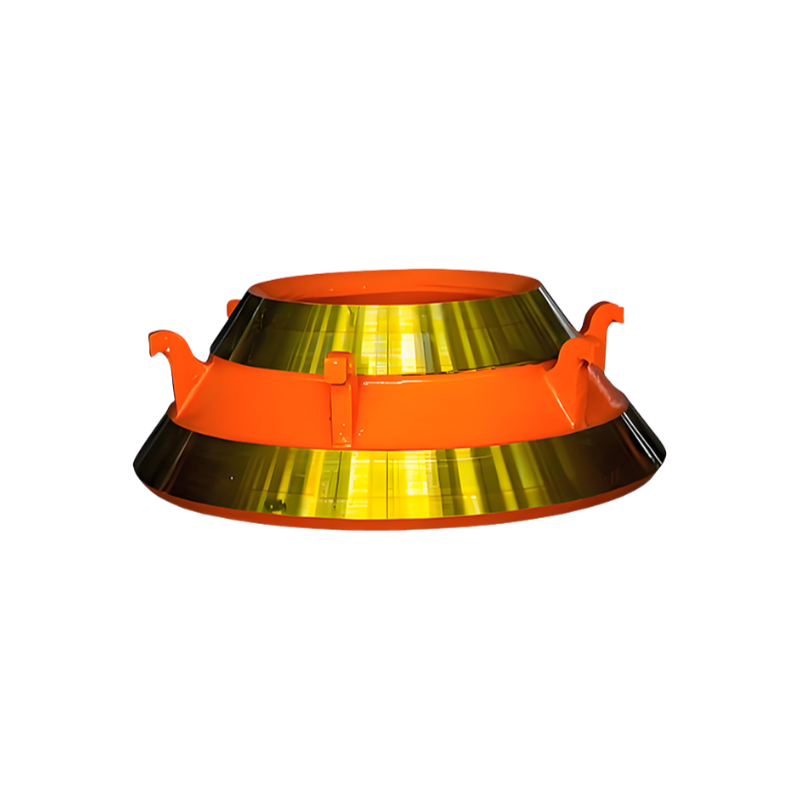

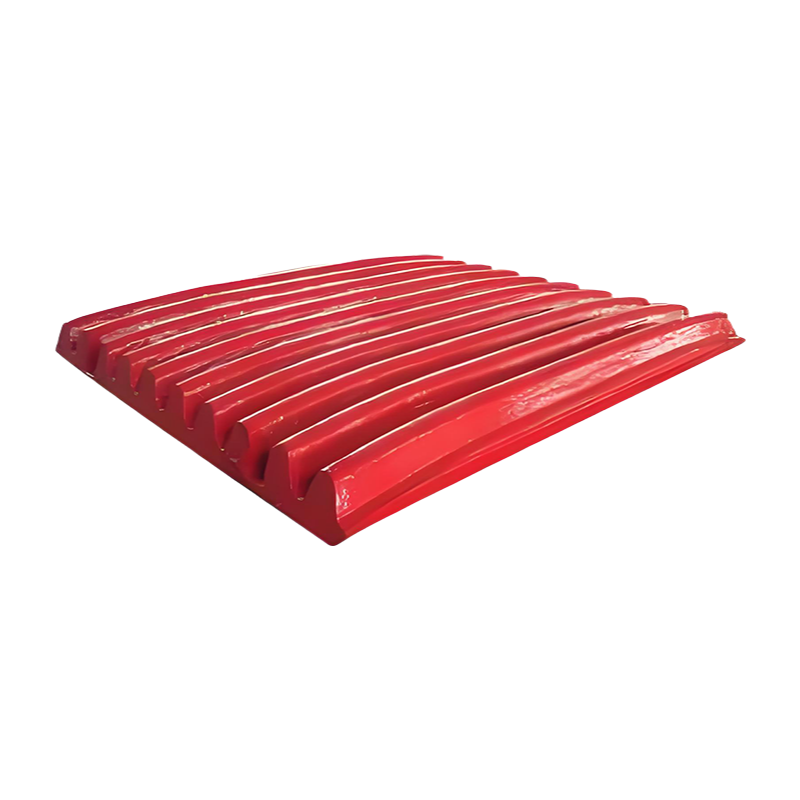

Cone crusher Bowl Liner

Material:

High Chromium Cast Iron

Application:Mining Industry

Features:Strong Wear Resistance、Noise Reduction、Easy Maintenance、High Adaptability、Improved Grinding Efficiency

- Product Description

- Product Advantages

- More Details

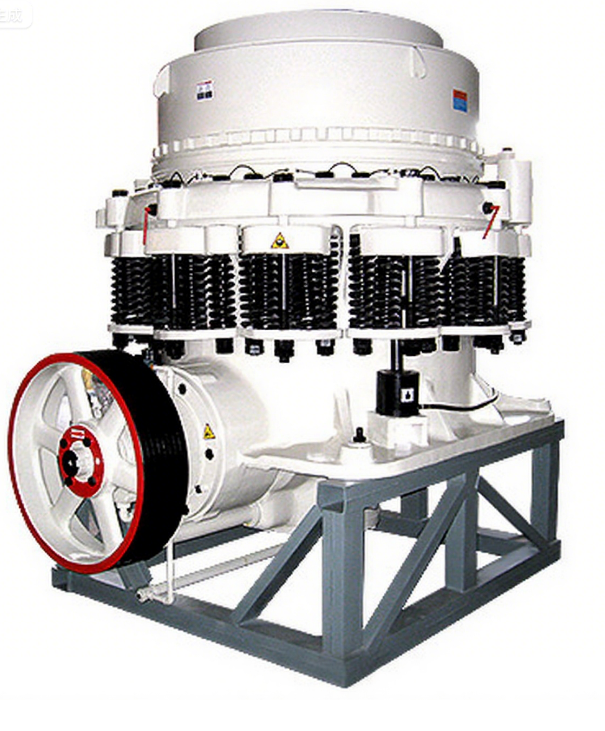

Our Cone Crusher Bowl Liners are manufactured from premium High Chromium Cast Iron, delivering exceptional hardness and superior wear resistance that stands up to the toughest mining conditions. Designed specifically for heavy-duty applications in the mining industry, these liners play a critical role in protecting the crusher’s mantle and ensuring consistent crushing performance over extended periods.

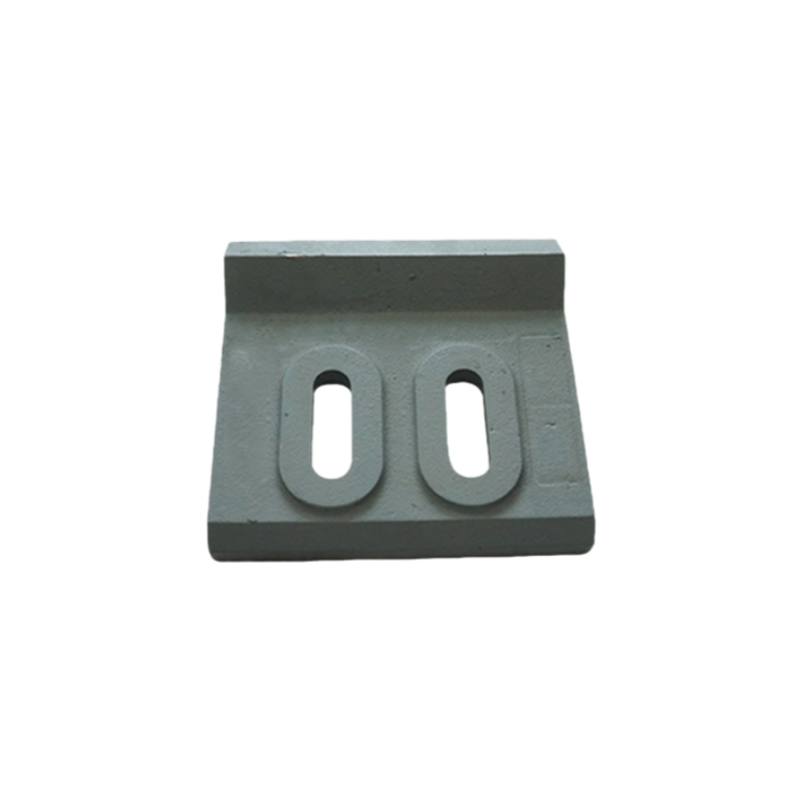

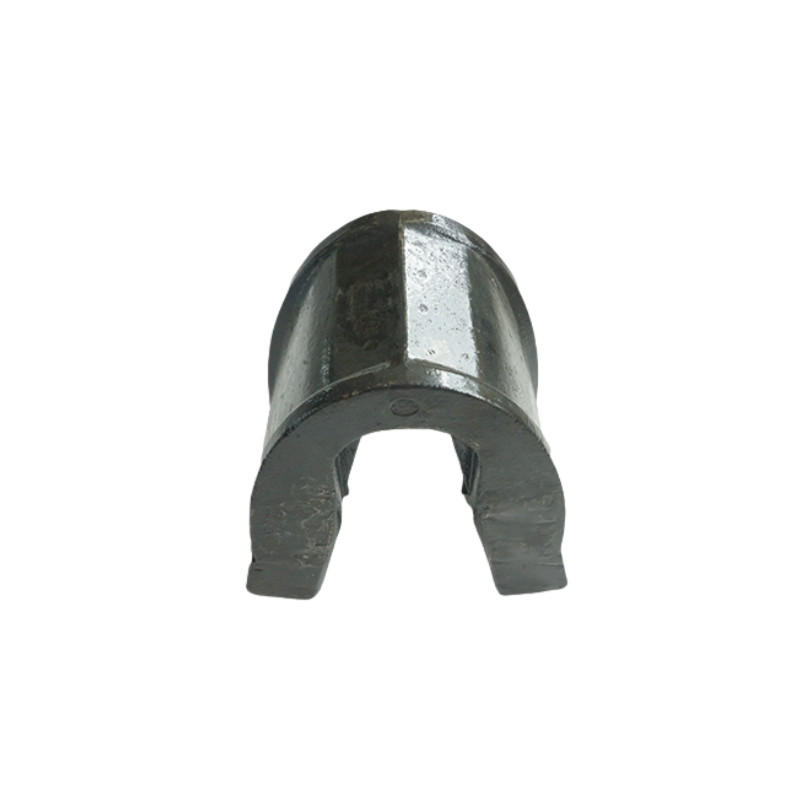

The bowl liner is a vital wear part of cone crushers, responsible for withstanding continuous impact and abrasive forces as the crusher processes hard rock, ores, and minerals. Our liners are engineered to provide an optimal balance between durability and toughness, minimizing downtime and maintenance costs for mining operators.Each bowl liner undergoes rigorous quality control and precision casting to ensure a perfect fit and dimensional accuracy, compatible with major cone crusher brands such as Metso, Sandvik, and Terex.

This guarantees seamless installation and reliable operation in various mining environments, from underground quarries to open-pit mines.Key features of our bowl liners include excellent wear resistance to extend service life, strong impact resistance to absorb shock loads, and noise reduction capabilities that contribute to a safer and more comfortable work environment.

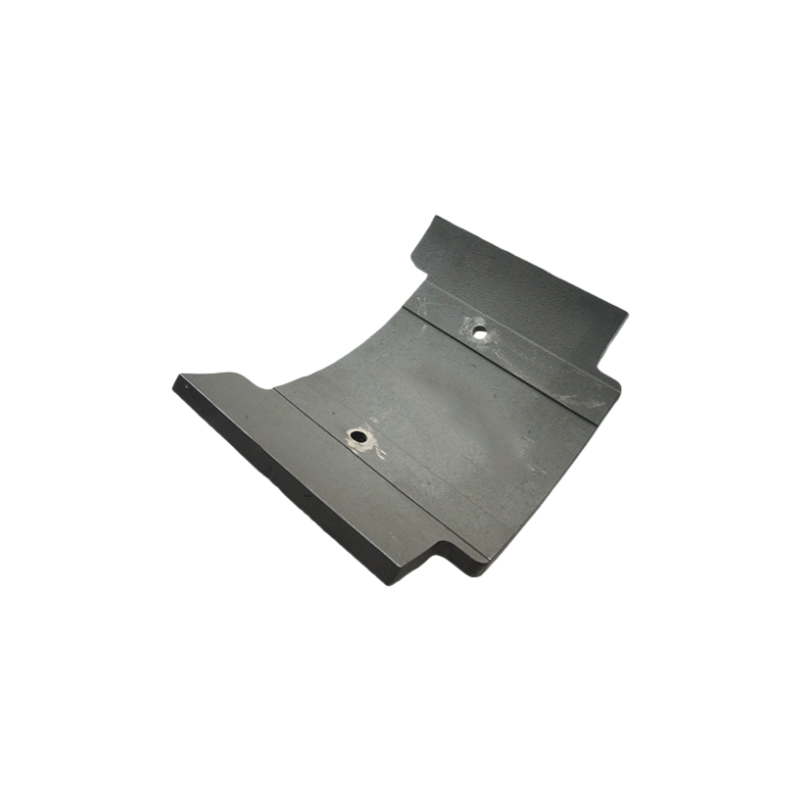

The design also facilitates easy maintenance and replacement, reducing operational disruptions.Additionally, the high adaptability of our liners allows them to perform effectively under diverse crushing conditions, enhancing grinding efficiency and overall crusher productivity.

By choosing our bowl liners, mining companies benefit from cost-effective solutions that improve equipment reliability and maximize throughput.Whether you require standard replacement parts or customized liners tailored to specific crusher models and site conditions, our engineering team is ready to support your needs with expert guidance and prompt delivery.

PRODUCT ADVANTAGES

-

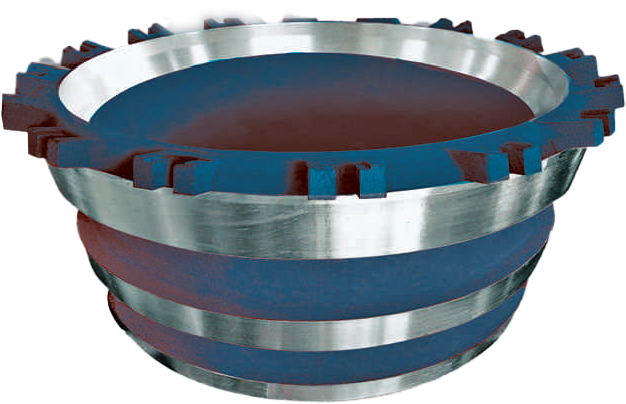

HIGH ASSEMBLY PRECISION

Haitian always adhere to efficient operation and ensure strict control of every link. 3D sand printing equipment can be used, with high product assembly accuracy and fast sample supply cycle. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

Haitian castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.With drawing numbers,Haitian can supply nearly 90% of wear-resistant parts for mining crushing equipment from major brands.

-

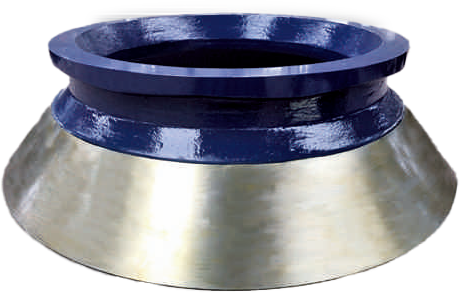

LONG SERVICE LIFE

Haitian cone liner uses advanced molten iron smelting with digital raw material control to ensure high purity and consistent quality. Combined with optimized casting, strict heat treatment, and rigorous inspections, each part delivers reliable performance, durability, and stable quality for demanding mining and crushing environments.

-

STABLE QUALITY

Haitian apply full-process quality control, from raw material sourcing to final inspection.

Each product undergoes strict testing, including spectrometric analysis, hardness testing, ultrasonic flaw detection, and metallographic inspection.With stable quality and reliable performance, Haitian parts deliver excellent wear resistance and strength, helping customers reduce downtime and maintenance costs in demanding mining environments.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok