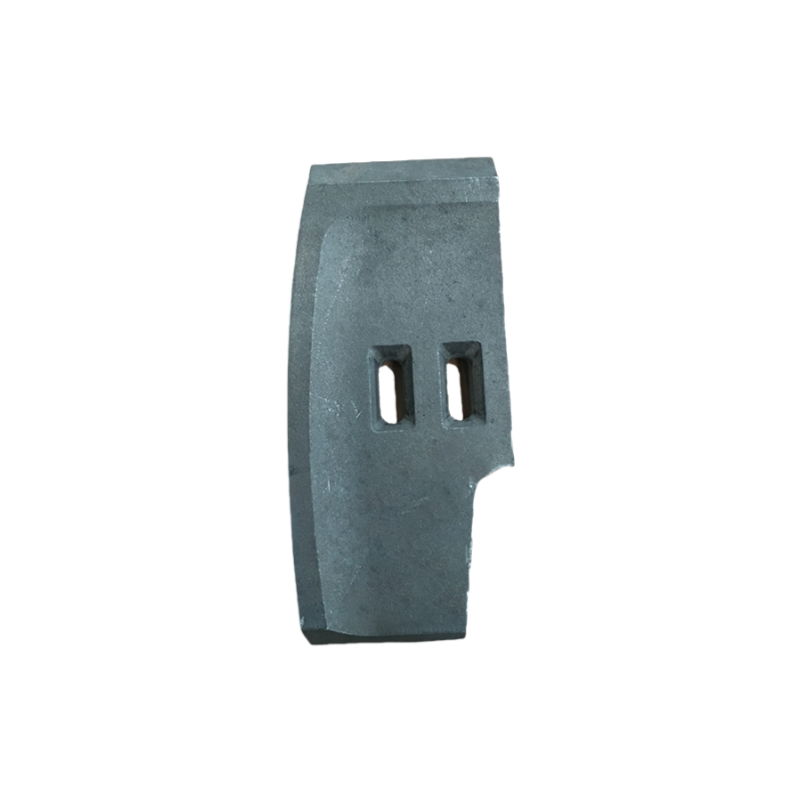

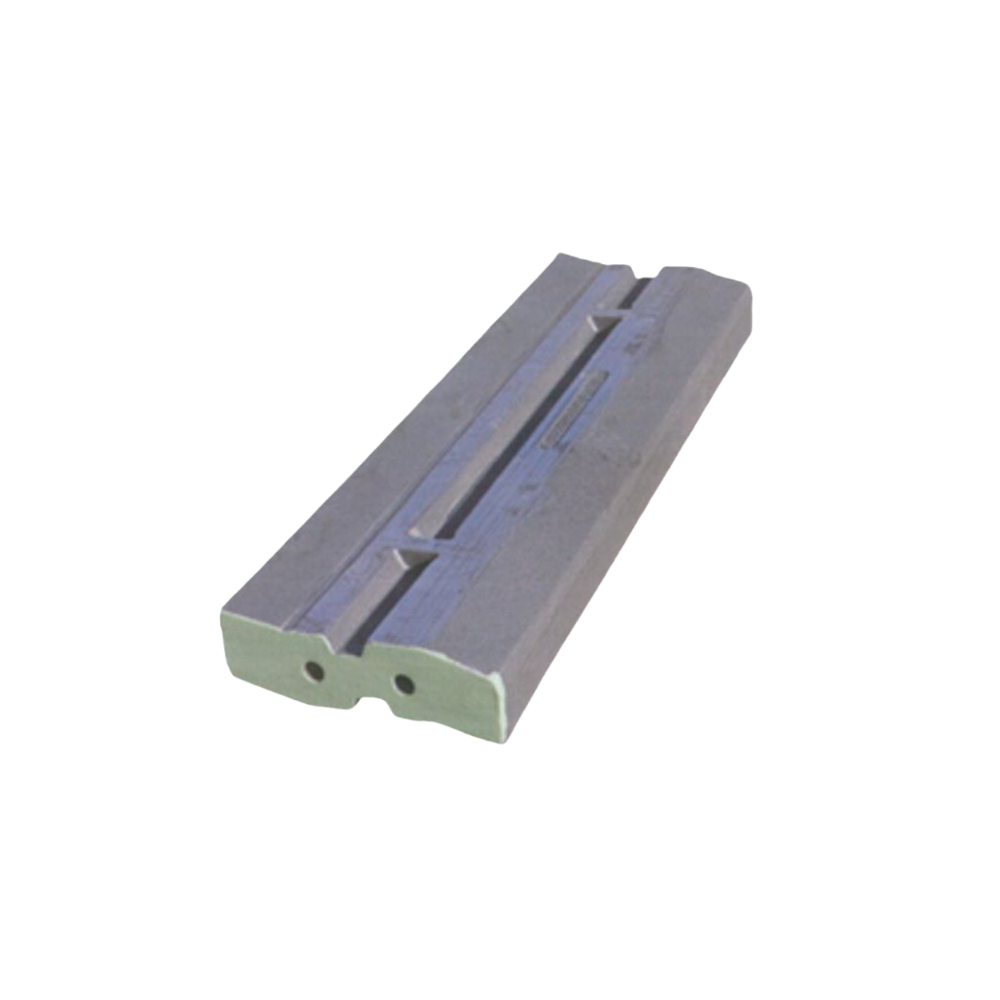

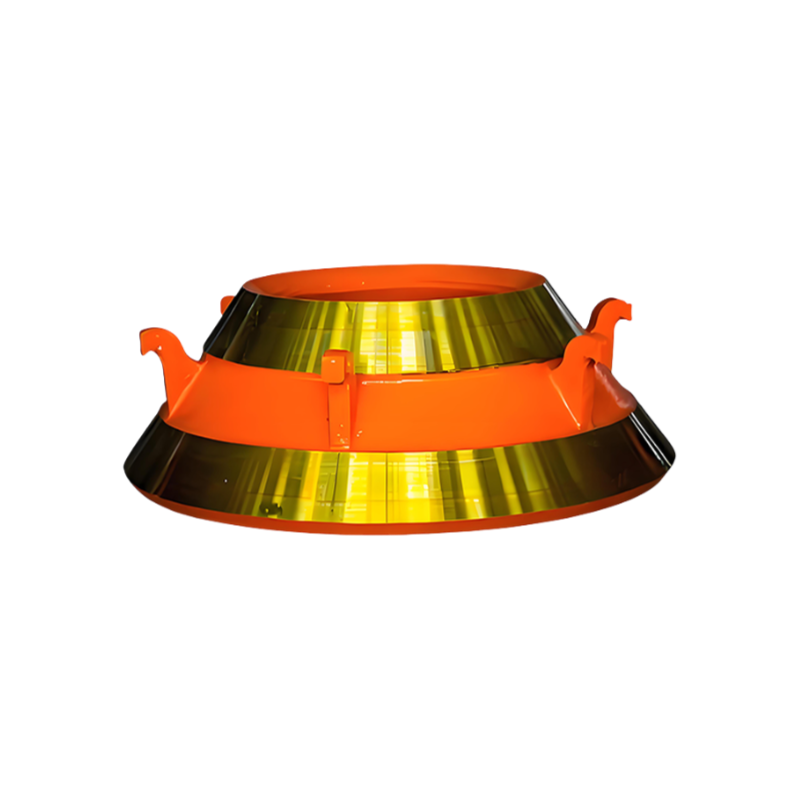

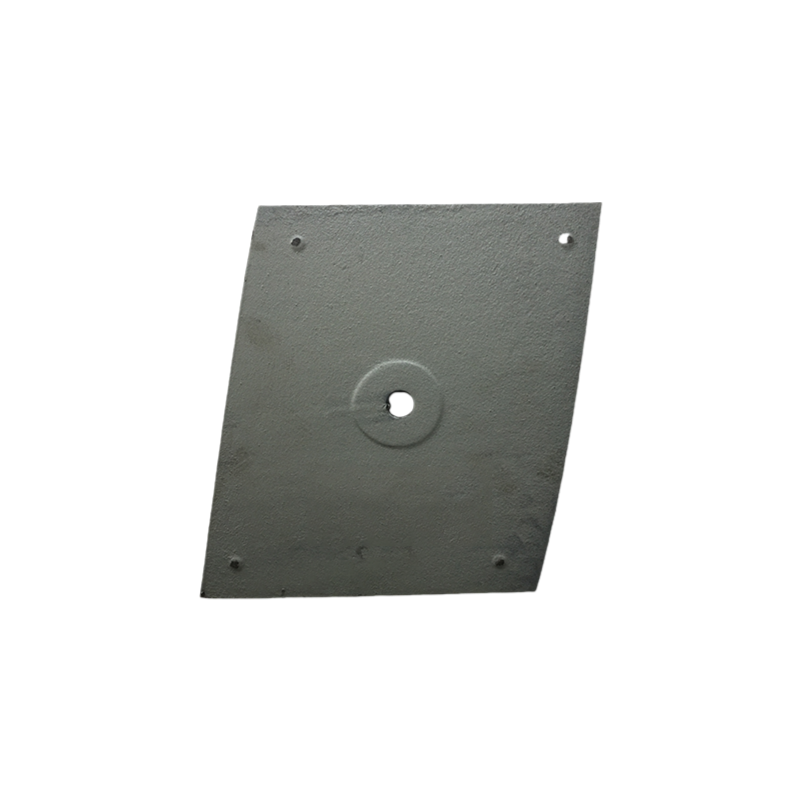

High‑Chrome Alloy Furnace Grate Bar

Material:High Chrome Cast Iron

Application:High-temperature thermal equipment

Process:Casting

Features:Excellent Heat Resistance、High Wear Resistance、Optimized Ventilation Design、Stable Structure & Customizable、Easy Maintenance & Replacement、Flexible Casting Techniques.

- Product Description

- Product Specifications

- Product Advantages

- More Details

Our furnace grate bars are engineered using high chromium cast iron, delivering exceptional wear resistance, thermal stability, and mechanical strength in extreme industrial environments. Designed to withstand prolonged exposure to high temperatures and abrasive materials, these grate bars are ideal for metallurgy, heat treatment plants, waste incineration systems, and other thermal processing industries.

Key Features:

High Wear Resistance: Made from premium high chromium cast iron (Cr content > 20%), the grate bars offer superior hardness and long service life even under constant exposure to abrasive particles.

Excellent Heat Resistance: Maintains structural integrity and mechanical strength at temperatures exceeding 1000°C, preventing deformation and cracking.

Corrosion Resistance: Outstanding performance against oxidation, slag attack, and chemical corrosion in metallurgical and thermal operations.

Customizable Designs: Available in various sizes, thicknesses, and geometries. We offer OEM services based on customer drawings and operational conditions.

Precision Casting Technology: Manufactured using advanced resin sand casting or lost foam process to ensure dimensional accuracy and surface quality.

Product Specifications

| Product Name | Hardness | Delivery Time | Model | Spray Painting | Inspection |

|---|---|---|---|---|---|

High-Chrome Alloy Furnace Grate Bar. | ≥60HRc | CT10 | 30 Days | Major Brand All Series | 100% Inspection Inspection Report |

PRODUCT ADVANTAGES

-

HIGH ASSEMBLY PRECISION

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

LONG SERVICE LIFE

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

STABLE QUALITY

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok