Premium Wear Solutions for Concrete Industry: Durable, High-Performance Wear Parts

Concrete Equipment Wear Challenges

Concrete industry equipment operates under extreme conditions, facing severe wear and impact challenges, including:

Rapid wear of critical parts leads to frequent replacements, causing production downtime and elevated costs.

Wear-induced uneven mixing affects concrete quality consistency.

Diverse equipment models and part specifications require complex customization.

Demand for materials combining wear resistance, impact toughness, and corrosion resistance.

Haitian Wear Solutions For Concrete Industry

For concrete equipment wear parts, Haitian provides a full range of services from material research and development, process innovation to full-process quality control:

Customize high-performance wear-resistant parts: precise customization of key wear parts such as mixing arms, blades, liners, mixing paddles, wear-resistant rings, etc. to meet customers' multi-brand and multi-specification needs.

High-toughness wear-resistant materials: high-chromium cast iron (Cr26), nickel-hard cast iron (Ni-Hard), martensitic steel and composite materials are used to achieve extreme wear resistance and impact toughness.

Advanced casting and processing technology: DISA vertical line, lost foam casting, 3D printing samples, combined with mechanical processing to ensure wear part dimensional accuracy and consistency.

Professional technical support and rapid response: provide drawing review, process optimization suggestions, 24-hour quotation service, to achieve rapid customization and delivery.

Quality assurance system: comprehensive quality testing covers chemical composition, mechanical properties, dimensional tolerances and wear resistance to ensure that each product meets the industry's top standards.

CONCRETE MACHINERY WEAR PARTS

Haitian provides high-performance concrete wear-resistant parts, including mixing arms, blades, liners, mixing paddles, and wear-resistant rings to meet customers' multi-brand and multi-specification needs.

- Concrete Mixing Plant Parts

- Concrete Pump Truck Parts

- Stabilized Soil Mixing Plant Parts

-

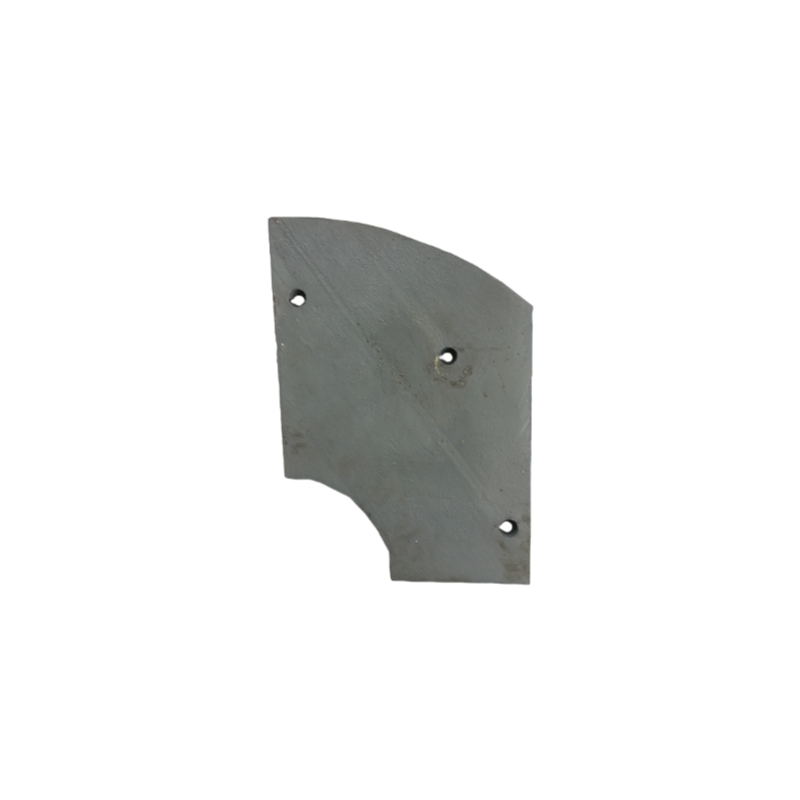

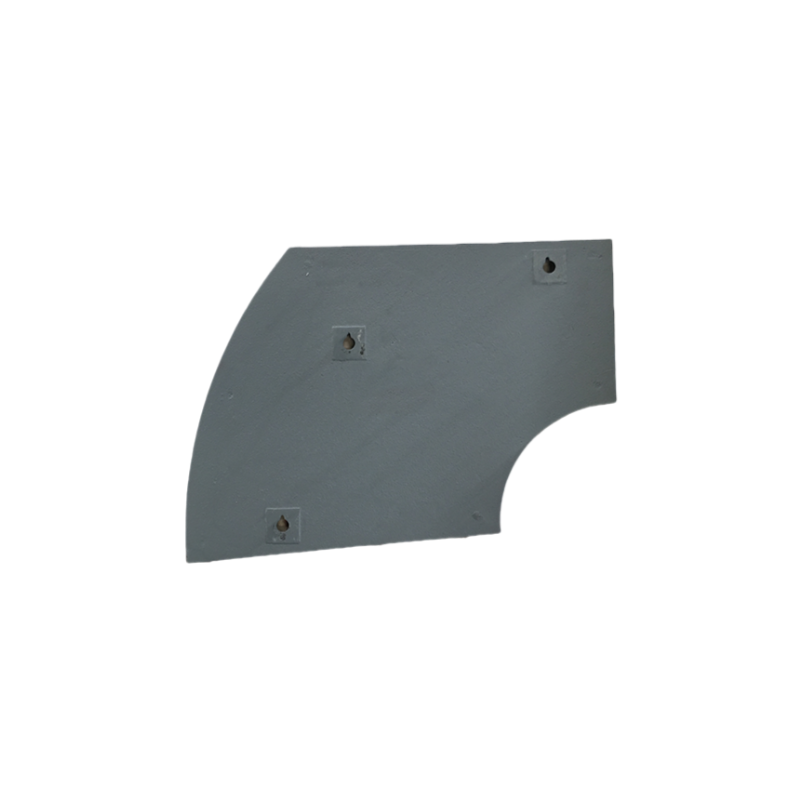

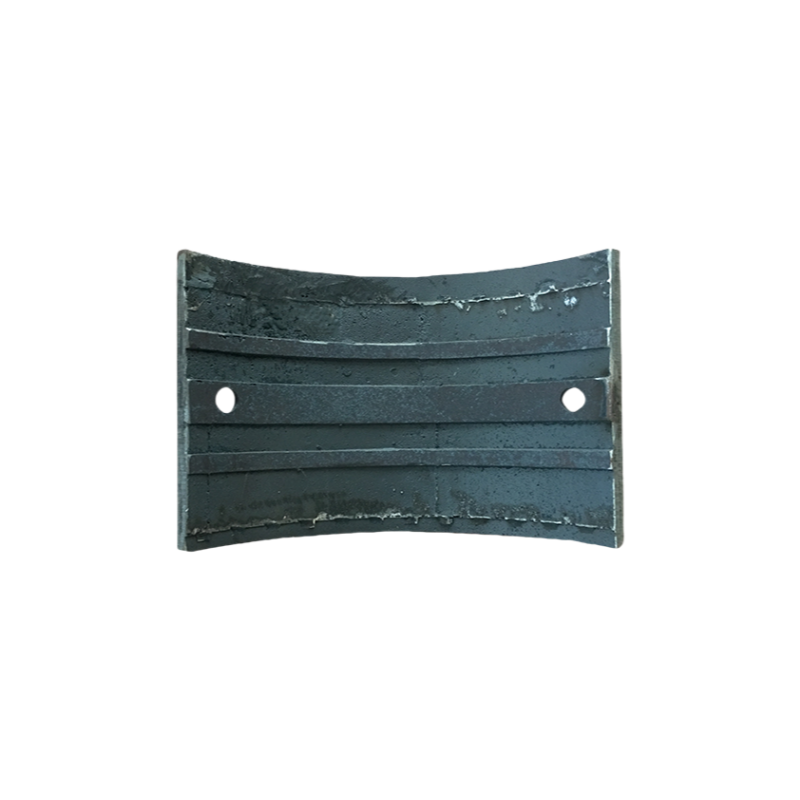

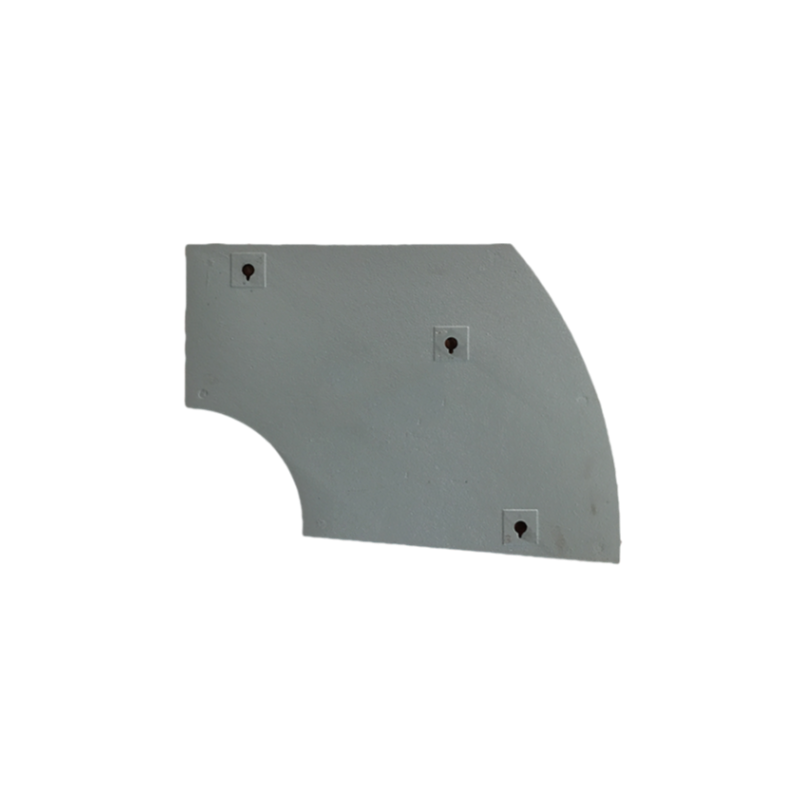

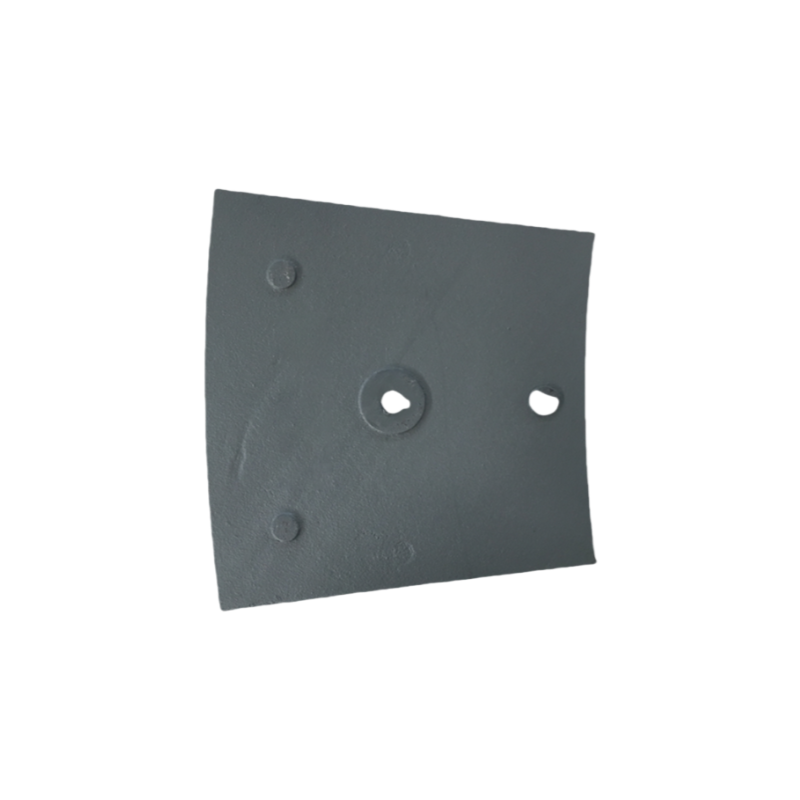

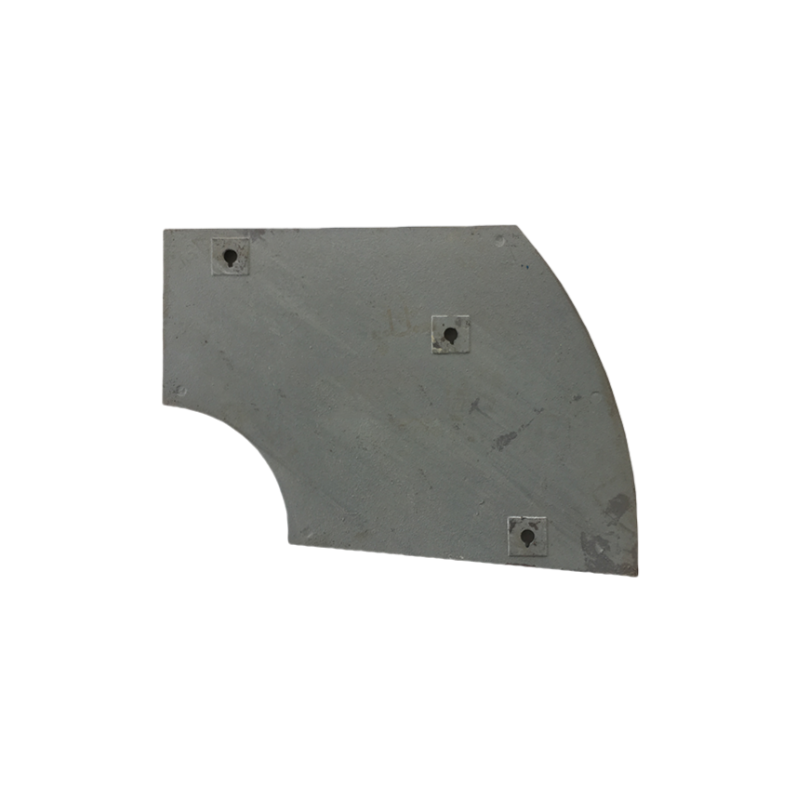

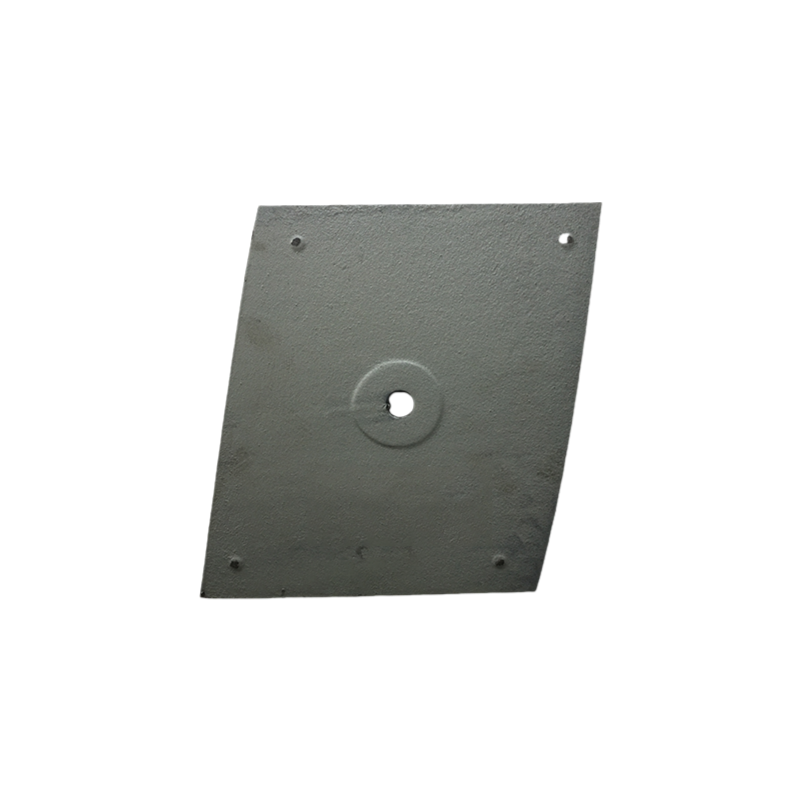

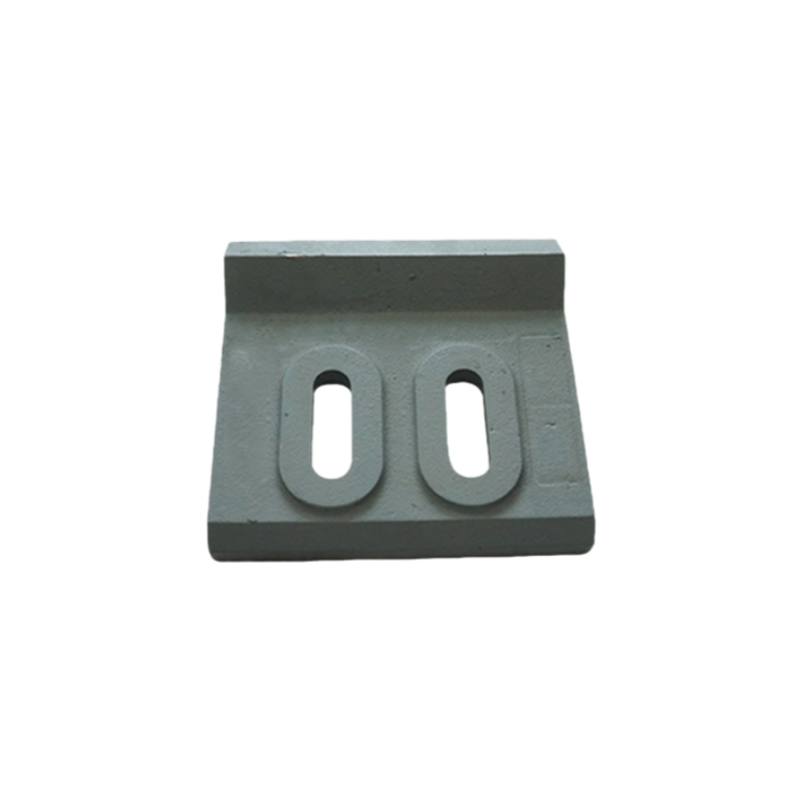

Wear-resistant Lining Plate

-

Impact Resistant Lining plate For Concrete Mixing Plant

-

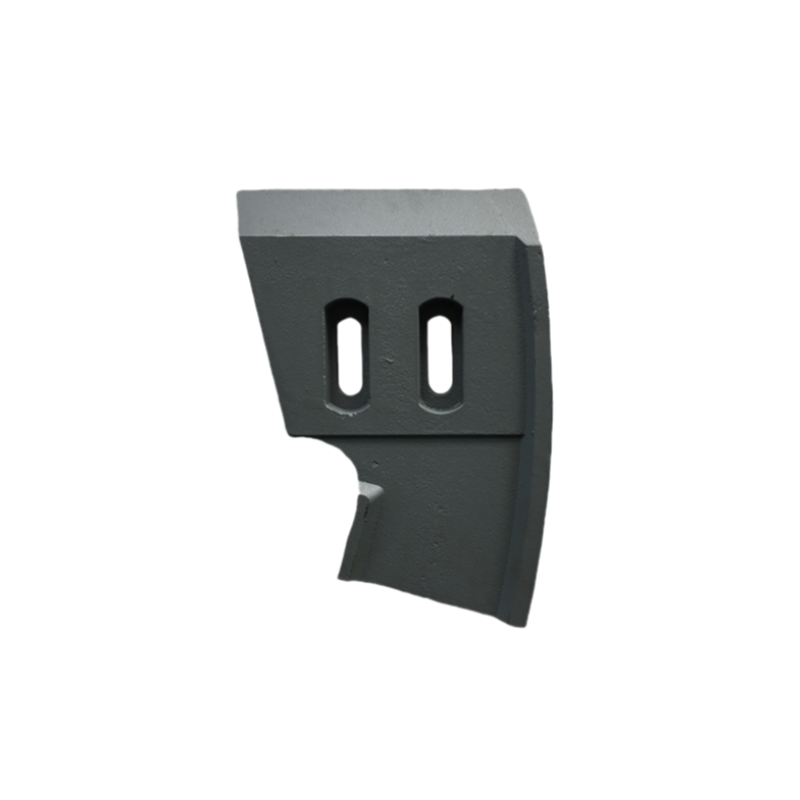

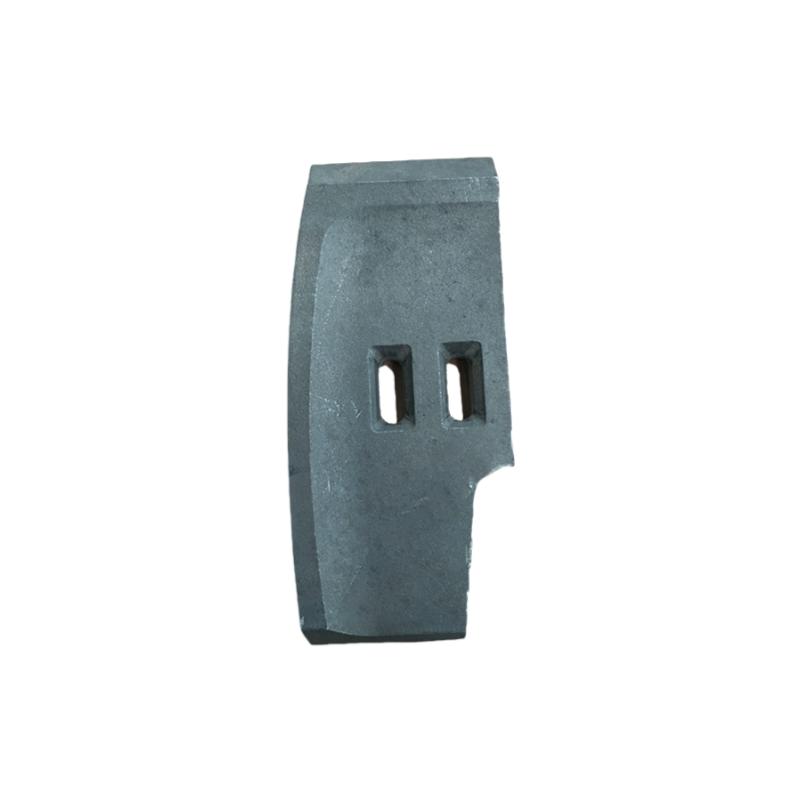

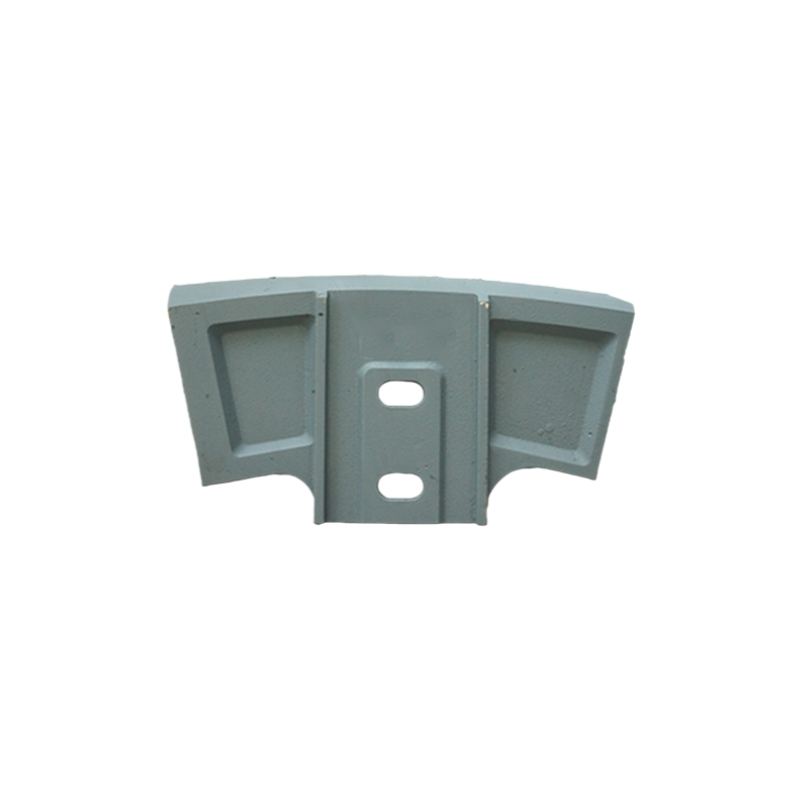

Mixing Arm For Concrete Mixing Plant

-

Concrete Mixing Plant Heat-resisting Lining Plate

-

Customizable Mixing Arm For Concrete Mixing Plant

-

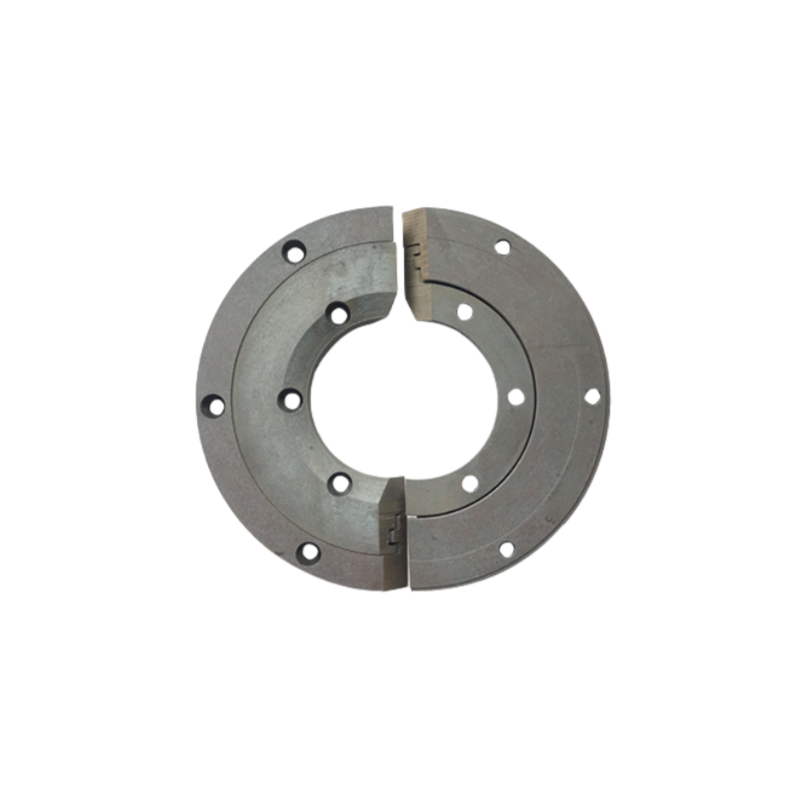

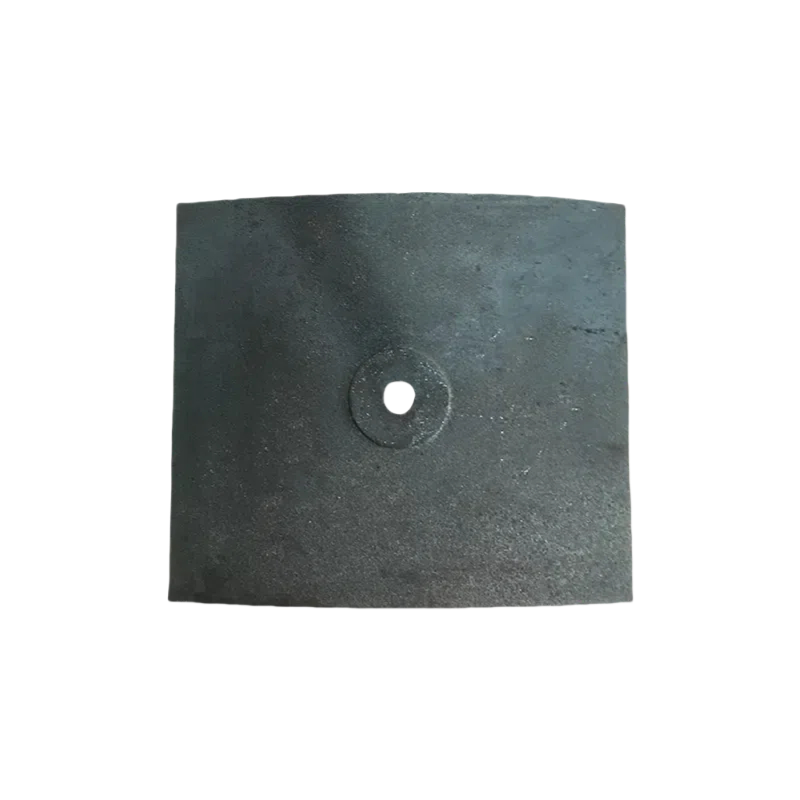

Concrete Mixing Plant Wear Resistant Seal

-

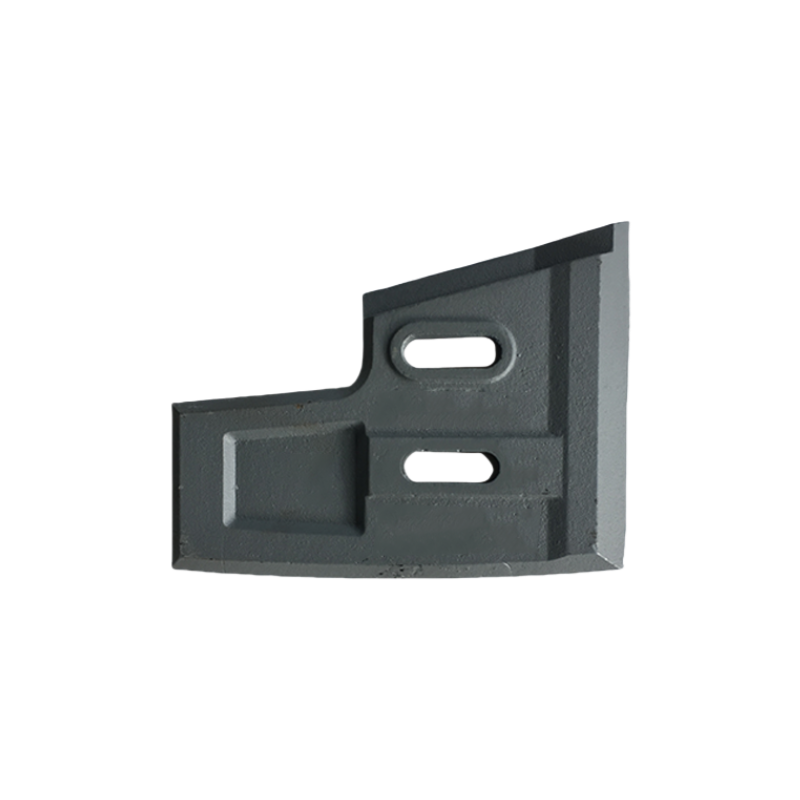

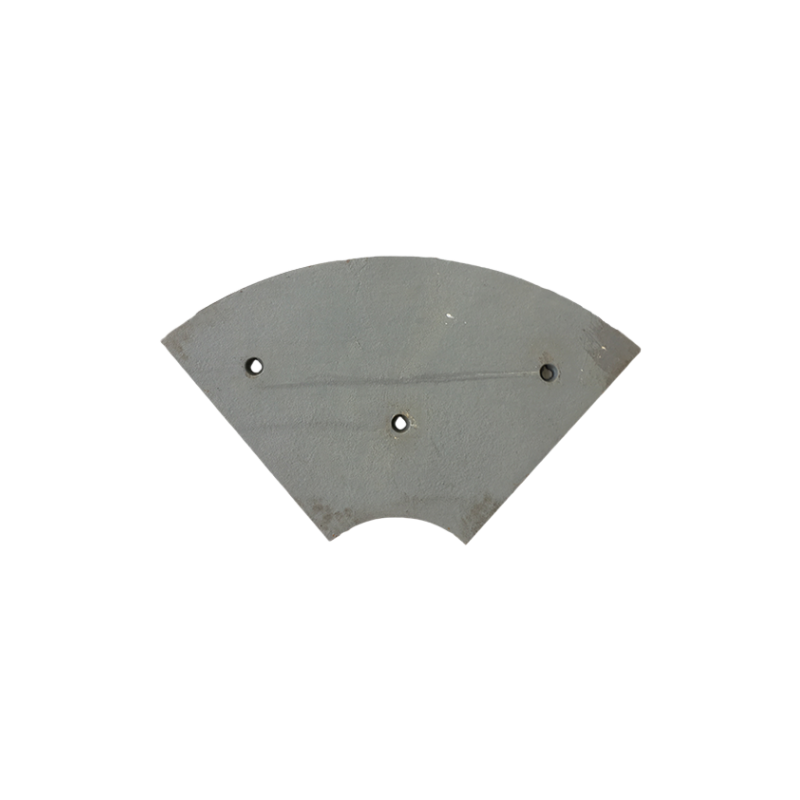

Discharge Door ARC Liner

-

Lining Plate-Concrete Machinery

-

High Temperature Tolerance Lining Plate

-

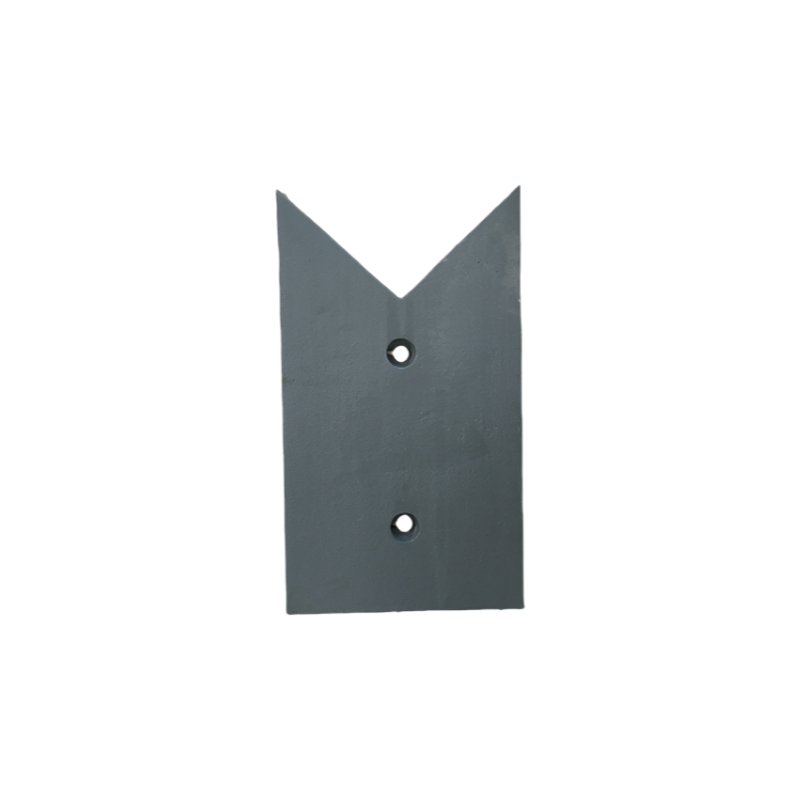

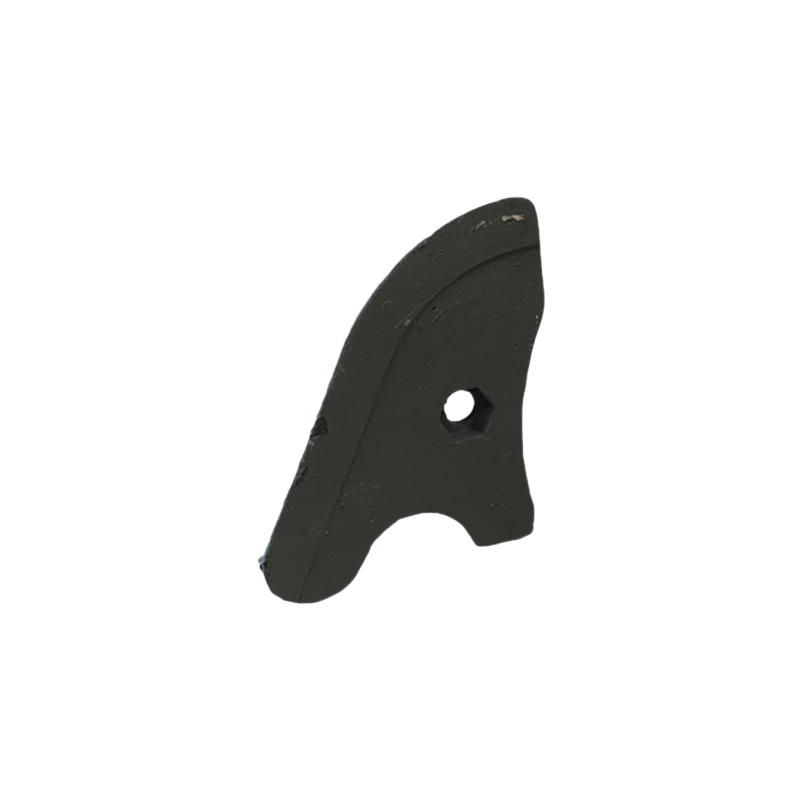

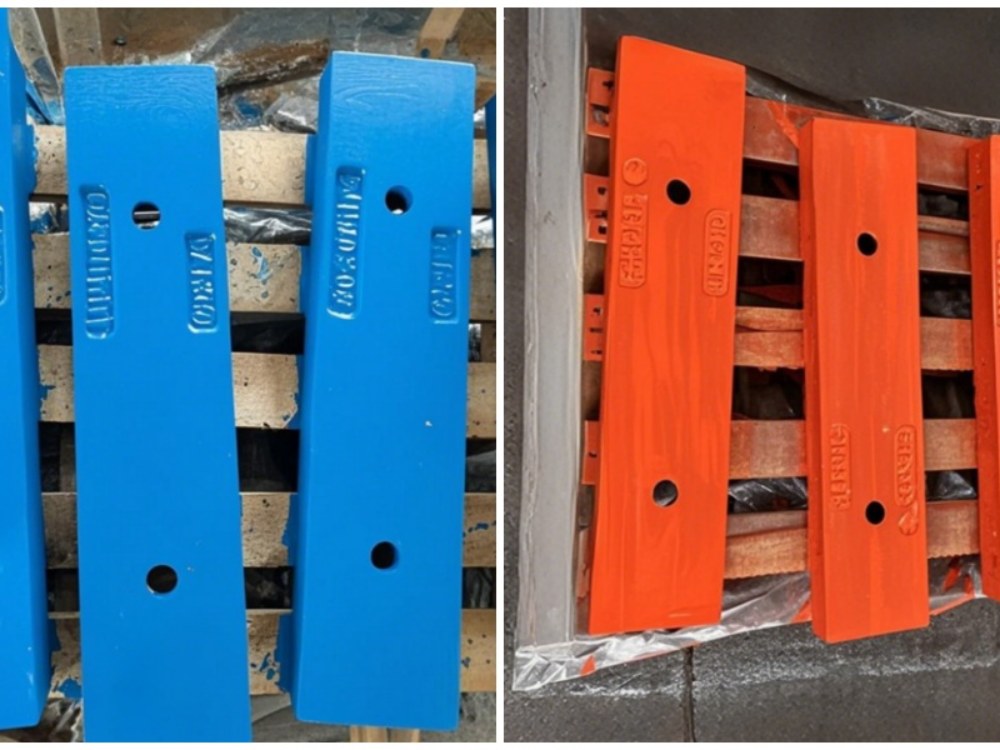

Economical & Corrosion Resistance Blade

-

Diverse Choices Lining Plate

-

Concrete Scraper High Efficiency

-

High Strength Lining Plate

-

Corrosion Resistance Scraper

-

Full Series Lining Plate

-

General Lining Plate For Concrete Mixing Plant

-

OEM Lining Plate For Concrete Mixing Plant

-

Concrete Mixing Plant Iron Casting Scraper

-

Concrete Mixing Plant Wear-resistant Lining Plate

-

High Hardness Lining Plate For Concrete Mixing Plant

-

Arm Protection-Concrete Mixing Plant

-

Mixing Arm-Concrete Mixing Plant

-

Concrete Mixing plant High-precision Scraper

-

Scraper-Concrete Mixing Plant

-

High Toughness Scraper For Concrete Mixing Plant

-

Concrete Mixing Plant Lining Plate

-

Concrete Mixing Plant High Wear-resistant Lining Plate

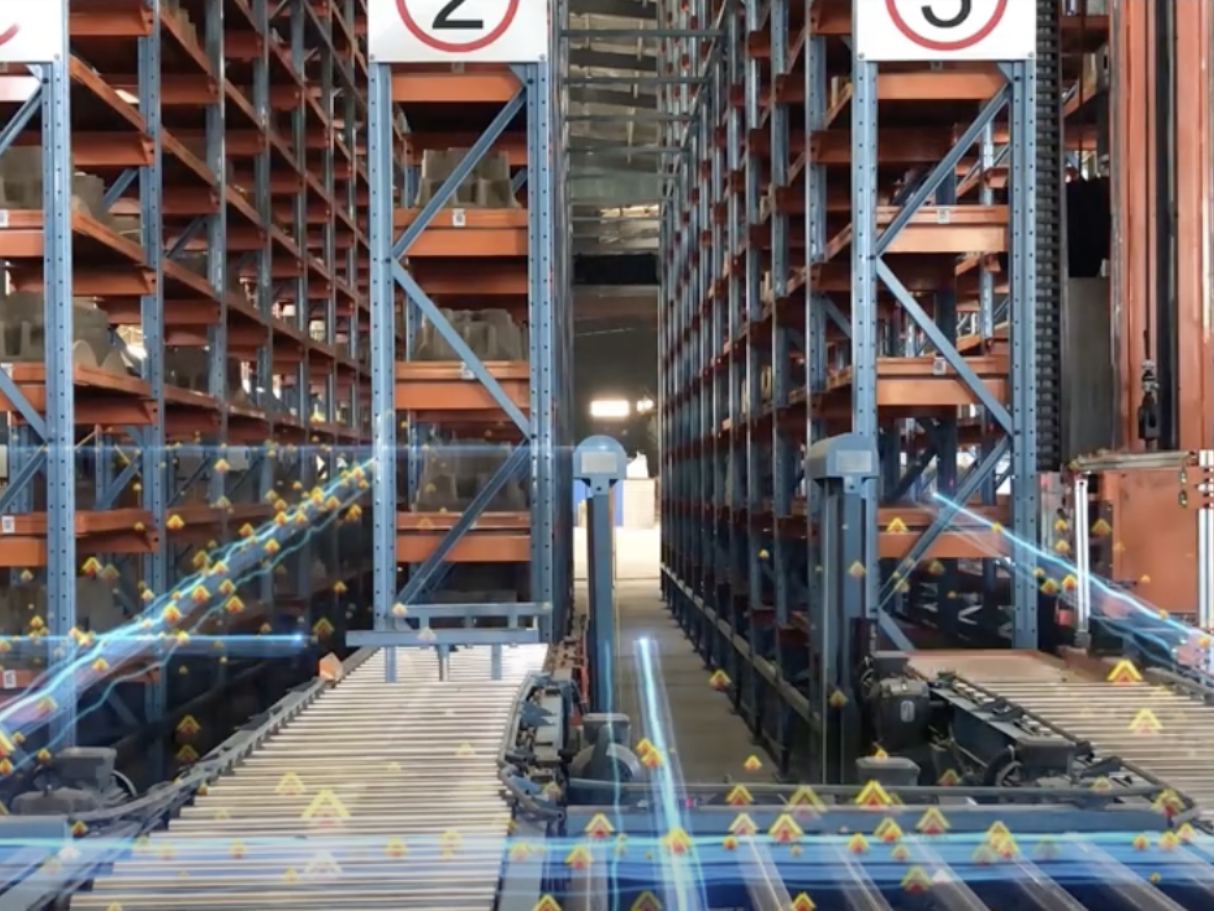

MANUFACTURING CAPABILITY

-

Advanced DISA Vertical Molding Line

The DISA vertical molding line enables high-speed, high-precision sand mold production for wear-resistant parts. It ensures consistent mold quality, improved surface finish, and tight dimensional tolerances—ideal for high-volume manufacturing of complex concrete equipment components.

-

Lost foam casting

Lost foam casting allows for the precise forming of intricate wear-resistant parts by using expendable foam patterns. This near-net-shape process reduces machining requirements, enhances accuracy, and is particularly useful for producing large or complex concrete equipment castings with fewer joints or seams.

-

3D printing prototyping

3D printing prototyping accelerates the development of new wear-resistant parts by enabling rapid design validation and mold creation. It reduces lead times and costs in the product development cycle, helping to optimize the geometry and performance of castings before mass production.

-

In-house Heat Treatment and Machining

In-house heat treatment improves the hardness, toughness, and wear resistance of cast parts, critical for enduring concrete abrasion. Precision machining ensures dimensional accuracy and perfect fitment, offering full control over final product quality and delivery time.

WHY CHOOSE HAITIAN CONCRETE WEAR PARTS

Reliable Performance for Uninterrupted Production

Haitian Casting's concrete machinery wear-resistant parts improve the reliability of concrete equipment, ensuring continuous production and consistent concrete quality.

Versatile Solutions for Every Equipment Need

Haitian concrete machinery wear-resistant parts support multi-brand compatibility and personalized customization, flexibly meeting the diverse needs of customers.

Timely Delivery for Seamless Operations

Haitian has a large inventory of molds and advanced production equipment to ensure rapid response, on-time delivery, and smooth execution of customer production plans.

Industry Expertise Built on 15 Years of Global Experience

With 15 years of experience in wear-resistant parts casting and export, we have a deep understanding of the operating scenarios and component requirements of the concrete industry.

Strategic Partnership for Long-Term Success

As a long-term and stable partner, we are committed to helping customers in the concrete industry create sustainable competitive advantages.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tel:

Tel:  Fax: 0555-6971198

Fax: 0555-6971198 Website:

Website:  Email:

Email:  Postal code: 243141

Postal code: 243141 Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Tik Tok

Tik Tok