In the engineering machinery, mining equipment, and concrete batching plant industries, equipment often operates under high load, continuous operation, and complex wear conditions.

Many customers encounter a common issue during actual use:

“The overall machine structure is intact, but key cast components require frequent replacement, affecting continuous production and maintenance costs.”

These components usually do not fail all at once. Instead, they gradually lose performance due to surface wear, fatigue failure, or localized pitting.

Simply upgrading to higher-grade materials or increasing part thickness often leads to higher costs, longer lead times, and may even affect the assembly and operational compatibility of existing equipment.

Based on this industry reality, Haitian Heavy Industry has developed a plasma diffusion casting solution, providing customers with more stable and durable critical castings without changing the equipment structure or significantly increasing costs.

Industry Status: Why Traditional Methods Are Becoming Less Effective

Traditionally, customers address casting wear issues by:

Upgrading material grades

Replacing spare parts earlier

Thickening critical sections

However, as equipment loads increase and operation time extends, these methods show limitations:

Material upgrades are costly, and not all areas truly require it

Overall thickening may affect structure and fit

Spare parts are consumed quickly, causing ongoing maintenance cost increases

Failure analysis shows:

👉 Over 80% of casting failures first occur at the surface working layer, not in the core structure.

This is exactly where plasma diffusion technology demonstrates its core value.

What is Plasma Diffusion Technology? (Customer-Friendly Explanation)

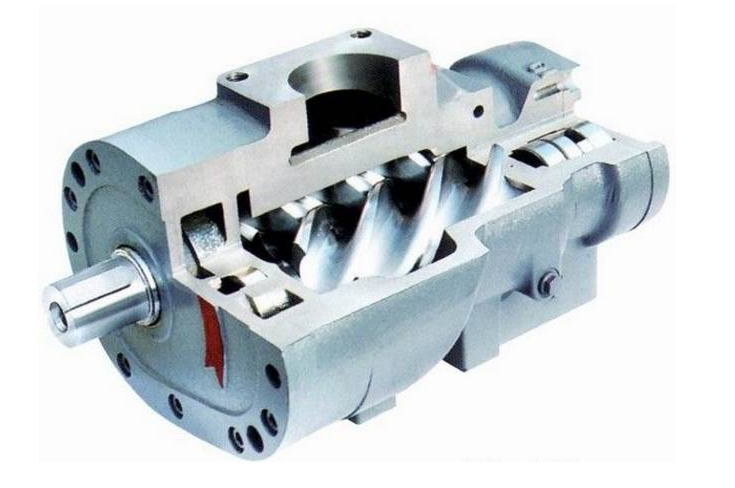

Plasma diffusion is a metal surface treatment process focused on surface strengthening.

Under controlled atmosphere and temperature, plasma activation diffuses strengthening elements into the metal surface, forming a metallurgically bonded hardened layer.

This process does not change the overall structure of the part and avoids the peeling risks associated with some coating methods.

Simply put:

Harder, more wear-resistant surface

Core retains original toughness and strength

Controlled dimensions and assembly precision

For high-precision, high-load cast components, it is an ideal solution that balances performance and reliability.

What Changes Can Plasma Diffusion Solutions Bring to Customers?

From a practical perspective, this solution is not just a "process upgrade," but a change in operational results:

🔹 Significantly extends the service life of critical cast components

🔹 Reduces surface wear rate

🔹 Improves operational stability, minimizing unexpected downtime

🔹 Extends maintenance intervals and reduces spare parts consumption

🔹 Does not affect existing equipment structure or assembly

For long-running equipment, this means:

less downtime, lower overall maintenance costs, and a more controlled production schedule.

Haitian Heavy Industry’s Approach: Not Just “Applying a Process,” But “Solving the Problem”

At Haitian Heavy Industry, plasma diffusion is not a standardized product option, but a customized solution based on working condition analysis.

1️⃣ Start from Real Customer Working Conditions

At the project’s initial stage, our engineers focus on understanding:

Equipment operation mode (continuous / intermittent)

Actual load levels

Speed range

Current component wear locations and failure cycles

Only after clearly identifying the “problem areas” do we decide whether to apply plasma diffusion technology.

2️⃣ Targeted Design Based on Material and Structure

Different castings and materials respond differently to diffusion. We evaluate:

Casting material system

Functional vs. non-functional areas

Dimensional and assembly precision requirements

We ensure reinforcement focuses on critical load-bearing and wear areas, rather than treating the entire part and adding unnecessary costs.

3️⃣ Controllable Process and Verifiable Results

During production and treatment, we strictly control:

Standardized process parameters

Hardness and appearance inspection before and after treatment

Compatibility with subsequent machining and assembly

The parts delivered to customers are fully verified and ready for immediate use.

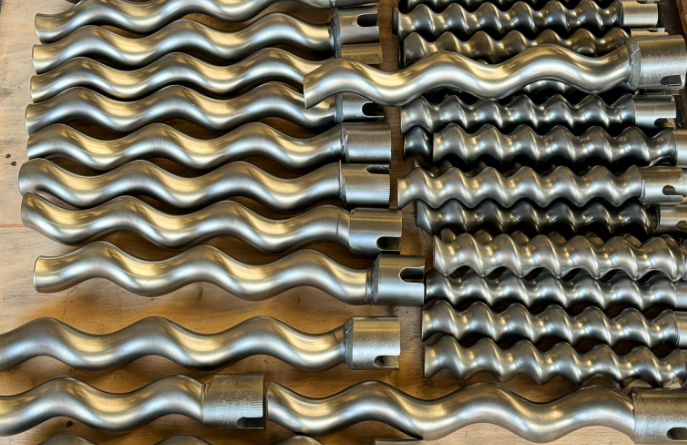

Customer Case: Plasma Diffusion Worm Rotor Solution

This solution has been successfully applied in a European customer project.

After the first batch of worm rotors was successfully delivered and accepted, Haitian Heavy Industry engineers further customized plasma diffusion worm rotors based on long-term operating conditions and wear feedback.

Through surface strengthening, the wear resistance and dimensional stability of the worm rotors under high-load, continuous operation were significantly improved, providing reliable support for the customer’s stable operation.

👉[View Customer Case | Italian Worm Rotor Plasma Diffusion Solution]

This project also marks the upgrade from single product delivery to long-term technical collaboration and working-condition-based solution partnership.

Typical Cast Components Suitable for This Solution

The plasma diffusion casting solution is particularly suitable for:

Worm rotors and transmission castings

Critical wear components in concrete batching systems

Functional castings under continuous load

Cast parts requiring high dimensional stability

If components show the characteristic of “surface fails first while the core remains intact,” they are usually ideal candidates.

Why Choose Haitian Heavy Industry?

✔ Deep expertise in engineering machinery components and wear-resistant castings

✔ Integrated casting + surface strengthening capability

✔ One-to-one customization based on working conditions

✔ Proven success with real customer projects

✔ Focus on long-term, stable collaboration

We provide not just a process, but a sustainable, replicable, and verifiable solution.

Conclusion

Plasma diffusion technology provides a rational, cost-effective way to improve performance in the casting industry.

At Haitian Heavy Industry, this technology always focuses on one core goal:

Enable critical cast components to last longer and operate more reliably under real working conditions.

If you wish to evaluate whether this solution is suitable for your equipment and working conditions, please contact our technical team, and we will provide you with targeted professional advice.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tel:

Tel:  Fax: 0555-6971198

Fax: 0555-6971198 Website:

Website:  Email:

Email:  Postal code: 243141

Postal code: 243141 Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Tik Tok

Tik Tok