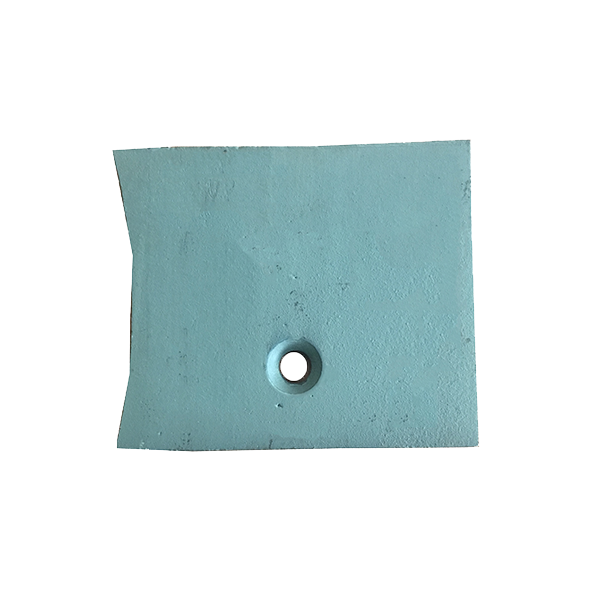

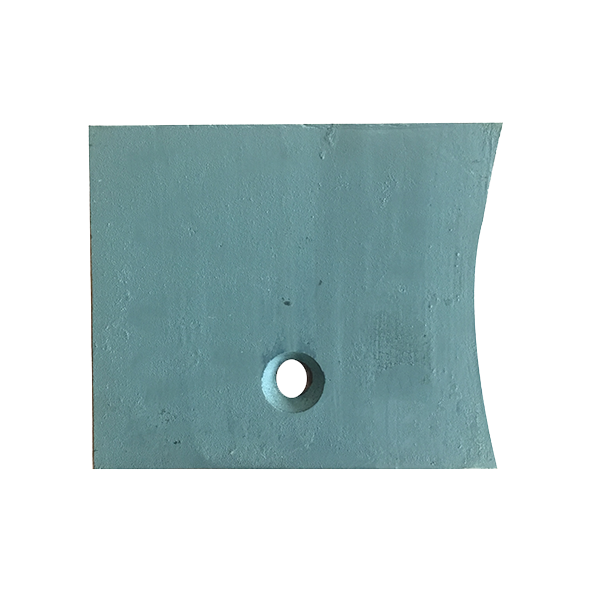

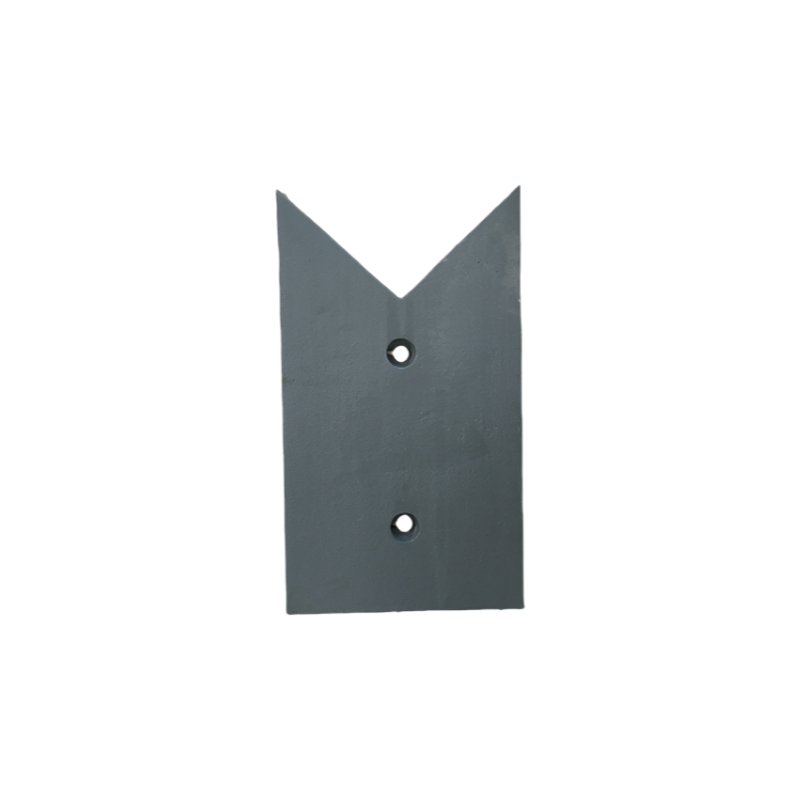

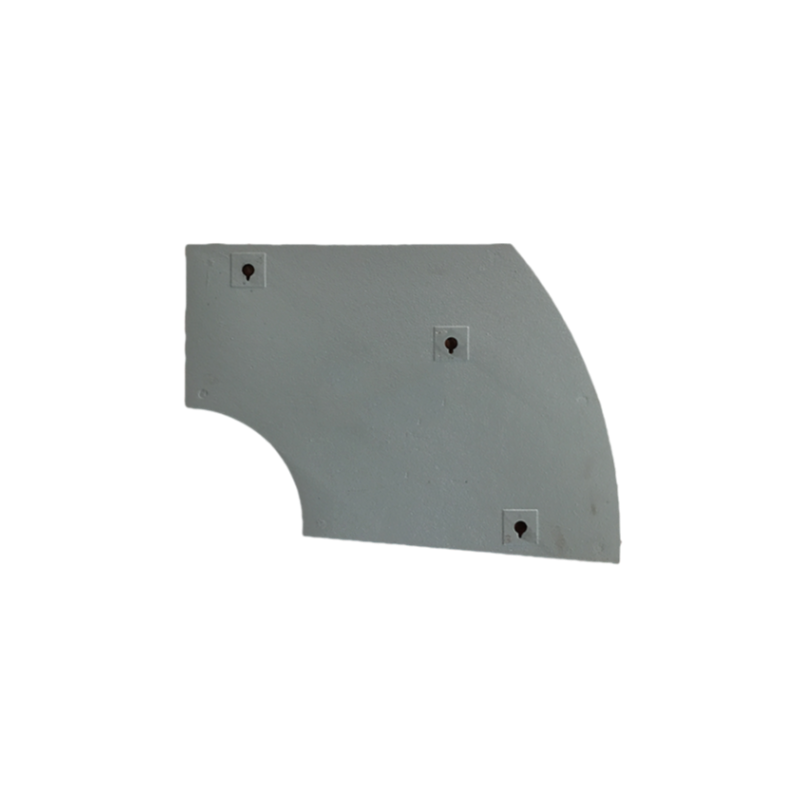

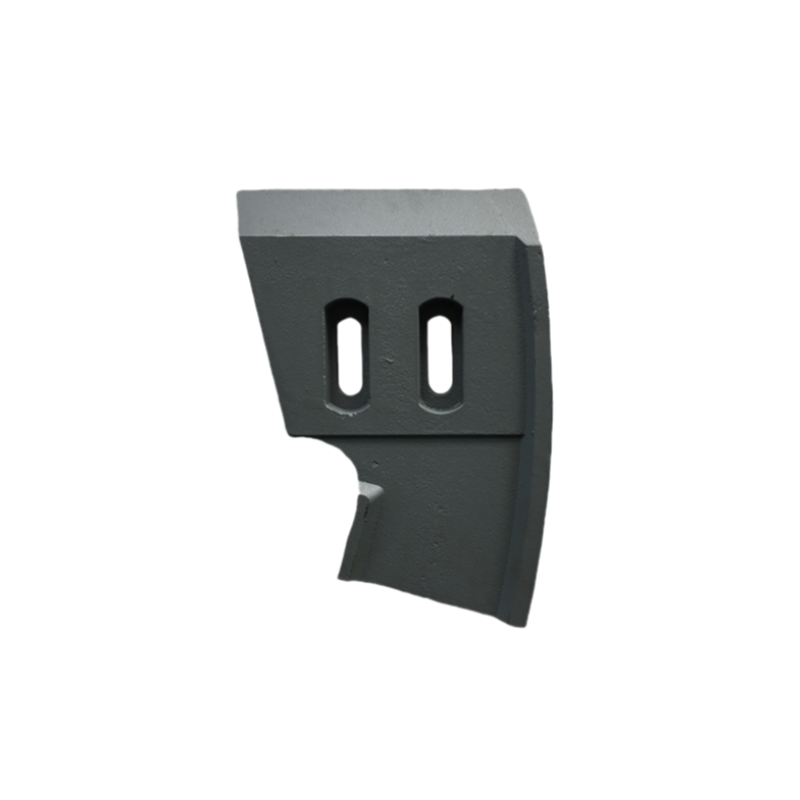

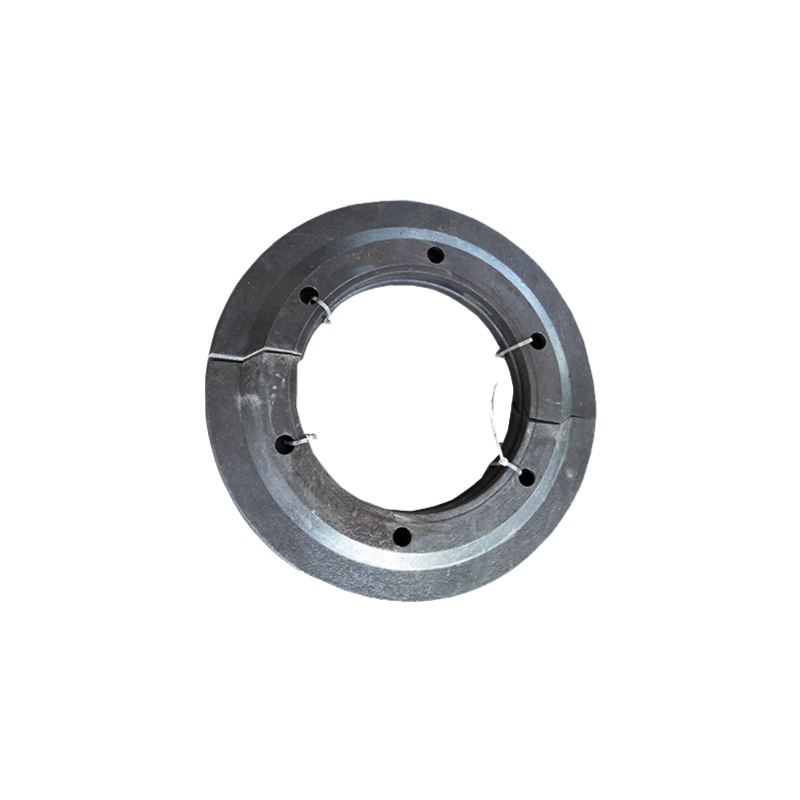

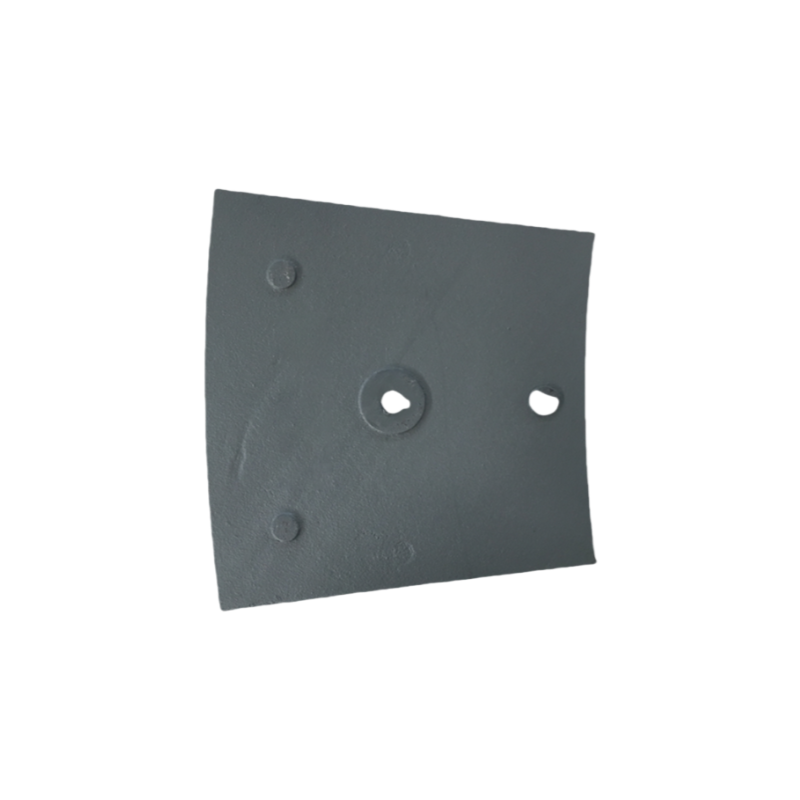

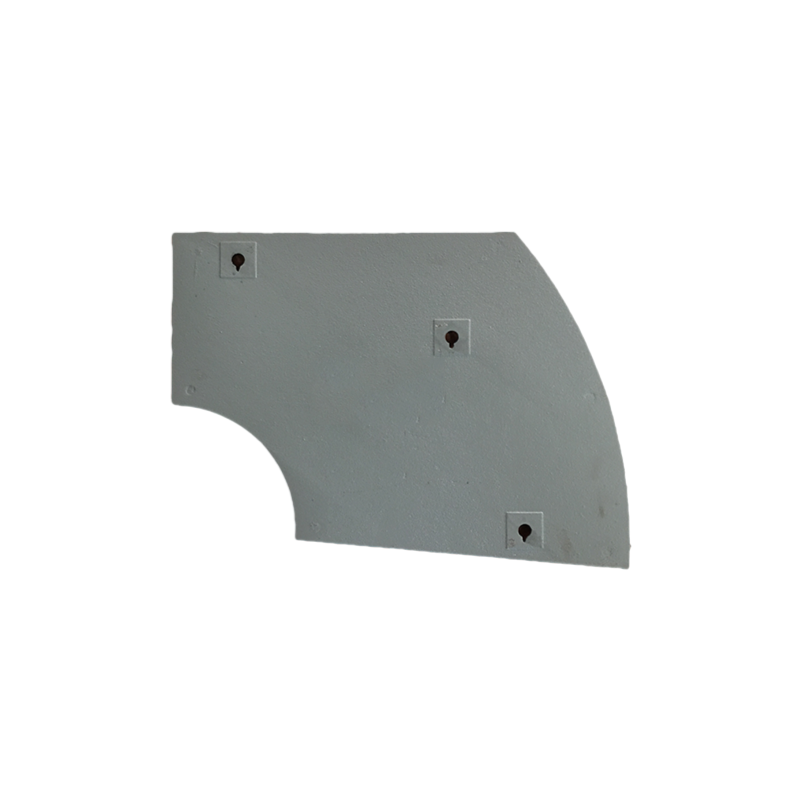

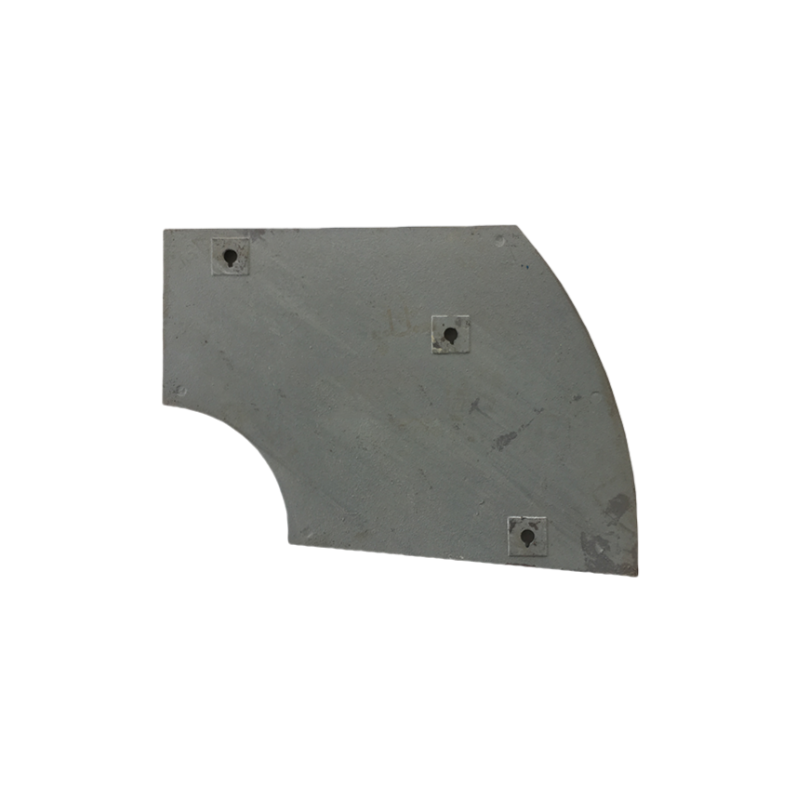

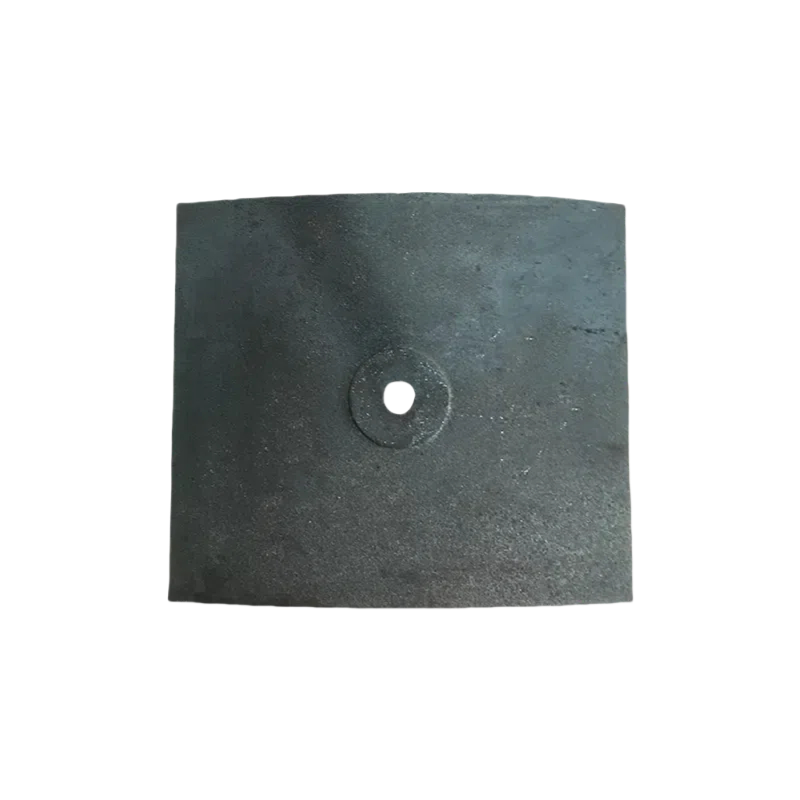

Good Toughness Lining Plate

Material:High Chrome Cast Iron

Application:Asphalt Mixers, Concrete Equipment,

Process:Precision Casting

Features:Excellent Toughness and Impact Resistance 、High Wear Resistance and Long Service Life、Easy Maintenance and Reduced Downtime

- Product Description

- Product Advantages

- More Details

The Good Toughness Lining Plate is a high-performance wear-resistant component specially designed for asphalt and concrete equipment, as well as heavy-duty industrial machinery. Manufactured from premium high-toughness alloy steel and processed with advanced heat treatment and precision machining, this lining plate offers excellent toughness, superior wear resistance, and long-lasting durability, making it ideal for high-impact and high-load operating environments.

Designed to meet the rigorous demands of the construction and asphalt industries, the Good Toughness Lining Plate ensures stable operation, reduced maintenance frequency, and longer equipment life. Its robust structure withstands high temperatures, abrasive materials, and continuous operation, providing reliable protection for mixers, hoppers, chutes, and other critical equipment components.

Key Features & Advantages:

High Toughness: Special alloy steel and optimized heat treatment provide exceptional impact resistance, preventing cracks and deformation.

Excellent Wear Resistance: Surface and material engineering enhance abrasion resistance for prolonged service life.

Durable & Reliable: Withstands heavy loads and continuous operation without compromising performance.

Precision Fit: Compatible with most asphalt and concrete mixers, enabling easy installation and replacement.

Easy Maintenance: Smooth surface and robust design simplify cleaning and replacement, reducing downtime and operational costs.

Cost-Effective: Long service life and reduced maintenance result in better overall investment value.

PRODUCT ADVANTAGES

-

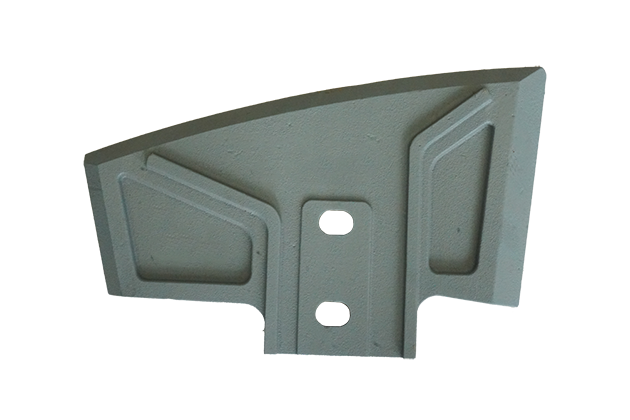

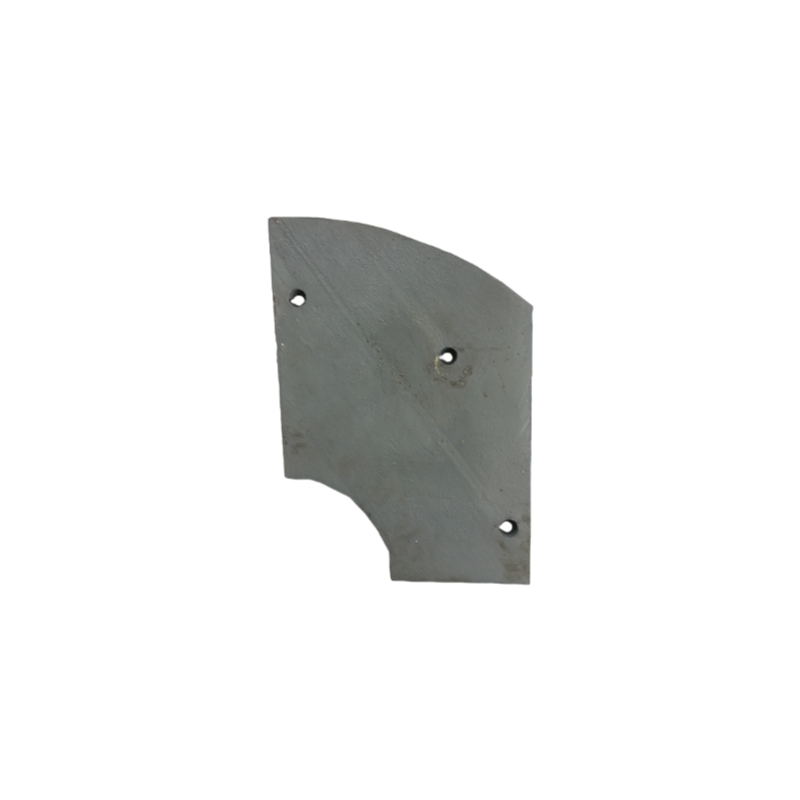

HIGH ASSEMBLY PRECISION

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

LONG SERVICE LIFE

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

STABLE QUALITY

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok