Cases

-

Italian Customer Customized Worm Rotor Project Successfully Accepted

Client Industry : Concrete Mixing Plant Industry

Product : Worm Rotor

Material : High Chromium Wear-Resistant Cast Iron

Order Lead Time : 30 days

View Details> -

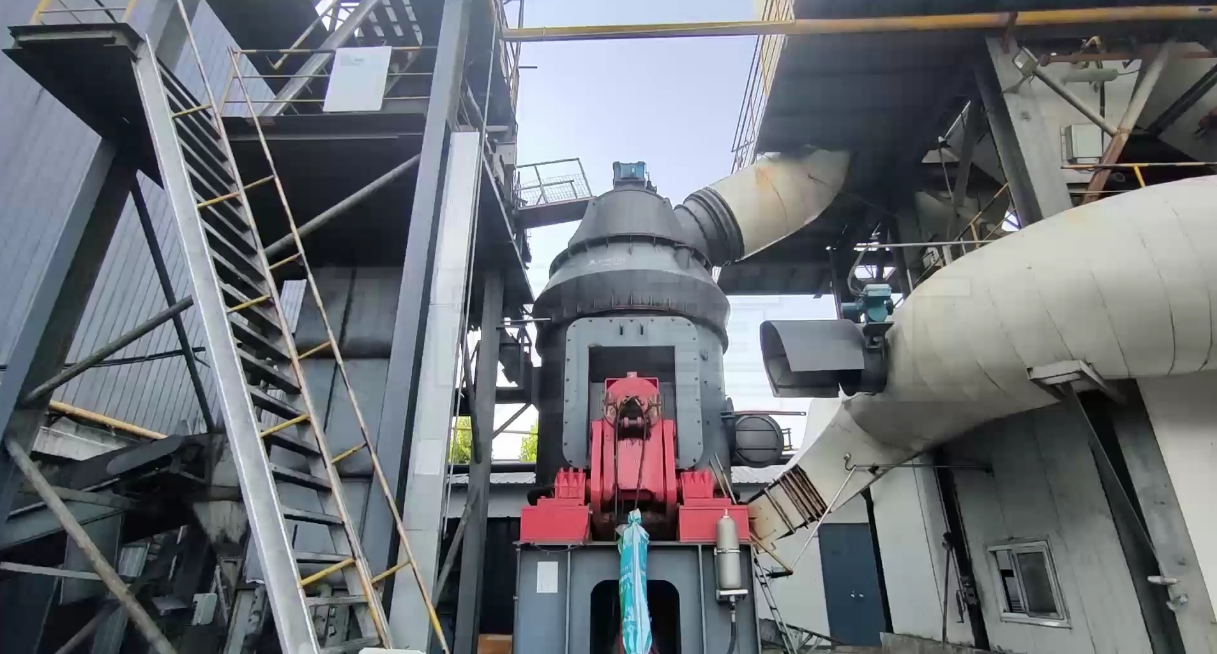

Custom Grinding Balls for EM80-5115 Vertical Grinding Mill

Client: From China

Ordered Product: Grinding Balls

Industry Application: Coal Pulverizer

Material requirement: ZG35

View Details> -

HAITIAN CASTING Helps American Customer Develop Highly Wear-Resistant Spiral Blades

Customer: Astec and its subsidiary ROADTEC

Ordered product: Highly Wear-Resistant Spiral Blades

Industry application: Asphalt Mixing and Paving Equipment

Casting Process: Denmark's DISA high-precision casting technology

View Details> -

HAITIAN CASTING Delivers Custom High-Standard Mixing Blades for Japanese corporation KYC

Customer: Japanese corporation KYC

Ordered product: Mixing Blades

Industry application: Mixing Equipment

Casting Process: Denmark's DISA high-precision casting technology, "quenching + tempering" process

View Details> -

Customer Success Story: Customized high precision and durable mixing arms and liners for D&G Machinery

Client: D&G Machinery

View Details>

Industry: Asphalt Mixing Equipment

Location: China (Global Exports)

Cooperation Since: 2025.04

Products Supplied: Mixer Arms (ZG310-570), High Chromium Liner Plates -

Customer Case | Putzmeister: Customized High-Chrome Blade Solution for Mortar Mixers

Client: Putzmeister, Germany

View Details>

Product: Mortar mixer blades

Material: High chromium cast iron

Application: Mortar pumping system in construction sites -

Customer Case: Custom-Made Liners for KYC Japan

Customer:KYC Japan

Ordered:Custom High-Chrome Liner

Industry:Concrete Mixing Components

Casting Process:DISA vertical molding

View Details> -

From Blueprint to Batch Production|A Case of Precision Wear Part Customization

Industry: Concrete Equipment Manufacturing

View Details>

Product: Custom Wear-Resistant Mixer Arms

Materials: High Manganese Steel (ZGMn13) / ZG-12 Alloy Steel

Client: KYC Corporation, Japan -

Customized Wear-Resistant Mixing Arm Assembly for Asphalt Mixing Plant

Industry: Concrete Equipment Manufacturing

View Details>

Product: Custom Wear-Resistant Mixer Arms

Materials: High Manganese Steel (ZGMn13) / ZG-12 Alloy Steel

Client: Japan -

German Client Custom Concrete Pump Pipe Bend Solution

Customer:German

Ordered:Hinged pipe elbow

Industry:Concrete Mixing Components

Casting Process:DISA vertical molding

View Details>

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tik Tok

Tik Tok