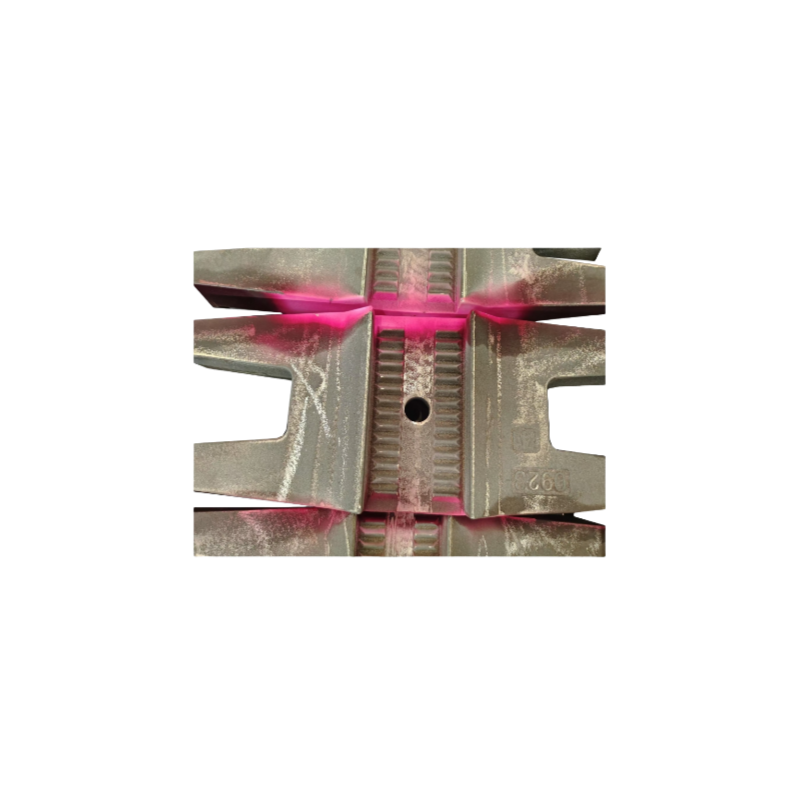

Asphalt Side Lining parts

Material:W3

Application:Asphalt Side Lining

Process: DISA Vertical Line

Features:Strong Wear Resistance,High Temperature Resistance,High Strength,Good Processing Performace,Corrosion Resistance,Easy to Replace and Maintain,High Efficiency.

- Product Description

- Product Specifications

- Product Advantages

- More Details

Asphalt side lining is an essential component in road construction and maintenance, engineered to fortify and shield pavement edges through the application of a sturdy asphalt layer. Its core function is to stabilize the roadway base, preventing erosion or splitting triggered by environmental pressures and vehicular demands. A well-designed asphalt side lining boosts resilience, cutting down on repair frequency and enhancing the road’s lifespan and economic efficiency. Superior asphalt side lining curbs damage to neighboring pavement zones by enduring abrasion and weather extremes, extending the infrastructure’s service life while reducing upkeep costs. Thoughtfully applied asphalt side lining lowers the chances of structural breakdowns, such as edge subsidence or water penetration, fostering safer and more consistent driving conditions. By curbing material wear and loss along pavement margins, asphalt side lining maximizes resource efficiency and minimizes waste, aligning with sustainable construction principles. The uniformity and robustness of the asphalt side lining directly shape the road’s functionality, ensuring compliance with engineering benchmarks and delivering top-tier performance. Through its stabilizing and protective capabilities, asphalt side lining indirectly advances environmental aims by lessening resource use and the demand for recurrent repairs.

Product Specifications

| Product Name | Material | Weight(kg) | Service Life | Precision | Delivery Time | Model | Spray Painting | Inspection |

| liner | W3 | 17.5 | 100,000batches | CT9 | 7-10/15-20days | all series | 100% Inspection |

PRODUCT ADVANTAGES

-

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok