Reliable, Wear-Resistant Components for the Mining Industry

Mining Equipment Wear Challenges

In the mining industry, equipment is in extreme working conditions such as high wear, high impact, high temperature, and corrosive media for a long time, resulting in serious loss of key components and frequent shutdowns for replacement, which directly affects production efficiency and operating costs.

Mining operations face:

High wear leads to short life of accessories

Sudden failures affect production capacity and increase maintenance costs

High dependence on imported brands, long procurement costs and cycles

On-site maintenance is complicated and replacement efficiency is low

Haitian Wear Solutions For Mining Industry

Haitian Heavy Industry specializes in R&D and manufacturing of premium wear-resistant parts for mining applications. Our end-to-end wear solutions optimize crushing, conveying, screening, and grinding operations through advanced material science and precision casting technologies.

Why choose Haitian mining wear solutions:

20 years of leading experience in the industry.

Provide one-stop mining wear solutions.

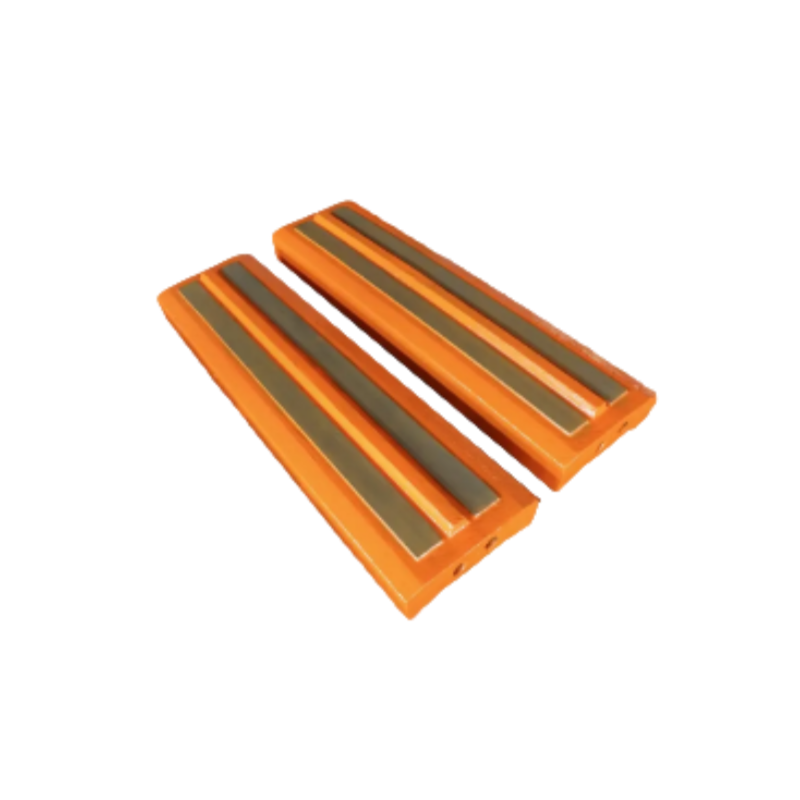

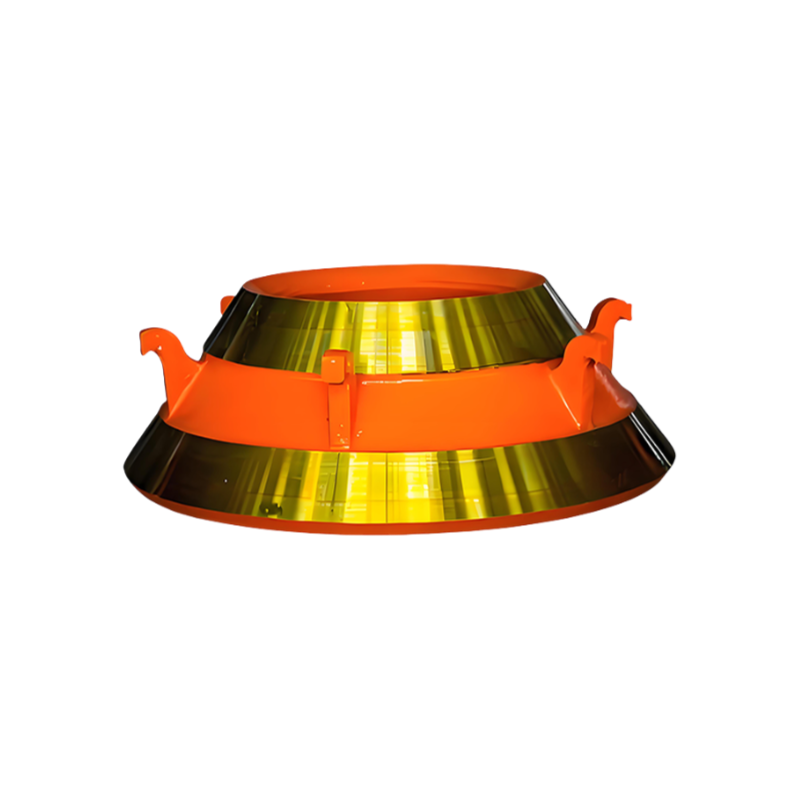

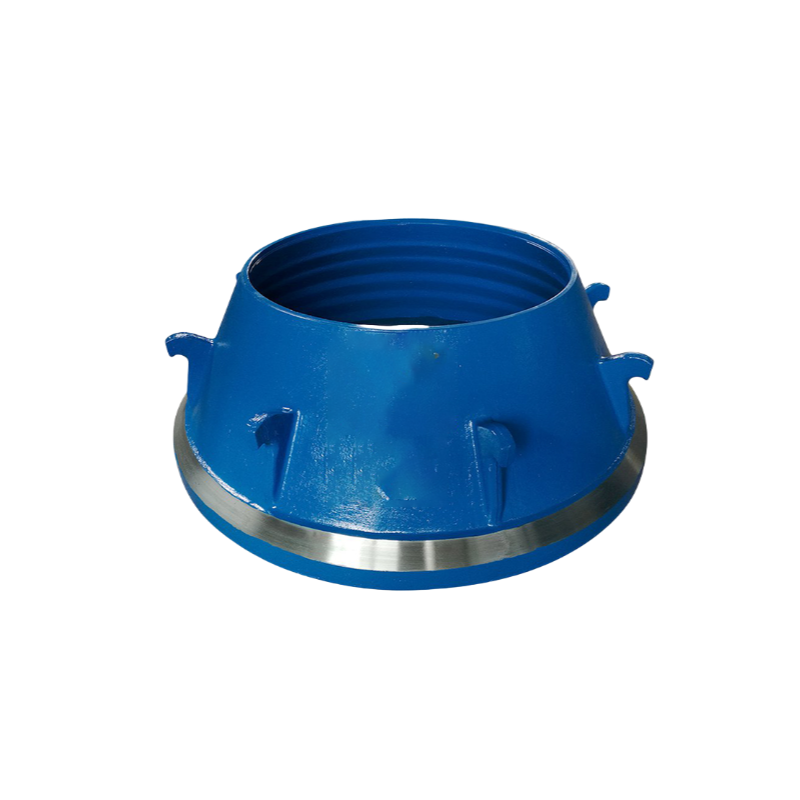

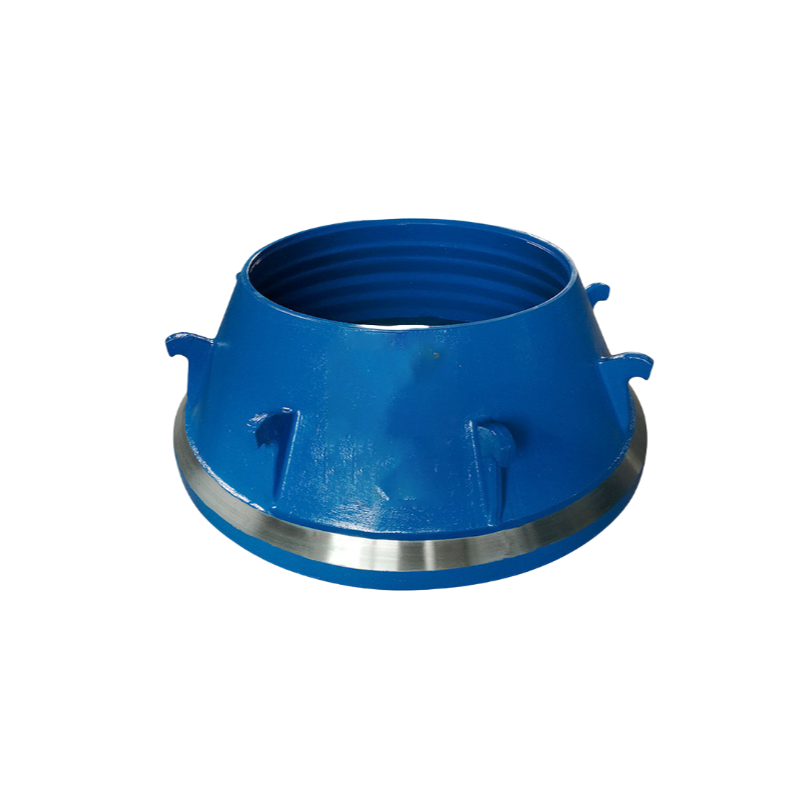

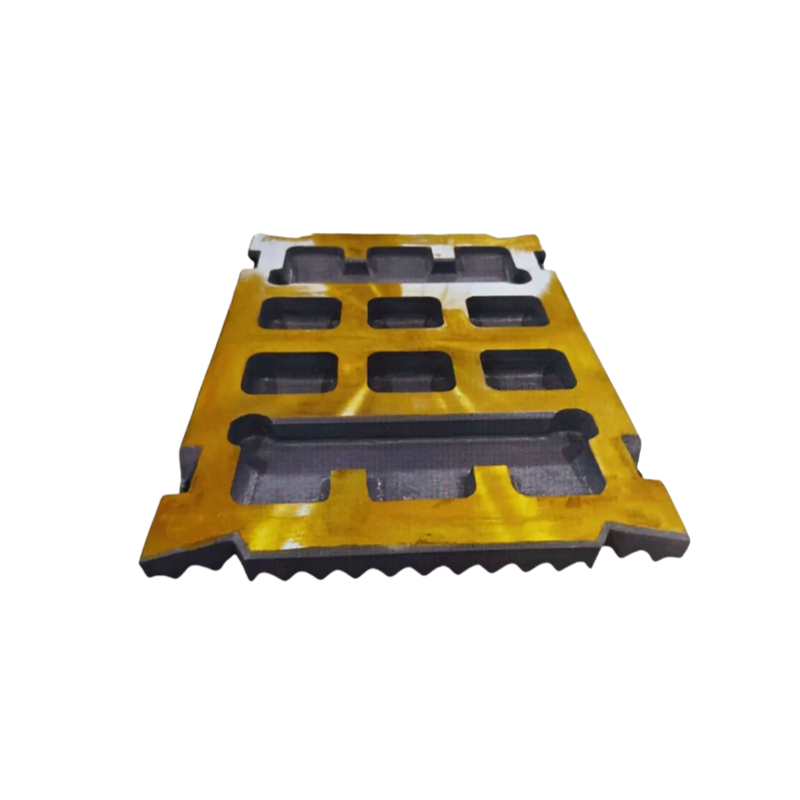

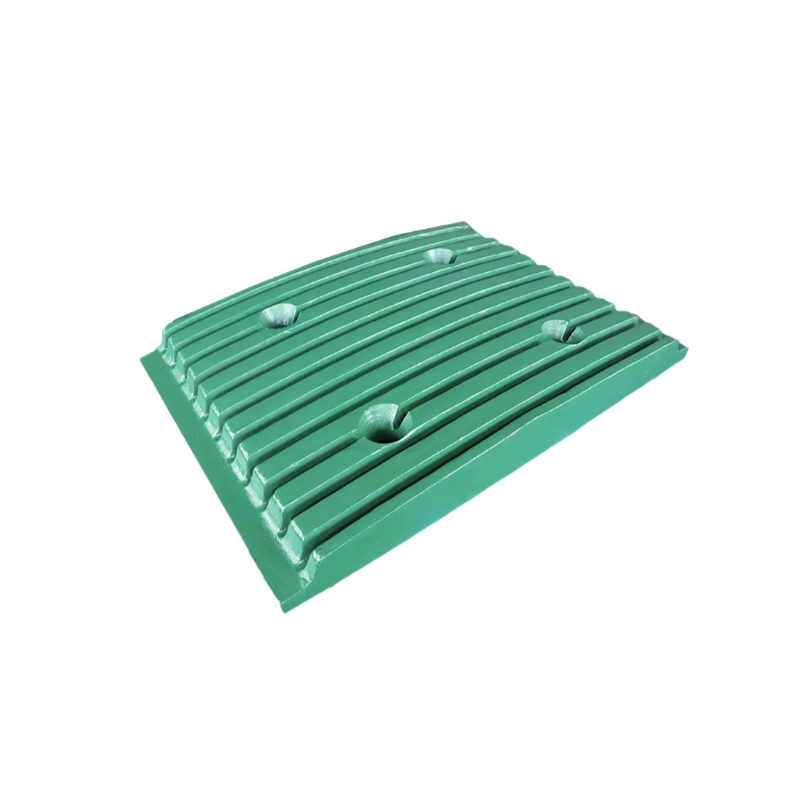

Excellent materials (composite ceramics, high chromium cast iron, alloy steel, etc.), good product quality, tested in South American mines, durability is 2 times that of peers.

Support customized production, develop new products according to drawings.

Rapid development, 3D printing, low cost, fast delivery.

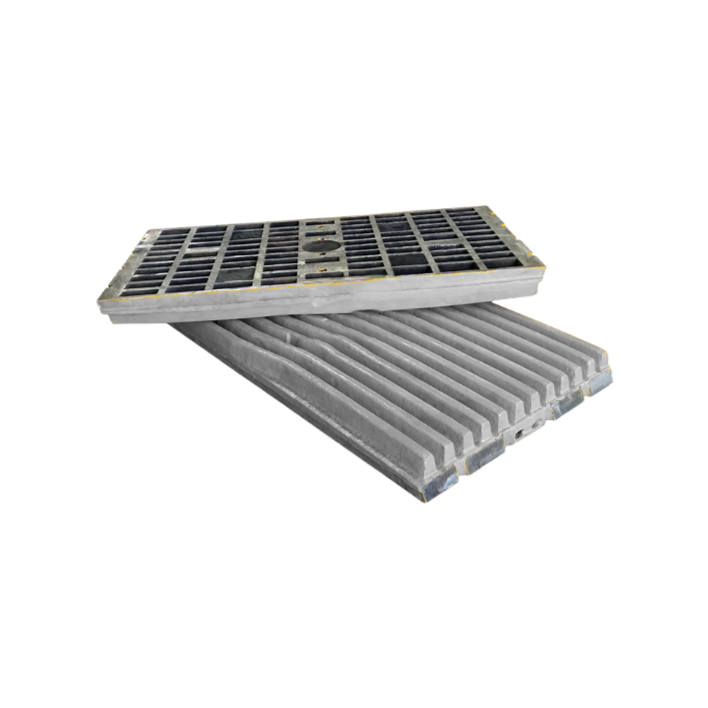

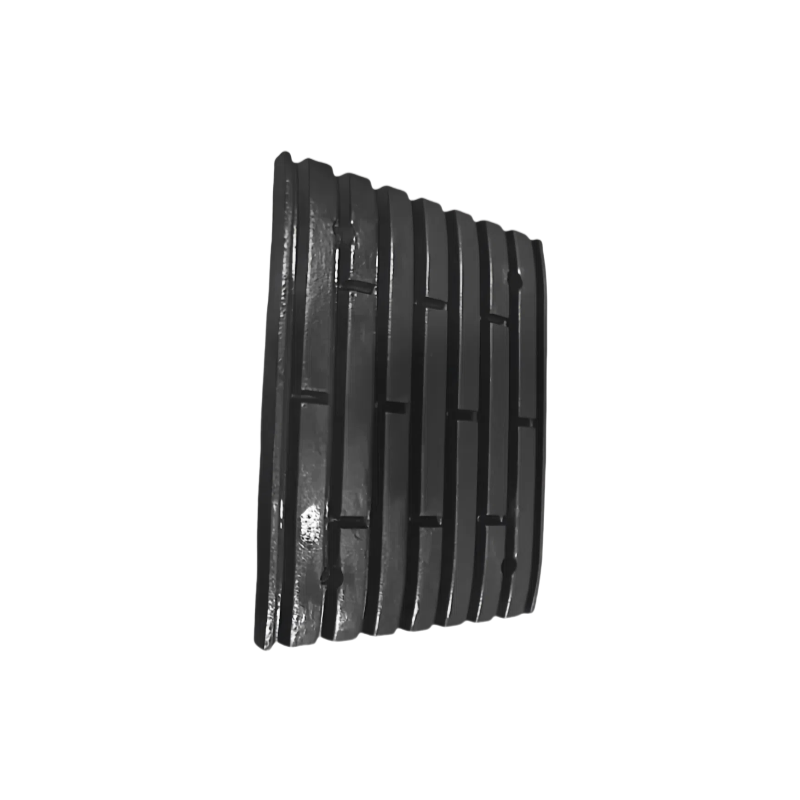

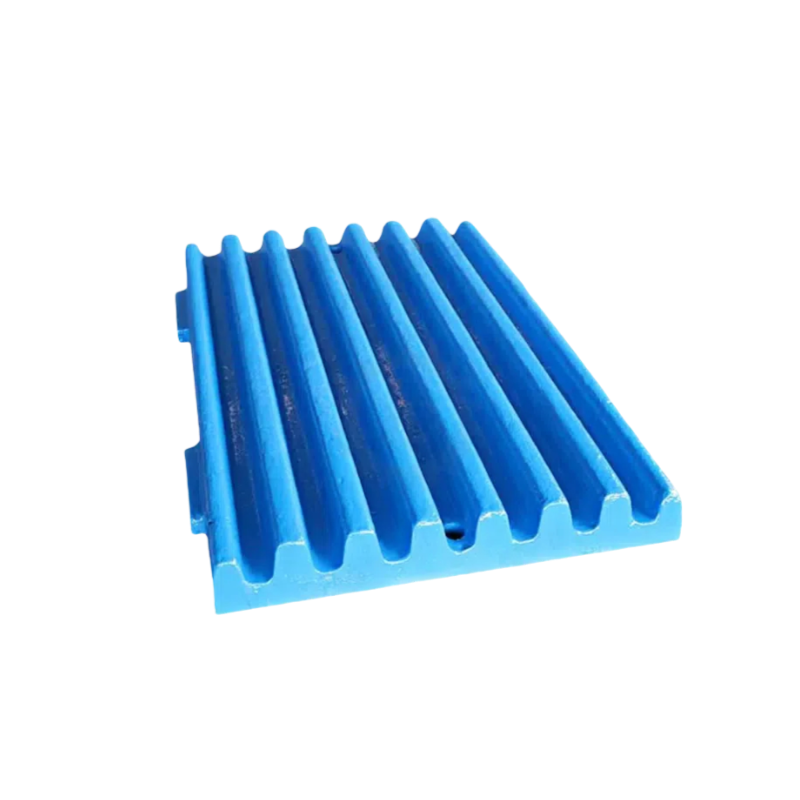

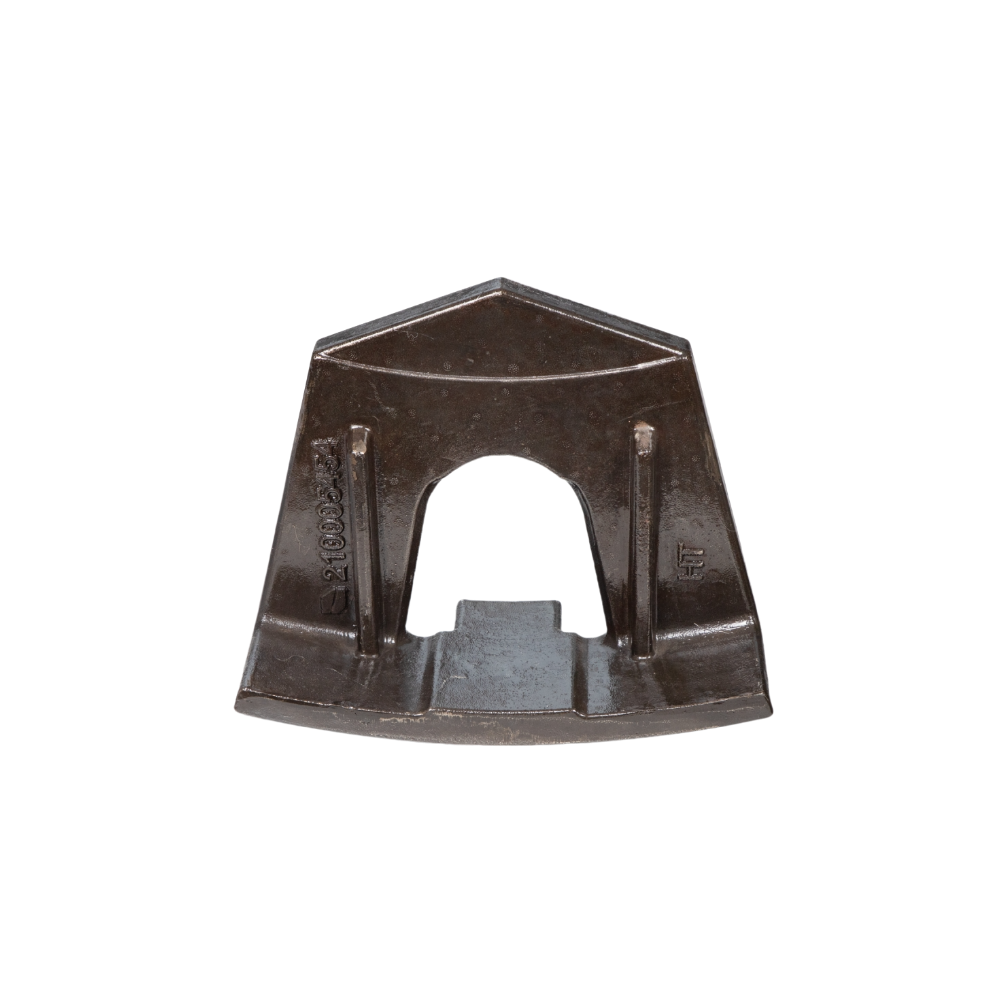

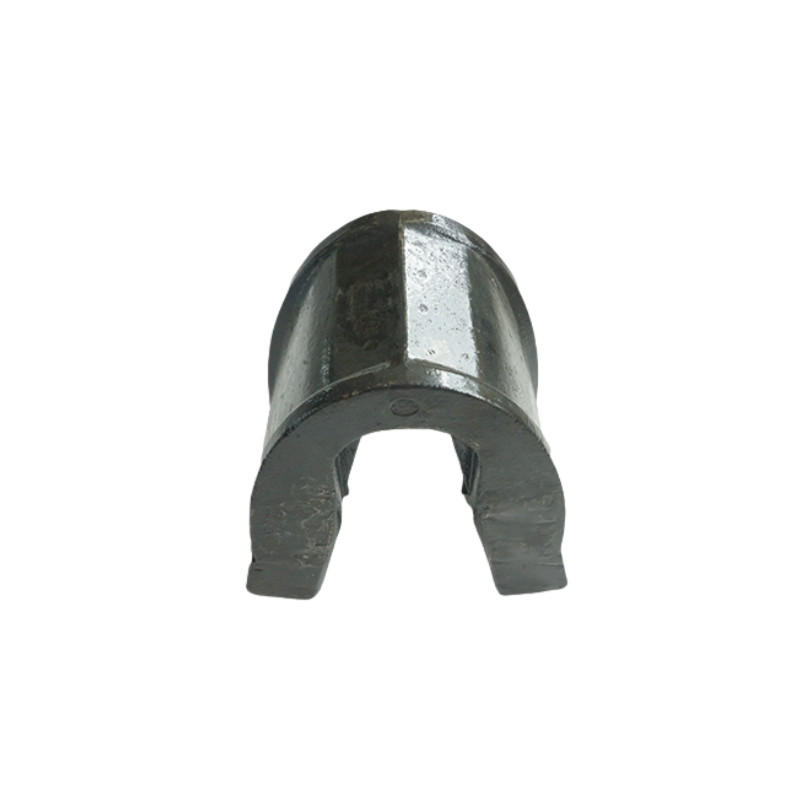

MINING WEAR PARTS

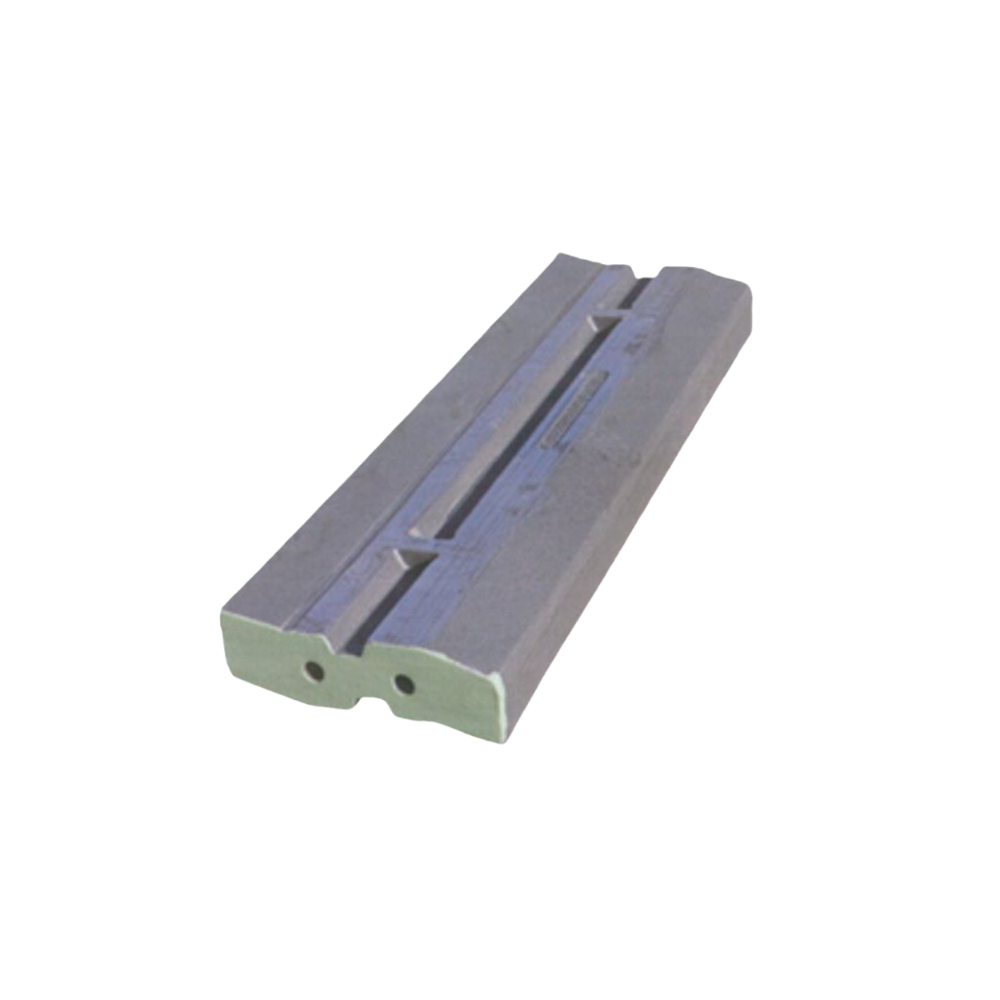

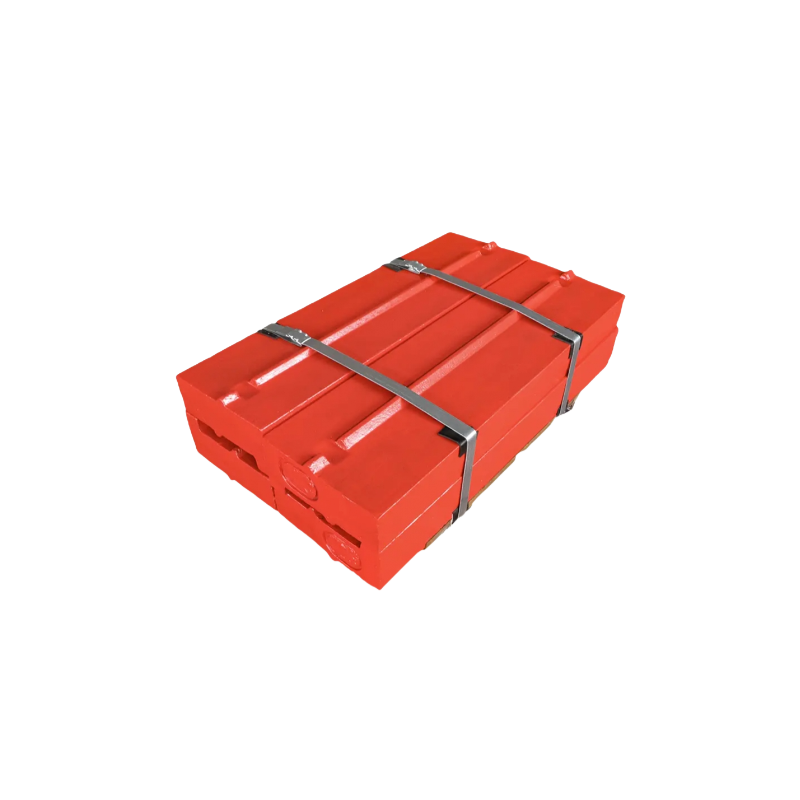

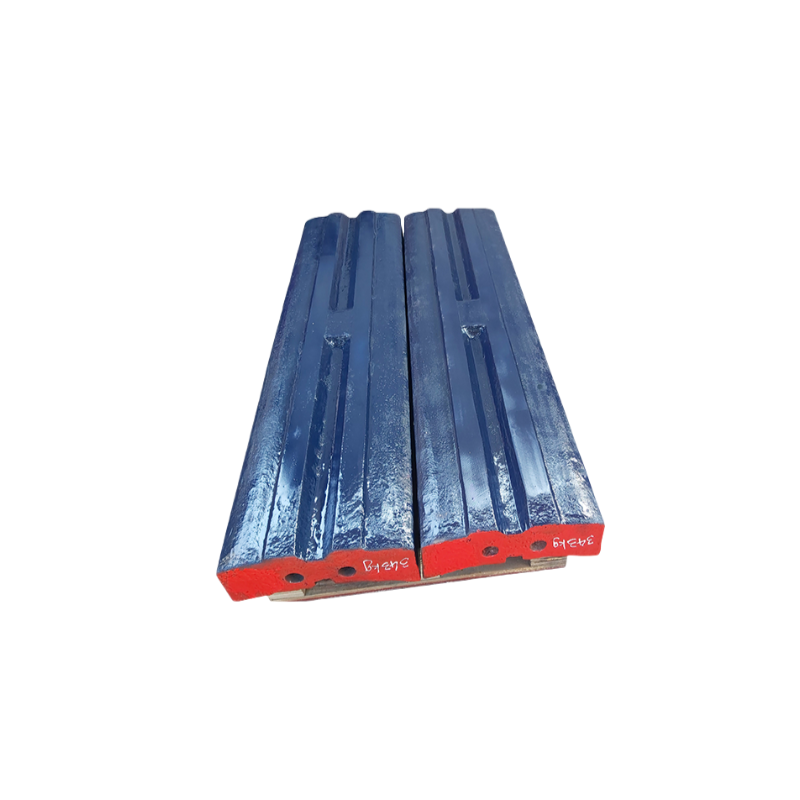

- Impact Crusher Parts

- Cone Crusher Parts

- Jaw Crusher Parts

- Gyratory Crusher Parts

- Sand Making Machine Parts

MANUFACTURING CAPABILITY

-

Advanced DISA vertical molding line

The DISA vertical molding line achieves rapid molding through vertical parting boxless injection molding technology. In the production of mining wear parts (such as liners, hammer heads, etc.), high-density molding is achieved, and automated assembly line operations can stably produce large quantities of small and medium-sized wear-resistant castings with strong consistency.

-

Lost foam casting of large complex parts

The lost foam casting uses foam models for direct casting, which is suitable for large and complex mining wear-resistant parts. The foam model is used to form complex geometric shapes such as cavities and holes in one go, avoiding the parting restrictions of traditional sand molds.

-

3D printing prototyping

Use 3D printing technology to accelerate the development of wear-resistant parts prototypes, directly print resin or sand mold prototypes, shorten the design verification cycle, and is especially suitable for testing new wear-resistant parts structures.

-

In-house heat treatment and machining

Control heat treatment and finishing processes independently to ensure that wear-resistant parts meet performance standards, adjust quenching and tempering processes according to materials (such as high chromium cast iron, manganese steel, etc.), optimize the balance between hardness and toughness, and improve impact wear resistance.

OUR DEVELOPMENT WORKFLOW

1. Technical Drawing Evaluation & Material Optimization

Based on customer needs, Haitian's engineering team conducts structural strength analysis of wear-resistant parts and optimizes the formulation of materials such as high-chromium cast iron and alloy steel to extend the service life of mining equipment.

2. Fully Controlled In-House Manufacturing Process with Stable Lead Times

From mold development to casting and heat treatment, an automated production line is used throughout the process to ensure the dimensional accuracy and performance consistency of wear-resistant castings, and to deliver on time without delaying production plans.

3. Customized Production Compatible with Multi-Brand Equipment

For crushers and sand making machines of different brands (such as Metso, Sany Heavy Industry, etc.), non-standard wear-resistant parts customization is provided to ensure perfect matching with the equipment and improve overall operating efficiency.

4. Batch Casting with Rigorous Multi-Stage Quality Inspection

Relying on DISA vertical molding line and lost foam casting technology to realize mass production of mining wear-resistant parts, each product undergoes multiple tests such as X-ray flaw detection, hardness test, and metallographic analysis.

5. Dedicated Engineering Support & Full Lifecycle After-Sales Service

Provide installation guidance for wear-resistant parts, wear monitoring suggestions and rapid replenishment services, and regularly visit to optimize usage plans to help customers maximize the reduction of ton consumption costs.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tel:

Tel:  Fax: 0555-6971198

Fax: 0555-6971198 Website:

Website:  Email:

Email:  Postal code: 243141

Postal code: 243141 Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Tik Tok

Tik Tok