Jaw crusher plates are the hardworking surfaces that directly contact and fracture rock and ore under extreme pressure and abrasive conditions—tens of thousands of tons of material processed daily. Yet among crushing equipment operators, jaw plates represent one of the most misunderstood components, with performance degradation often attributed to mechanical failures when the real culprit is preventable wear, misalignment, or operational error.

The consequences of overlooking jaw crusher plate performance are severe: a single worn plate reduces crushing efficiency by 35-55%, forcing operators to run equipment harder to achieve the same throughput. This creates a cascading failure pattern where accelerated wear demands more frequent replacements, increasing downtime from hours to months annually. For operations running fleet of eight jaw crushers, the cumulative cost penalty exceeds $100,000 annually when using standard materials and reactive maintenance practices.

This comprehensive guide addresses the diagnostic framework, troubleshooting methodology, and preventive maintenance strategies that mining and aggregate operations professionals require to identify performance issues before they escalate into equipment failure.

Jaw crusher plate performance is governed by two concurrent physical processes: the intended crushing action and the inevitable wear mechanisms that degrade surface integrity over time. Understanding this duality separates operators who maximize equipment lifespan from those who experience chronic performance degradation.

A properly functioning jaw crusher plate exhibits specific operational characteristics: consistent material fracture across the entire jaw surface, predictable wear patterns that progress uniformly from top to bottom, and maintained throughput (tons per hour) relative to feed rate and material properties. When any of these baseline characteristics change—sudden efficiency loss, uneven wear patterns, or declining throughput—the root cause involves one of five diagnostic categories: wear progression, misalignment, material contamination, operational error, or structural damage.

The complexity emerges because multiple causes can produce identical operational symptoms. Efficiency loss, for example, can result from worn plates (material sliding instead of breaking), misaligned plates (preventing proper jaw closure), excessive material (choking the chamber), or bearing degradation (altered crushing geometry). Accurate diagnosis requires systematic symptom evaluation against known mechanical relationships.

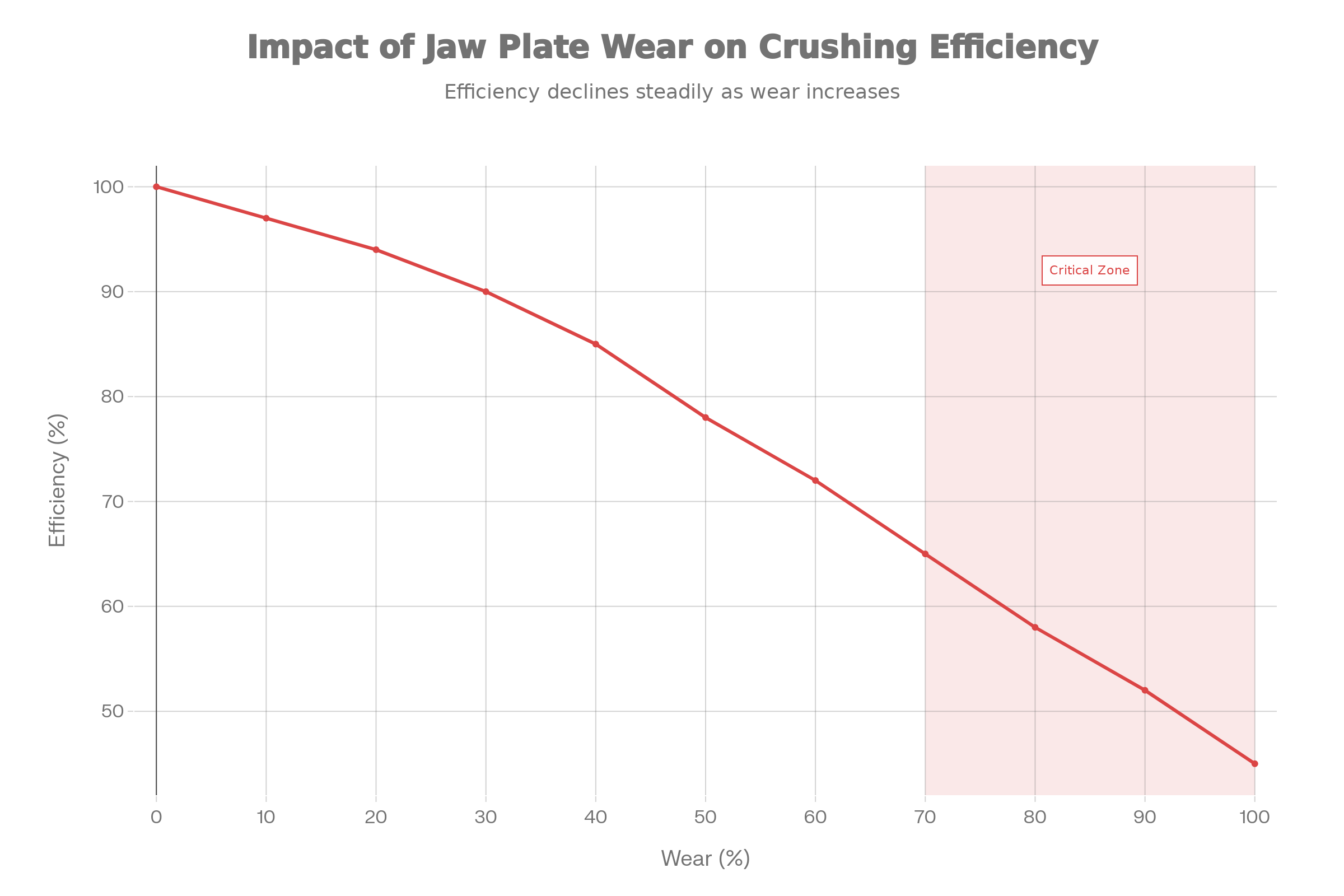

Jaw plate wear directly correlates with crushing efficiency. As plates wear, the "bite" (the aggressive grip on material) becomes shallower. Rock begins slipping vertically instead of fracturing. The crusher must operate longer, generating more vibration and noise, to process identical material volumes. When plates reach 30% thickness loss, efficiency typically drops 15-25%. At 50% wear, efficiency loss reaches 35-40%. Beyond 70% wear, efficiency collapses to 50-65% of nominal performance.

This relationship is not linear in real operations—efficiency decline accelerates as wear progresses. This explains why experienced operators prioritize plate replacement at the 30% wear threshold, despite plates remaining mechanically functional. The operational economics strongly favor replacement at early wear stages rather than operating worn plates to catastrophic failure.

Symptom Profile: One jaw plate wears significantly faster than its counterpart. Left jaw wears 40% while right jaw remains at 15%. Top sections of plates wear rapidly while lower sections remain intact. Material exiting the crusher shows inconsistent sizing with excessive fines (fine material) and oversized chunks.

Uneven jaw plate wear almost always originates from material flow misalignment rather than plate material defects. When material feeds unevenly into the crushing chamber, one plate bears disproportionate impact load. On belt-drive crushers, material naturally concentrates toward one side during feeding. On gravity-fed systems, hopper design directs material to preferential paths. In both cases, the result is concentrated stress on one jaw plate.

Feed angle represents a critical variable. Material entering at vertical angles (straight down from hopper) concentrates impact force at the jaw centerline, creating a vertical wear stripe. Material entering at 15-20° angles distributes force more evenly across the jaw width.

Closed-side setting (CSS) misalignment produces similar symptoms. CSS—the gap between jaws at their closest approach—must be identical on both sides. If the left CSS is 25mm and right CSS is 35mm, material exits preferentially from the right side, creating imbalanced jaw loads.

Corrective Solutions:

Implement Feed Distribution: Install a vibrating feeder with adjustable material flow distribution. Ensure material spreads uniformly across jaw width. Monitor for bridging (where material jams above the jaw, creating temporary starvation).

Verify CSS Alignment: Measure CSS on both sides of the crusher using precision gauges every 8-10 hours of operation. Adjust CSS using the manufacturer's adjustment mechanism to achieve identical dimensions on both sides. CSS tolerance: ±2mm between sides.

Optimize Material Entry Angle: Adjust feed chute angle to 15-20° from vertical. This provides directional momentum that distributes material laterally across jaw width while preventing straight-down impact concentration.

Rotate Jaw Plates Periodically: When unilateral wear reaches 50%, relocate the more-worn plate to the position of the less-worn plate. This forces material distribution to different jaw regions and distributes total wear more evenly. A second rotation at 90% wear maximizes plate utility before replacement.

Weekly: Inspect material distribution at the jaw entrance. Watch for material streaming to preferential sides.

Monthly: Measure CSS on both sides. Plot data to detect gradual drift.

Quarterly: Physically examine jaw plates for wear stripes or pattern irregularities.

Symptom Profile: Rock enters the jaw but exits partially intact without fracturing. The feed rate appears normal, but crushable material passes through without size reduction. Finished product contains oversized particles exceeding specifications. Operator reports equipment "just pushing material through without grinding it."

Material slippage indicates a critical geometric failure: the material can move vertically through the jaw without adequate grip. This occurs when jaw plate ridges (teeth) have worn flat and smooth. Original jaw plate teeth feature aggressive profiles—sharp edges that penetrate rock surface. After 50-100 hours of processing abrasive materials, these teeth become rounded. The flattened surface increases contact area but reduces the "bite" that locks material in place.

The jaw's mechanical geometry—the nip angle—becomes critical. Nip angle is the angle formed between the fixed and movable jaws. Optimal nip angles range from 22-26°. When material encounters this angle, it cannot slide back upward without fracturing. If the nip angle is too shallow (18-20°), material can slide vertically without resistance. This occurs either through design limitation or through misalignment where wear has altered the jaw geometry.

Feed rate imbalance compounds slippage problems. If jaw capacity is 150 tons per hour, feeding 180 tons per hour creates a continuous backlog. Material spends insufficient time in contact with jaw surfaces to achieve complete fracture. Smaller particles exit unfractured.

Replace or Rotate Jaw Plates Immediately: Slippage indicates wear has progressed beyond 40-50%. Replace movable jaw plates when this occurs. Fixed jaw plates typically wear more slowly. Rotate movable plates to the fixed position when movable wear reaches 50%, providing additional service life to the less-worn section.

Verify Nip Angle Geometry: Measure the angle between jaw plates at three vertical positions: top (jaw opening), middle, and bottom (discharge end). Proper nip angle should be consistent ±2° across jaw height. If variance exceeds this, misalignment or extreme wear has altered geometry. Realign or replace plates.

Reduce Feed Rate Proportionally: Calculate crusher capacity for your specific material type. Implement feeding rate controls ensuring feed rate remains at 80-90% of rated capacity. Exceeding capacity creates perpetual backlog where material moves too quickly to achieve full fracture.

Implement Material-Specific Tooth Profile Selection: Different material types require different tooth patterns. Hard granite requires sharp, aggressive teeth. Recycled concrete requires corrugated, flatter tooth patterns that prevent rebar and embedded steel from catching. Select tooth type matching material characteristics to maximize grip and minimize slippage.

Prevention Protocol:

Daily: Watch discharge material. Any oversized particles exceeding specifications signal slippage development.

Weekly: Perform manual material grip test. Insert a test sample between stationary jaw and moving jaw. Sample should not slide downward when jaw reaches closest approach.

Monthly: Measure tooth height. When tooth height wear exceeds 50%, schedule plate replacement.

Symptom Profile: Crusher suddenly becomes inoperative with material wedged solidly in the jaw chamber. Jaw cannot move despite power application. Acoustic signal often shows grinding or squealing indicating tremendous mechanical stress. Hydraulic pressure (if equipped with relief systems) shoots to relief valve setting.

Chocking occurs when material becomes mechanically locked in the crushing chamber, preventing jaw oscillation. This develops through several distinct mechanisms:

Oversized Material Introduction: Material exceeding the crusher's gape width (maximum jaw opening) enters from the hopper. The jaw cannot close fully because material physically blocks complete jaw closure. The fixed jaw strikes the oversized piece at an angle, forcing material sideways into the jaw chamber corner where it locks solid.

Arching and Bridging: When granular material (crushed product or fines) accumulates in the jaw chamber faster than it discharges, finer particles create a self-supporting arch above the discharge opening. Large pieces above the arch cannot fall through. The configuration becomes mechanically stable (arch supports load) and prevents material flow.

Moisture-Induced Stickiness: Materials with high moisture content (clay-bearing rock, wet ore) become tacky. Particles adhere to jaw plates and chamber walls, accumulating faster than discharge removes them. Once buildup reaches sufficient thickness, it physically prevents jaw movement.

Rapid Feed Dumping: When material is dumped into the jaw chamber suddenly rather than fed gradually, the entire mass lands in the jaw simultaneously. The jaw cannot process the volume rapidly enough. Overload causes material to pack solidly in the chamber corners.

Incorrect Closed-Side Setting: CSS that is too tight (jaw gap too small) prevents adequate material discharge. Material cannot fall through the discharge opening. It accumulates in the chamber until jaw closure is physically prevented.

Corrective Solutions:

Stop the crusher immediately using full power cutoff (not just emergency stop, but complete lockout).

Do NOT attempt to dislodge material through reverse operation—this risks broken components and material ejection.

Remove feeder connection and allow gravity to remove accessible material.

If material remains wedged, use manual excavation from the discharge end. Use penetrating lubricant on fasteners to ease jaw plate removal if necessary.

Once unjammed, inspect jaw plates for damage before restart.

Prevent Oversized Material Introduction:

Install a grizzly screen (parallel-bar screening) immediately upstream of the jaw crusher. Set bar spacing at 80-90% of crusher gape width.

The grizzly screen allows properly sized material to fall through directly to the crusher while deflecting oversized pieces to secondary crushing equipment.

Canadian mining operations reduced chocking by 68% through this single modification.

Replace gravity-dump feeders with vibrating feeders that distribute material gradually over time.

Vibrating feeders break arches and prevent material bridging by continuous gentle agitation.

Adjust vibrating feeder stroke and frequency to match crusher processing capacity.

CSS determines material discharge size and rate. CSS that is too tight prevents discharge.

Measure CSS every 8-10 hours during operation. Gradually increase CSS if material accumulation is observed.

Typical CSS adjustment: 2-5mm increase in CSS can resolve minor chocking issues.

Monitor finished product size—expanding CSS too much produces oversized product.

For naturally wet materials or high-clay-content rock, implement drying pre-treatment.

Pre-drying reduces moisture below 5%, eliminating stickiness and adhesion.

Alternatively, install baffle walls in the feed chute directing material toward chamber center, reducing side-wall adhesion.

Hourly: Observe hopper discharge rate. Any deviation indicates developing blockage.

Every 4 hours: Measure CSS. Log trend data to detect gradual CSS drift.

Daily: Inspect discharge opening for material buildup. Clean immediately if accumulation is observed.

Shift change: Verify grizzly screen bars are not damaged or bent (bent bars allow oversize material through).

Symptom Profile: Visible cracks develop in jaw plates, initially appearing as surface cracks but propagating deeper with continued operation. Acoustic monitoring (if available) detects high-frequency cracking sounds. Vibration increases noticeably. Eventually, jaw plate sections spall (break off) creating dangerous ejecta and severely impacting crushing performance.

Jaw plates fail through brittle fracture when subjected to shock loads exceeding material capacity. High-manganese steel jaw plates are engineered to "work-harden" under repeated stress—becoming progressively harder with use. However, shock loads (sudden impact forces many times the normal operating load) can exceed work-hardening capacity and cause immediate fracture.

Rapid Feed Dumping: Material dumped suddenly into the jaw chamber applies concentrated impact load to one small region. The jaw plate experiences momentary stress many times its steady-state operating load. Manganese steel can absorb significant shock, but extreme cases cause cracking.

Tramp Iron Impact: Metal objects (bolts, rebar pieces, equipment fragments) hidden in feed material strike jaw plates at full jaw closing force. Metal-to-metal impact concentrates force in microscopic contact areas, creating pressures that exceed material yield strength locally.

Closed-Side Setting Collision: When jaw closes completely (at CSS), if material is wedged in the chamber, the impact between fixed and movable jaws transmits enormous forces through any material between them. Hard materials may not fracture, but they transmit shock that can fracture jaw plates.

Operating Parameter Extremes: Running crushers at excessive speeds (RPM above design specification) or with excessive loads (continuous CSS adjustment toward tighter gaps) creates chronic shock loading that eventually leads to fatigue cracking.

Corrective Solutions:

Install metal detection at feed hopper entrance. Metal detectors trigger conveyor belt stoppages before contaminated material enters the crusher.

Implement material screening and visual inspection protocols before feeding.

Use permanent magnet systems in gravity-feed chutes to capture small magnetic metal pieces.

Eliminate sudden material dumping. Replace gravity chutes with vibrating feeders.

Vibrating feeders regulate material entry rate, preventing shock concentration.

Feed material gradually at rates the crusher is designed to process continuously.

On hydraulic jaw crushers, verify relief valve settings are correct (set by manufacturer, typically 250-350 bar depending on model).

Pressure relief prevents jaw from excessive force. If relief is set too high, jaw generates excessive closing force.

Check relief valve setting monthly, especially after maintenance.

Surface cracks are visible before deep propagation. Monthly visual inspection detects early cracks when plates can still be safely operated.

Once cracks exceed 50mm in length or show signs of active propagation (growth observed over successive inspections), replace plate immediately.

Do NOT attempt to repair cracks through welding—welding manganese steel creates hard, brittle zones prone to catastrophic failure.

If cracking occurs repeatedly with standard Mn13 material, upgrade to Mn18Cr2 or bimetal composite materials.

These advanced materials exhibit superior impact resistance. Bimetal composites are specifically engineered to absorb shock loads without cracking.

While material cost increases 100-150%, elimination of chronic cracking reduces labor and replacement frequency, providing positive ROI within 12-18 months.

Weekly: Visually inspect jaw plates for cracks, particularly at plate corners and bolt holes (stress concentration areas).

Monthly: Perform acoustic monitoring (listen for metallic cracking sounds during operation). High-pitched sounds indicate developing cracks.

Quarterly: Engage ultrasonic plate thickness measurement equipment. Cracks create ultrasonic reflections detectable as thickness variations. Advanced warning before visible cracking.

| Observed Symptom | Primary Root Causes | Secondary Verification Tests | Recommended Solutions |

| Efficiency drops 20%+ without feed changes | Jaw plate wear >30%, Misaligned CSS, Loose bearings | Measure plate thickness, check CSS both sides, bearing temperature check | Replace plates at 30% wear, verify CSS ±2mm, check bearing temperature trending |

| Uneven wear (one plate significantly more worn) | Uneven material distribution, Angled feed chute, CSS drift on one side | Visual inspection of feed pattern, measure CSS both sides, check feed chute angle | Install vibrating feeder, adjust feed angle to 15-20°, equalize CSS both sides |

| Oversized material in discharge | Worn plate teeth (>50% height loss), Excessive CSS, Insufficient jaw closing force | Measure tooth height, verify CSS vs. specification, check hydraulic pressure | Replace plates, reduce CSS 2-5mm, verify jaw closing pressure at relief valve |

| Material slipping without crushing | Flattened jaw ridges, Nip angle too shallow, Feed rate excessive | Check for shiny, smooth plate surfaces, measure nip angle at 3 heights, calculate capacity vs. feed rate | Replace plates, verify nip angle 22-26°, reduce feed rate to 80-90% capacity |

| Sudden jaw lockup (cannot close) | Oversized material wedged, Bridging/arching in chamber, Moisture-induced packing | Try to manually remove material, measure chamber dimensions, assess moisture content | Use grizzly screen upstream, implement vibrating feeder, reduce material moisture or CSS setting |

| Abnormal vibration or noise | Loose jaw plate bolts, Misaligned plates, Bearing wear, Cracking development | Check bolt torque (should be snug, not stripped), measure bolt hole dimensions, listen for metallic crackling | Retorque all bolts per manufacturer spec, realign or replace plates, replace worn bearings |

| Discharge opening blocked | Material buildup from high moisture, Inadequate CSS, Slow discharge rate | Measure CSS, check material stickiness, assess chamber cleaning frequency | Increase CSS, reduce moisture content, increase cleaning frequency, consider anti-stick liner coating |

| Bearing overheating (>80°C) | Inadequate lubrication, Bearing wear/degradation, Misalignment stress | Check lubrication system operation, measure bearing radial play, verify jaw alignment | Replenish grease, replace bearings if play >0.5mm, realign jaw plates |

| Intermittent equipment shutdown (safety interlock) | High vibration trigger, Temperature limit exceeded, Hydraulic pressure relief cycling | Check if shutdown occurs at specific jaw position (alignment issue) or random (bearing issue), measure temperatures | Address specific cause: realign if position-dependent, replace bearings if random, verify relief valve |

| Finished product quality declining (fines increase, oversized chunks appear) | Worn plates, Jaw misalignment, Operating at excessive speed | Measure plate wear, check CSS and jaw parallel alignment, verify crusher speed is within spec | Replace plates when >40% wear evident, adjust CSS and alignment, reduce speed if excessive |

Observe material discharge characteristics. Any change in product size distribution warrants plate inspection.

Monitor equipment noise and vibration. Abnormal acoustic signatures often precede visible wear.

Verify feeder operation. Consistent, even material flow prevents uneven wear.

Check for material accumulation in the jaw chamber discharge. Clean if observed.

Weekly Maintenance:

Measure jaw plate thickness using precision calipers at three vertical positions (top, middle, bottom) on both fixed and movable plates. Record measurements. Compare to previous week's data to calculate wear rate.

Measure CSS on both left and right sides of the jaw. Verify CSS difference is less than 2mm. Record data.

Inspect jaw plates visually for cracks, particularly around bolt holes and plate corners.

Check vibration levels. Most modern crushers have vibration sensors. Vibration exceeding 5 mm/s RMS indicates developing problems.

Verify all jaw plate bolts are snug. Use a torque wrench to check 4-6 random bolts. If any are loose, torque all bolts to manufacturer specification.

Monthly Maintenance:

Perform detailed plate wear analysis. Calculate wear rate (mm per week or mm per 100 operational hours). Use wear rate to project replacement date.

Measure jaw crushing chamber width at three vertical positions. Jaw chamber should remain parallel. If width varies more than 5mm between top and bottom, plates have become misaligned.

Check jaw bearing temperature during operation. Record temperature. Normal bearing temperature is 40-60°C. Temperatures above 75°C indicate bearing degradation or inadequate lubrication.

Perform jaw alignment check using a straightedge or laser alignment tool. Jaw faces should remain parallel ±2mm across full jaw width.

Rotate movable jaw plates from crushing jaw to opposite position (or vice versa) if wear reaches 50%. This distributes wear to less-worn plate region.

Quarterly Maintenance:

Engage advanced measurement techniques: ultrasonic plate thickness measurement (detects internal cracks before surface failure), laser rangefinder wear mapping (creates visual wear profile across plate surface), and thermal imaging (identifies friction hotspots indicating misalignment).

Test hydraulic system (if equipped): verify relief valve pressure, check for leaks, assess fluid condition.

Inspect toggle plate and all safety components. Toggle plates can fracture under high stress, becoming safety hazard.

Assess crusher structural integrity. Check frame for cracks or permanent deformation, particularly around bearing mounts and jaw pivot points.

Semi-Annual Review:

Analyze complete maintenance log data over 6-month period. Identify trends: are plates wearing faster than baseline? Is vibration gradually increasing? Is bearing temperature drifting upward?

Conduct economic analysis: compare cost of early plate replacement (at 30% wear) versus continued operation to 60%+ wear considering labor, downtime, and potential bearing or frame damage.

Review operational procedures with crew. Common causes of early wear often involve preventable operational errors (rapid feed dumping, inadequate material screening, negligent lubrication).

Modern jaw crushers increasingly incorporate real-time monitoring systems that provide continuous visibility into equipment condition:

Vibration Monitoring: Accelerometers detect abnormal vibrations indicating misalignment, bearing wear, or cracking development. Vibration trends over time reveal progressive degradation before equipment failure. Alarm thresholds (typically 5 mm/s RMS) trigger maintenance notifications.

Temperature Sensors: Infrared sensors monitor bearing temperature continuously. Temperature trending reveals bearing degradation progression. Sudden temperature spikes indicate friction issues from misalignment.

Acoustic Monitoring: Microphones detect metallic cracking sounds, grinding noises, and other acoustic signatures. Artificial intelligence algorithms identify cracking development weeks before visible cracks appear.

Wear Measurement Systems: Laser-based systems measure jaw plate thickness continuously, tracking wear rate in real-time. Automatic alerts trigger when wear reaches 20%, 30%, and 50% thresholds.

These systems reduce reactive maintenance (responding to failures) and enable predictive maintenance (replacing components before failure occurs), improving uptime and extending equipment life.

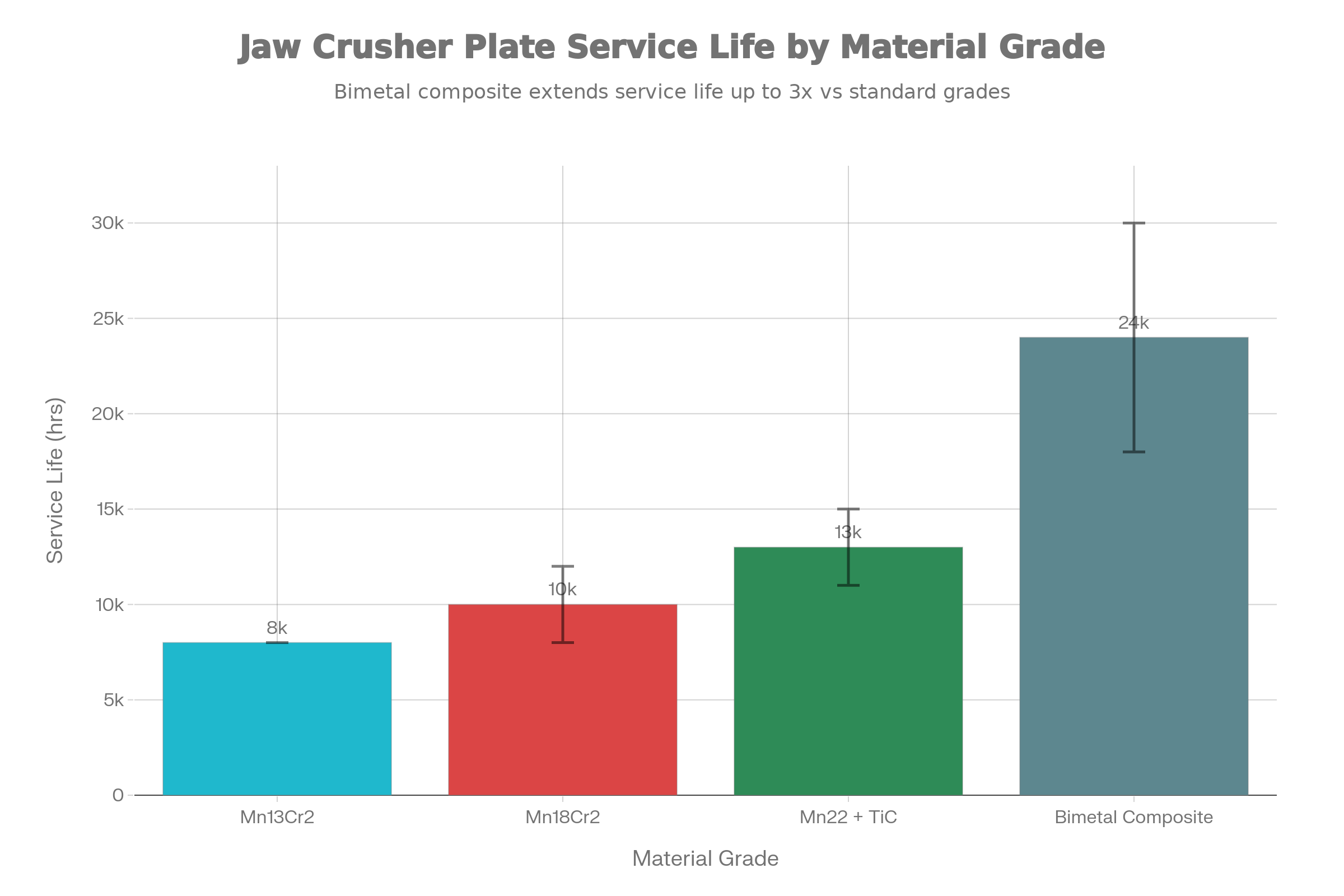

Jaw crusher plate performance varies significantly based on material grade selection. Understanding material properties prevents premature wear and enables optimal performance for specific applications.

Mn13Cr2 Standard Grade: Baseline manganese steel, containing 13% manganese and 2% chromium. Work-hardens from initial hardness 200-250 HB to 450-550 HB in service. Suitable for: soft-to-moderate materials (limestone, coal, aggregate). Service life 400-600 hours (soft materials), 200-300 hours (moderate hardness). Cost: $1,500-2,000 per plate.

Mn18Cr2 Premium Grade: Higher manganese content (18%) provides superior work-hardening response and impact resistance. Hardens to 500-600 HB. Superior for: hard materials (granite, basalt, iron ore), recycled concrete, mixed aggregate. Service life 8,000-12,000 hours. Cost: $3,500-4,500 per plate.

Mn22 with TiC Inserts: Maximum manganese (22%) plus titanium carbide particle inserts for extreme abrasion resistance. Maintains hardness throughout service life without significant work-hardening dependency. For: extreme abrasive applications (silica-rich materials, recycled materials with ceramic tiles embedded). Service life 11,000+ hours. Cost: $6,000-8,000 per plate.

Bimetal Composite: Dual-layer construction with high-chromium iron wear surface (64 HRC hardness) bonded to tough manganese steel base. Superior shock resistance and abrasion resistance through layered design. For: applications with mixed hazards (hard plus impact shock). Service life 200-300% extension versus Mn13. Cost: $8,000-12,000 per plate.

| Material Type | Hardness | Manganese Content | Optimal Applications | Typical Service Life | Cost per Plate |

| Mn13Cr2 | 200-250 HB initial | 13% | Limestone, coal, soft aggregate | 400-600 hrs | $1,500-2,000 |

| Mn18Cr2 | 400-600 HB | 18% | Granite, basalt, iron ore, recycled concrete | 8,000-12,000 hrs | $3,500-4,500 |

| Mn22 + TiC | 550-650 HB | 22% + inserts | Silica-rich rock, ceramic-embedded recycled | 11,000+ hrs | $6,000-8,000 |

| Bimetal Composite | 450-650 HB | 13-18% base | Mixed applications (hard + shock) | 200-300% vs Mn13 | $8,000-12,000 |

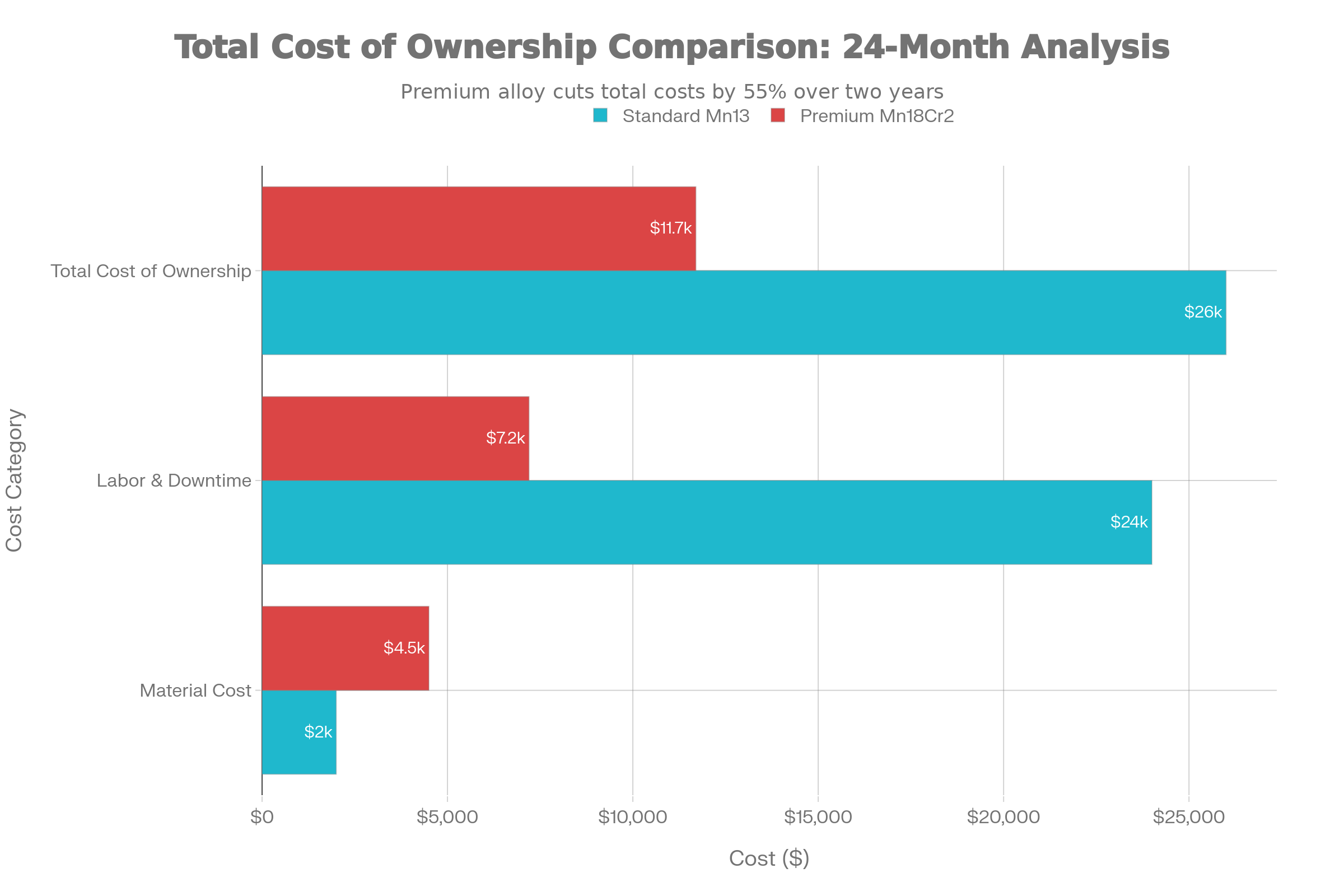

The financial analysis comparing standard Mn13 versus premium Mn18Cr2 materials over a 24-month operational period illustrates why material selection profoundly impacts profitability.

Material cost: Replacing jaw plates 8-10 times annually = $2,000 × 9 replacements = $18,000

Labor cost: Each replacement requires 4-6 hours shutdown + 2-3 hours installation = 40-50 hours labor annually = 100 hours over 24 months × $80/hour = $8,000

Downtime cost: Production loss during replacements = 4-6 hours per replacement × 9 replacements × 2 years × $150/hour lost production = $10,800

Total 24-month cost: $36,800

Premium Mn18Cr2 Cost Structure (24 months):

Material cost: Replacing jaw plates 2-3 times over 24 months = $4,500 × 2.5 replacements = $11,250

Labor cost: Fewer replacements = 10-15 hours labor over 24 months × $80/hour = $1,200

Downtime cost: Minimal downtime = 4-6 hours × 2.5 replacements × $150/hour = $1,800

Total 24-month cost: $14,250

Financial Impact: Premium Mn18Cr2 reduces total cost of ownership by $22,550 (61% reduction) over 24 months, despite 125% higher initial material cost ($4,500 vs $2,000). The payback period for material upgrade is 6-8 months, after which cumulative savings accelerate. For mining operations running multiple crushers, the cumulative savings across a fleet of 10-15 jaw crushers easily exceed $300,000-500,000 annually.

Beyond quantified cost reduction, premium materials provide secondary benefits: reduced operational disruptions improve production scheduling, fewer equipment maintenance crises reduce staffing stress, and improved equipment reliability increases safety (equipment failures are common accident sources).

A 50-person granite crushing operation in Queensland processed 2,000 tons daily using three double-toggle jaw crushers equipped with Mn13Cr2 standard plates. Plates were replaced 6-7 times annually per crusher (18-21 total replacements). Chronic chocking occurred 4-5 times weekly, requiring emergency unjamming procedures averaging 2 hours each.

Operational Problem: Equipment downtime exceeded 150 hours annually due to both replacement intervals and chocking incidents. A particularly severe chocking event caused feed angle misalignment, accelerating uneven wear on one jaw plate to 60% within two months.

Diagnostic Process: Detailed wear measurement revealed asymmetric wear pattern with 2mm CSS difference between left and right jaw. Investigation discovered feed hopper directing material preferentially to left jaw. Additionally, material moisture content exceeded 8% (unusual for Australian quarries), and grizzly screen sizing allowed 5% of feed to exceed design gape width.

Upgraded to Mn18Cr2 plates to reduce replacement frequency

Installed vibrating feeder with adjustable material distribution

Tightened grizzly screen bar spacing to 85mm (90% of jaw gape)

Implemented pre-drying equipment reducing moisture to 4%

Established weekly CSS verification protocol with tolerance ±1mm

Results: Replacement frequency reduced to 2-3 times annually per crusher. Chocking incidents dropped to 1-2 monthly. Uneven wear eliminated—both jaw plates now show uniform wear patterns. Equipment uptime increased to 96% (from 92%). Total operational cost reduction: $185,000 annually across the three-crusher fleet.

A demolition waste recycling facility in Johannesburg processed 150 tons daily of mixed concrete and asphalt (both contain hard aggregate particles and fine dust). Standard Mn13Cr2 plates were causing two recurring problems: brittleness with occasional spalling from impact, and material accumulation in discharge due to sticky fine dust adhesion.

Operational Problem: Jaw plates lasted only 200-250 hours due to multiple causes: impact shock from rebar embedded in concrete, abrasive dust coating surfaces, and discharge blockages from fines accumulation requiring manual chamber cleaning 3-4 times weekly.

Diagnostic Process: Acoustic monitoring detected cracking development every 150-200 hours, well before visible plate failure. Moisture measurement showed discharge-end accumulation of fines creating 60-70% moisture concentration. Material analysis revealed 15-20% fines (<2mm) in input material.

Upgraded to bimetal composite jaw plates engineered for impact resistance and improved surface hardness

Installed anti-stick liner coating (Teflon-based) on discharge end of crushing chamber

Implemented automatic spray system adding moisture-dispersal agent to reduce sticky fines adhesion

Added secondary screening system to separate fines before crushing (reducing crusher load by 15-20%)

Quarterly plate rotation extended utility

Results: Jaw plate service life increased to 800+ hours (300% improvement). Spalling and cracking eliminated. Discharge blockages reduced from 3-4 weekly to less than monthly. Maintenance labor reduced 40%. Economic benefit exceeded investment within 14 months.

A large-scale copper mine processing 20,000 tons daily operated eight double-toggle jaw crushers. Standard operations replaced plates monthly (96 plates annually). A 2022 productivity drive identified jaw crusher downtime as a major throughput bottleneck. Investigation revealed efficiency had degraded progressively as plates aged.

Operational Problem: Detailed measurement showed average plate wear reached 45-50% before replacement (crew replaced only when equipment failed or efficiency dropped noticeably). At this wear level, crusher efficiency dropped to 60-65% of nominal, requiring doubled energy input to maintain throughput, cascading to other equipment through the processing line.

Diagnostic Process: Advanced monitoring installed on three crushers provided baseline data: wear rates, efficiency curves, maintenance labor per crusher, and energy consumption per ton processed. Data revealed dramatic efficiency difference between crushers with fresh plates versus worn plates. Energy consumption increased 35% when plates reached 45% wear.

Established aggressive plate replacement schedule: replace all jaw plates at 25-30% wear (not 45-50% wear)

Upgraded to Mn18Cr2 material on all eight crushers

Standardized feed preparation with enlarged grizzly screens

Automated monitoring system tracking jaw plate wear continuously

Crew training on optimal CSS settings and feeding procedures

Results: Despite increasing plate replacement frequency from 8 to 10 per crusher annually (higher number of replacements), total operational cost decreased 28% due to material longevity, elimination of high-labor emergency unjamming, and reduced energy consumption from operating at 85%+ efficiency continuously. Production throughput increased 12% using same number of crushers. ROI on monitoring system and upgraded materials: 18 months.

Jaw crusher plate performance and longevity are not predetermined by equipment design alone. Operational excellence emerges from the intersection of proper material selection, systematic monitoring and diagnostics, planned preventive maintenance, and continuous optimization of operational parameters. Operations demonstrating mastery across these dimensions achieve 50-70% reduction in equipment downtime, 35-45% reduction in maintenance costs, and production increases of 10-20% using identical equipment.

The transition from reactive maintenance (responding to failures) to predictive maintenance (preventing failures) requires initial investment in monitoring technology, crew training, and operational discipline. Yet this investment yields returns that typically exceed 25-30% annually in mining and aggregate operations processing high-volume, low-margin materials where equipment reliability directly determines profitability.

For operations seeking additional technical guidance on jaw crusher plate selection, installation, or troubleshooting specific to your equipment and materials, consult with specialized wear parts manufacturers. Visit https://www.htwearparts.com/ for comprehensive technical resources, material specifications, and access to expert engineering support. Haitian Casting, as a leading manufacturer of jaw crusher wear plates across all material grades and a provider of real-time monitoring integration services, offers technical consultation enabling precise material selection for your specific operations and applications.