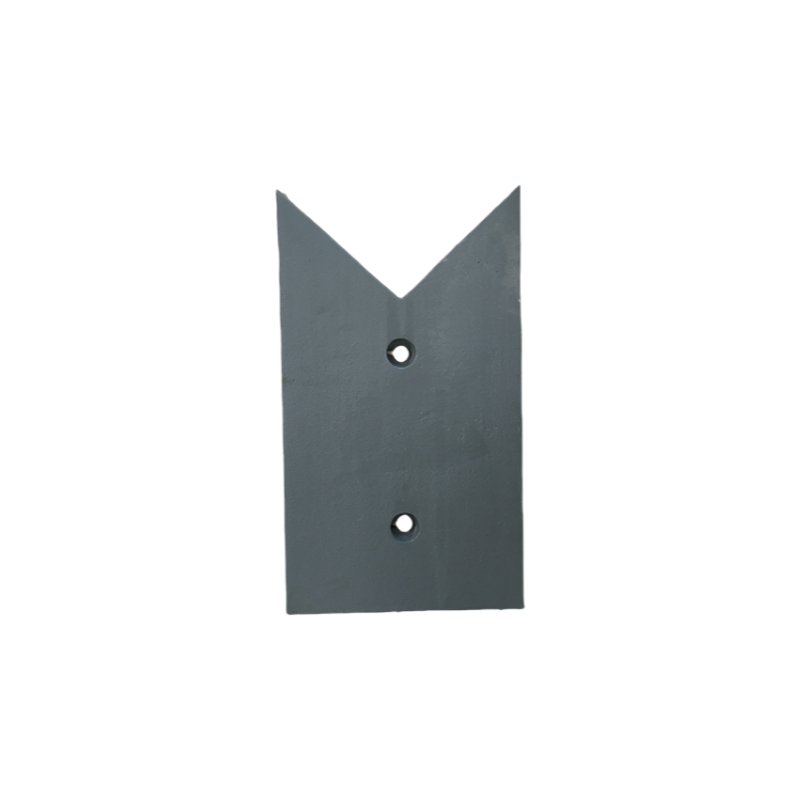

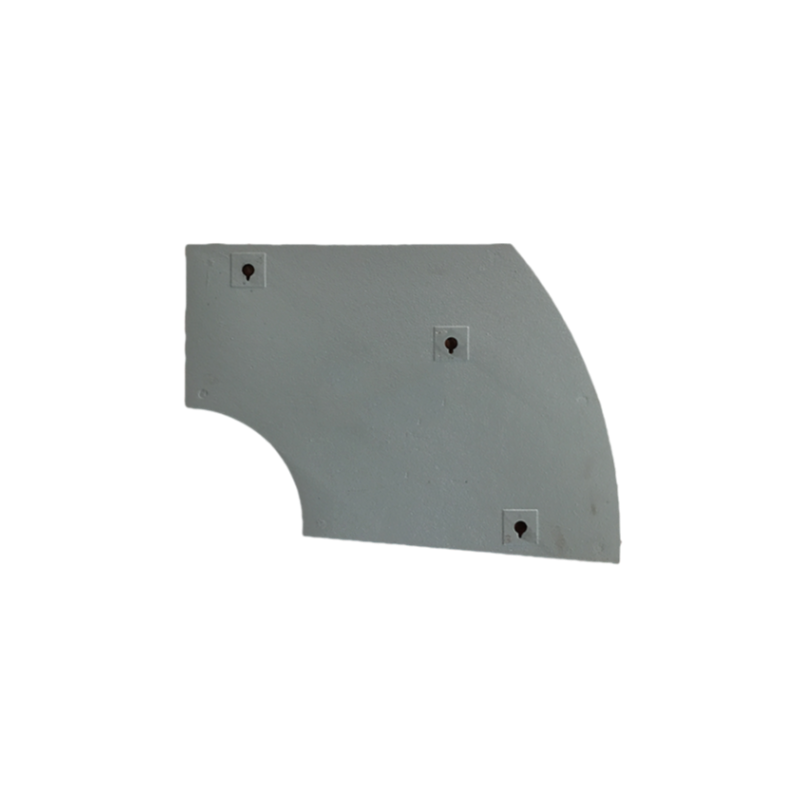

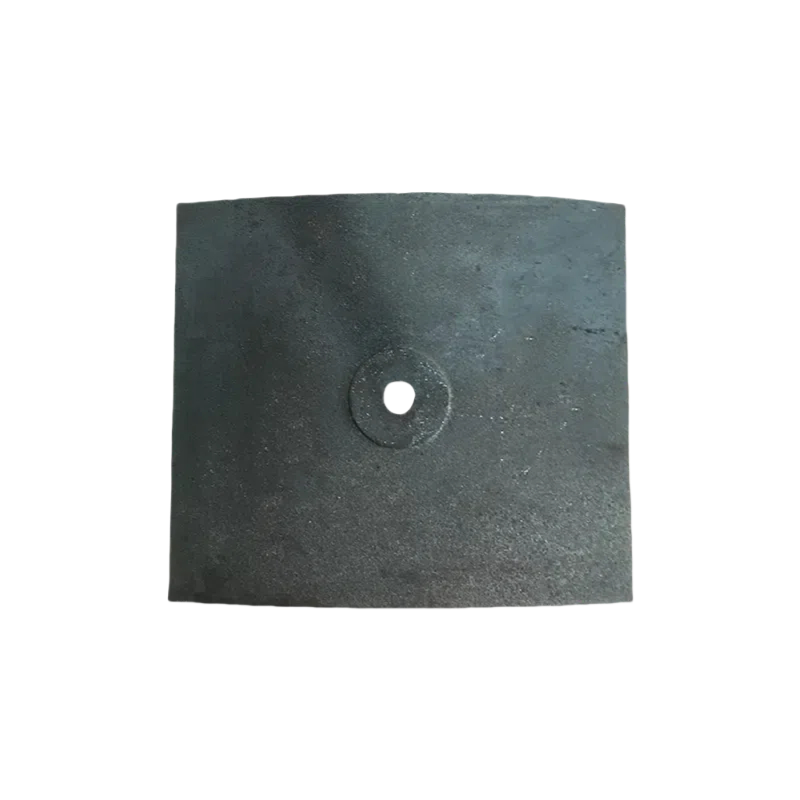

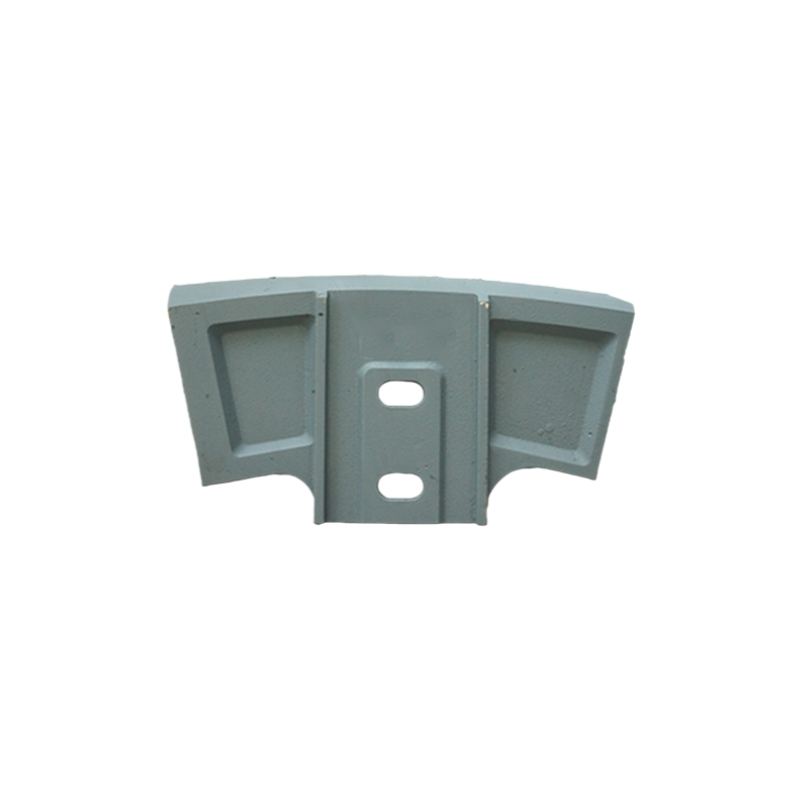

Economical & Corrosion Resistance Blade

- Product Description

- Product Advantages

- More Details

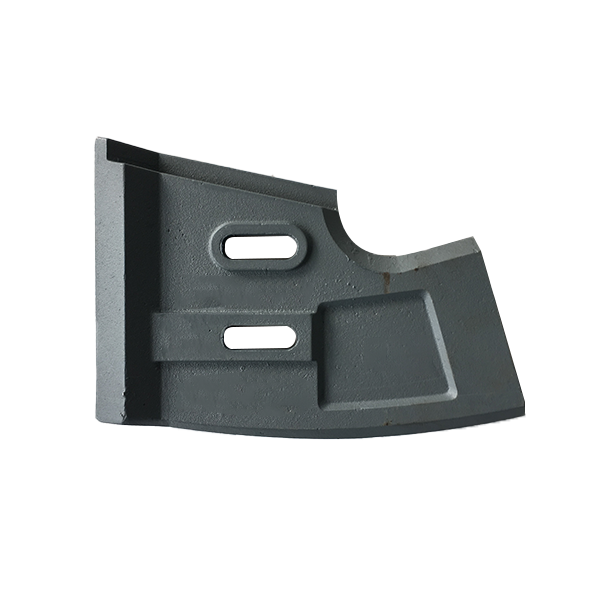

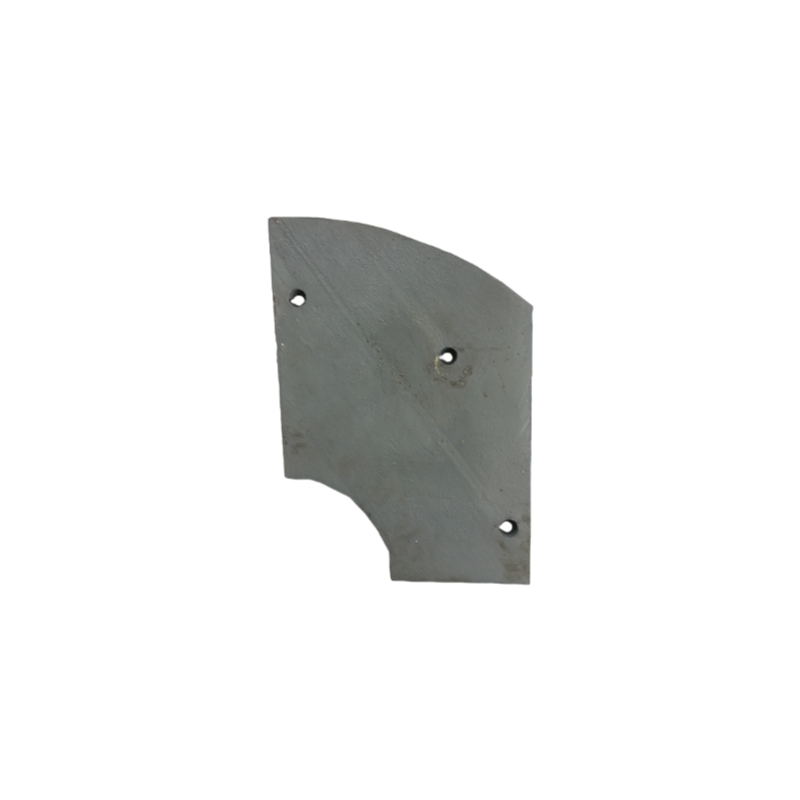

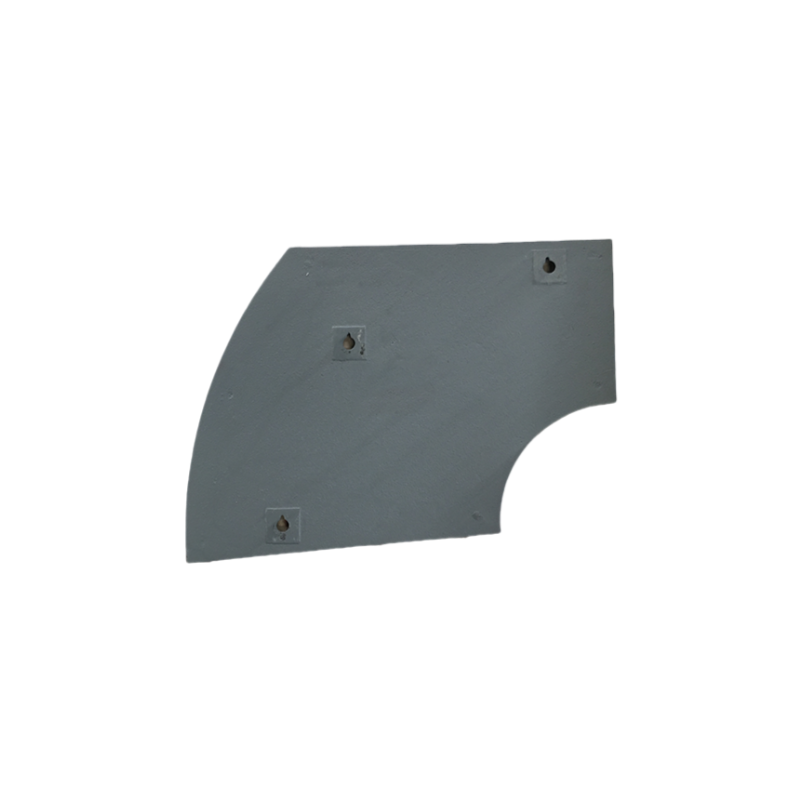

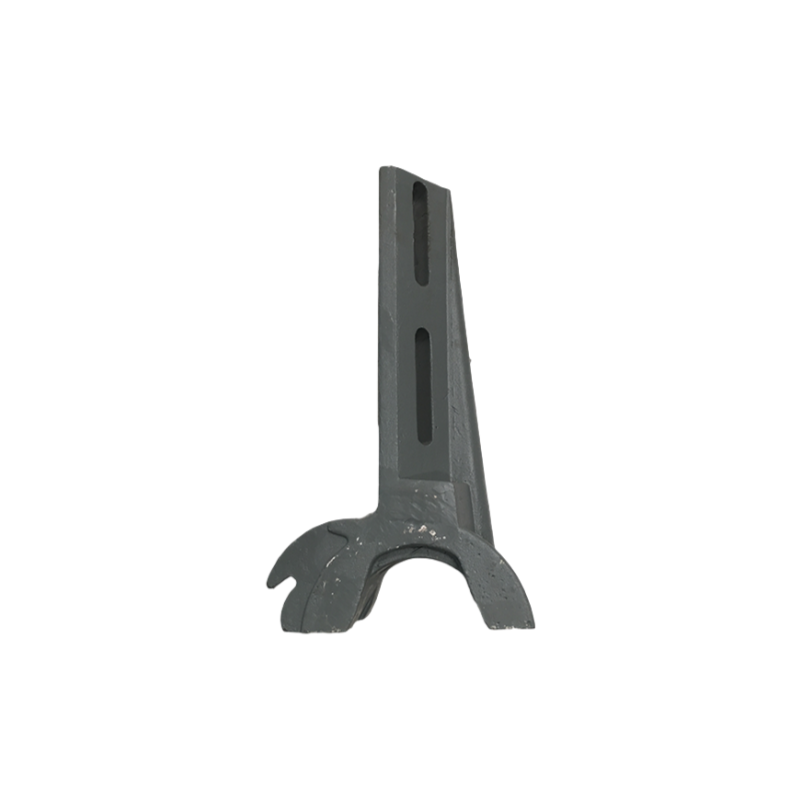

Economical & Corrosion-Resistant Blade is a practical and cost-effective wear solution developed for industrial applications where stable performance, corrosion protection, and controlled operating costs are essential. It is widely used in concrete mixing plants, asphalt mixing equipment, and other material handling or mixing systems that operate in humid, corrosive, or chemically aggressive environments. By balancing material performance and manufacturing efficiency, this blade delivers dependable service life while maintaining an attractive cost-performance ratio.

The blade is manufactured from carefully selected corrosion-resistant materials, such as optimized alloy steel or specially formulated wear-resistant alloys, designed to resist oxidation, moisture, and chemical exposure commonly encountered in industrial production. Through controlled casting or forming processes combined with appropriate heat treatment, the blade achieves a stable microstructure that enhances corrosion resistance without compromising basic mechanical strength. This makes it particularly suitable for applications where standard carbon steel blades may suffer from premature rusting, surface degradation, or reduced service life.

In daily operation, the Economical & Corrosion-Resistant Blade provides reliable scraping and material handling performance. Its optimized geometry allows effective removal of residual material from equipment surfaces, reducing material build-up and ensuring consistent process efficiency. At the same time, the corrosion-resistant surface helps maintain dimensional stability and functional integrity over extended operating cycles, even in environments with high humidity, water contact, or mild chemical exposure. This contributes to smoother equipment operation and more predictable maintenance intervals.

PRODUCT ADVANTAGES

-

HIGH ASSEMBLY PRECISION

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

LONG SERVICE LIFE

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

STABLE QUALITY

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok