One-Stop Wear Parts Solutions

To meet the high-demand operational needs of mining, cement, metallurgy, concrete, and asphalt industries, Haitian Heavy Industry offers a high-performance, all-in-one wear-resistant parts solution. From design to casting, machining, inspection, and shipment, our complete production process helps clients reduce downtime, extend equipment lifespan, and cut procurement costs.

What Can We Help You Solve?

1. Too many part categories to manage?

We integrate all your wear parts in one shipment – from spiral blades and crusher liners to mixing arms and cutting tools – reducing procurement costs and streamlining operations.

2. Not sure which material suits your needs?

Our engineers will guide you in selecting optimal materials such as high-chrome iron, manganese steel, and heat-resistant alloys – extending wear life up to 1.5–2x longer than industry standards.

3. Hard to find compatible spare parts?

We support custom drawing-based casting, old-part replication, and OEM replacement, compatible with most mainstream equipment brands.

4. Long delivery cycles and unstable quality?

With in-house tooling and casting lines, we ensure delivery in 7–15 days for standard parts and offer stock reservation services for long-term partners.

POPULAR WEAR PARTS FOR SALE

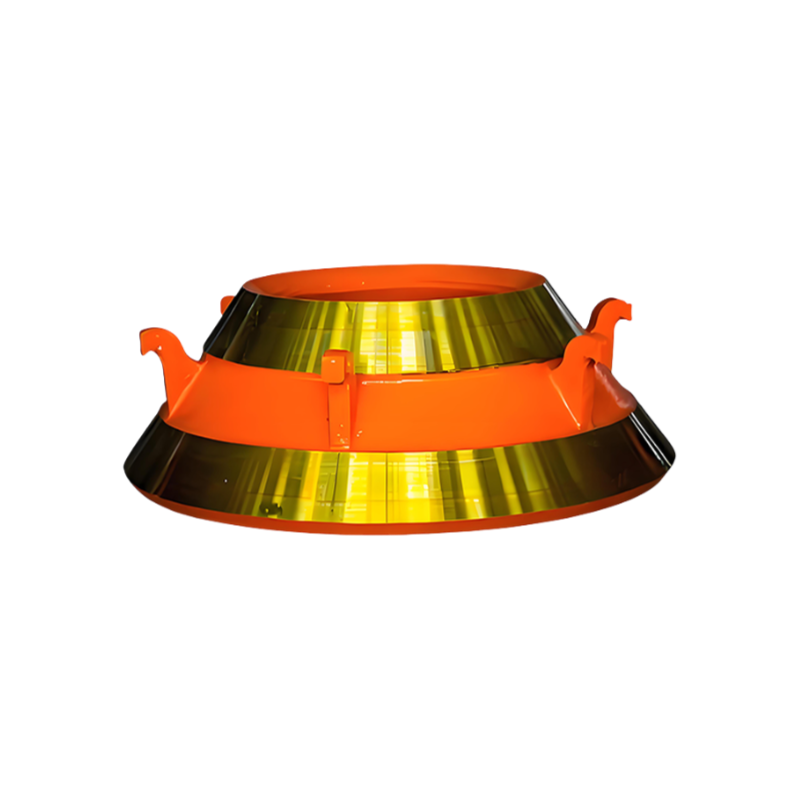

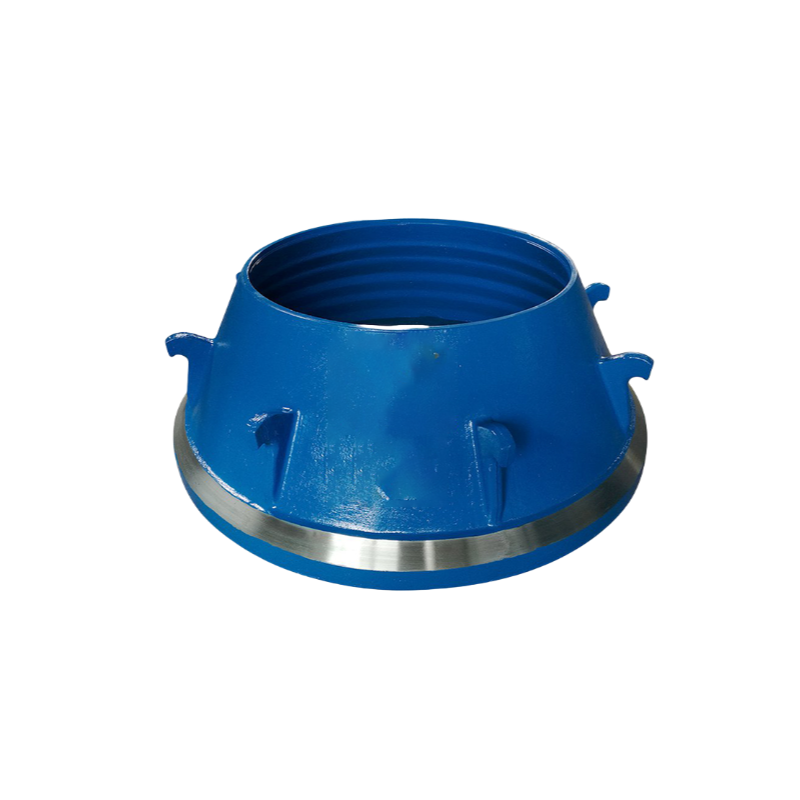

- Cone Crusher Parts

- Concrete Pump Truck Parts

- Asphalt Paver Parts

MANUFACTURING CAPABILITY

-

23 Senior Engineers & 37 Process Consultants

Our expert team covers mining, cement, metallurgy, and more, delivering customized solutions with rapid response—2-hour technical support and 48-hour on-site service to maximize equipment uptime.

-

Daily Casting Output 40+ Tons, Annual Capacity 12,000 Tons

Large-scale production ensures stable supply, with expedited 72-hour delivery for urgent orders. Bulk purchase discounts help reduce total procurement costs.

-

Comprehensive Mold Library for 1,000+ Equipment Models

Compatible with leading global and domestic brands, we offer 3D scanning and reverse engineering for fast 7-day mold development, ensuring precise fit and minimal downtime.

-

Advanced Heat Treatment for Enhanced Wear Resistance

In-house natural gas heat treatment furnaces optimize microstructure, achieving HRC62-65 hardness and 30% higher impact toughness, extending component lifespan 2-3x.

SERVICE WORKFLOW

1. Requirement Consultation & Technical Evaluation

We establish an efficient communication channel with clients to deeply understand equipment conditions, operating environments, and performance requirements. Through comprehensive data collection and technical evaluation, we ensure the solution is precisely tailored from the start—eliminating guesswork and reducing resource waste.

2. Customized Solution Development

Leveraging advanced CAE analysis and extensive material expertise, we tailor optimal part materials and structural designs for clients. Our solutions fully consider wear resistance, mechanical strength, and manufacturability, paired with transparent pricing and reliable lead times—helping clients maximize cost-effectiveness.

3. Efficient Tooling Development & Sample Validation

Our in-house tooling design and manufacturing team ensures short lead times and high precision in mold development. Samples undergo rigorous multi-dimensional inspections and field testing. Only upon client approval do we proceed to mass production, ensuring product performance and quality meet expectations.

4. Comprehensive Quality Control System

We implement full-process quality monitoring including dimensional checks, chemical composition analysis, mechanical performance tests, and nondestructive examinations. Every product leaving our facility meets or exceeds industry standards. Detailed inspection reports are available for client review, enhancing transparency and trust.

5. Professional Packaging & Global Logistics Support

We design diversified protective packaging tailored to product characteristics to ensure safety during transit. Integrating multimodal transport channels, we deliver worldwide quickly with real-time tracking—minimizing customer lead times.

6. Continuous After-Sales Technical Support

Offering 24/7 response service with dedicated account managers, we swiftly resolve technical challenges encountered onsite. We continuously improve products based on client feedback, jointly ensuring stable and efficient equipment operation.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tel:

Tel:  Fax: 0555-6971198

Fax: 0555-6971198 Website:

Website:  Email:

Email:  Postal code: 243141

Postal code: 243141 Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Tik Tok

Tik Tok