Concrete Pump Truck Straight Pipe

Material:GCR15+Q345

Application:Concrete Pump Truck

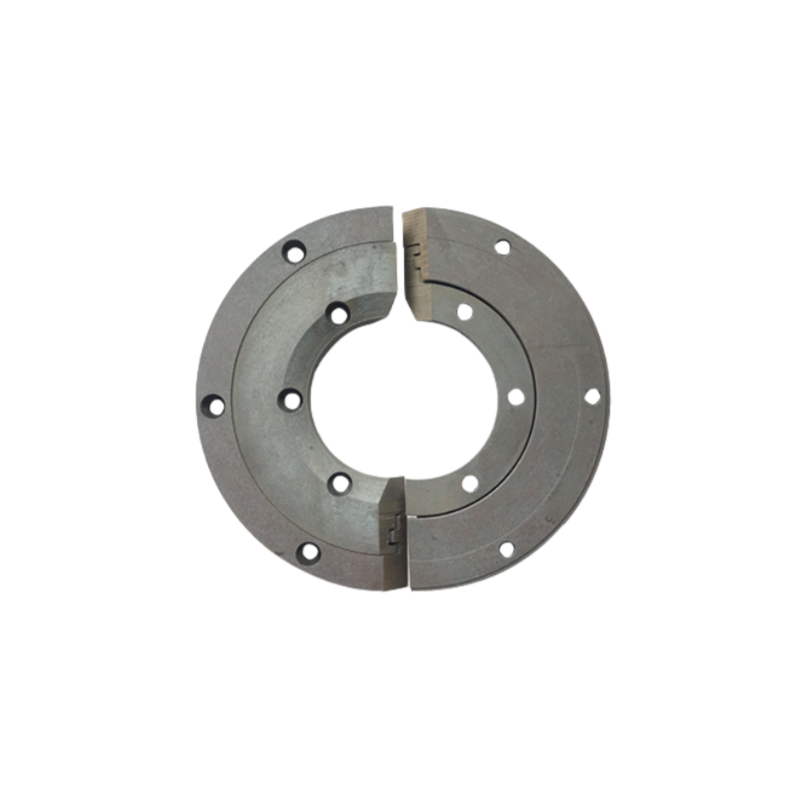

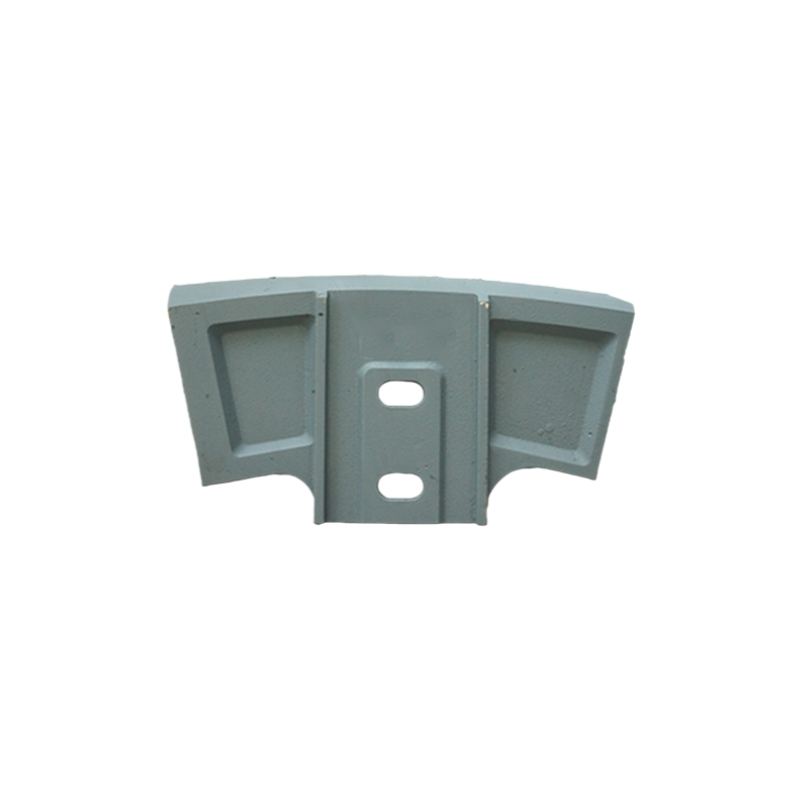

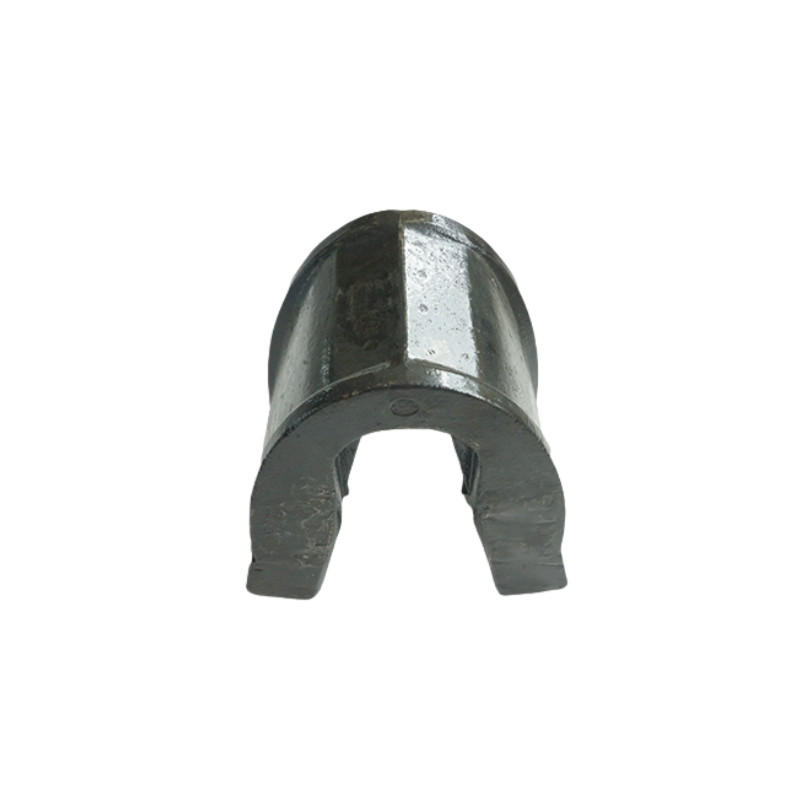

Process:Double Layered Composite Straight Pipe

Features:High Wear Resistance,High Hardness,Smooth Inner Wall,Convenient Connection,Corrrosion Resistance,Easy Maintenance,Economical.

- Product Description

- Product Specifications

- Product Advantages

- More Details

Concrete mixing plant straight pipe is a kind of conveying pipe used in concrete mixing plant, which is specially used to transport the mixed concrete from the mixer to the pouring site.

Straight pipes can stably transport concrete slurry, avoid segregation or stratification during transportation, ensure the uniformity and quality of concrete, and adopt a closed straight pipe transportation system to reduce the chance of concrete being exposed to the air during transportation, reduce pollution and material loss. It can achieve continuous transportation of concrete, reduce downtime, and improve construction efficiency. Straight pipes made of highly wear-resistant materials can greatly reduce the wear on the inner wall of the pipe during transportation, extend the service life of the pipe and equipment, and reduce the cost of frequent replacement and maintenance.

Product Specifications

| Product Name | Material | Weight(kg) | Service Life | Precision | Delivery Time | Model | Spray Painting | Inspection |

| straight pipe | GCR15+Q345 | 25 | 50,000cubic meters | CT9 | 7-10/15-20days | all series | Painting | 100% Inspection |

PRODUCT ADVANTAGES

-

HIGH ASSEMBLY PRECISION

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

LONG SERVICE LIFE

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

STABLE QUALITY

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok