Concrete Machinery Series

Haitian casting pecializes in providing a comprehensive selection of premium wear parts essential for concrete machinery such as concrete mixing plants, concrete pump trucks and stabilized soil mixing plant. These wear parts are designed to withstand the harsh conditions of concrete handling and pumping to ensure optimal performance and service life.

Our concrete machinery series product range includes:

Concrete mixing plant wear parts: liners, mixing arms, scrapers, seals, blades, etc.

Concrete pump truck wear parts: elbows, straight pipes, etc.

These wear parts feature strong materials and advanced engineering to reduce downtime, improve operational efficiency and lower maintenance costs. Ideal for concrete pump trucks, concrete batching plants, these wear-resistant parts are a reliable choice to ensure that concrete machinery maintains durability and efficiency even in the harshest environments.

-

Lining Plate-Concrete Machinery

Wear-resistant casting concrete liner is a high wear-resistant part designed for concrete mixing equ

See More> -

Mixing Arm-Concrete Mixing Plant

The mixing arm is mainly used to mix concrete mixture, which is very important for the uniformity an

See More> -

Concrete Pump Truck Bend Pipe

The bend pipe is a key component designed for concrete transportation and construction, mainly used

See More> -

Concrete Pump Truck Straight Pipe

Used for the straight pipe section of concrete delivery pipeline to ensure smooth delivery of concre

See More> -

High Hardness Lining Plate For Concrete Mixing Plant

Wear-resistant casting concrete liner is a high wear-resistant part designed for concrete mixing equ

See More> -

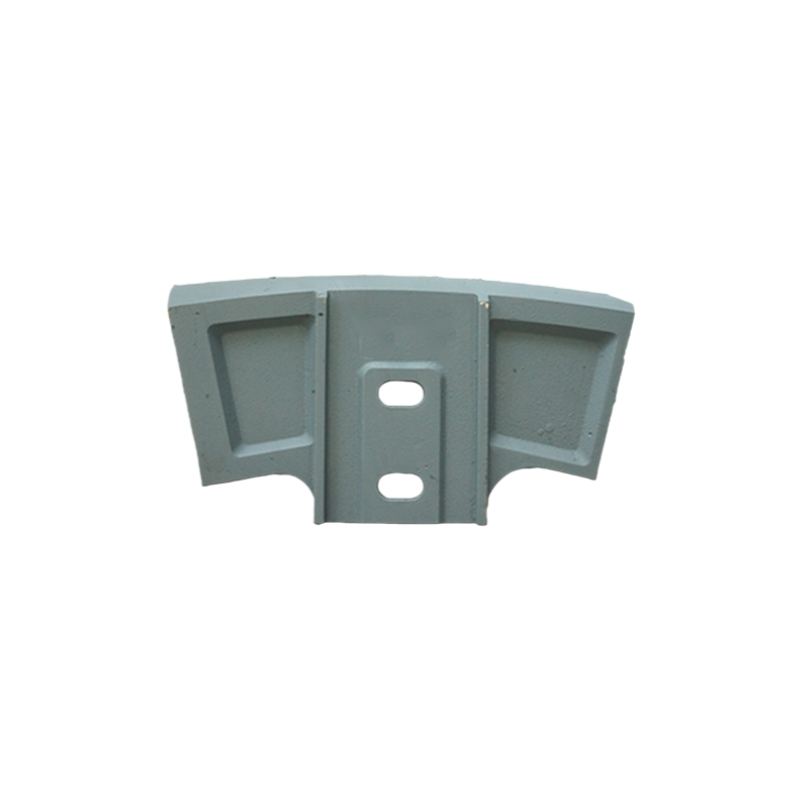

Concrete Mixing Plant Lining Plate

Wear-resistant casting concrete liner is a high wear-resistant part designed for concrete mixing equ

See More> -

Concrete Mixing Plant High Wear-resistant Lining Plate

Wear-resistant casting concrete liner is a high wear-resistant part designed for concrete mixing equ

See More> -

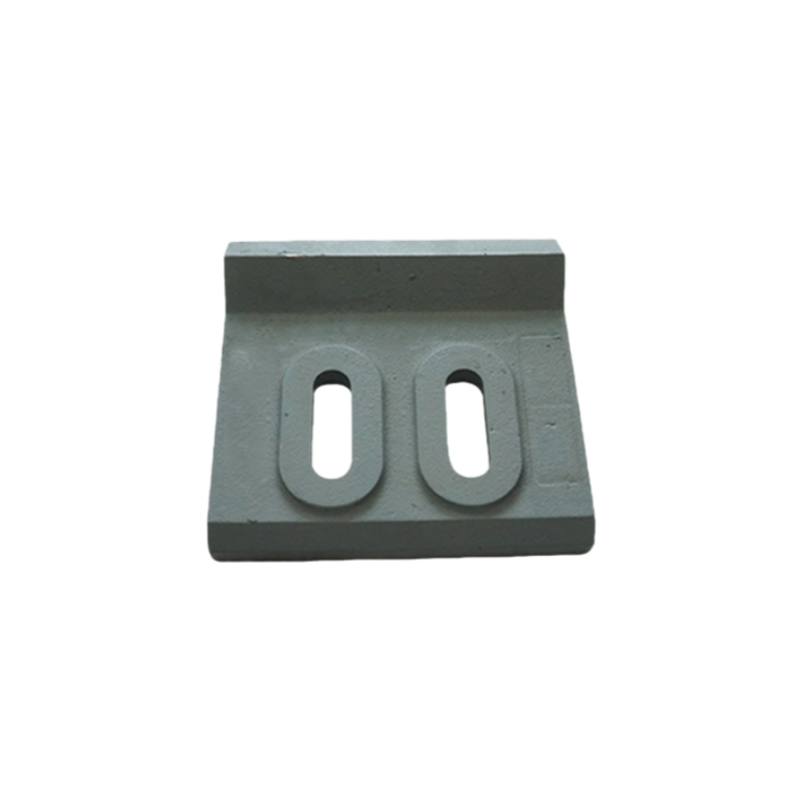

Concrete Mixing plant High-precision Scraper

The scraper is a highly wear-resistant part designed for concrete mixing and construction equipment,

See More> -

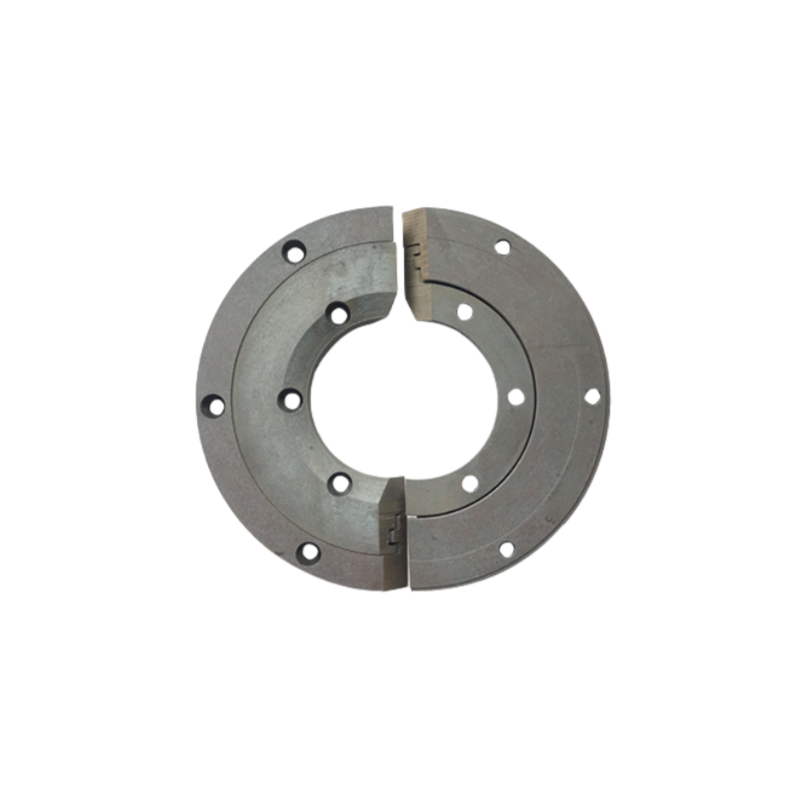

Concrete Mixing Plant Wear Resistant Seal

The seal is specially designed for concrete mixing and construction equipment, aiming to prevent the

See More> -

Scraper-Concrete Mixing Plant

The scraper is a highly wear-resistant part designed for concrete mixing and construction equipment,

See More> -

High Toughness Scraper For Concrete Mixing Plant

The scraper is a highly wear-resistant part designed for concrete mixing and construction equipment,

See More> -

Concrete Mixing Plant Durable Lining Plate

Durable wear-resistant liners designed for asphalt, concrete, and mining equipment protection.

See More>

Why Choose HAITIAN Concrete Wear Parts?

Engineering Excellence for Unmatched Concrete Equipment Performance

1. Precision Customization

Tailored Solutions: Bespoke designs for mixing arms, blades, liners, and wear rings to match OEM specs (Putzmeister, Schwing, SANY, Zoomlion, Liebherr, and CIFA, etc.) or unique operational needs.

Multi-Brand Compatibility: CAD-driven reverse engineering for 50+ equipment brands.

2. Advanced Material Science

| Material Type | Key Properties | Ideal Application |

| High-Chromium Iron (Cr26) | 58-62 HRC hardness, corrosion-resistant | Mixing blades in abrasive slurries |

| Nickel-Hard Cast Iron | High impact resistance (450+ J/cm²) | Pump truck elbows |

| Martensitic Steel | Optimal cost-performance balance | Liner plates for batch plants |

| Composite Alloys | Gradient hardness layers | High-impact mixing paddles |

3. Cutting-Edge Manufacturing

Casting Tech: DISA vertical lines (±0.5mm tolerance) + lost foam for complex geometries.

Digital Prototyping: 3D-printed samples validated via ANSYS wear simulation.

Machining: 5-axis CNC finishing for critical interfaces.

4. Responsive Technical Service

Pre-Purchase: Free drawing review & process optimization (avg. 12% cost savings identified).

Emergency Support: 24-hour quotation + 72-hour expedited production for breakdowns.

Field Guidance: On-site wear pattern analysis via our WearScan diagnostic toolkit.

Concrete Wear Solutions

Haitian offers premium wear solutions tailored for the concrete industry, addressing challenges such as rapid wear, inconsistent mixing, and complex part customization. Their services span material R&D, process innovation, and full quality control. Haitian customizes key wear parts—like mixing arms, blades, and liners—for various equipment brands and models. Using advanced materials such as Cr26, Ni-Hard, and martensitic steel, they ensure superior wear and impact resistance. With state-of-the-art casting technologies and precision machining, they guarantee high dimensional accuracy. Haitian also provides expert technical support, fast quoting, and a robust quality assurance system to deliver high-performance, durable parts efficiently.

[View Full concrete industrywear solution →]

Concrete Wear Part Success Story

HAITIAN CASTING cooperated with JCI, a subsidiary of Astec, a US engineering machinery giant, to develop an innovative ceramic composite plate hammer for its mixing station mainframe. Haitian adopted high-chromium cast iron + ceramic particle composite casting technology to improve wear resistance. The product has undergone wear resistance/impact resistance/fatigue tests and mine simulation verification.

If you are interested in our products or have any questions, please feel free to contact us.

We will provide professional consulting services and customized solutions according to your needs.

SEND INQUIRY NOWContact information

Tel: 0555-71661667166199

Tel: 0555-71661667166199

Fax: 0555-6971198

Fax: 0555-6971198

Website: https://www.htwearparts.com

Website: https://www.htwearparts.com

Email: info@mashthi.com

Email: info@mashthi.com

Postal code: 243141

Postal code: 243141

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe VIDEO FREQUENCY

VIDEO FREQUENCY

Tik Tok

Tik Tok