Reliable Wear Parts for Asphalt Mixing Plants

Tailored Solutions to Maximize Durability and Performance

Asphalt plants Wear Challenges

Asphalt plants operate under high-temperature, high-friction conditions. Components are exposed to thermal cycling, material abrasion, and chemical wear from bitumen and aggregates.

Key Challenges Include:

Frequent wear of mixing blades, paddles, and liners

Deformation or cracking caused by thermal stress

High replacement frequency increases maintenance cost and downtime

Inconsistent quality due to wear-related mixing inefficiencies

Haitian Wear Solutions For Asphalt plants

Haitai provides specialized wear parts for asphalt mixing plants, made from high-chromium cast iron and optimized alloys. With advanced foundry processes and strict QC, our products offer extended service life and compatibility with international OEM standards.

Why choose Haitian Asphalt wear solutions:

Provide end-to-end customized asphalt wear solutions.

Stable delivery guarantee.

Cover a variety of high-performance wear-resistant materials such as high-chromium cast iron, high-manganese steel, nickel-vanadium alloy, etc.

Sand casting process to reduce production costs.

Reduce costs and increase efficiency, long-term cooperation.

ASPHALT EQUIPMENT WEAR PARTS

- Asphalt Mixing Plant Parts

- Asphalt Paver Parts

-

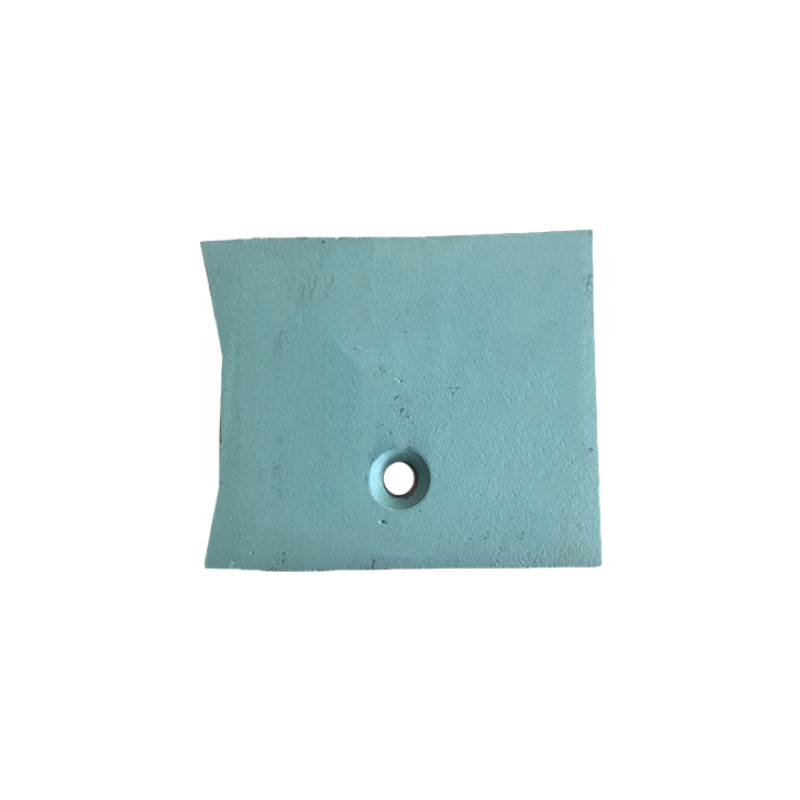

Good Toughness Lining Plate

-

Strong Wear Resistance Lining Plate

-

High Temperature Resistance Plate

-

Good Strength Lining Plate

-

Lining Plate For Asphalt Mixing Plant

-

Lining Plate-Asphalt Mixing Plant

-

Asphalt Side Lining parts

-

Asphalt Machinery Series

-

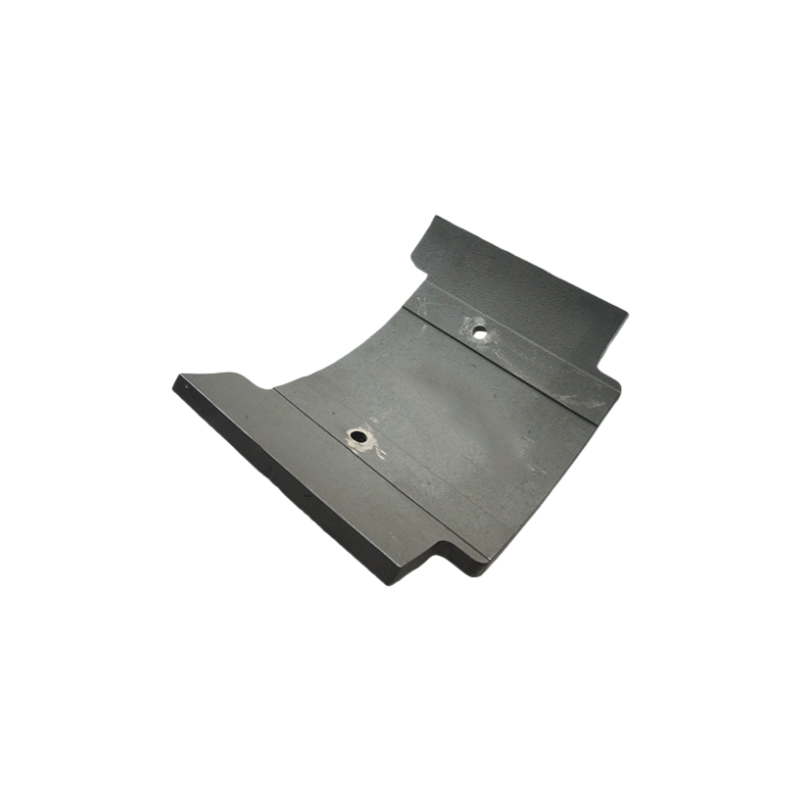

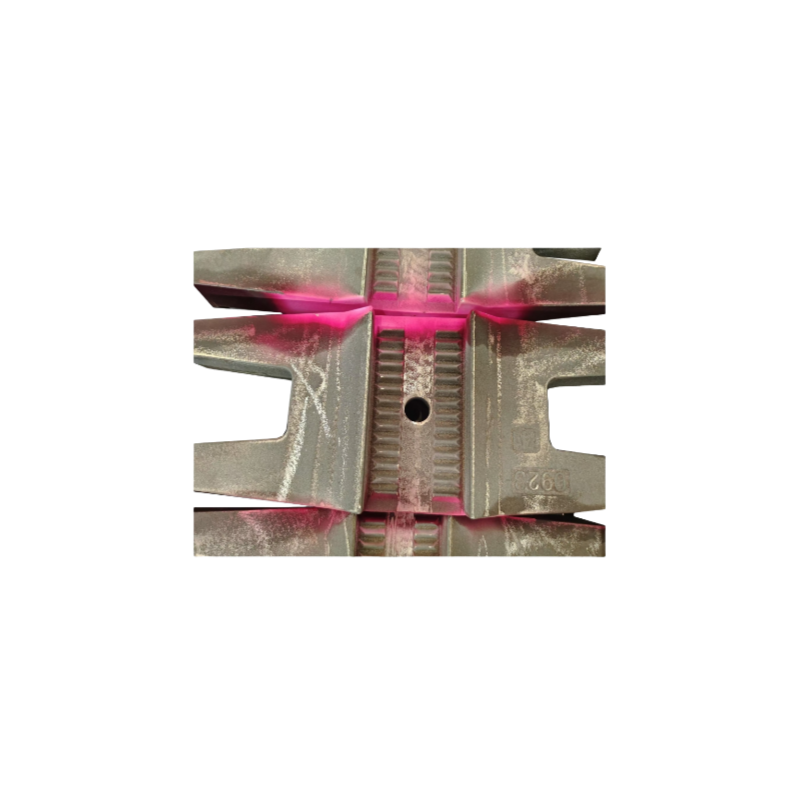

Mixing Arm-Asphalt Mixing Plant

-

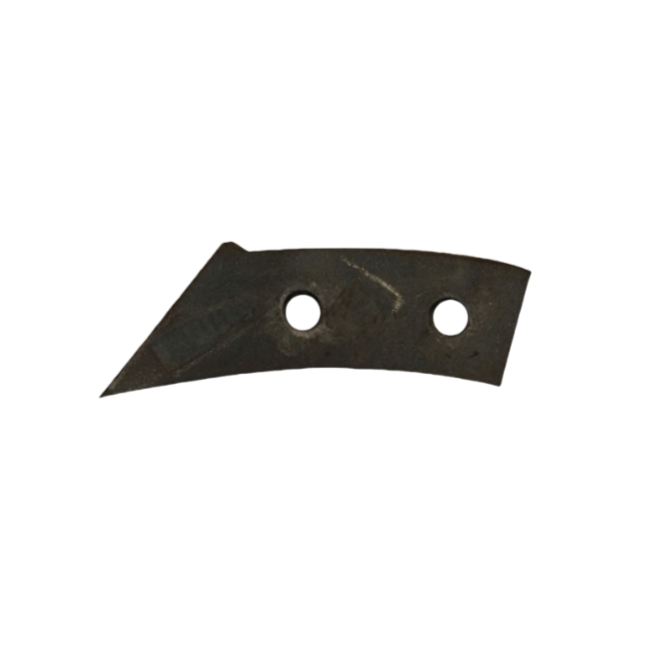

Spiral Blade For Asphalt Mixing Plant

-

Sealing element-Asphalt Mixing Plant

-

Scraper-Asphalt Mixing Blade

-

Spiral Blade-Asphalt Mixing Plant

-

Asphalt Side Lining

MANUFACTURING CAPABILITY

-

Advanced DISA vertical molding line

The DISA vertical molding line ensures high-efficiency, high-precision sand molding for casting asphalt equipment wear parts. It delivers excellent dimensional accuracy and surface finish, ideal for high-wear components like mixer blades or auger segments. Its automation boosts productivity and consistency, supporting large-scale production with minimal defects.

-

Lost foam casting of large complex parts

Lost foam casting is ideal for complex or large asphalt wear parts such as mixing arms or liners. It enables near-net-shape casting with minimal joints and machining, reducing material waste and production time. This method ensures high casting integrity, making it suitable for components exposed to high temperature and abrasive asphalt mixtures.

-

3D printing prototyping

3D printing prototyping accelerates the development of new or customized wear-resistant parts for asphalt equipment. It allows engineers to quickly test part geometry, fitment, and performance before tooling investment. This shortens the design cycle and enhances precision, especially for parts subjected to extreme mechanical and thermal stress in paving and mixing applications.

-

In-house heat treatment and machining

In-house heat treatment significantly improves the hardness and wear resistance of cast parts like scrapers and paddles, ensuring durability under harsh asphalt processing conditions. Precision machining further guarantees dimensional accuracy and surface quality, enabling proper fit and extended service life of wear components used in continuous, high-load asphalt equipment operations.

Four Key Advantages of Haitian Casting

1. Fully Customized Workflow

From drawing evaluation and material selection to prototyping and full-scale production, Haitai offers end-to-end customization tailored to your equipment and operational needs.

2. Reliable Lead Times

With advanced vertical molding lines and full-process control, we ensure stable delivery and efficient production to meet tight project schedules.

3. Superior Material Performance

Offering a wide range of materials including high-chromium cast iron, manganese steel, and Ni-V alloys to ensure wear resistance, impact strength, and corrosion protection.

4. Modeling technology (sand casting)

Haitian provides wooden, foam and steel molds according to the products and performance required by customers. The production adopts "modified water glass + ceramic sand process" to improve product surface quality and reduce product defects. Improve the recycling rate of old sand and reduce production costs.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tel:

Tel:  Fax: 0555-6971198

Fax: 0555-6971198 Website:

Website:  Email:

Email:  Postal code: 243141

Postal code: 243141 Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Tik Tok

Tik Tok