Corrosion Resistance Scraper

- Product Description

- Product Advantages

- More Details

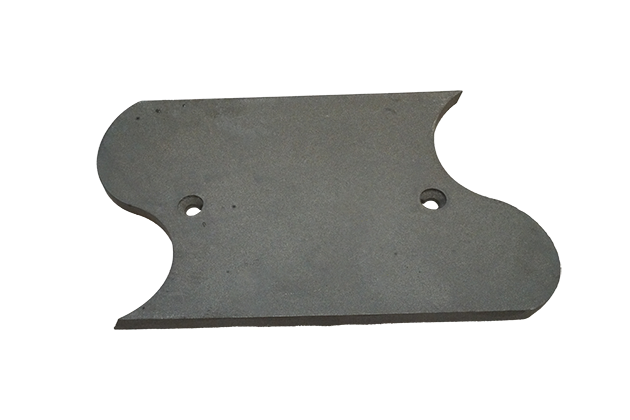

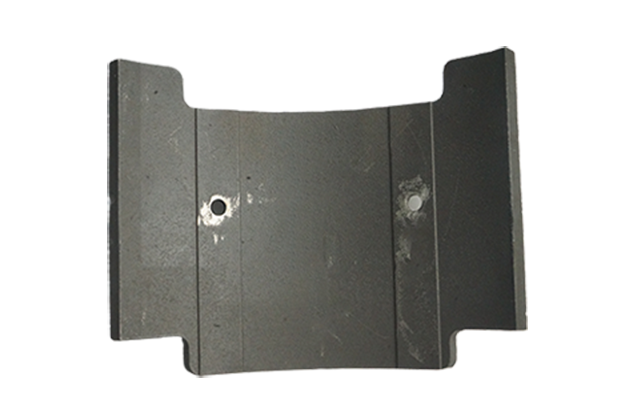

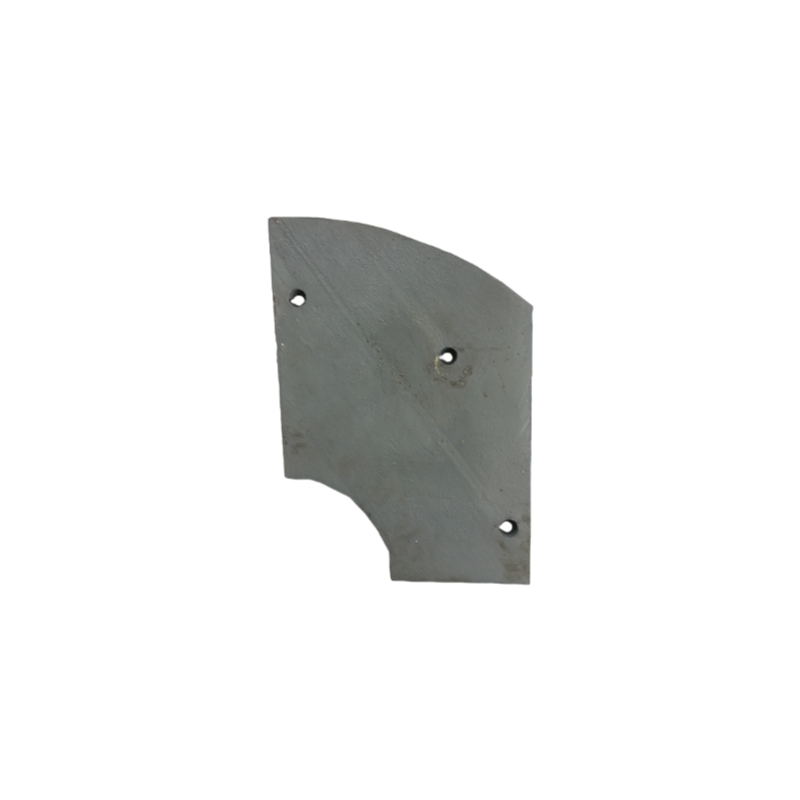

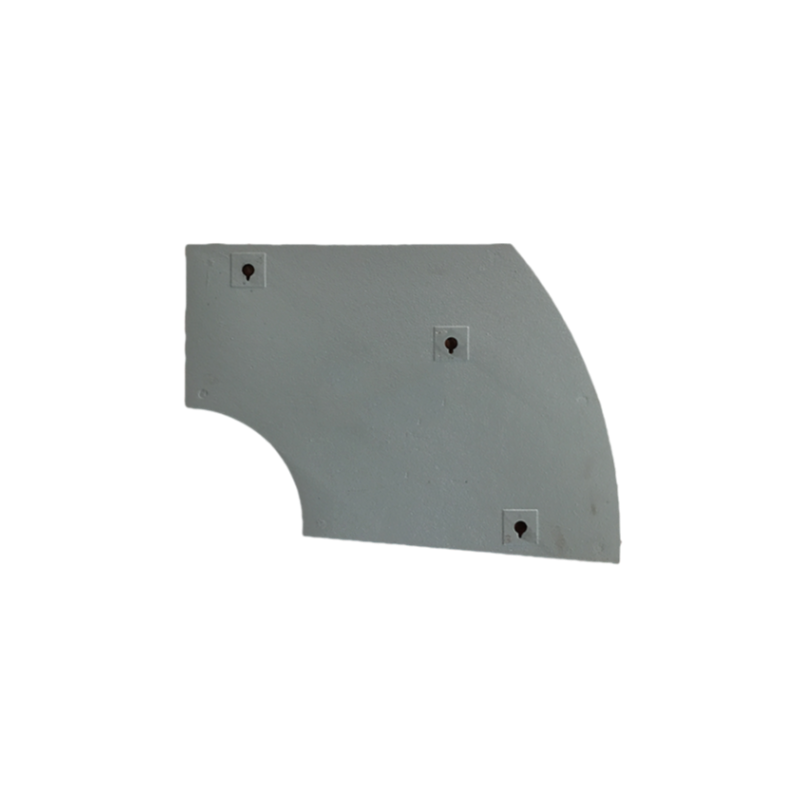

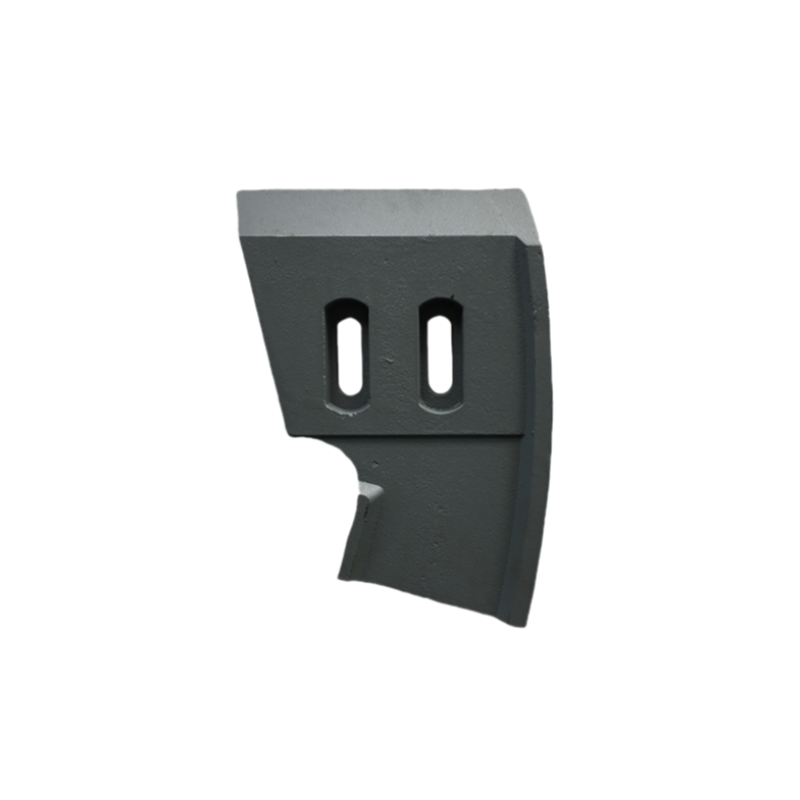

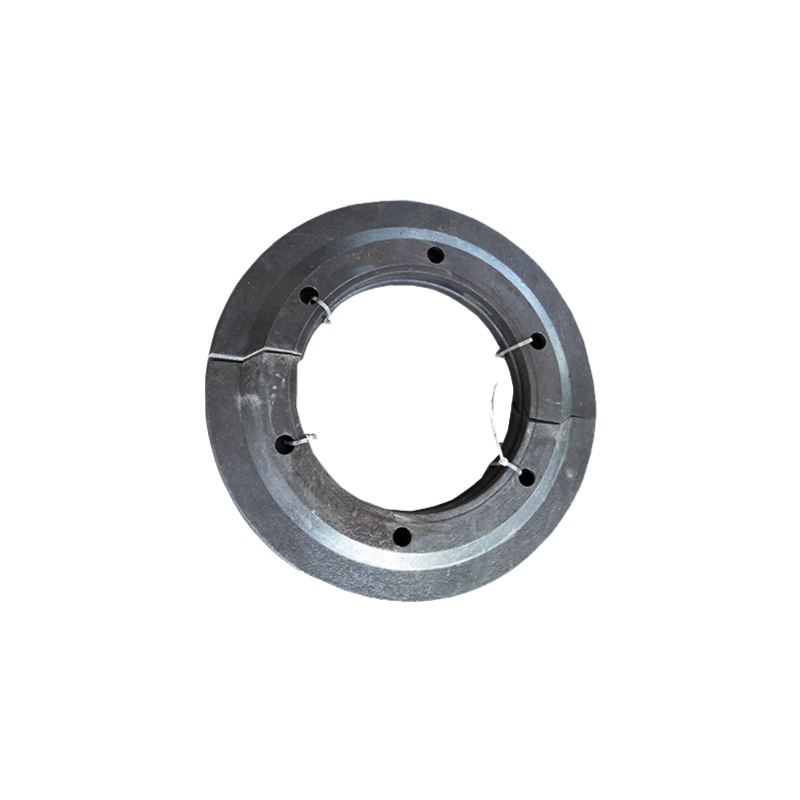

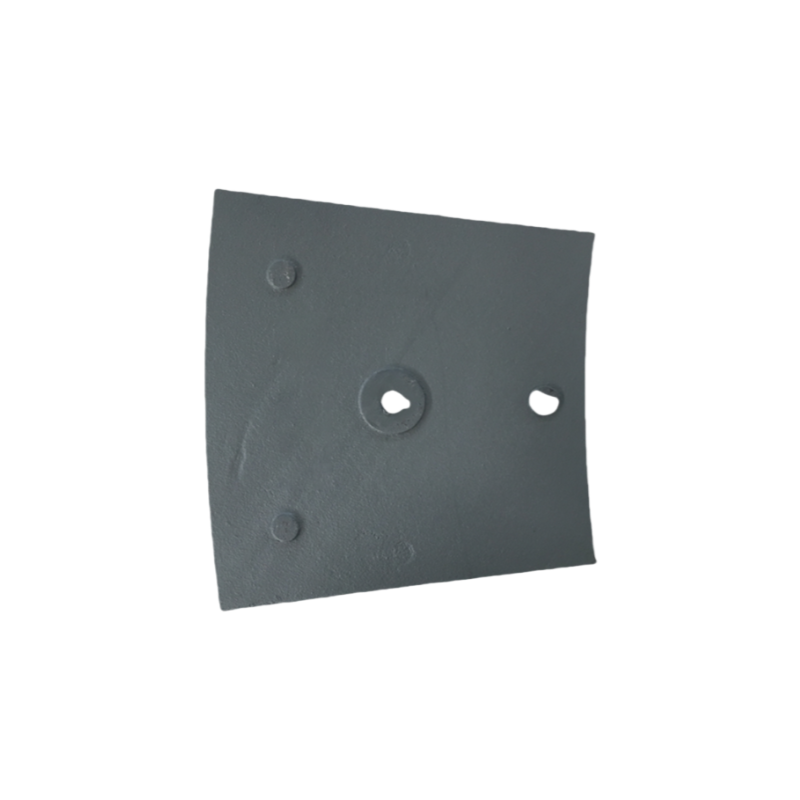

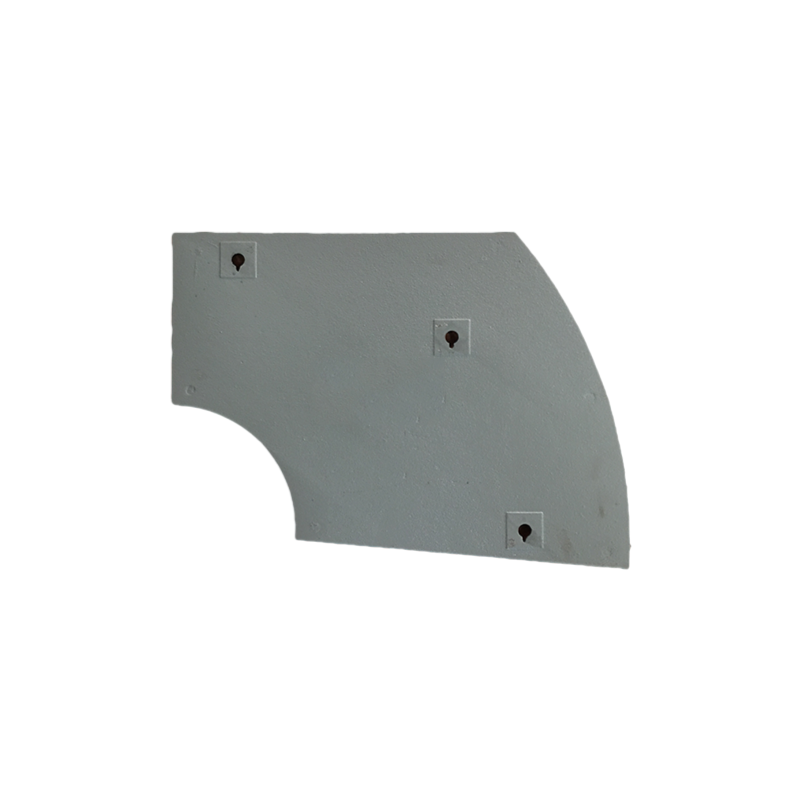

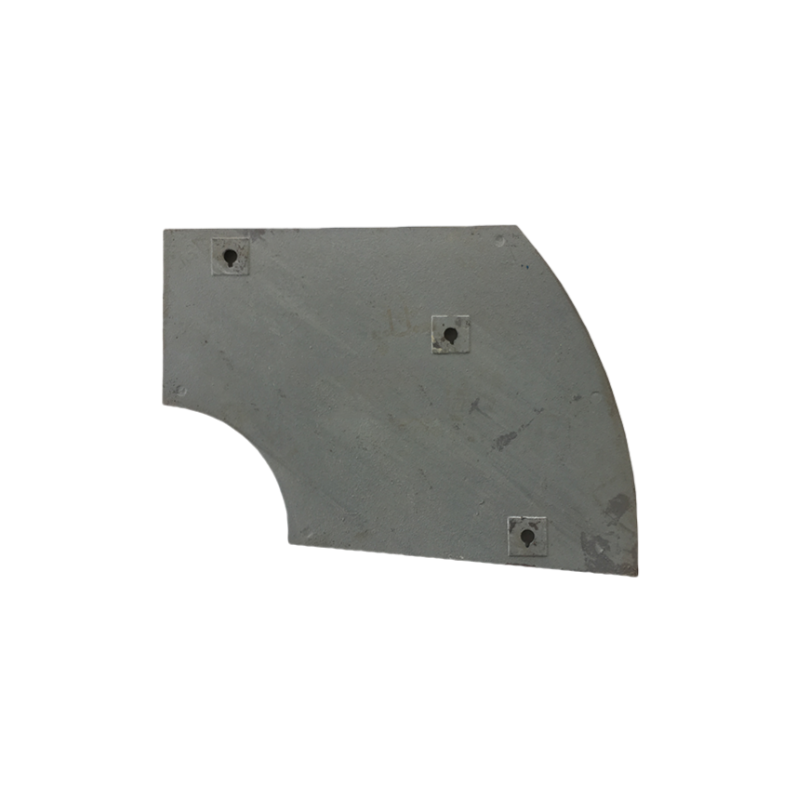

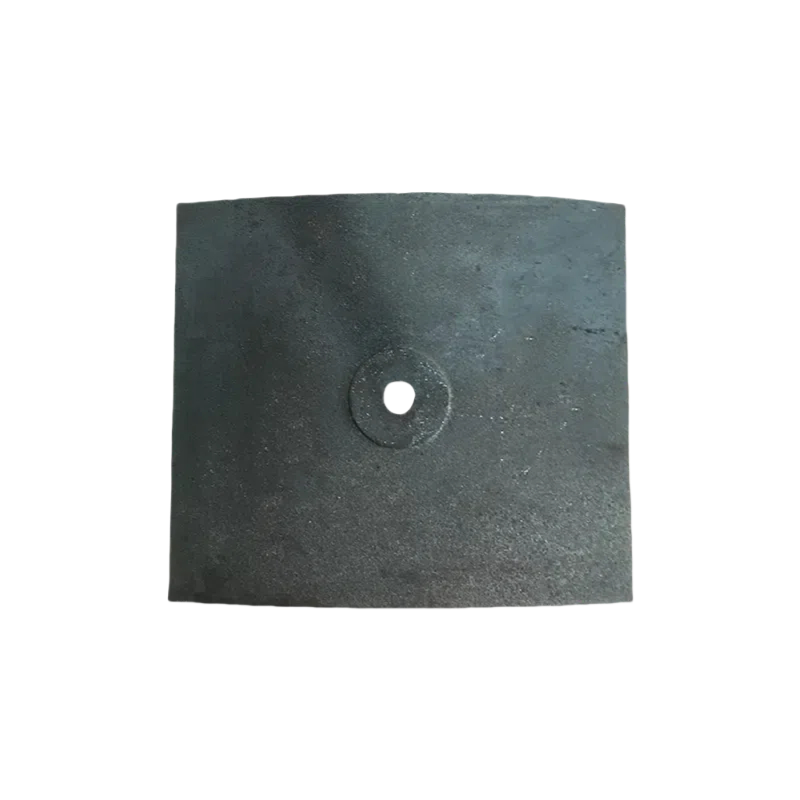

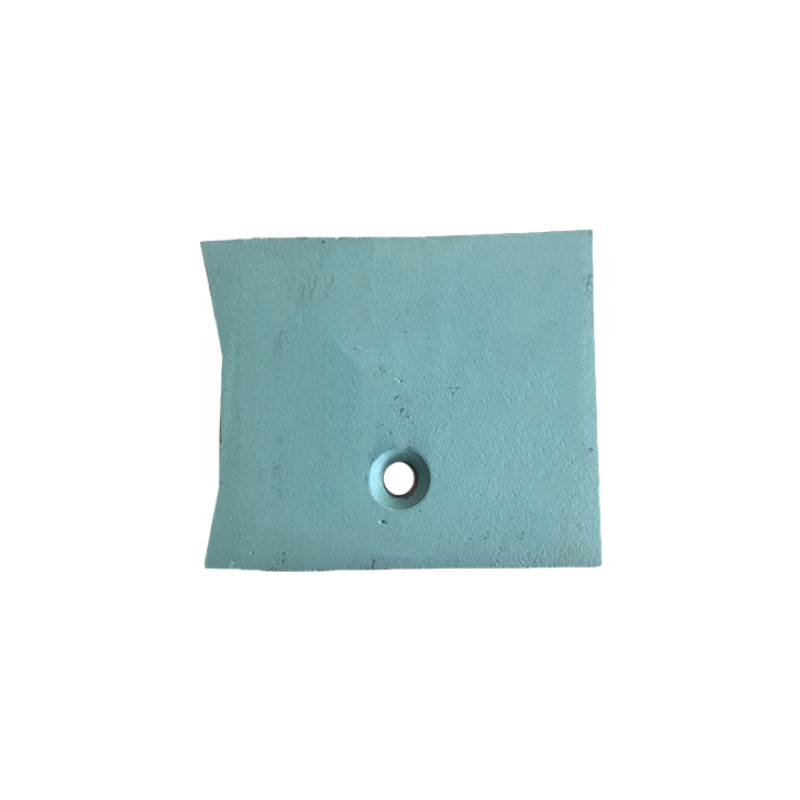

The Concrete Scraper Blade is a key wear-resistant component used in concrete mixing equipment. It is mainly installed on the inner wall of the mixer drum or on the mixing arms, where it effectively removes residual concrete material from the drum surface during operation. By preventing material build-up, the scraper blade ensures uniform mixing, improves discharge efficiency, and supports stable, long-term operation of the mixer.

Material & Manufacturing

Concrete scraper blades are manufactured from high-performance wear-resistant materials, including high-alloy steel, high-manganese steel, and high-chromium cast iron. Advanced casting and heat treatment processes are applied to achieve an optimal balance of wear resistance, impact toughness, and structural strength, ensuring reliable performance under harsh mixing conditions.

Key Features

Excellent wear resistance for extended service life

Strong impact resistance under heavy-load mixing conditions

Precise dimensions for accurate fit and easy installation

Effective material scraping to reduce residue and downtime

Low maintenance and reduced replacement frequency

Application

Twin-shaft concrete mixers

Planetary concrete mixers

Pan mixers

Ready-mix concrete plants and precast concrete production lines

Quality Control

Each concrete scraper blade undergoes strict quality inspection, including dimensional checks and material testing, to ensure consistent performance and full quality traceability. Inspection reports can be provided upon request.

Customization & Supply Capability

Customized scraper blades are available based on customer drawings, mixer models, and operating conditions. The company also supplies a full range of concrete mixer wear parts compatible with major equipment brands, helping customers reduce operating costs and improve production efficiency.

PRODUCT ADVANTAGES

-

HIGH ASSEMBLY PRECISION

During the assembly process of wear-resistant castings, we always adhere to efficient operation and ensure strict control of every link. Excellent quality comes from exquisite craftsmanship and efficient management, so that every product can meet your expectations.

-

COMPLETE SERIES

These castings are widely used in mining, metallurgy, construction, power generation, cement and other industries to withstand harsh working environments such as friction and impact, extend equipment life and reduce maintenance costs.

-

LONG SERVICE LIFE

It uses high-chromium cast iron, high-manganese steel, chromium-nickel alloy steel and other high-quality wear-resistant materials. These materials have extremely high hardness and wear resistance and can effectively resist wear and impact.

-

STABLE QUALITY

We use advanced casting techniques, such as precision casting and vacuum casting, to ensure the density and uniformity of castings. We implement full-process quality control, from raw material procurement, production process to finished product testing, and strictly control every link.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok